Preface

I recently received a commission request from Australia for a pullback. Nothing strange here, except the darts they use in homemades. The FVJs used down under sport a larger caliber foam than typical stefans or even stock elites. This poses problems for homemades; it means hoppering a blaster reliably is impractical if not impossible with full length darts, and the barrel materials available here are limited in their ability to feed these darts. The barrel length needed to fire these darts accurately is about 18-20 inches, and common materials that do fit higher caliber darts only come in lengths of a few inches (brass, crayola markers, etc.), and PETG is a looser fit, but very weak unless it is sheathed in a (heavy) PVC barrel shroud. Telescopic barrels suffer the same problems as the aforementioned shrouded PETG barrels, and are even more complicated. Thus I present the community with my solution.

Directions

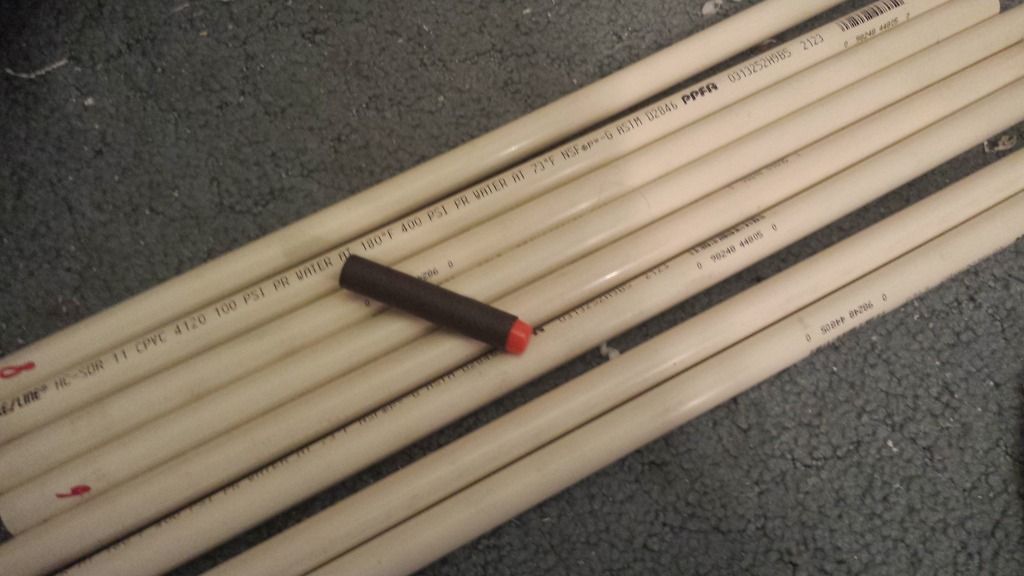

CPVC is a material readily available at most hardware stores. The approximate ID according to my research is around 0.485, whereas the DIA of the FVJs were around 0.520-0.510. So we have to bridge that gap just a bit.

This is the unmodified CPVC barrel. The FVJ doesn't even go in an inch. It's a VERY tight fit, can't twist it in any further without damage.

Measuring the dart returns a length of about 2-7/8"

