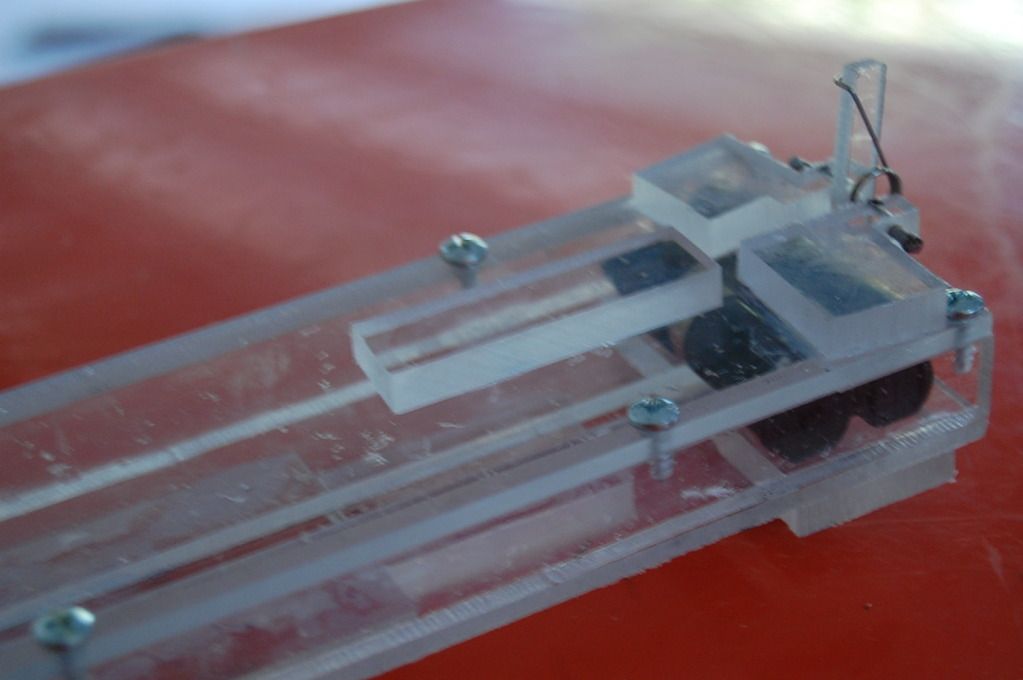

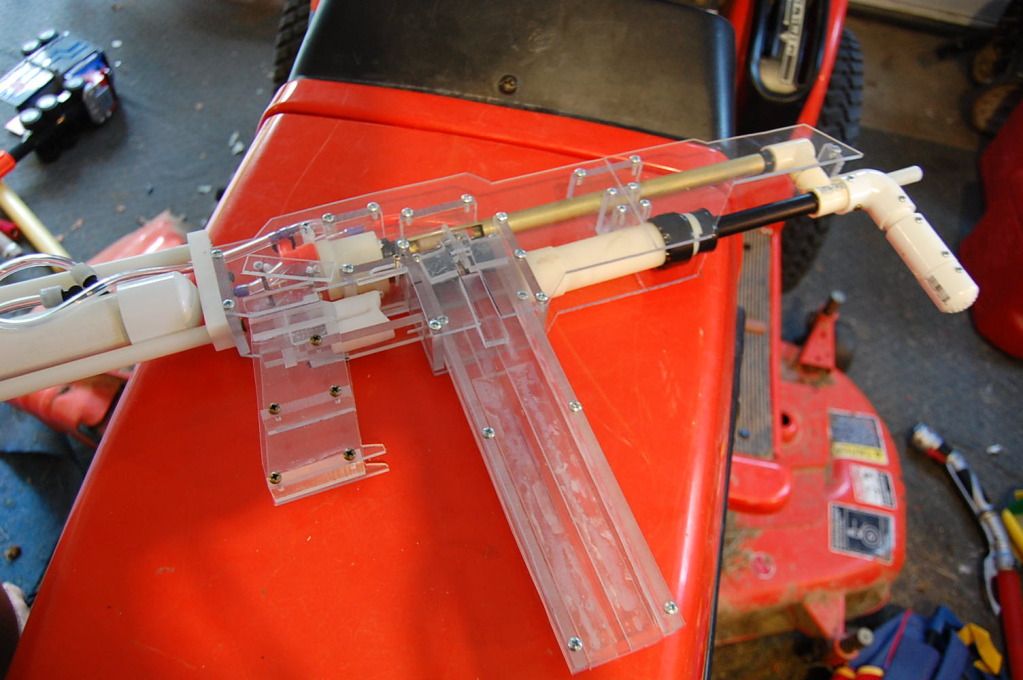

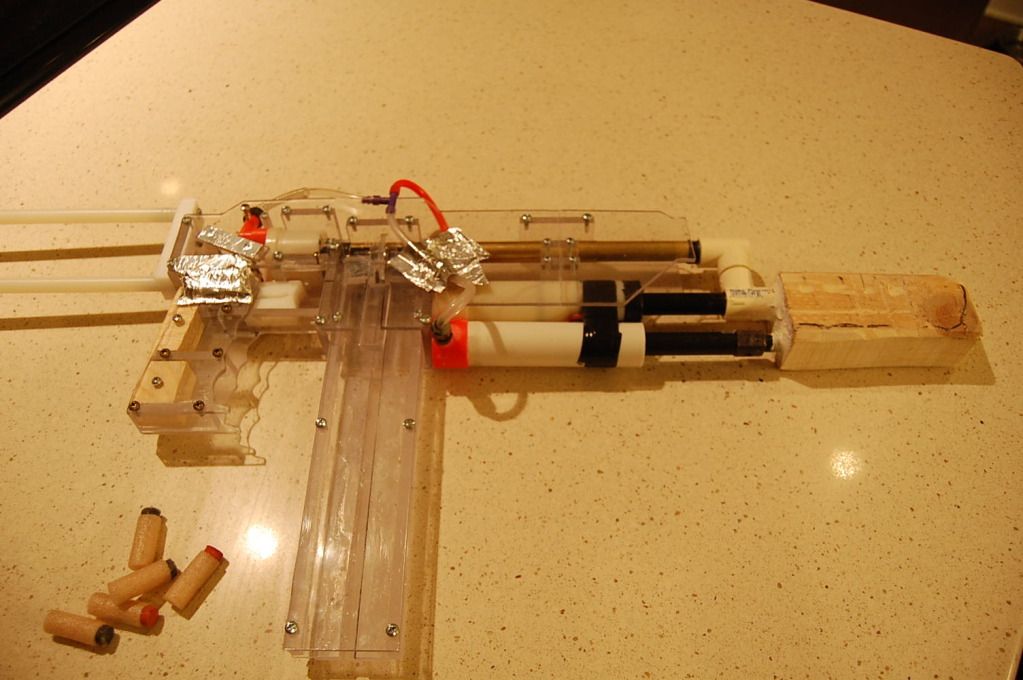

This project has been in the works for about a month now, and I can safely say it turned out pretty good.

