Posted 09 June 2016 - 11:54 PM

Posted 10 June 2016 - 12:44 AM

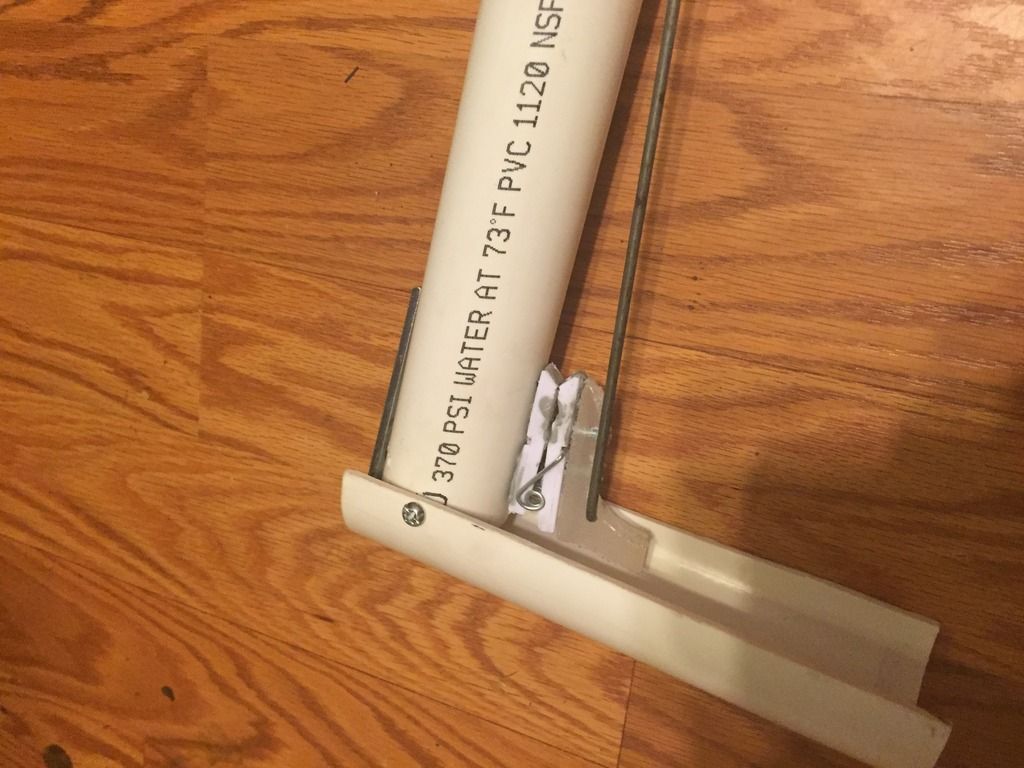

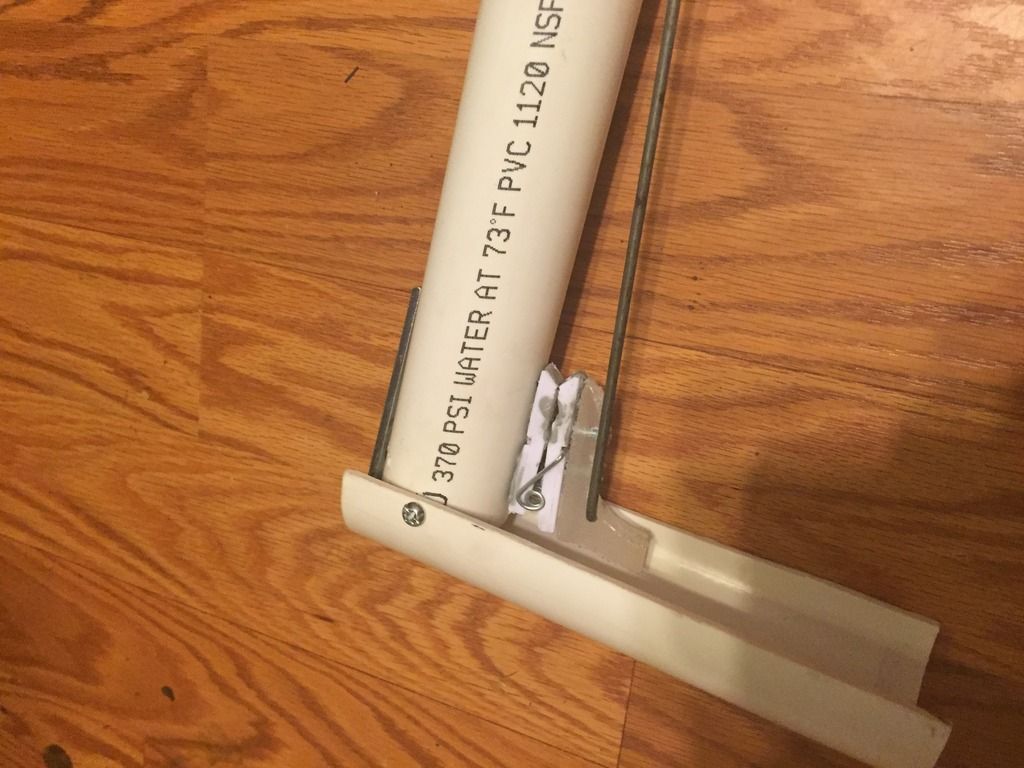

The PCSR has a floating plunger head in the stock.

http://nerfhaven.com...omemade-design/

The main difference there is that the catch is a 3d printed catch with a ramp that the spring would easily slide over. You might be able to cut the hole the catch pin goes through into a slot and bend a wire into a triangular shape that would act as a ramp. It depends on whether your pin binds up in the hole in the plunger tube the way Carbon describes in the clothespin trigger thread or if the clothespin bears all of the weight (aka the Beaver method, more info here). Obviously if you're using the Carbon method, putting that ramp on your catch pin is just going to royally fuck up your catch.

There's also a nub thing at the back of the plunger tube in the PCSR that keeps the spring centered. As long as it is shorter than the compressed length of the spring it won't get in the way, you just need to taper it at the end so the spring doesn't get fouled up on that too. This might not completely solve the problem, but it would probably keep the spring from buckling so much that its resting right against the pin side of the plunger tube.

Edit: Those extra rubber washers must be adding friction. I'm guessing you're doing that just to keep the plunger straight in the tube? You might be better off using something rigid that isn't too snug, and won't press against the sides of the tube so much. Maybe a 3/4 endcap, or I think there might be a weird metric washer that just fits inside a plunger tube. You could also try to build up the catch ramp to be wider than the metal washers, and then sand it and polish it to reduce friction. You could just use a piece of cardboard cut to side taped to the washer as a backing just to get the size and shape right while the putty is soft.

You can poop in my toilet anytime champ.

2016 Nerf War Schedule

Bless you, my son. Now recite 3 New Members Guides and 5 Code of Conducts for your sins.

Posted 10 June 2016 - 07:28 AM

