Decided that NerfHaven would probably be the best place to document the step-by-step development of my newest blaster design, the SuperSledge.

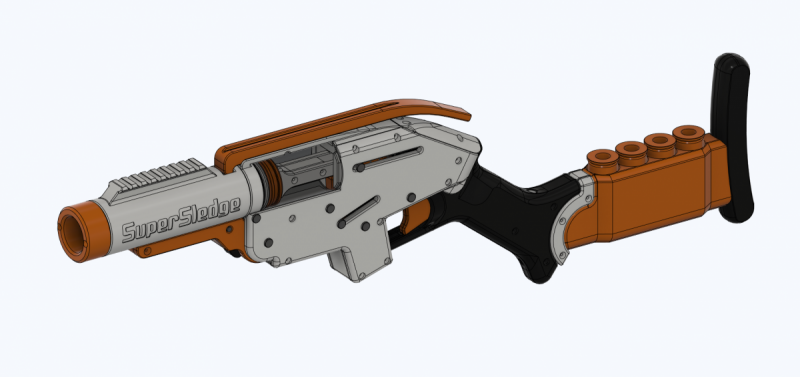

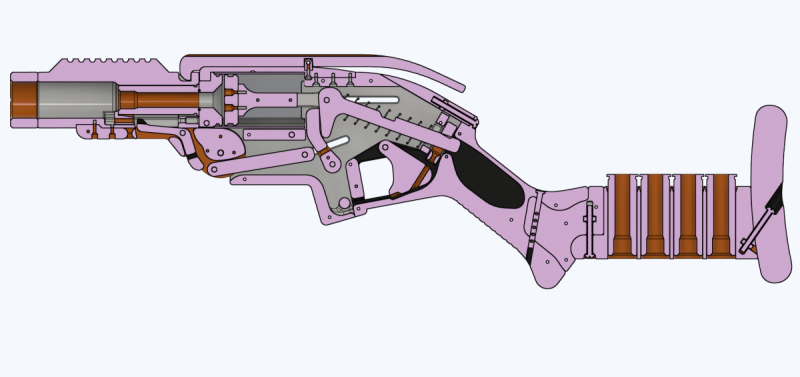

The SuperSledge is a full recreation of the Nerf SledgeFire, but improving it for NIC use in every way. Larger plunger tube, stronger springs, community designed shells (Spring Thunder right now, more later), quick takedown functionality, quick barrel, stock, spring, and ammo type swapping (no screws, all takedown pins), and the whole blaster uses easily accessible hardware and pretty simple 3d prints.

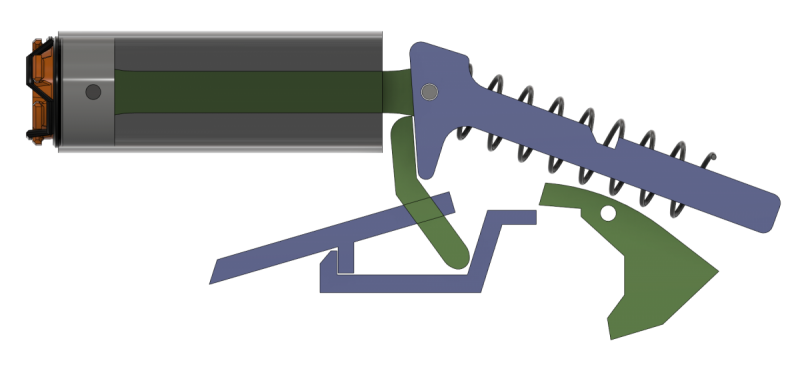

The only spring in this blaster is a chunk of [[[k25]]] for the plunger. The catch, trigger return, priming lever return, and ejection are all covered by two pieces of elastic cord. The top barrel locking lever uses a rubber band or hair tie.

The barrel and stock can be easily removed, with two takedown pins for the barrel, and one takedown pin for the stock. The ammo type can be swapped quickly with a swap of the barrel and breech face, only three takedown pins. The spring can be swapped easily as well, with only three takedown pins removed. All able to be done at a game, maybe even on the field if you wanted to.