The whole point of this gun was to create a reliable primary that could shoot straight up, fire with decent range, and without all the internal stress of a Springer. The only option that would fill all those criteria would be a clip-fed air-gun. (plus I really felt like building something, that helps two!) Without further ado: the RAD-V1 write-up!

Parts list:

McMaster number or store.

Amount:

2] 12” by 12”, 1/8” thick polycarbonate sheets. 8574K26

1] 12” by 6” , ¼” thick polycarbonate sheet. 8574K282

1] 9/16” brass tube. 8859K35

1] 19/32” bras tube. 8859K36

1] 5’, 7/16” Nylon rod 8538K17

1] ½” thick cutting board. Wal-Mart

100] 3/8” long pan-head Phillips screws. Lowes

1] Scrap of 1/16” Plexiglas aka acrylic

2] ½” cpvc tees VVVV

1] ½” cpvc pipe

1] 1”pvc

2] 1” pvc end-cap

1] 4’ of ¼” vinyl tubing

3] ¼” tubing coupler

1] Electrical tape

1] ½” pvc elbow

1] ½” pvc coupler

1] ½” pvc end-cap

1] ½” pvc pipe

1] AT3k tank OR Robomans aluminum At2k tank. Nerf parts bin.

1] AT3k pump OR equivalent VVVV

1] AS-20 bleed valve

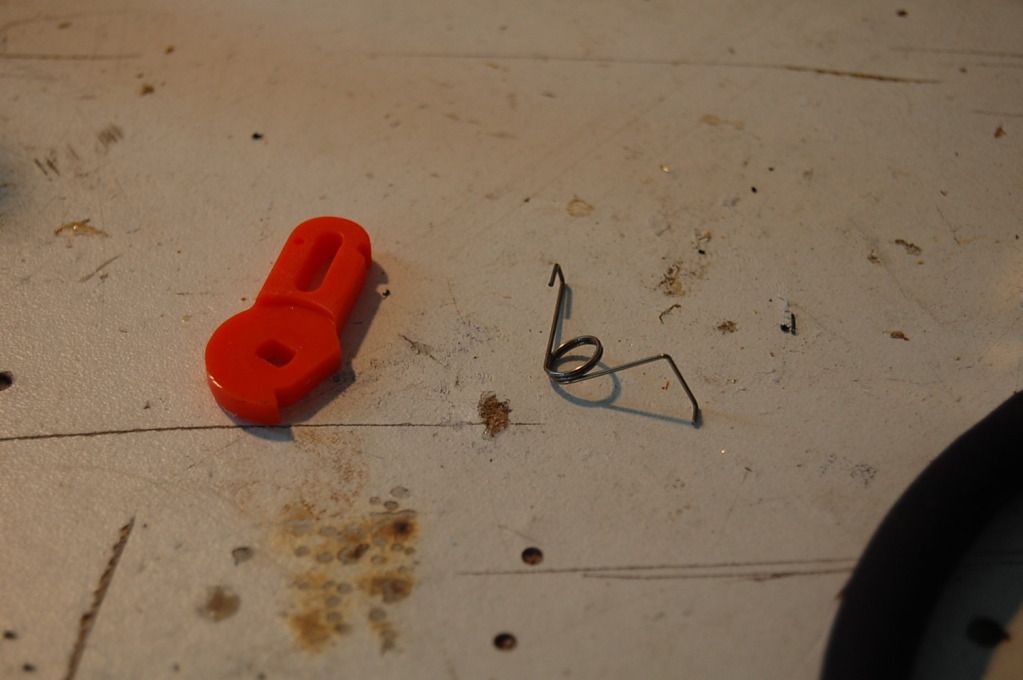

?] Assorted small springs, all the ones I used are from an AT3k.

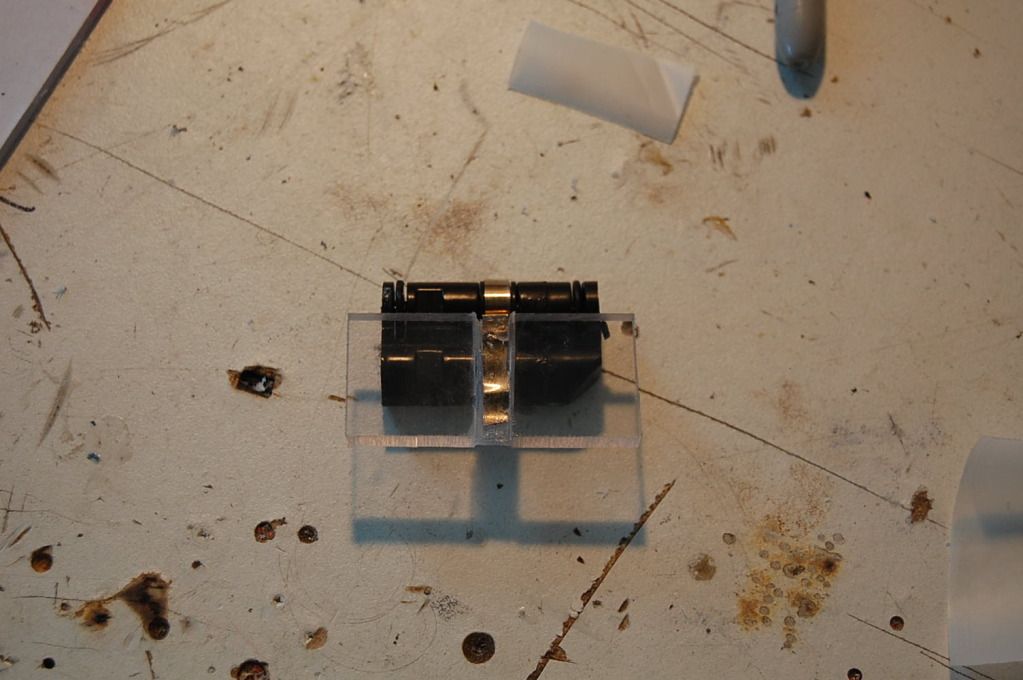

1] Alpha-trooper magazine dart pusher thingy (the black piece with the constant-force spring)

------------------------

Tools.

Band saw or scroll saw, although I guess you could do all the cutting with a dremel. : P

Dremel, with a few bits.

Assorted pliers and screwdrivers.

