Question - do you have a picture of a tank with your MiG-approved 3/8" tubing attached? I don't run my tanks at very high pressures, but I do have hella problems with leaks at the joints and attachment points.

I too would like to see this since I'm trying to replicate your hypermax1500 but with a spare AT2K tank I have. I will most likely try your tank reinforcement now, but would like to see how you attach the tubing.

I knew this would be the next topic of interest. ..Coming soon.

nice job man! Just so I can get a frame of reference, what are the normal operating pressures for like a at3k tank and a sm1500 tank? I know you mentioned they rupture pretty quickly at 45 psi, but I'm trying to guage whether or not to do this to my airguns if they'll last just fine on say 30 psi and still get great ranges.

In most cases, people will

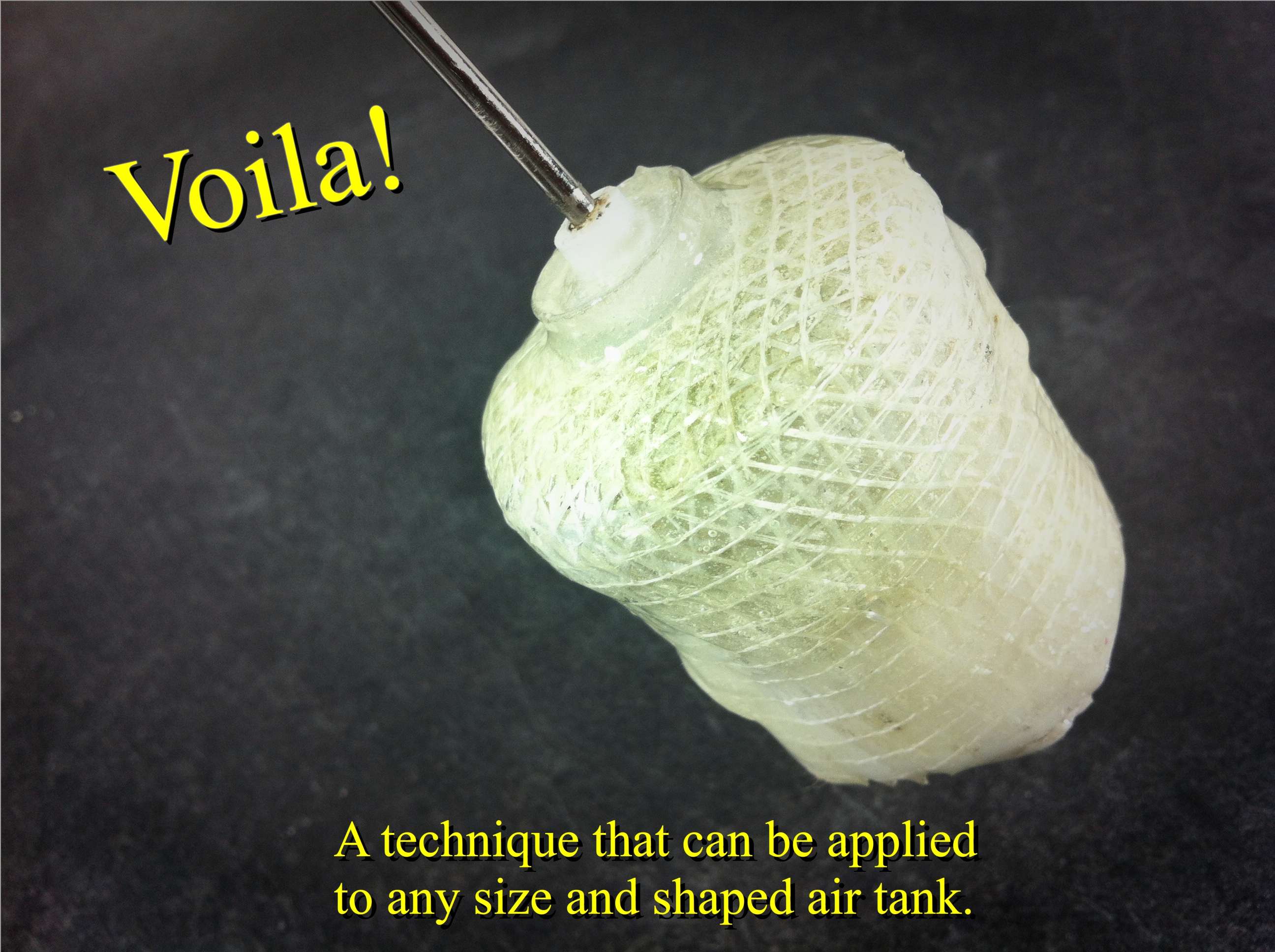

say that 30psi to 35psi is enough for AT2K's, SM1500's and AT3K's (plugged pumps), which is true, but that usually only gets you 80' to 90' ranges. 30psi to 35psi is safe for the tank and will ensure the longevity of your tank. However, in practice EVERYONE tries to get in that last extra pump which usually pushes it to 40psi/45psi. This is great for getting 110' foot ranges (or more) but will eventually rupture most air tanks in a relatively short amount of time. Let's say 3 or 4 wars of heavy use max.

This mod does not make the tank(s) indestructible but at least allows for greater longevity with that extra pump at 45psi to 50psi giving you the desired century range status.

Have you tried to do this without the mesh, just the epoxy? I know the mesh/epoxy combo is to replicate high pressure air tubing, but do you think you could you use a hard-setting epoxy, like JB weld, without the mesh?