Here are some development photos:

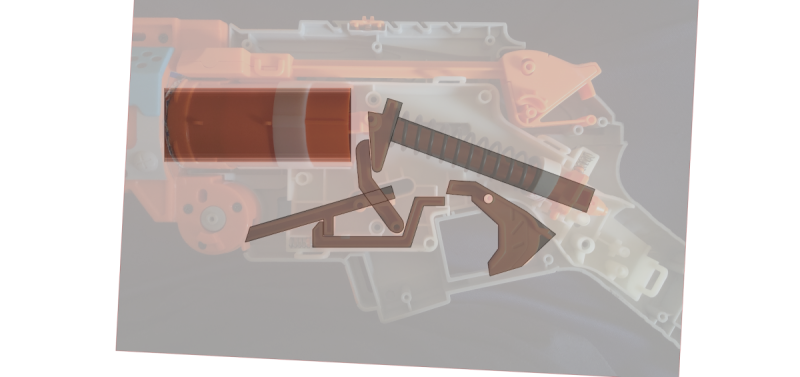

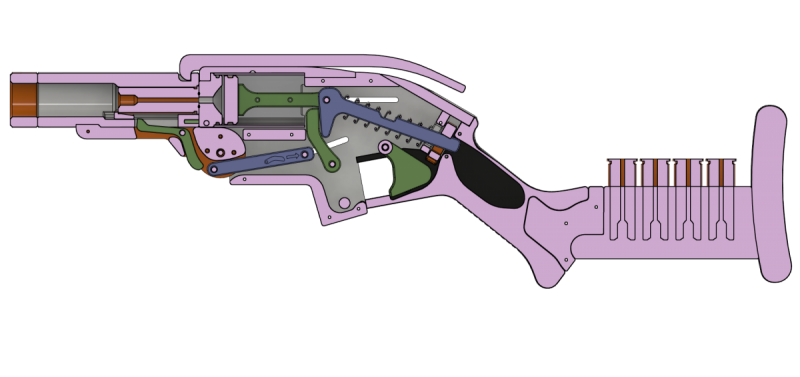

I started out by doing a straight 1:1 sketch of my SledgeFire's internals.

https://www.youtube....h?v=OJQCfiQKtqw

I also took some video of the SledgeFire's internals, just to work over them in my head.

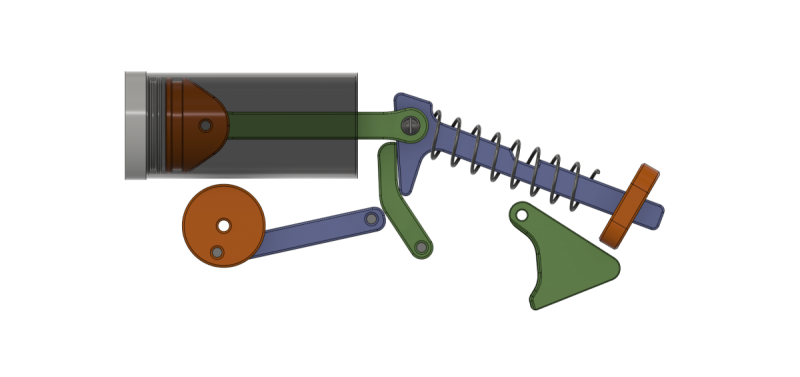

This is where the 1:1 sketch ended up after some refining.

Here you can see that I have removed the trigger lock and fleshed out all the internal components. There is a rudimentary priming pivot, as well as more properly sized levers and bars. I have also added a segment of FLAK 2"OD plunger tube and begun work on a plunger.