Ruler

Pens, markers and pencils.

Sandpaper

Drill

Drill bits

Razor blade

Straight edge

A lot of patience!

-----------------------

Bonding agents:

Super glue

PVC solvent

Epoxy (optional)

White glue (for the templates)

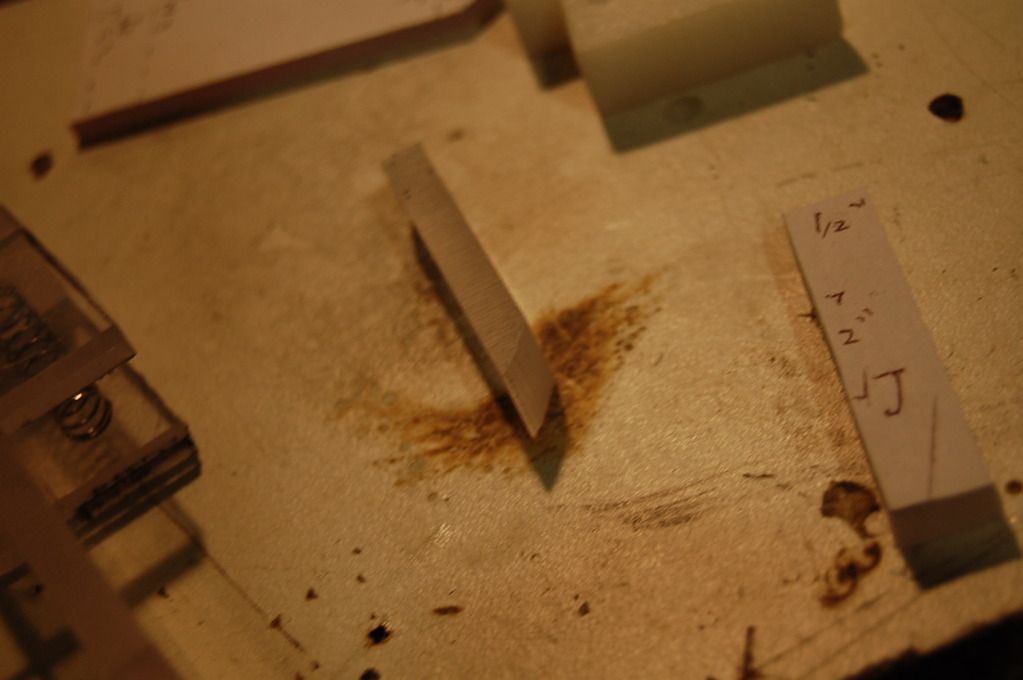

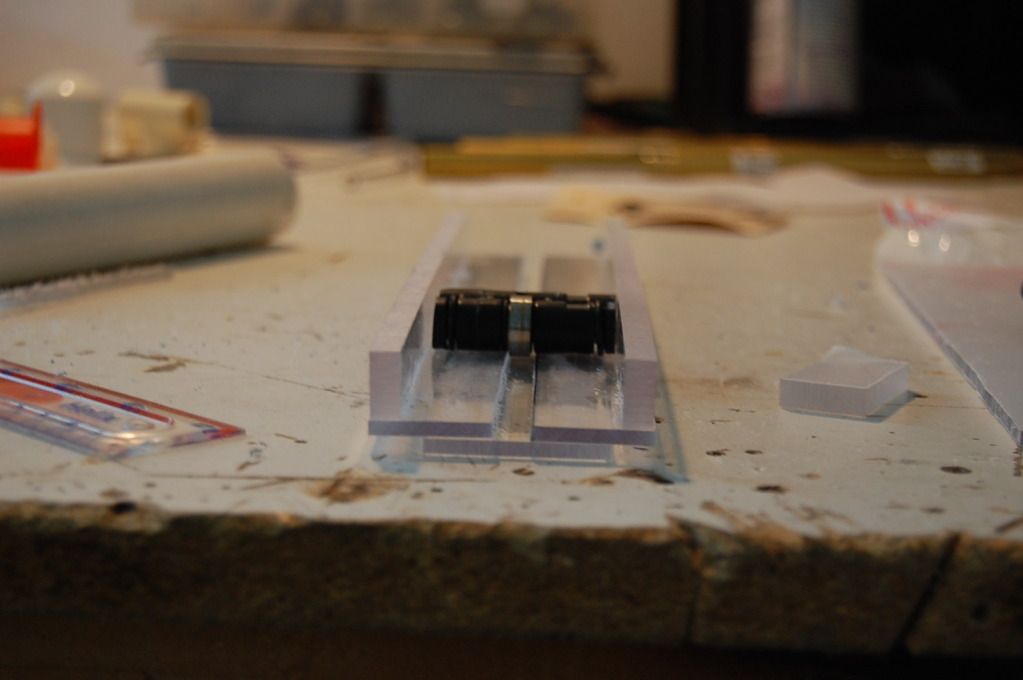

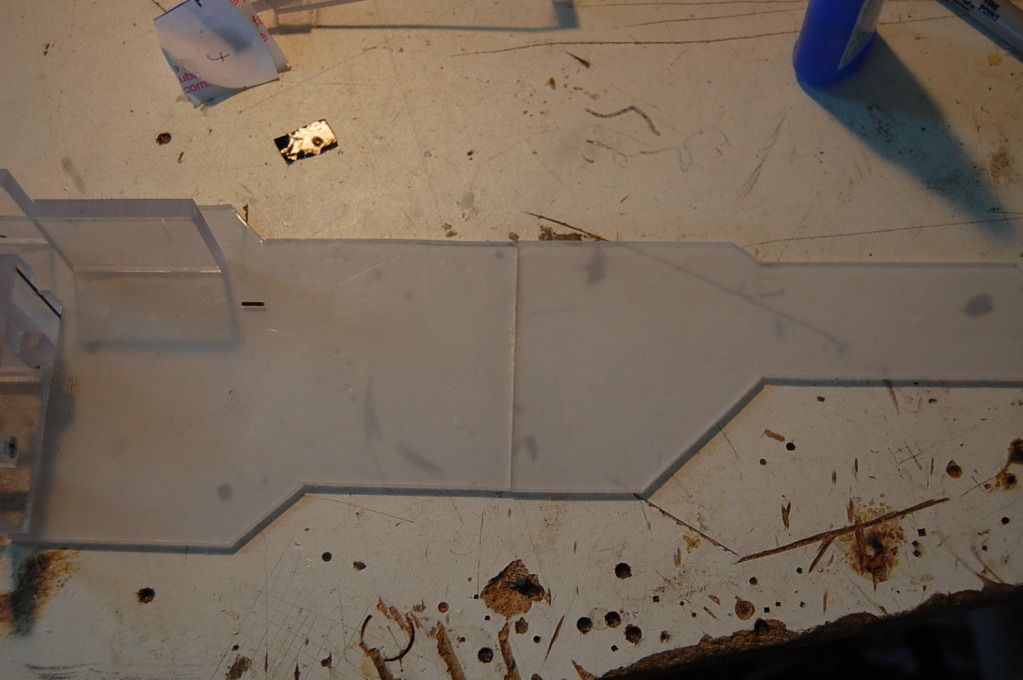

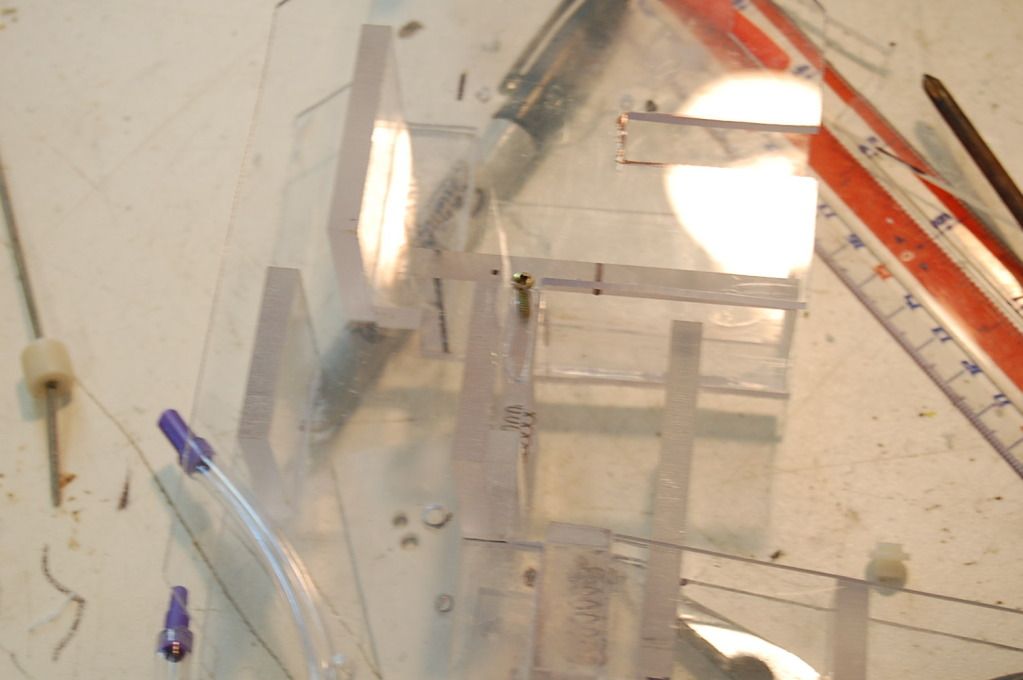

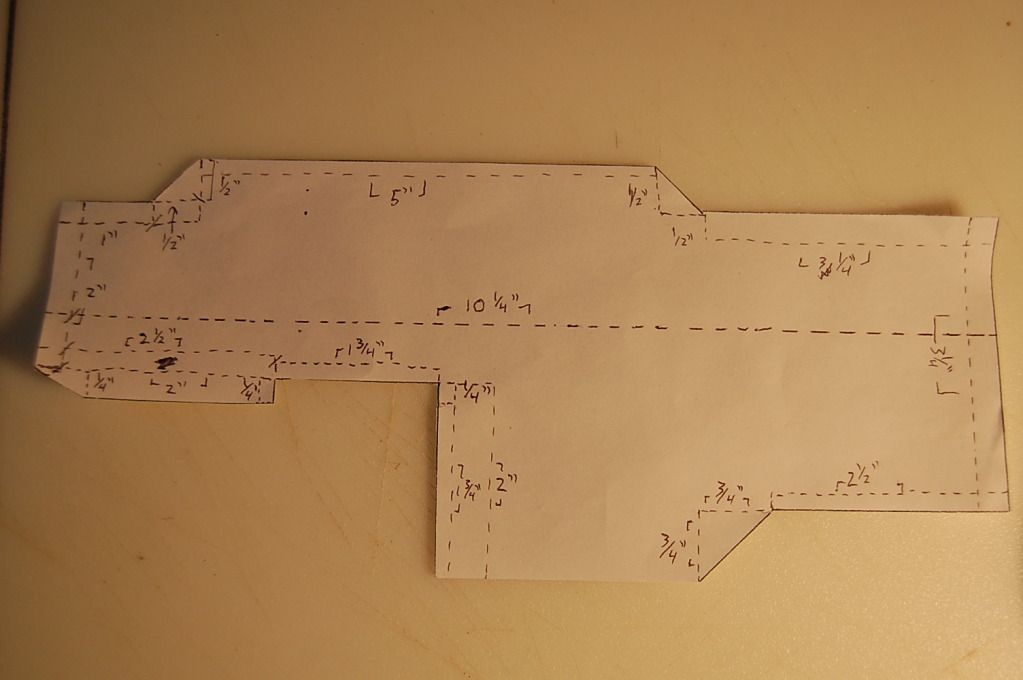