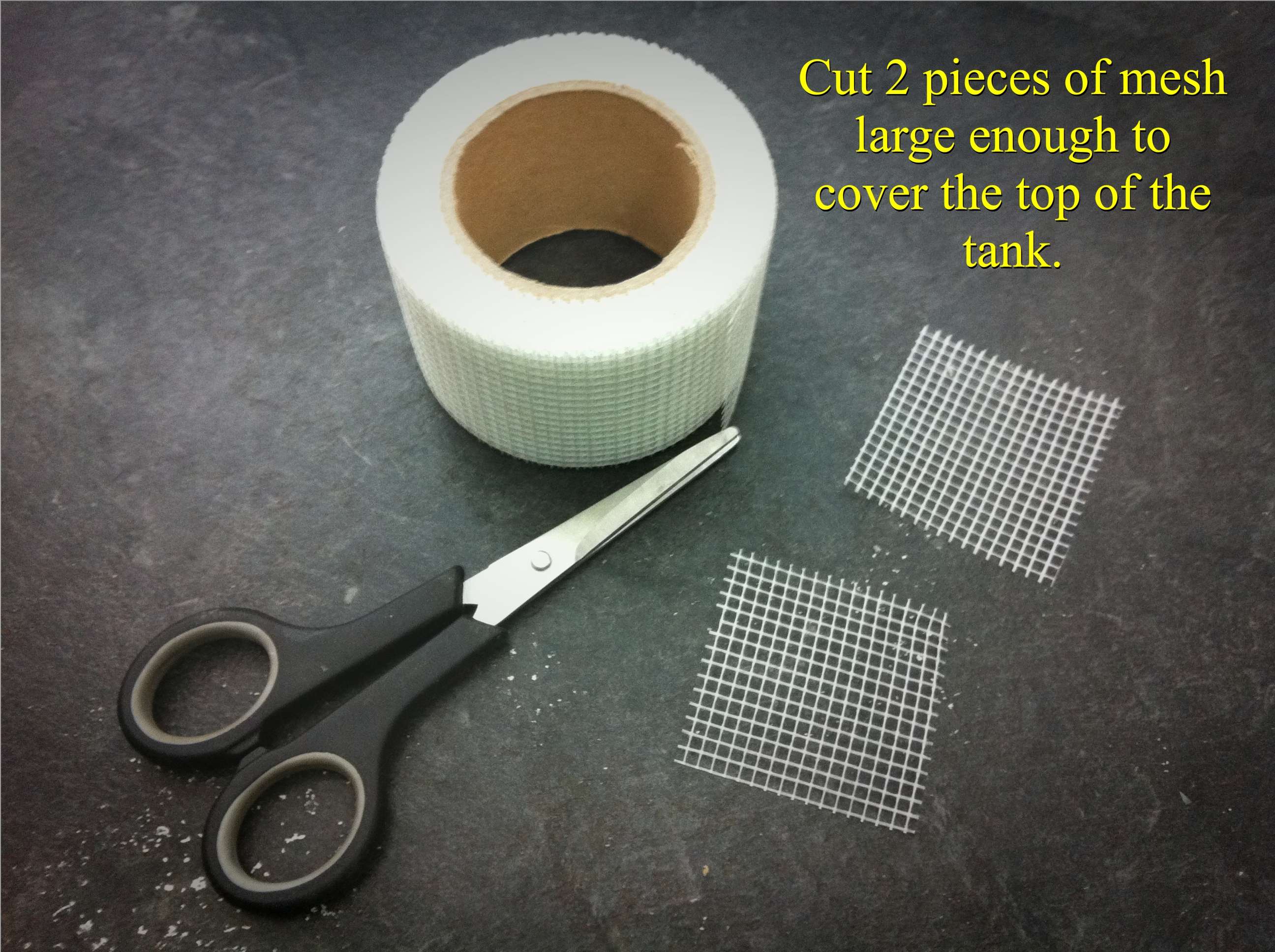

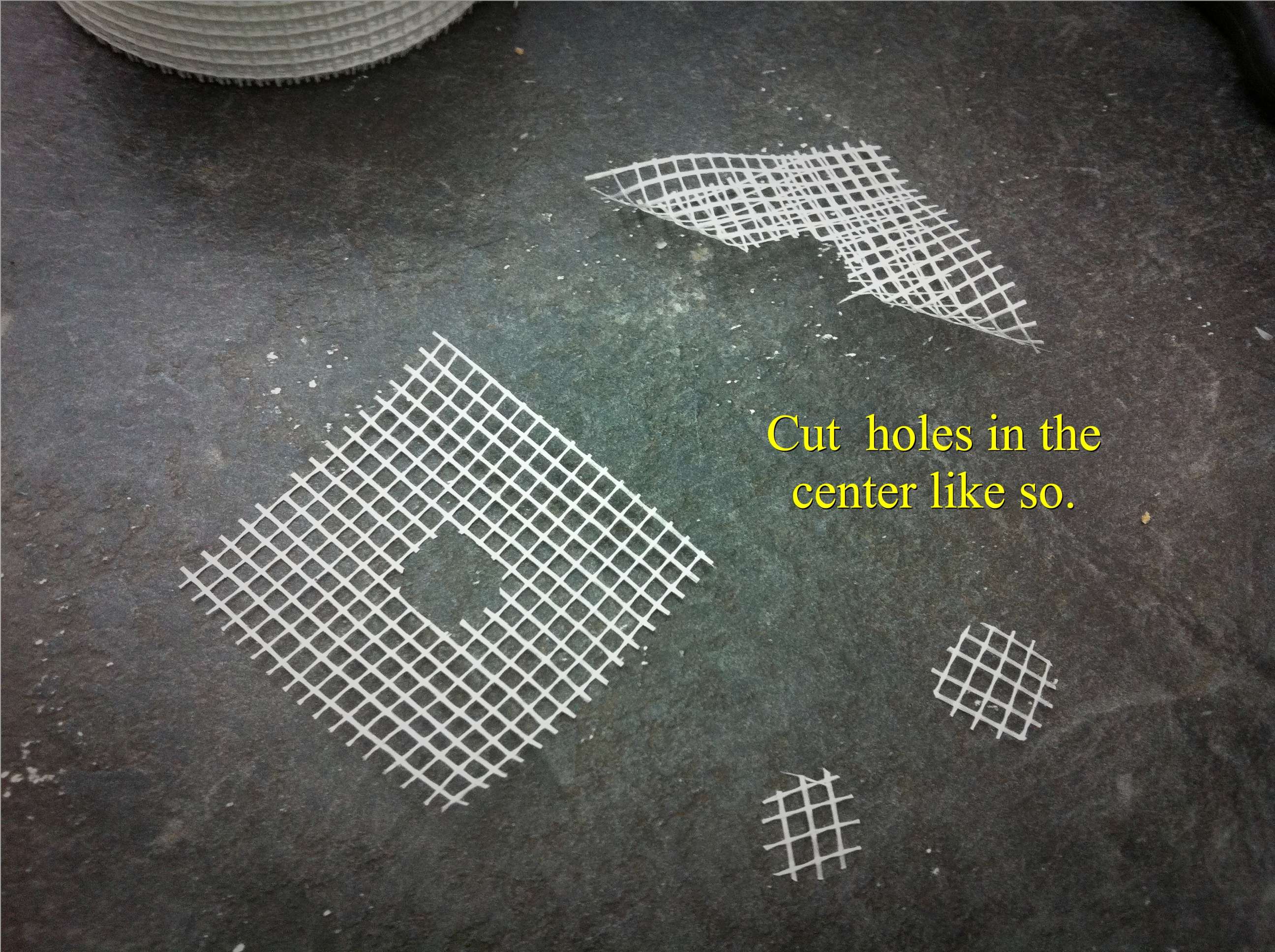

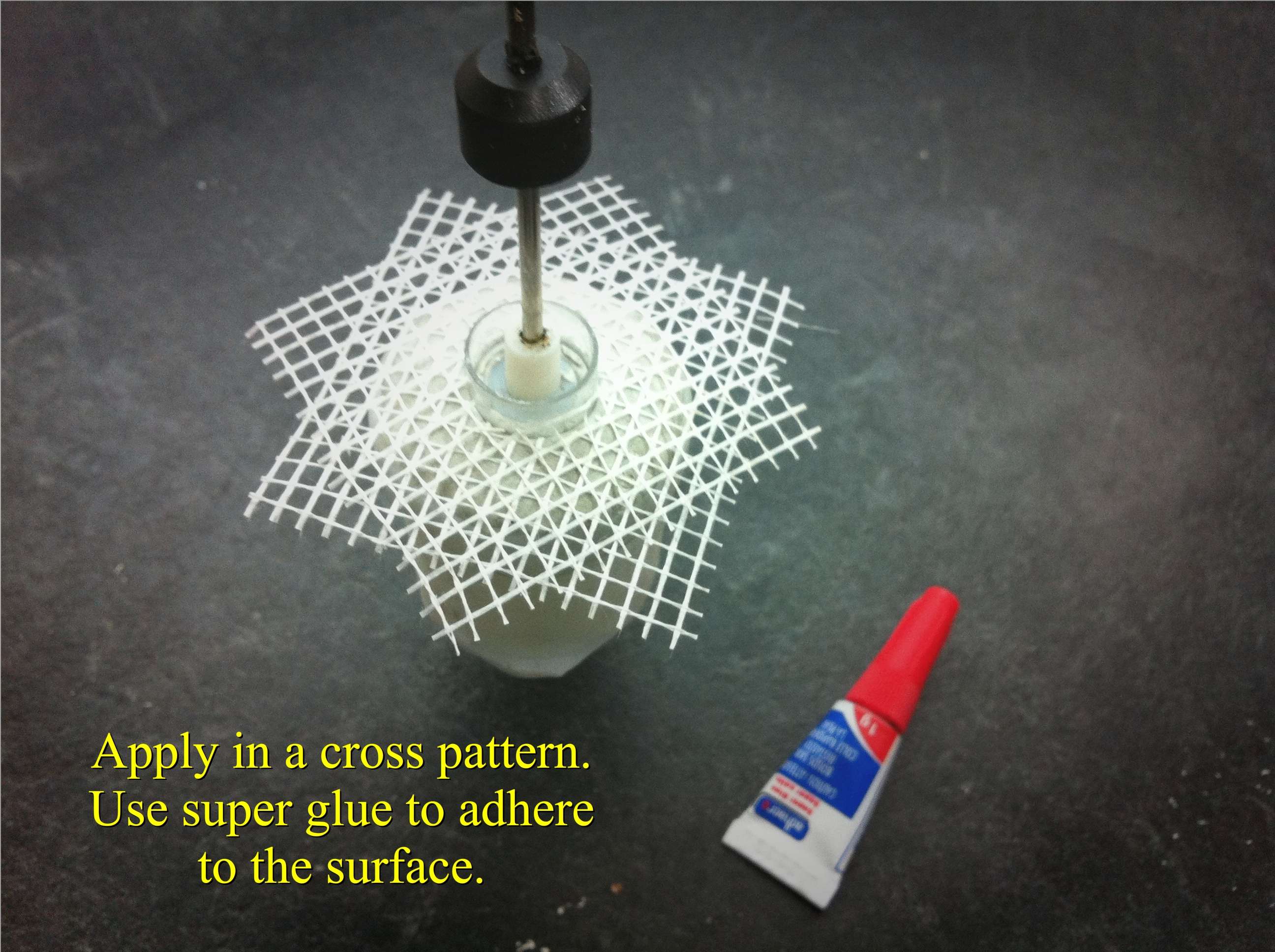

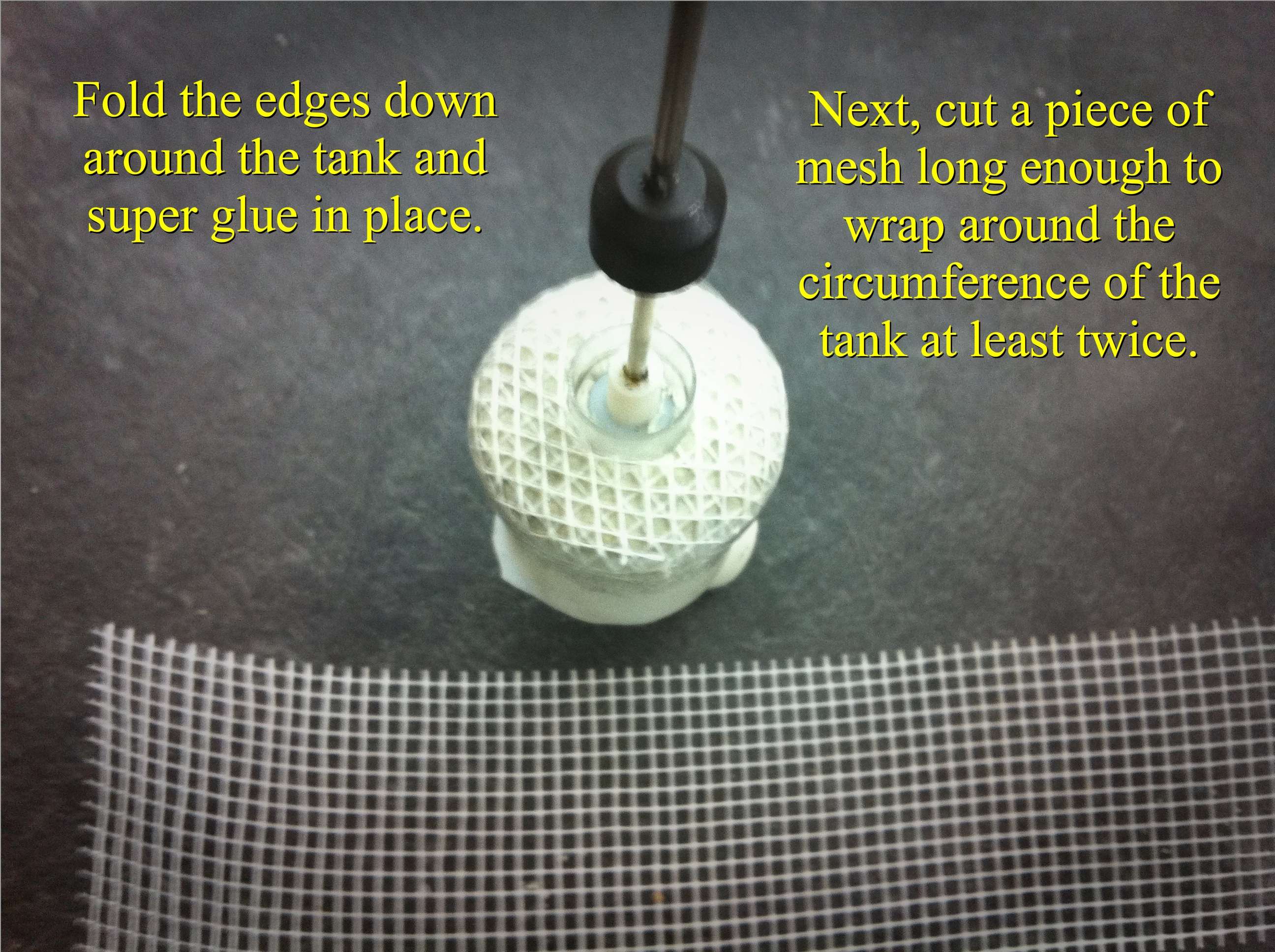