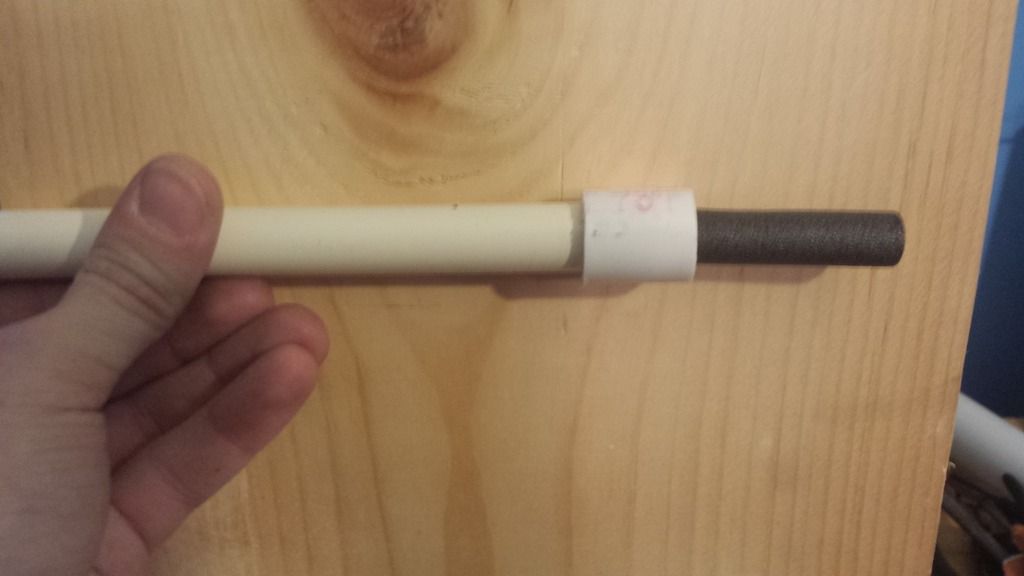

So I marked off 3" on a brand new 1/2" drill bit. This is important. I tried this the first time with an older, less-sharp, more beat up drill bit and it did not work as cleanly. Invest the extra ten/twelve dollars if you plan on actually doing this.

Clamp that shit down. Leave at least the three inches you want to drill poking out of the barrel. I say 4 or so, just so the vice clamping on the barrel doesn't deform the section you're actually drilling too much.