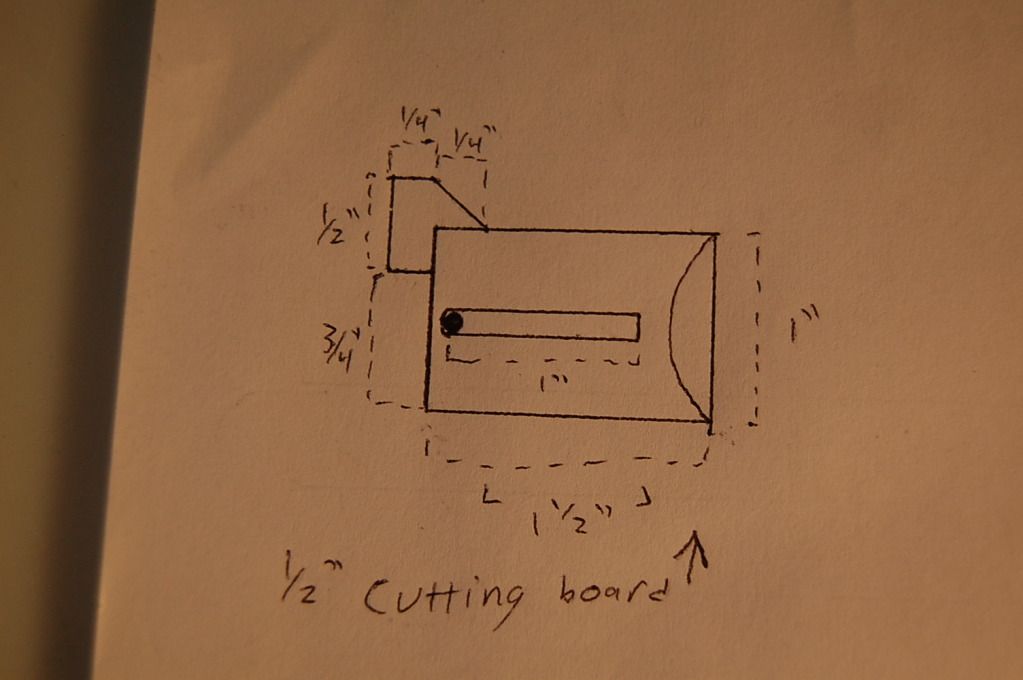

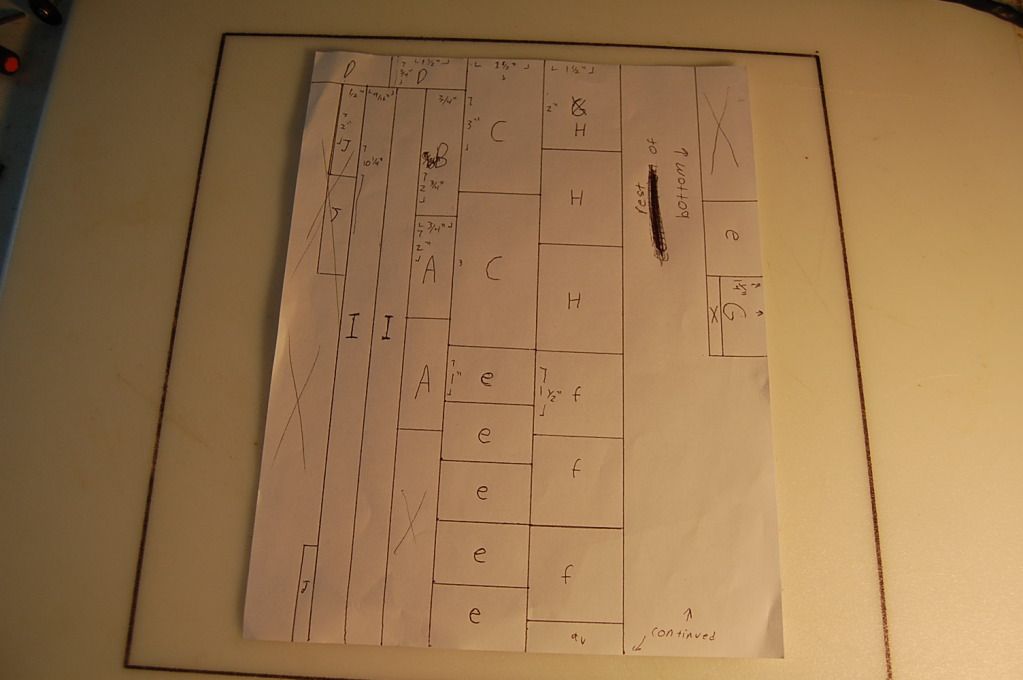

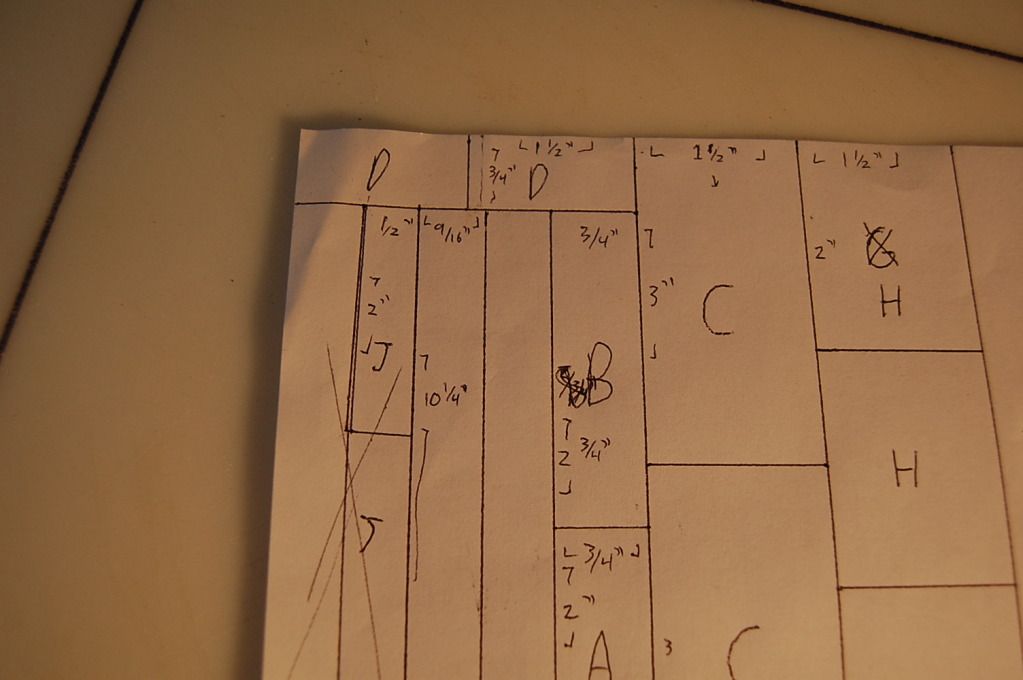

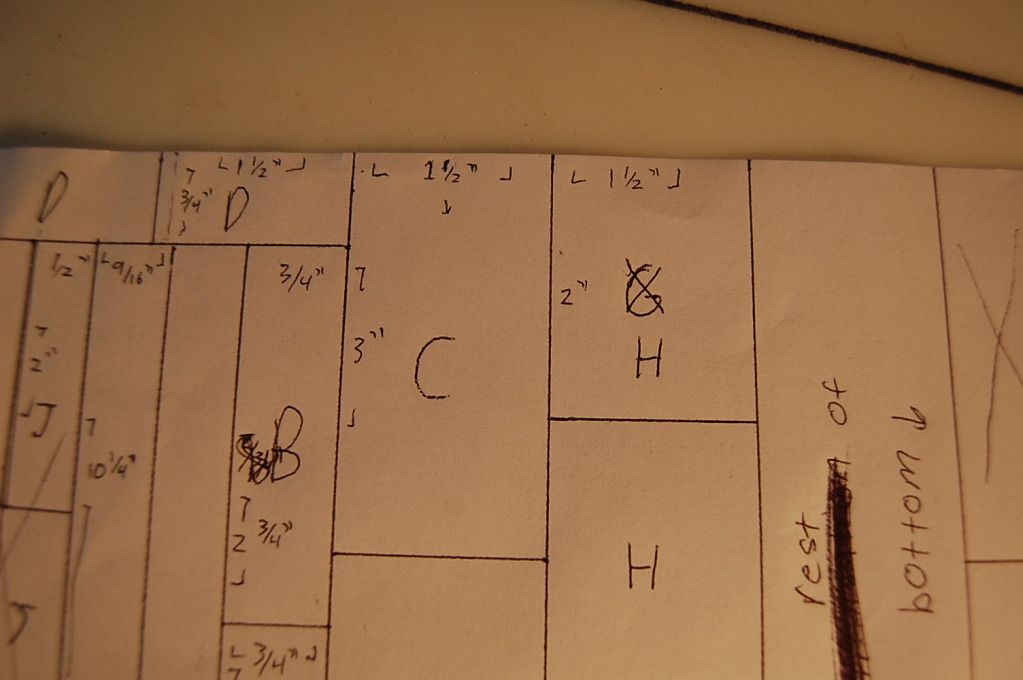

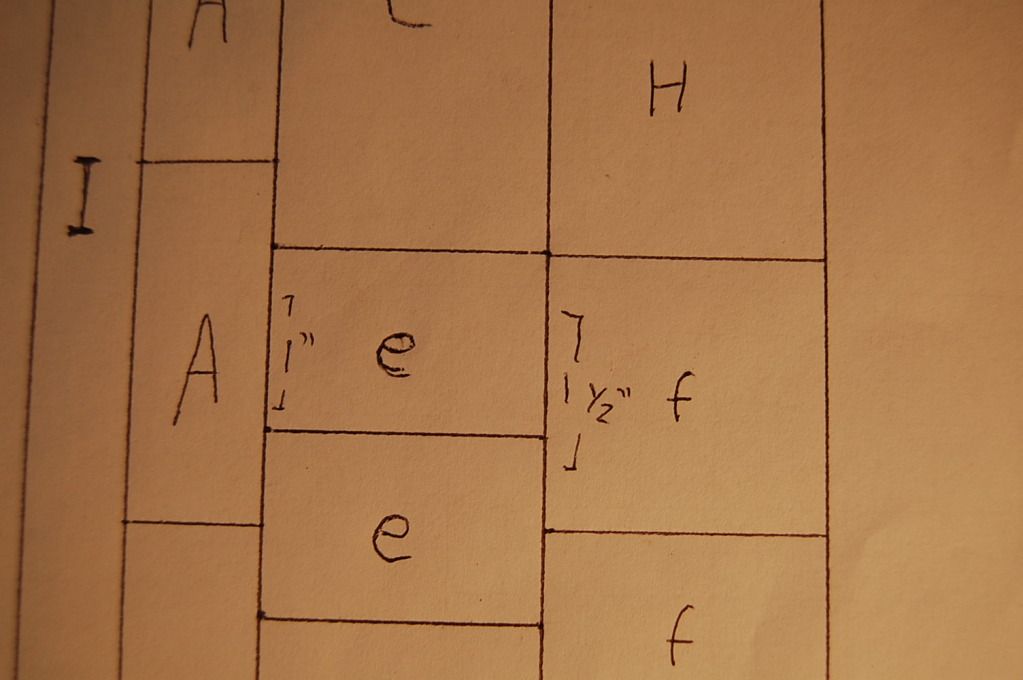