Not applicable to a [k26], but the SNAP-5 used a collapsing plunger rod to get around the issue. The forepart was 1/2" aluminum, while the rear was 17/32" brass. I found the amount of friction it added to the system to be negligible (at least compared to the friction added by a spring binding against a plunger rod).

Posted 15 June 2016 - 02:19 AM

I've build multiple blasters using a compression spring and stub of a plunger head. You need to have some sort of endcap on the back of your plunger head to seat around the spring and also stabilize the plunger head in the plunger tube, and then a thicker plunger "rod" bit as well.

What's extra helpful is having a tube in your spring rest that can fit inside your spring but outside the plunger rod. Here's a picture from my FAL-3 writeup

The red section is a rainbow catch + spring rest. Since you're building a snap this would just be your endcap in the plunger tube. You can barely make out a white rod that comes out of the red section, that's a piece of tube that fits inside my spring but also outside the plunger rod. Since I have to catch on my plunger rod, the tube is quite thing -- you're catching on the plunger head itself so you can probably use something like 1/2" PVC and center it in your rear bushing with creative plumbing.

Posted 15 June 2016 - 10:53 AM

You know, the SNAPoid catch in the Mark-8 gets around binding by keeping the catch and the spring totally separate. You can't really do a true floating plunger head with it (you need the rod so the catch can engage), but it might be something to look into.

homemade

Community Forums →

Homemades →

Re-creating the Nerf SledgeFire: The SuperSledgeStarted by Silly, 27 Dec 2021 |

|

|

||

Community Forums →

Homemades →

Clarification of differences between Hoppers, RSCBs, Choppers, and BRIStarted by Silly, 17 May 2021 |

|

|

||

Community Forums →

Homemades →

Project 12: 100% brushless Vortex blasterStarted by snakerbot, 16 Aug 2020 |

|

|

||

Community Forums →

Modifications →

I need help putting together my Star wars Qi’Ra Nerf gunStarted by Tytt, 04 Aug 2019 |

|

|

||

Community Forums →

Homemades →

Nerf M-1 Garand conceptStarted by Silas4lagoon, 28 Jun 2019 |

|

|

0 members, 1 guests, 0 anonymous users