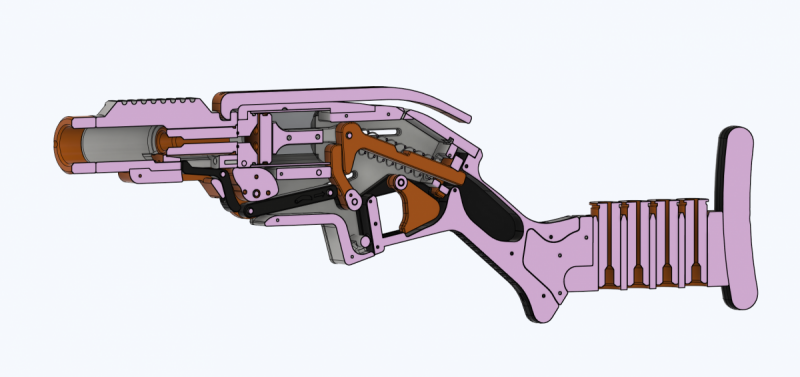

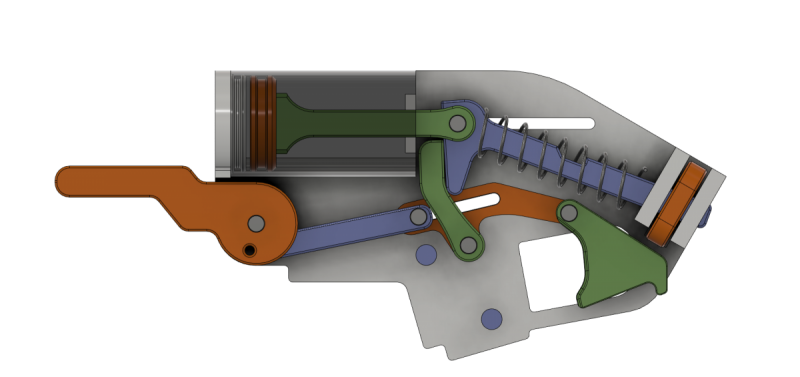

The first side panels are now in place! Lots of small tweaks were made to all the internals, tweaking thicknesses and lengths. The catch is now properly supported, there are spacers to keep the internals centered between the side plates, and the plunger has been simplified. The priming lever is now an actual lever. There is a small dingus on the back of the trigger used for attaching an elastic through the catch, but it was pretty quickly removed in favor of a simple hole through the whole trigger.

https://www.youtube....h?v=UtcTChv5F5E Video overview of the design so far.

This was the point where I made my first test print, just to check internal functionality and printability. There were definitely tweaks to be made to improve reliability, but this was when I was 100% sure that this concept could work in the real world, not just in CAD.

https://www.youtube....h?v=8y1QMHJ7zKs

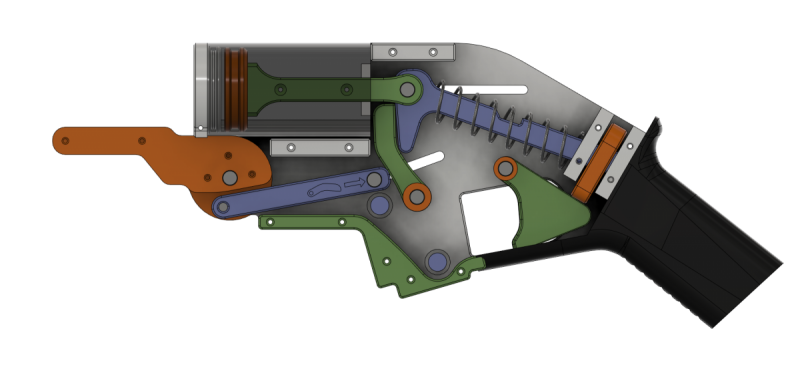

This is where I began modeling the grip. I used the basic thickness and length of a v4 Caliburn grip, but that didn't last for long as you will see next. You can also see that the internal spacers are now small discs instead of larger parts. There are now also connection blocks and a bottom cover.