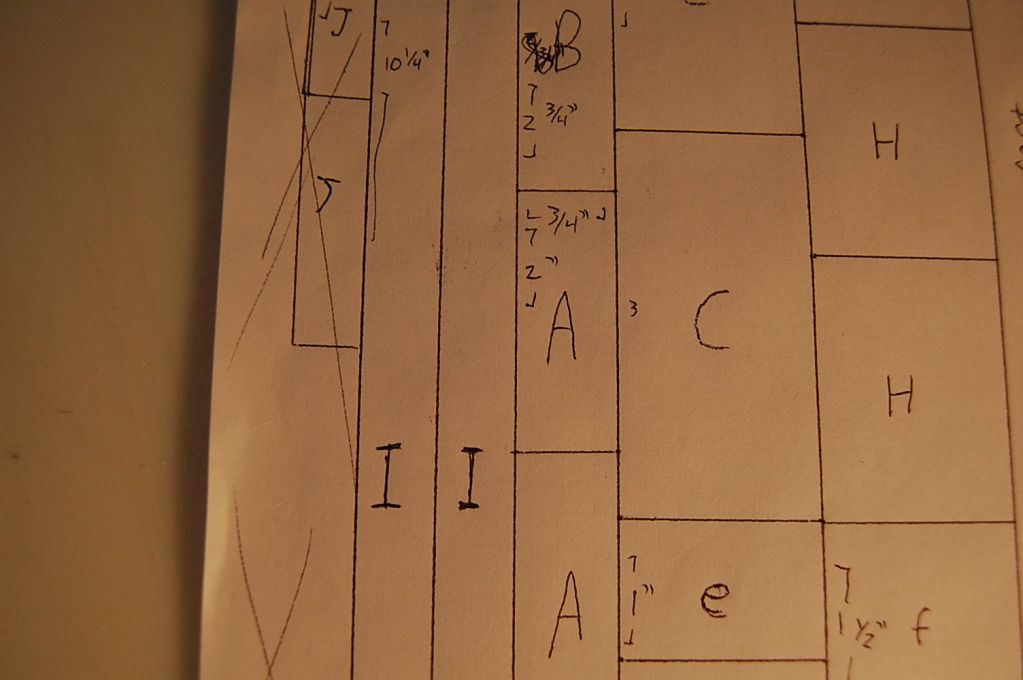

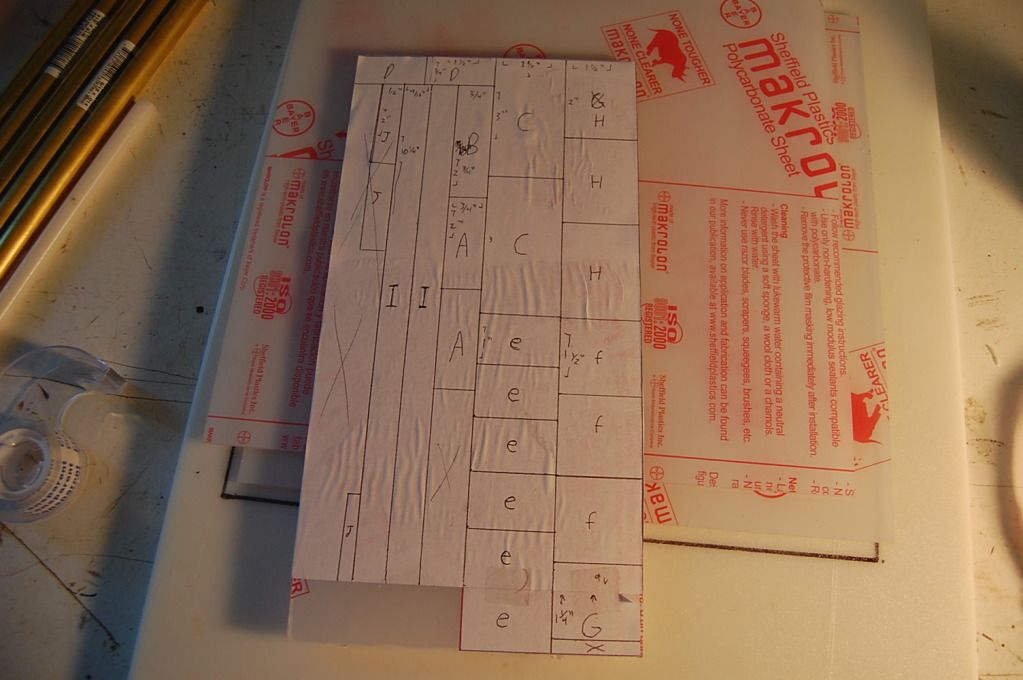

Alright, time to start! I painstakingly made all the templates for this gun by hand, and here are pictures of all of them. Most of the main body of