Now, I love the feel of the PAS. It's great for aiming with, the stock feels great against my shoulder and its really easy to pump. That being said, although the internals are great they tend to break easily and are in constant need of repair. Because of constantly fixing my main primary MR.T I had tons of the PAS shells sticking around and I decided I wanted to make something that had the comfort of the PAS but would last longer then 2-3 wars.

Things you will need:

- A PAS shell

- An AT2K pump

- A Big salvo tank

- A blast button (thanks to XIII for selling me his from his hornet)

- A Check valve

- A 2 way splitter

- Lots of tubing

- Lots of Epoxy putty

- Lots of super glue or other epoxy

- Plumbers goop

- Some sort of cutting device. Dremels work best.

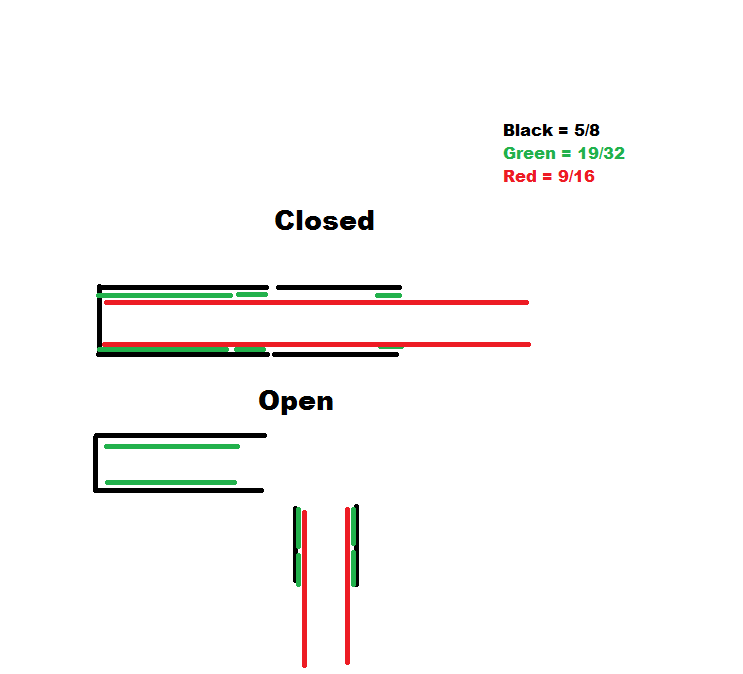

Optional for my Breech

- 1/2 brass

- 17/32 brass

- 9/16 brass

- 19/32 brass

- 5/8 brass

- a hinge of some sort

First thing I did was connected my internals together.

This is probably the easiest part, attach the AT2K pump to the check valve, attach the check valve to the T splitter, and then attach the two parts of the T splitter, one to the blast button and the other to the salvo tank. Don't worry about tubing length right now, we'll figure out all that stuff when we get further along.

Take your PAS shell and grab the brown handle that is used to pump up the gun. Make sure you know which part is the front and the back, dremel out the back part so that there is a large open area for the 2K pump to attach to.

Now, take the end of your 2K pump, the part with the 2 large holes in it and make the holes a little bit bigger until they fit over the screw port on the pump on your PAS. It should look like this when it is done.

I made the mistake of first trying to sand down the screw port to fit inside of the 2K pump hole, big mistake. The screw ports are hollow on the inside. If you replicate this mod make the hole in the AT2K pump bigger. It should fit on fine after a little tweaking.

Next, you want to remove the trigger guard on the PAS. It will just get in the way of your pumping, use a cutting tool to remove this. After this is done you are going to want to make a large hole where the trigger was in the PAS. This is so that the rest of your AT2K pump will be able to fit in there.

Take your time before you epoxy the rest of the 2K pump to the inside of your PAS shell. This can take some time but you want the PAS shell to be able to close around the 2K pump. Plus, if the 2K pump is on an angle then it will bend and possibly break when you try to pump your gun. My advice is try to get the 2K pump as high up in the gun as possible. If you are having problems with this it may be easier to attach the 2K pump to the middle notch in the PAS pump. It is slightly lower then the screw ports.

Use your dremel and a drill bit to make a tiny hole in the top of the stock of the PAS. This is where your tubing will come out of.

Another hole in the back part of the PAS will allow your tubing to flow seamlessly from the pump back into the gun where you want to put all the good stuff. It should look something like this.

For the blast button I really wanted to put it where the PAS trigger was, either on the side or right on the front, sadly there is only so much you can cram into a PAS shell and I didn't want to put the blast button on the outside on account of too much tubing to get stuck on trees and corners plus it just looks sloppy. My backup spot was on the left side of the gun right near the pump.

This will allow me to fire quickly after pumping. Its not ideal but its the best place I could come up with. Dremeling a nice snug hole until the blast button fits then anchoring it in with Super glue and epoxy putty will do the trick.

Now one thing I will comment on, which is probably the most difficult part of this mod.

I hate big salvo tanks. They are oddly shaped, they get smaller more towards the front and I have a tough enough time keeping regular barrels straight, keeping the tank straight for these is a nightmare.

Although I used 2 inch PVC as a sleeve for it I don't really recommend it. It didn't really help. Just eyeball it the best you can and anchor the tank in with some epoxy putty when you have the barrels where you want. Try to make as much of the barrel stick out the front of the gun as possible.

Now you could stop here and have a pretty cool gun by adding your favourite barrel material to the front of this, or you can take this one step further and do what I did.

More to come. Please don't post until finished.