The idea for this actually came to me by happenstance a while ago, just before "Hell Before Halloween 5". I never got around to creating a write up about it because life became complicated. I lost a job, started a new job, bought a house, moved, family issues ... you know ... just life in general. Everything has settled. So no worries guys.

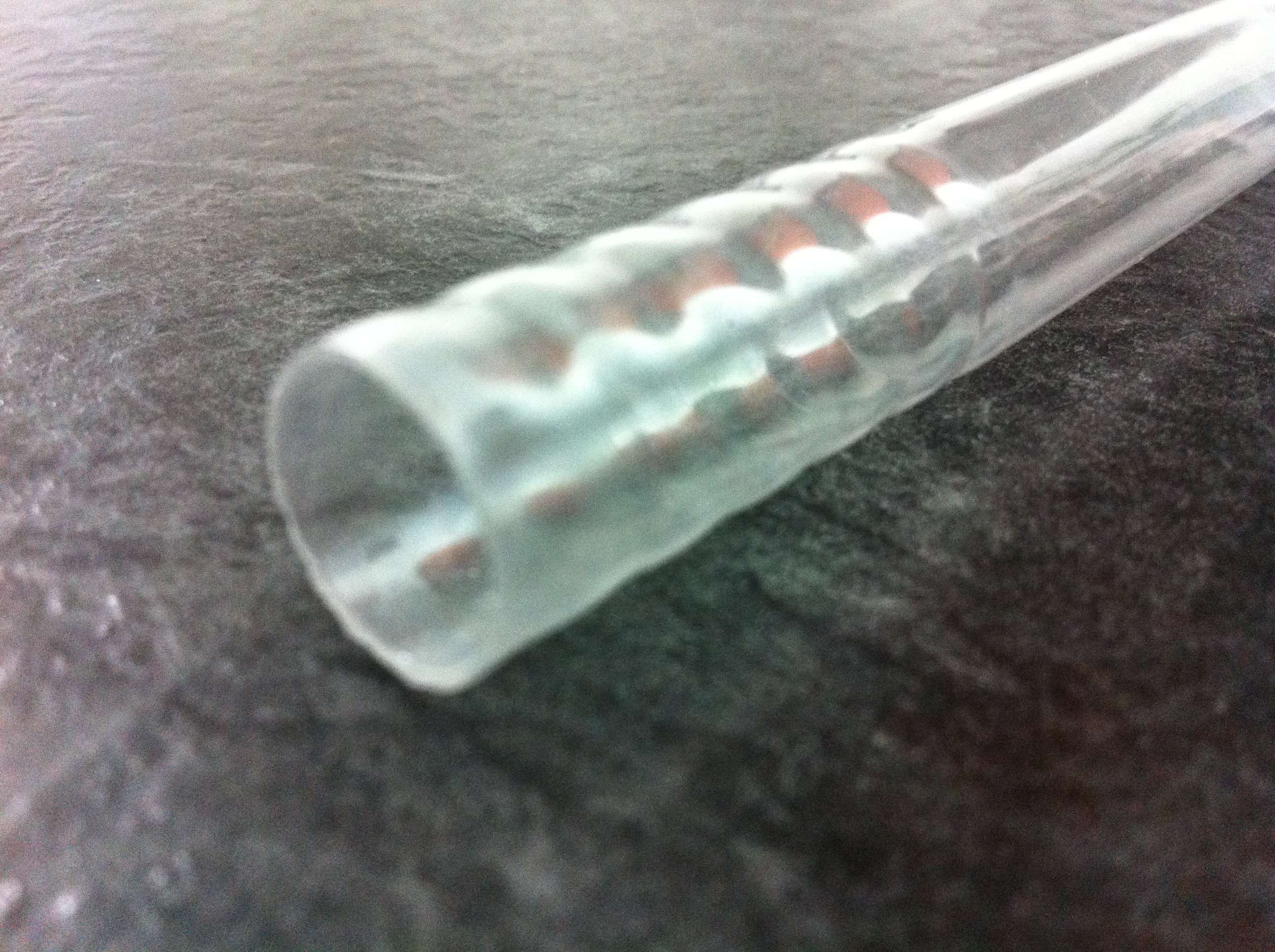

While I was making darts for HBH 5, I accidentally left my hot glue gun a little too close to some PETG (who hasn't done that?).

Much to my dismay, it had melted my PETG, something awful.

But as they say, "Where some see adversity, others see opportunity."

I had already known about various methods of creating tightening rings using stubs of brass or a pipe cutter with a washer. However, brass can be hard to find and can get expensive. Especially, if you like modding turreted blasters, like myself. Using a pipe cutter, even replacing the blade with a washer, I could never get the rings 'consistent' enough. i.e. each barrel had a different fit. Some looser, some tighter. Very annoying in turrets.

