After taking the advice of the community in my previous topic (link for those who want to see), I ordered a pair of brushless motors the equivalent in speed to a stock Nerf blaster. Here are my findings.

1. Brushless motors are expensive

I probably bought some of the cheapest motors I could probably buy, however, if I was going to do this again, I would probably buy ones that are a little bit more powerful. The problem with brushless motors is that you cant just buy the motors and be done with it. You also need ESC's and a servo tester to run your setup. While My ESC's were already coded, you may even want to buy a programming card so you can add this like electronic braking if you want (more on that later).

2. Lipos or other rc batteries are a necessity

Brushless motors are meant to work off of Lipo batteries. The product description should tell you which one. That means, in order to use brushless motors, you must have a lipo battery and a charger at least (battery alarm recommended). You can use other battery chemistries, but you might have to figure out the power equivalent yourself.

3. ESC's are a cool Idea for nerf

Because ESC's are programmable you can have your motors do all sorts of things. Perhaps most useful to nerf is electronic braking. Forget complicated circuitry, with an ESC you have the ability to have electronic braking built right in.

4. Inrunner vs. Outrunner motors

There are two main types of brushless motors, Inrunner and Outrunner. Inrunner motors act similarly to regular brushed motors in that only the shaft spins. However these tend to overheat easier and need to have flywheels attached to work in Nerf blasters. Outrunner motors on the other hand act a little different to regular brushed motors. Instead, the outer bell of the motor turns while the inside stays stationary (the bottom of the motor mounts to whatever the motor is being placed on). These motors are great because they act as their own flywheels. On top of that, they have more torque because the outside is spinning and they run cooler. The motors I bought were outrunners.

5. Wiring

Brushless motors require a lot of wiring. None of the wiring is that difficult, however there are a couple things you have to keep in mind. First, you may have to wire battery connectors. My ESC's came with leads to connect to my battery, but I had to wire the connectors themselves. On top of that, I had to wire the harness to split the battery so that both motors ran off the one battery, it was a lot more solodering and shrink wrap than your basic stryfe mod.

6. Sound

My brushless motors are very quiet. I don't know how much sound level increases as the power does, But my motors only change in pitch when they are "revved" up.

Overall I think brushless motors are for those who really want to go all out in a flywheel mod. They are especially helpful for rivals rounds so that is where they might shine, but they only other reason you would need such torque was if your flywheels were metal (assuming you're going to use an inrunner motor). While Brushless motors may have the option of electronic braking, they will also require massive shell modification. Perhaps they are most useful in flywheel homemades like the one I am building. I don't really want to put down how to wire them up, but if enough people are interested, I guess I could try my best.

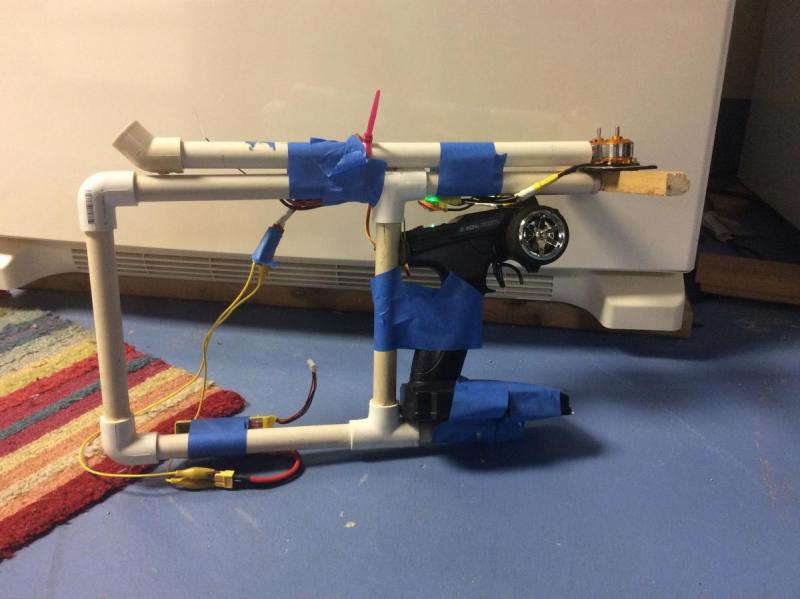

Here is my setup.

Edited by Quack, 27 January 2016 - 05:01 PM.