Preface: This thing isn't working perfectly. Darts feed through it too easily and I'm currently getting double and triple-feeding issues. This is however something I have wanted to try making for a long time and it really only involves a 45-degree conduit elbow.

Step1: What the fuck am I doing?

Step 2: No really, this looks retarded. But if I go slowly it seems to be working. 1/2" 4-flute end mill in a lathe drill chuck where it doesn't belong.

Step 3: Huh, it worked.

Step 4: Using Dykem Steel Red Markup Layout Fluid to see how much of the 1/2" OD aluminum tube I need to sand off.

Step 5: Sand sand sand, check fit.

Step 6: Use lathe and drill chuck on the 1/2" OD aluminum tube as well as some rubber bands to keep all the parts in alignment.

Step 7: Apply Super Super Glue for a temporary hold, then tip the part over so the excess glue doesn't work its way inside the elbow.

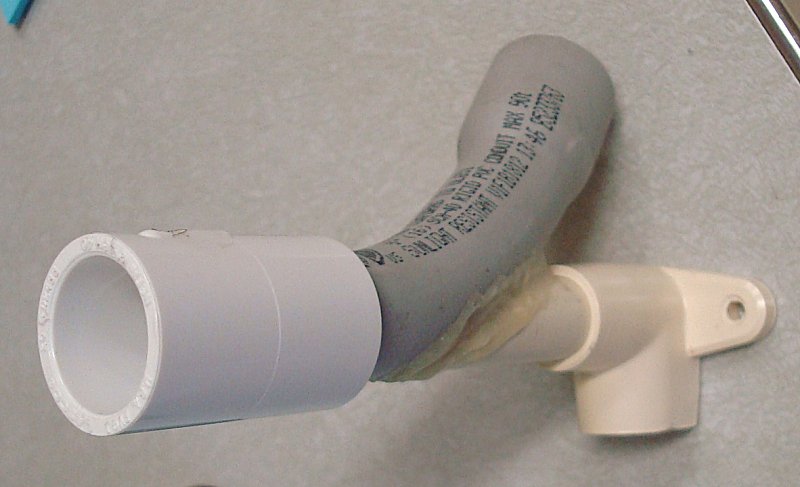

Step 8: Make a CPVC piece to slip over the aluminum. Had to drill out the CPVC and sand down the aluminum because we want a nice fit that won't require too much force or we risk braking the super glue joint. If it does break take everything back to the lathe and use it as a fixture again.

Step 9: PLEXUS OVER EVERYTHING

Step 10: Let it cure overnight. Also make sure to put it in a cabinet with someone else's cereal so that when they come in the next day they get a face full of glue fumes when they open it.

Step 10: Plug in the other parts and test it.

Step 11: Shoot more darts that you intended to every time.

Step 12: Get frustrated with Wye hoppers because they only work perfectly in certain very specific proportions.

Step 13: ????