This guide is meant to provide a bit more power, change the method of priming, and make a breech for either Megas or Micros. This, of course, means modifying the magazine well to accept standard streamline clips.

PARTS AND TOOLS LIST (As I used in this writeup)

Dremel

Mini phillips screwdriver

Tubing cutter

Sharpie

File (for deburring aluminum after cutting it)

Electrical tape

JB Weld

Hot glue gun & hot glue

Super glue

Epoxy putty

7/8" OD, 3/4" ID aluminum tubing

3/4" OD, 5/8" ID aluminu tubing

1/2" CPVC

3/4" CPVC

1 1/2" PVC sink drain tubing

5/8" OD, 1/2" ID polyester tubing

1/2" OD polyester tubing

1 3/8" OD, 7/8" ID machine bushings (hardware section, parts drawers. It's a common part, actually!)

.093" thick polycarbonate sheet

1/2" wide plastic or wooden square rod.

PUMP GRIP CONVERSION

This section involves somewhat major shell work. REMOVE ALL OF THE INTERNALS BEFORE YOU DO THIS.

You need to cut the blaster cleanly in half, turn the front piece over, then reassemble. The easiest way to do this is to mark a straight line down the side of the shell and use a band saw. However, a Dremel cutting wheel will also suffice.

Take some electrical tape, and wrap it around the blaster in a vertical fashion. See those curved portions on the shell, in line with the barrel and the plunger tube? You need the edge of your tape to sit a the back edge of the largest bulge, where the Air Max sticker sits. Take a marker and trace a straight line along the tape, then make your cuts. I elected to keep the tape on, but it isn't necessary.

You should be left with two clean halves.

At this point, you can then line up the blaster halves, with the priming grip now on the bottom. Put your internals back inside (except for the safety lock box, which now has no place to sit), and use the plunger assembly as your guide for orienting your blaster.

If you're an idiot like me and you've modded the blaster prior to this, take some 1" CPVC and a 3/4" x 1/2" CPVC bushing and insert them into the end of the plunger tube. Wrap a tiny bit of E-tape around the 1" CPVC to get a snug fit in the plunger tube, and position the bushing so that it rests inside the slot for the stock breech. Believe me, it's easier doing the shell changes first - otherwise, you have to be VERY careful not to screw up your alignment.

Use generous amounts of hot glue to reconnect the shell pieces. This is a temporary measure; if it turns out you can't put the shell back together because of an alignment issue, you can remove the glue and try again. After you're satisfied, you can slowly begin replacing the hot glue on the outside with putty.

Congratulations! You've dramatically improved blaster usability by turning the priming handle into a shotgun-style pump grip.

PLUNGER MODIFICATION

There really isn't a lot to do, other than take a piece of 3/4" CPVC (or a 7/8" OD, 5/8" ID spacer) and place on the spring post. A piece 5/8" long should allow near-full compression of the stock spring while still being able to use the stock catch.

Note that even with the modified shell, the plunger area is wide enough to fit 1 1/2" PVC inside. Wider plunger tubes are a possibility.

MICRO DART BREECH

First, we need to modify the existing magazine well to accept straight clips. Take your thin polycarb sheet, and measure two rectangles as shown (90mm x 73mm). These will fit in slots within the shell perfectly. This simply makes loading the magazine easier, having flat surfaces on either side.

Then use 1/2" wide rectangular rod to fill in space and the front and rear of the well. Dowel rods work great, as do plastic rods. When arranged in this fashion, regular magazines should now fit perfectly in the well. Note that since the polycarb sheets have eliminated all sideways movement, you only need to attach the square rod pieces to one half of the shell, not both.

Do not worry about using the stock magazine release mechanism; the new breech will be wide enough for you to slip on the magazine (with some force) and have it stay there until you pull it out (again, with some force).