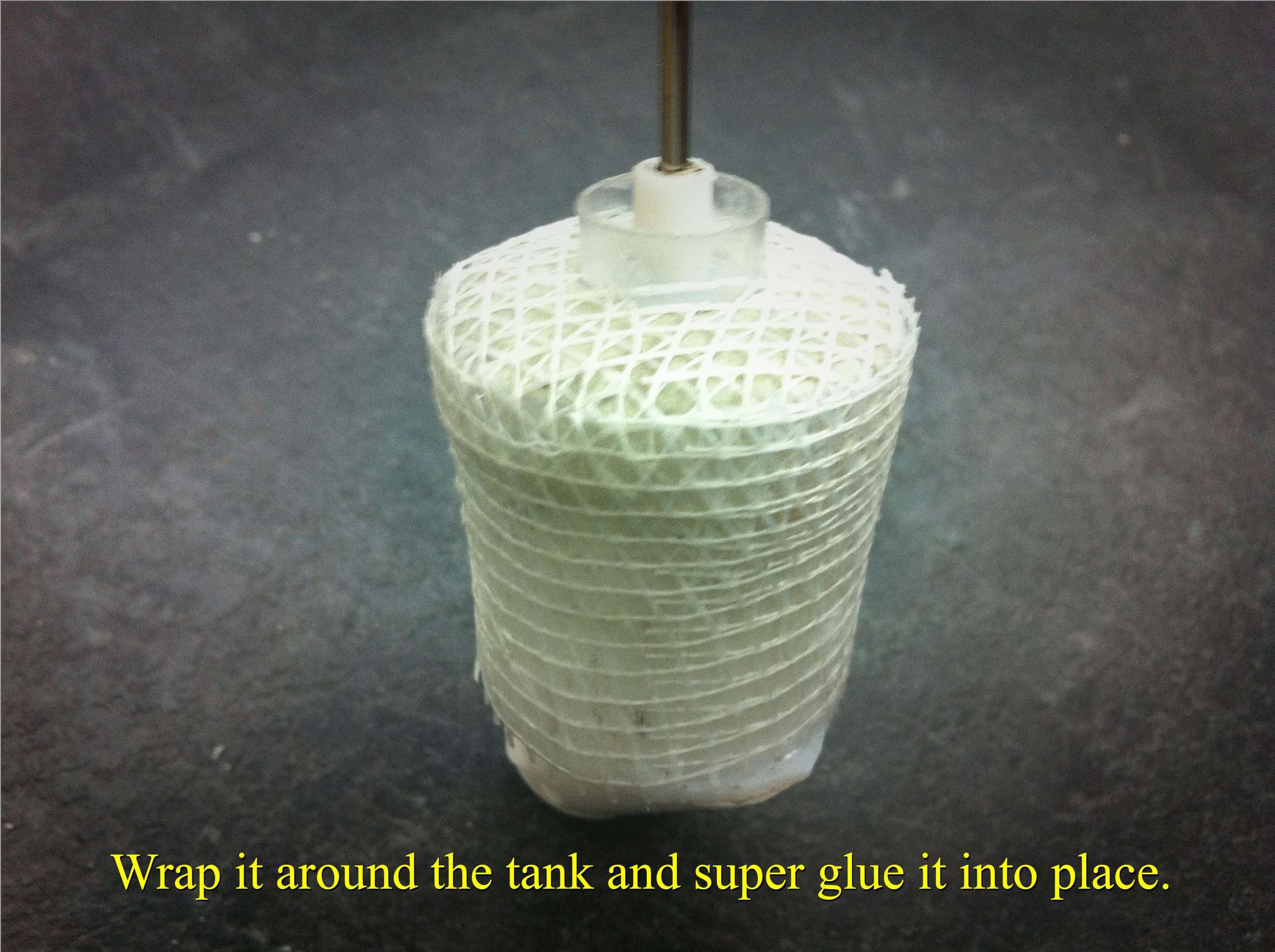

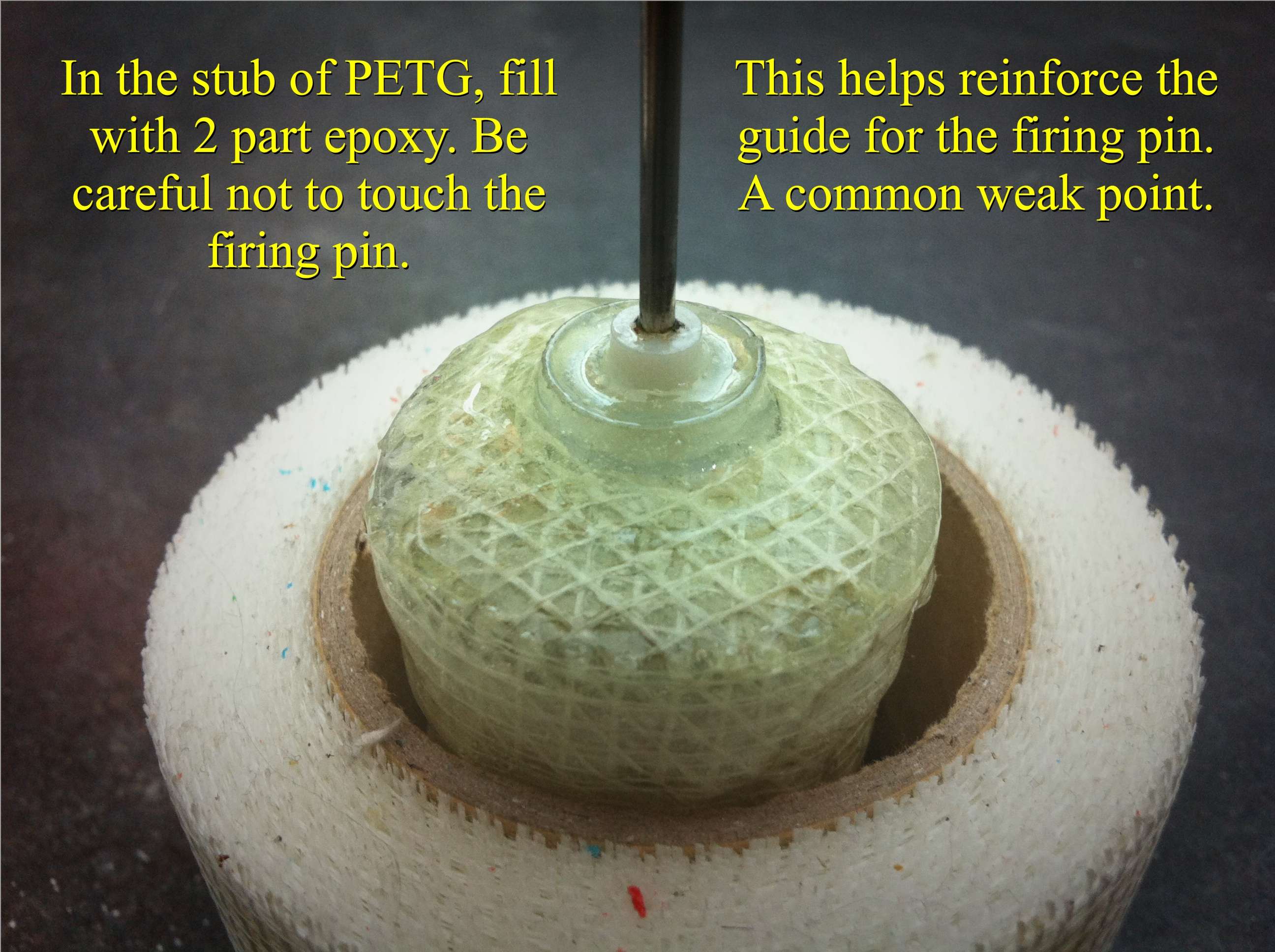

I have tried this and I don't recommend it. The epoxy resin isn't strong enough on its own unless you plan to make it really, really thick. I would assume the same is true for JB weld. The mesh is actually weaved nylon thread. Much like fiberglass and carbon fiber, combined with Resin, creates a much stronger and efficient composite.

The other issue is the 'shrapnel' danger. The epoxy resin alone is pretty much thick plastic. If the tank were to blow the pieces would fly off at high velocity flinging shards of sharp plastic everywhere. The mesh, along with giving it strength, also acts much like safety glass. If the tank were to rupture with the mesh in place, the risk of shrapnel would be greatly reduced. The nylon fibers would cling to the epoxy shards.

Edited by makeitgo, 16 May 2012 - 02:39 PM.