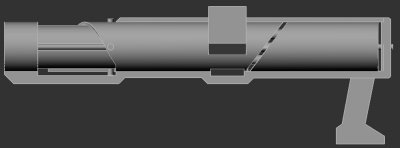

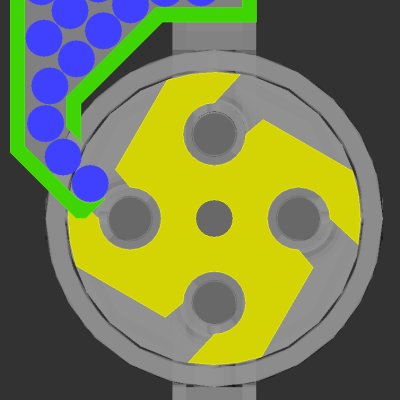

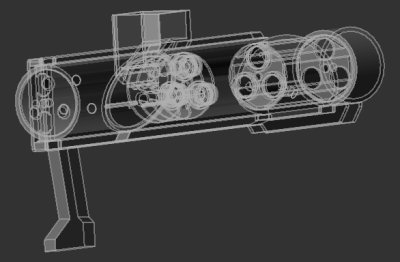

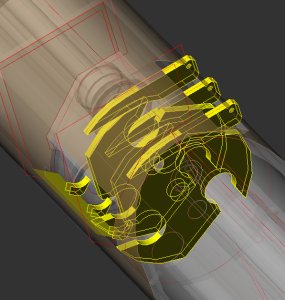

The breech is actuated by the track in the middle of the gun just ahead of the dart hopper.how is it going to open and close on demand?

Edited by CaptainSlug, 26 March 2006 - 04:07 AM.

Posted 26 March 2006 - 04:07 AM

The breech is actuated by the track in the middle of the gun just ahead of the dart hopper.how is it going to open and close on demand?

Edited by CaptainSlug, 26 March 2006 - 04:07 AM.

Posted 26 March 2006 - 04:13 AM

Edited by SKIZ, 26 March 2006 - 04:16 AM.

Posted 26 March 2006 - 04:39 AM

It is tempting to just copy his work which is known to produce positive results. The only downside is that in order to fit 1-1/4" PVC plunger tanks into this design I would have to go from 4 barrels to 3. I think I'll stick with 1" PVC for the tanks but I will use the fender washer.O that easy ay.

Cool sounds great and with your simplified explanations on how everything works... lets just say i have high hopes of this being one hell of a support weapon. All you have to do now is figure out how you can put a basic sight on it.

Jokes of coarse if this can do what your saying it will be able to do screw aiming just spray and pray.

For your plunger you might want to use carbon's idea of having a washer fastened to an end cap.

http://nerfhaven.com...?showtopic=6232

Seems that his plunger would offer alot of power.

Edited by CaptainSlug, 26 March 2006 - 05:32 AM.

Posted 26 March 2006 - 07:52 AM

Posted 26 March 2006 - 09:34 AM

Edited by Denaeron_12, 26 March 2006 - 09:35 AM.

Posted 26 March 2006 - 10:54 AM

Posted 26 March 2006 - 11:15 AM

Posted 26 March 2006 - 12:16 PM

Posted 26 March 2006 - 03:21 PM

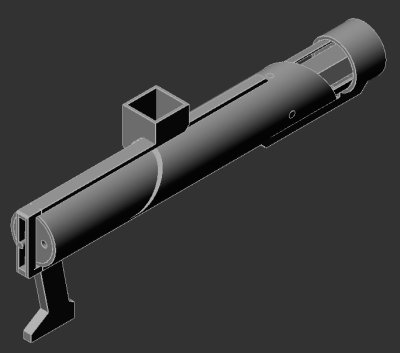

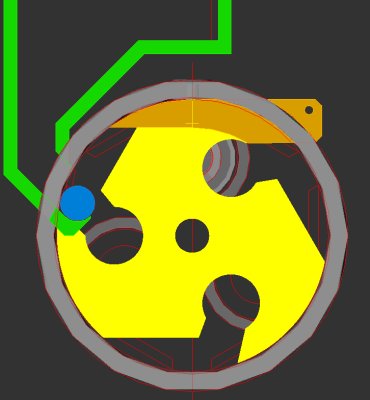

Nothing really, but it's much easier to drill a precise 4-hole pattern than it is a 3-hole pattern and I was trying to keep this simple. I'm going to make a 3-barrel CAD model after I refine some of the parts further just to see if it has any functional advantages besides having one less barrel to make. If I were to go with 1-1/4" tanks and try to fit them into a 4-barrel pattern it would require shaving down certain areas of the outside of the tanks in order for them to fit.Hey, what's wrong with three barrels?

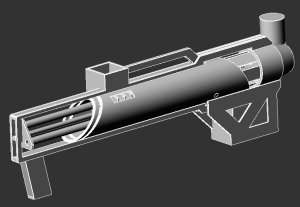

Indeed. The powerdrill grip will have the removable battery in it and I already realized that the dart hopper will need a spring-loaded lid so that the darts stay inside.I would make sure there's an easy way to switch batteries, and make sure there's a way to have a crapload of ammo without making it to hard to lug around.

You're correct. Fortunately the changes I'm making on the dart feeding system will allow me to get rid of the ejection port so I'm thinking about making the grip adjustable.For this to be tripod-mounted, he would probably have to build a different one, because as it is now, the handle is at the very front, and it's shoulder-fired. If you mounted that on a tripod, it would be very awkward.

Edited by CaptainSlug, 26 March 2006 - 06:10 PM.

Posted 26 March 2006 - 06:49 PM

Edited by CaptainSlug, 26 March 2006 - 07:15 PM.

Posted 26 March 2006 - 08:45 PM

Posted 26 March 2006 - 09:57 PM

Posted 26 March 2006 - 11:03 PM

Posted 26 March 2006 - 11:34 PM

Edited by CaptainSlug, 03 April 2006 - 08:12 AM.

Posted 27 March 2006 - 12:24 AM

Edited by CaptainSlug, 03 April 2006 - 08:12 AM.

Posted 27 March 2006 - 12:56 AM

Posted 27 March 2006 - 01:04 AM

I would give this to the Germans.The Russians have the best firearms designs for simplicity, functionality, and real world performance. They are the definitive firearms manufacturers.

Posted 27 March 2006 - 01:22 AM

Edited by CaptainSlug, 27 March 2006 - 01:35 AM.

Posted 30 March 2006 - 05:30 AM

Edited by CaptainSlug, 03 April 2006 - 07:49 AM.

Posted 06 April 2006 - 12:18 PM

Edited by CaptainSlug, 06 April 2006 - 12:36 PM.

Posted 06 April 2006 - 12:48 PM

Posted 06 April 2006 - 12:53 PM

Edited by CaptainSlug, 06 April 2006 - 04:20 PM.

Posted 06 April 2006 - 06:56 PM

Edited by CaptainSlug, 06 April 2006 - 07:08 PM.

Posted 06 April 2006 - 07:41 PM

Posted 06 April 2006 - 08:42 PM

0 members, 4 guests, 0 anonymous users