the gun is made from 1/8” polycarb, and all the standoffs are made from ¼” polycarb.

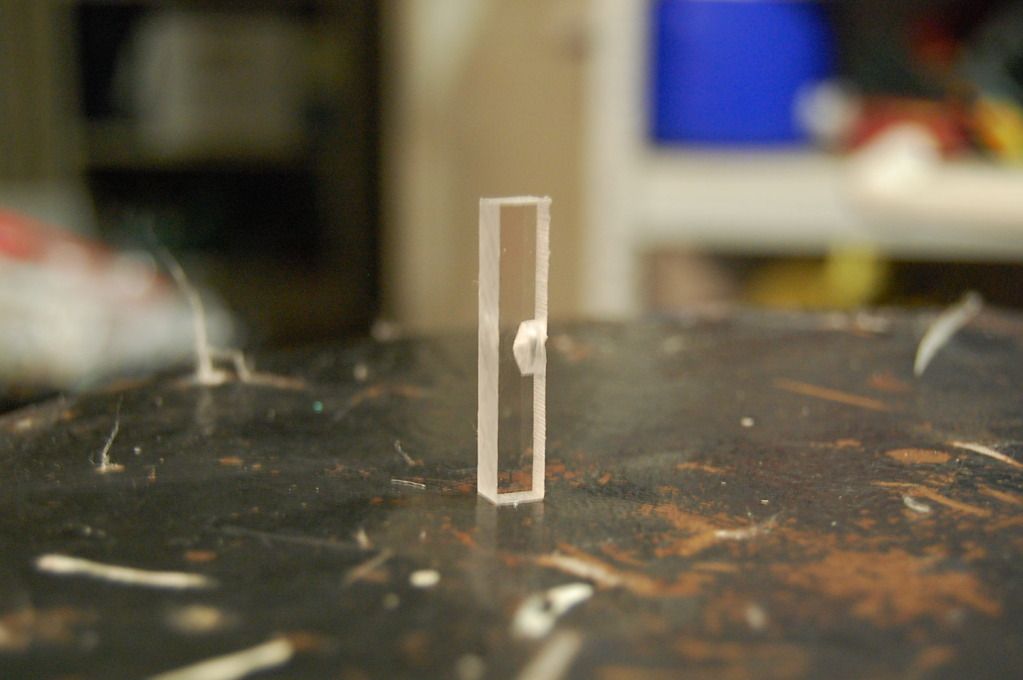

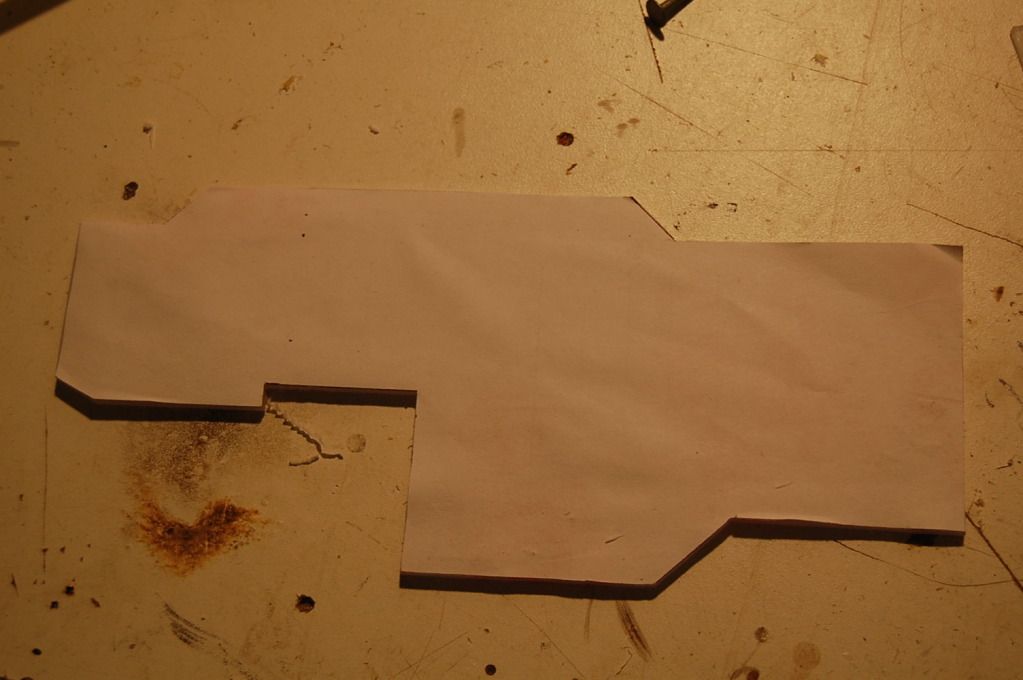

Here is the first template:

Make two of these.