After examining my distorted piece of PETG, I had a stroke of genius. If you've ever seen the movie, "A Beautiful Mind" starring Russel Crow, I had one of those moments. The items in my immediate workspace started to float and glow and connect.... Here's what I came up with;

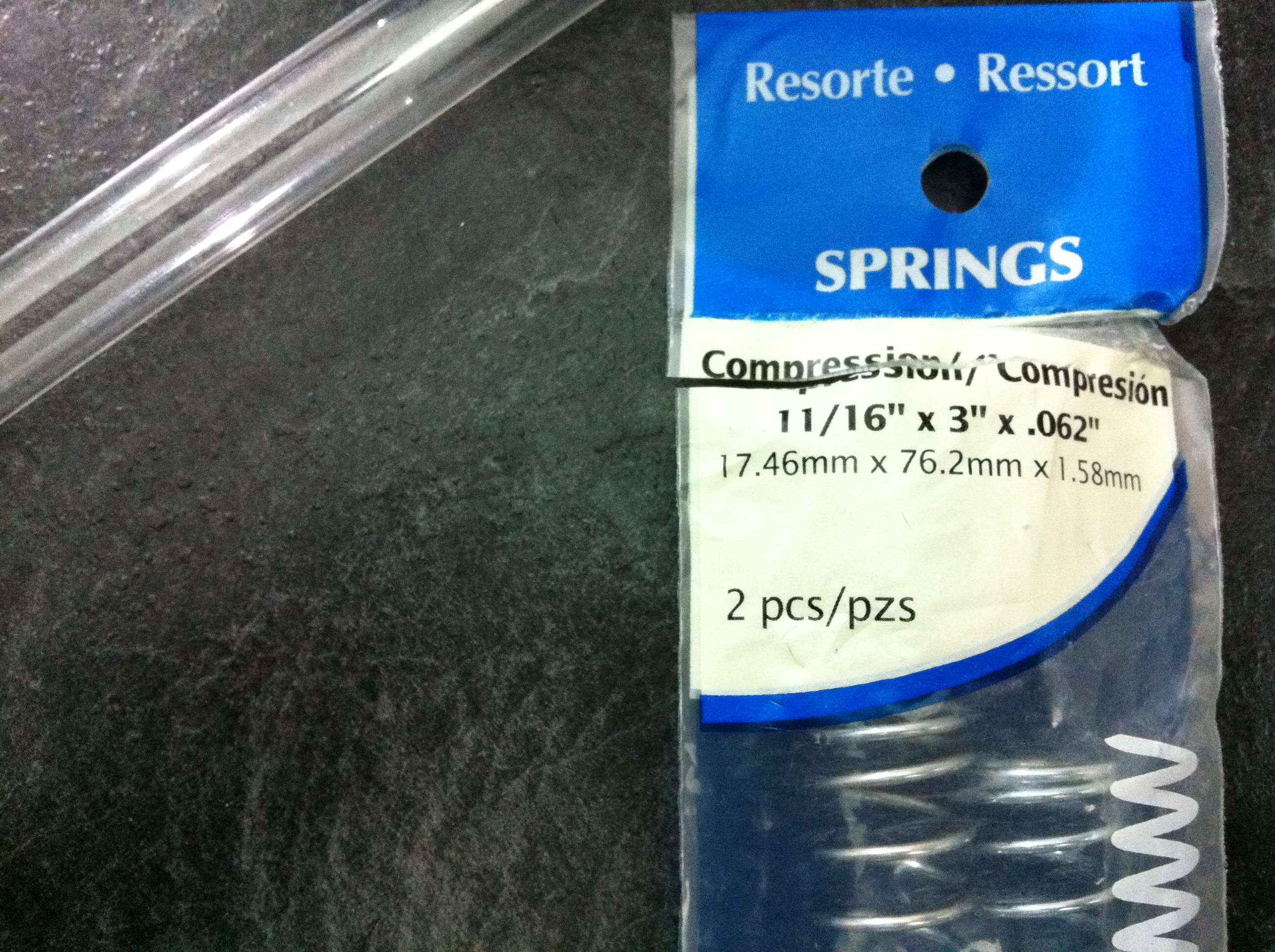

A hair dryer, some PETG and springs I had previously found at Lowe's.

I discovered that my PETG fit 'very' snuggly within these springs. A twist fit if you will. They come in a pack of 2 but you only need one of them.

I began by simply measuring my darts (dart length will depend on personal preference). In my case, it was about 4 cm.

So, I nested the PETG into the spring that amount.

Here's the part that makes this method cool.. or should I say hot (

Since the inner diameter of the spring is slightly smaller than the outer diameter of the PETG, when the spring gets hot enough, it will begin to bite into the PETG.

Before removing the spring, I waited for it to cool down. Maybe, 15 to 20 seconds. (Trust me. Let it cool down hanging vertically. Don't attempt to remove the spring before it's ready. You'll burn your fingers or at the very least, bend your PETG. Also, I don't suggest trying to speed up the process by running it under cold water.)

Voila!

- Buzz Bee foam

- cheap grey FBR (notorious for being too loose for PETG)

- Streamline... why not?

P.S. I've tried this with rubber o-rings but found it to be temper mental. The spring method is definitely more reliable.

Edited by makeitgo, 18 January 2012 - 01:26 PM.