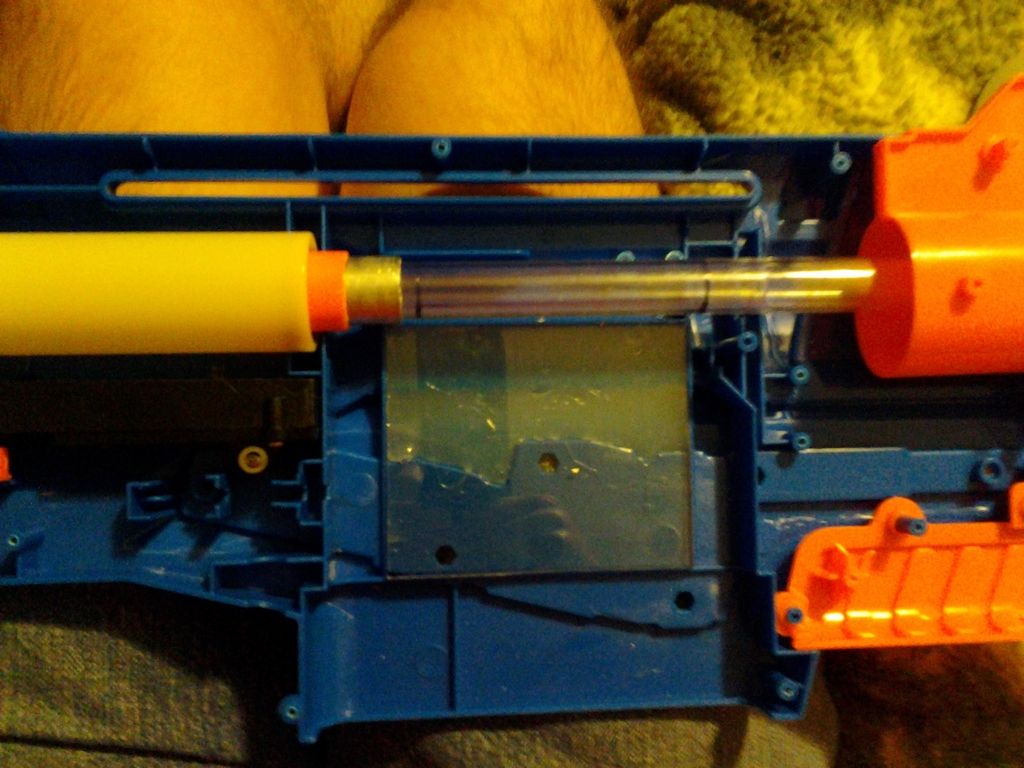

For the breech, I used 5/8" OD tubing as my barrel material, and 1/2" OD tubing as the dart pusher. If you wish, you can also set up a brass breech in here, as you would for a Longshot. There are some changes to be made, though, especially since the entire front wall of the plunger tube moves when you prime the blaster. I'll show what I did, and you can adapt it however you wish.

Cut off the stock breech completely, AR and all. Leave only 1/2" or so of the stock breech tubing on the front of the plunger wall/piston. Then take your tubing and cut these pieces:

1/2" OD tubing, plastic or aluminum.

1/2" CPVC

Nest the CPVC inside the remainder of the stock breech; there are ridges inside which will hold it tight. Then put your 1/2" tubing inside the CPVC for a REALLY tight fit. This will push your darts out of the clip and into the barrel.

You will also need to take a 5" long piece of your 7/8" OD aluminum tubing, and cut it like this, with a 1/4" wide strip remaining at the top. This won't be used as a dart tooth/dart stop within the breech, but it still needs to be narrow enough to clear the space withing the lips of the magazine. Nest it over 3/4" OD aluminum.

For your barrel, cut a half-circumference slot into the side, as you would for a CPVC breech.

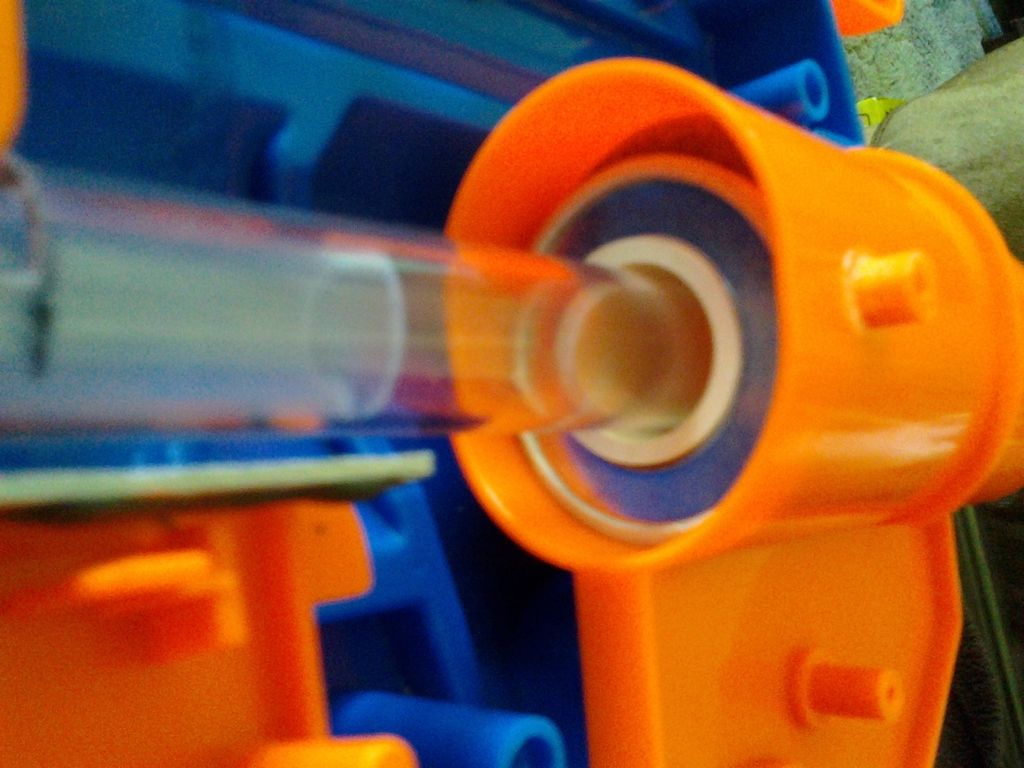

This part is important for barrel alignment and making the entire thing work. The stock "barrel" piece is an oblong shape, but the curves themselves are 1 1/2" in diameter. Use tubing of that size, either from your drain plumbing material or your +bow plunger tube supply, and glue it in place. Use spare dart blanks to fill in the remaining space. From this point, you can devise ways of using bushings or spacers to narrow the passage down to 5/8". In my case, I used 1 3/8" x 7/8" machine bushings and 3/4" CPVC tubing, liberally applied adhesive, and then just put an extra wrap of E-tape around my barrel material before insertion.

Put these pieces together, and get this! Yes, I realize I'm using this picture twice. But we're focusing on a different part of the picture

You use the leftover tab from the stock breech and JB Weld it onto the aluminum, similar to how you would attach the plastic nub from the boltsled of a Longshot to the new breech. (Example seen HERE) Let cure for 24 hours, and reassemble.

Using 1 1/2" micro slug darts, with a 3/16" steel ball bearing as weight, I easily hit 90' flat. Nerf Elite darts went just as far, but flew more erratically as expected.

Next post will be for setting up a Mega breech.

Edited by Buffdaddy, 31 July 2015 - 10:31 PM.