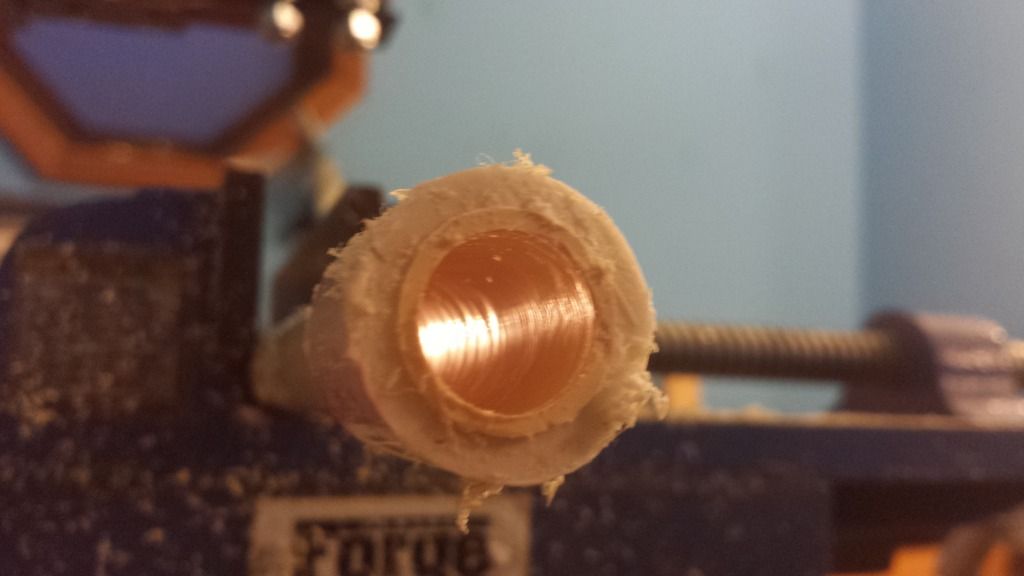

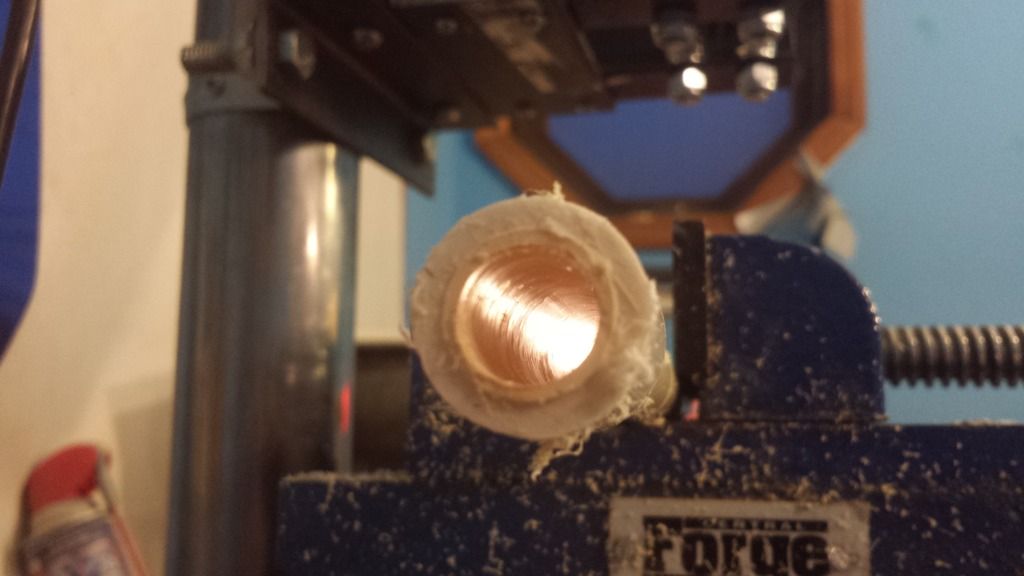

Now, carefully drill all the way into the marked part of your drill bit. Drill on a high speed so it doesn't bite too much, and guide it in slowly and carefully.

The final product has a chamber expansion to 0.500 inches, which is a much better fit for FVJ darts, now they're a twist fit. The walls of the chamber are a little rough, but honestly not too bad. Certainly not as smooth as the rest of the barrel, but the dart is not going to be under as much force here.

Results and Ramblings

The inspiration for the solution comes from the idea of the .223 Wylde barrels found in AR-15 rifles. Yeah, I know it's not really applicable don't give me bullshit, and the direct comparison doesn't really work, but basically the dimensions of different barrel and chamber types on real steel firearms (maybe) improves the feeding of the rounds into the chamber. Similarly here, the darts begin in an expanded chamber section and feed into the reduced (normal) barrel ID. This means that at some point, the transition must be made from 0.500 to 0.485 barrel ID. Is the transition smooth? Not really. It's the end of a drill bit after all, which is 135 degrees, and with a little math, the angle relative to the wall is found to be 67.5 degrees. So that's kinda sharp, I would've preferred more like 30. So with that steep angle, does this rip apart the darts? Nope, shockingly darts don't rip or tear due to the chamber transition angle. I believe this is because the transition is so small, each surface of the dart only has to deal with a transition of .0075 inches, ( (chamber DIA - barrel DIA) / 2). That's pretty small, so the propensity to shear is not that great.

The barrels do seem to wear darts though, probably because it is so tight in the barrel section. A [k25]'d pullback with a skirt seal and very good air seal will feed these darts no problem. So even if the difference in foam diameter and barrel diameter is relatively large, the thing will not give a fuck and cycle them through anyway. So obviously the foam will be squished more than usual. This is bad because it wears down your darts at a faster rate, but this is good because even the most worn out of darts that you have in a random darts bag will cycle without any issues. In a way, this makes a barrel very robust when using FVJ or even stock darts.

Where this will not work (I suspect) is with #8 washer weighted stefans. This is because the #8 darts have a large OD than #6 darts that feed through CPVC with no problems. Obviously the chamber to barrel transition squishes foam, but it cannot squish steel washers. I could be wrong, but this would probably not work well with #8 stefans (which you shouldn't be using anyway you energy junkie). If somebody wants to prove me wrong, go for it. With denser or thicker foam and a #6 washer, however, this thing should chug all day.

EDIT: Everyone is saying CPVC should feed #8 slugs. I just never use #8s and when I pick them up from the ground at wars, I'm sure there are other factors involved, I just avoid them based on my own experiences.

This may also be a bad idea for poor sealing blasters a la ESLTs/ poorly made SNAPs/ dicked up plunger heads in general. This is because the tighter barrel fit on darts requires a higher pressure to launch them, as your friction force is now much greater. On the flipside, this also means your barrel is damn efficient, and basically no air will leak out of your barrel unless your dart breaks in half or something. So where is the "weak link" in our air system? The air seal made by the plunger head, of course.

The pullback is proving to be an incredibly versatile design. More on the project when it's finished. The turret has eight expanded chamber CPVC barrels.

And it will soon be launching Chinese darts from an American blaster in Australia.

-Aeromech

Edited by Aeromech, 23 February 2016 - 01:52 AM.