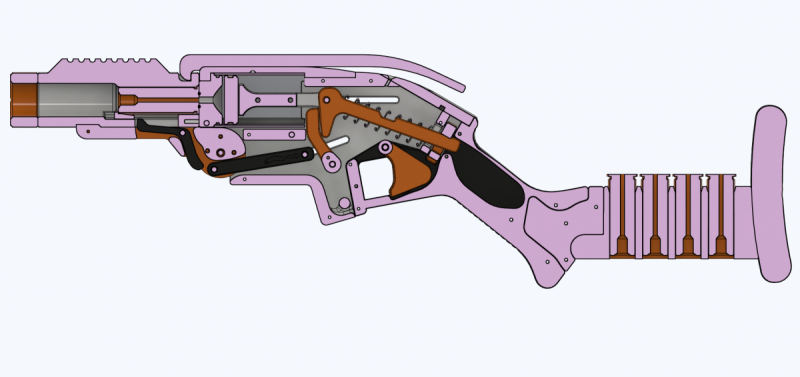

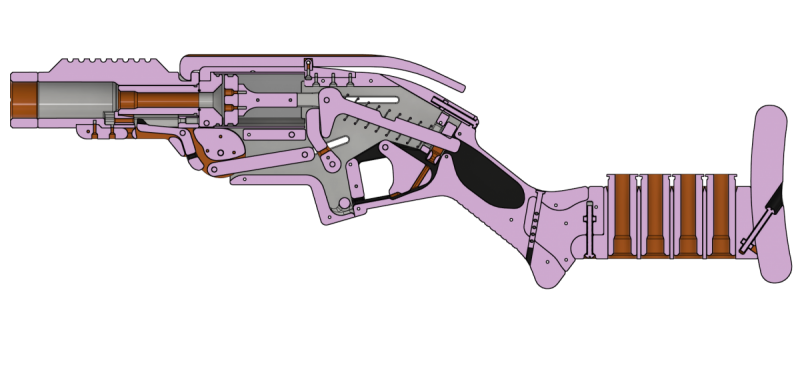

Here I've begun to smooth out the edges and corners of the side panels. The top-back of the blaster now has nice covering plates. The grip has also progressed into it's basic final design, split into 3 pieces; a core and two side panels (SpudSpudoni helped me a bit with figuring out the Fusion tools to make the finger groove curve near the trigger well. Thanks Spud!). There is now a shell storage stock as well.

Barrel! The shell ejection mechanism can be seen much better in the next image. You can see the stock lug now too.

https://www.youtube....h?v=R51Mks6aqek I also did another video overview around this point.

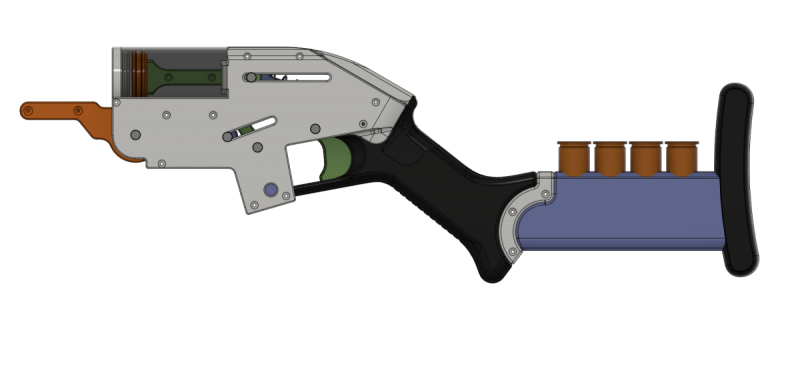

Lots of work around the plunger tube. The breech face is now thicker and locked in place with a top strap and a takedown pin. The barrel latch is now also in place.

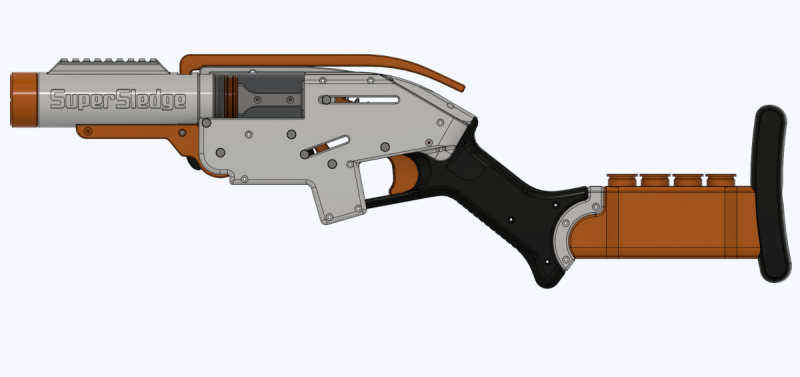

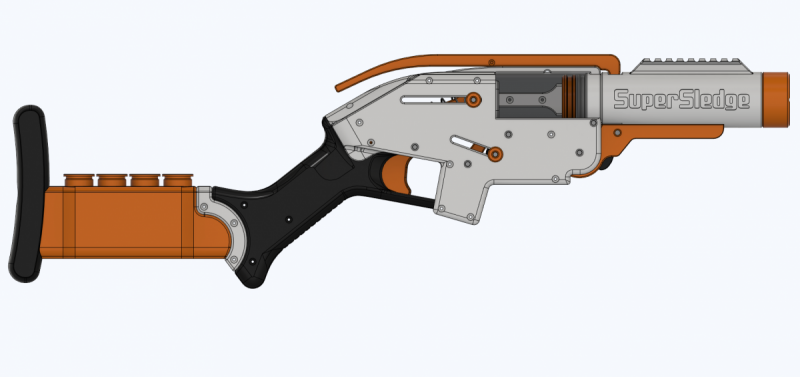

And here is the current design! Lots of small tweaks to parts, lots of smoothing and print optimization. Previously, some parts were just floating in place. Now, all the screws and connections are modeled. Some parts have been combined (the bottom cover and the elastic guide pin). I also made all the hardware visible in this photo (minus some screws and the three pieces of elastic).

Edited by Silly, 27 December 2021 - 02:34 PM.