The FANG will be a semi-automatic nerf gun. Right now I have all of the moving parts aside from the magazine complete. I might redo some of them if it'll improve the function later but it essentially functions as it should. The only problem at the moment is that my bolt returns slowly, which was likely due to some gunk on the outside of it from it's construction.

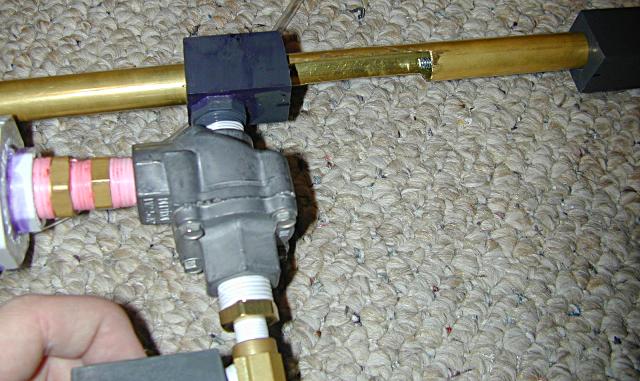

This gun uses the same DCV actuated QEV that I've mentioned before and that CaptainSlug intends to use in ARR. This makes the gun very efficient, too efficient in fact. I've reduced the pressure chamber volume since describing the valve assembly and my stefans are still falling apart on impact. I'll definitely lower the pressure from 40 PSI but if more change is needed I could add more pilot volume or reduce the pressure chamber volume more.

Let me state that this is just a prototype using parts I could easily source and tools I had available at my home (a drill press, a rotary tool, and some saws). This is far from the best way to build this design, in fact, I think it's a hack job. I wholeheartedly intend to replicate the basic design with aluminum using the machine shop at my university sometime in the next few years, but until then I'm sure this will serve me fine.

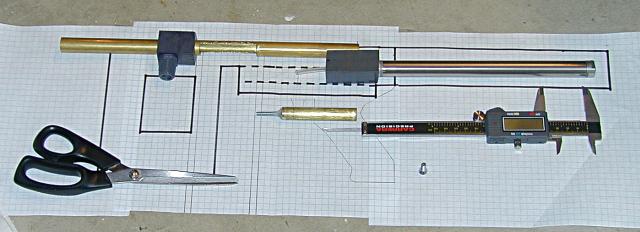

Pictures follow.

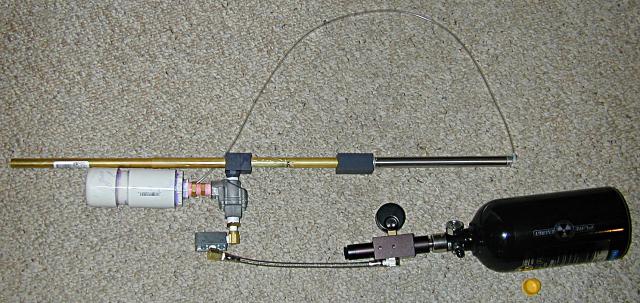

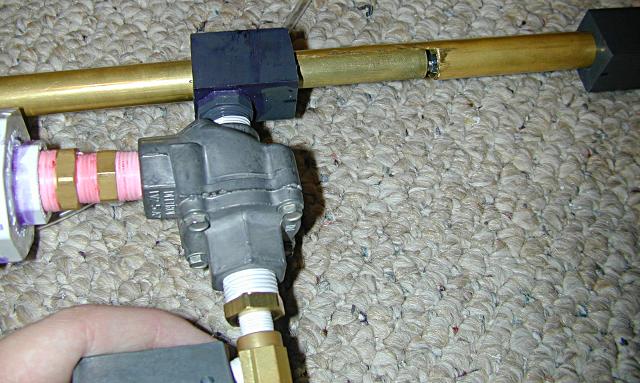

An overview of the current system. The moving parts aside from the magazine are complete so I can test the system under pressure.

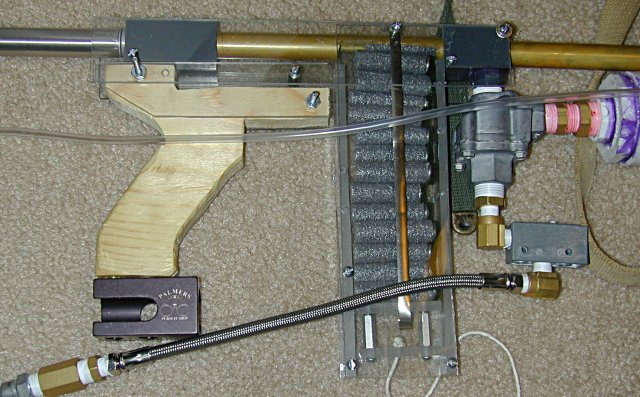

The bolt is open. My finger is on the button on the directional control valve.

The bolt is closed.

There's obviously a good deal of work to be done, and some of it's not very obvious. I'll post more later. Right now I have other things I need to do. I've already spent too much time on this project.

Any questions, comments, suggestions, etc. are welcome.

One last thing. FANG stands for FANG automatic nerf gun. It's a recursive acronym.

Edited by Doom, 06 December 2008 - 04:26 PM.