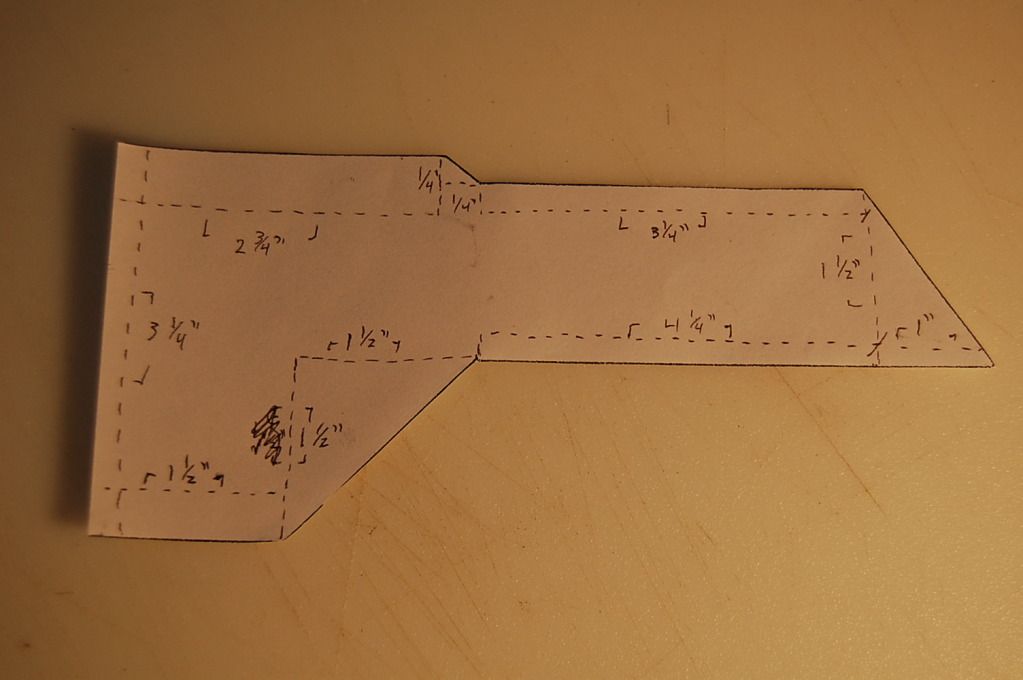

Front of gun:

Make two of these.

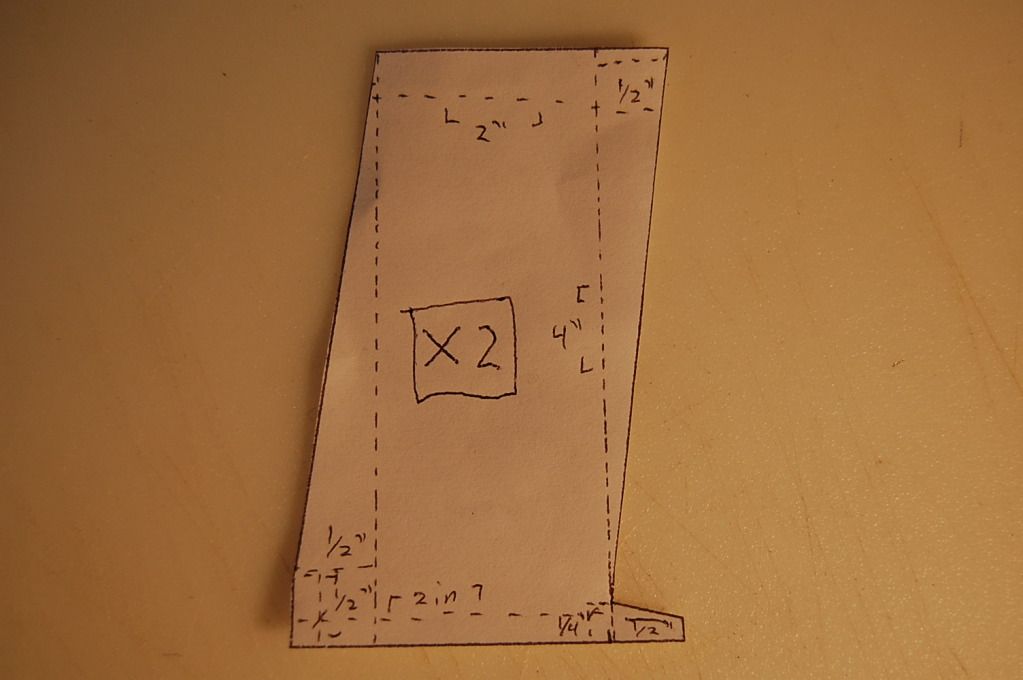

Handle:

Make two of these.

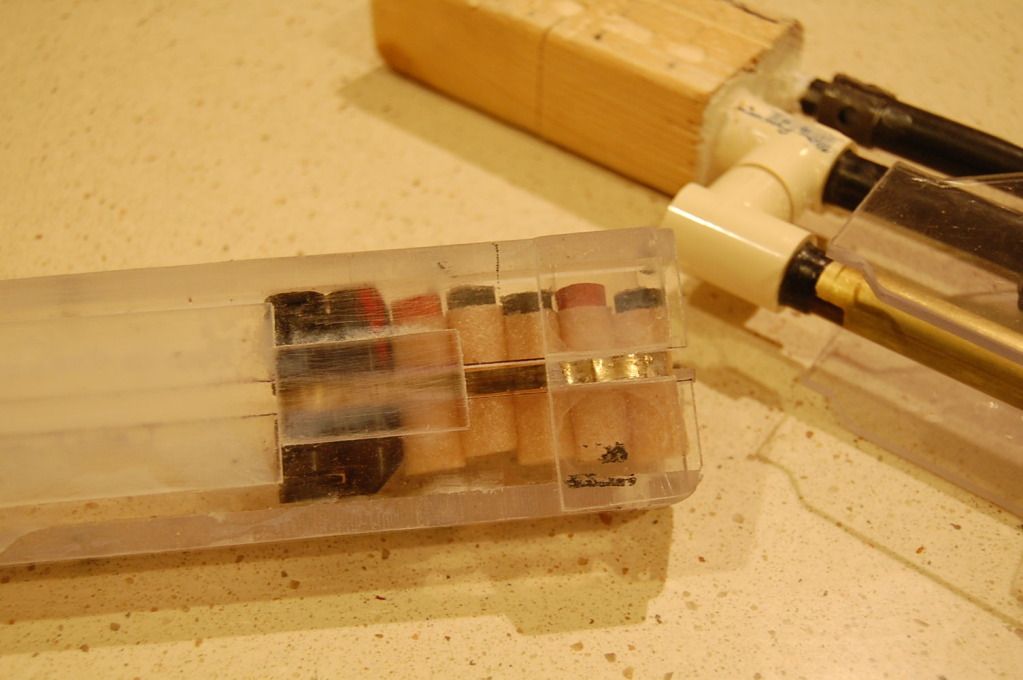

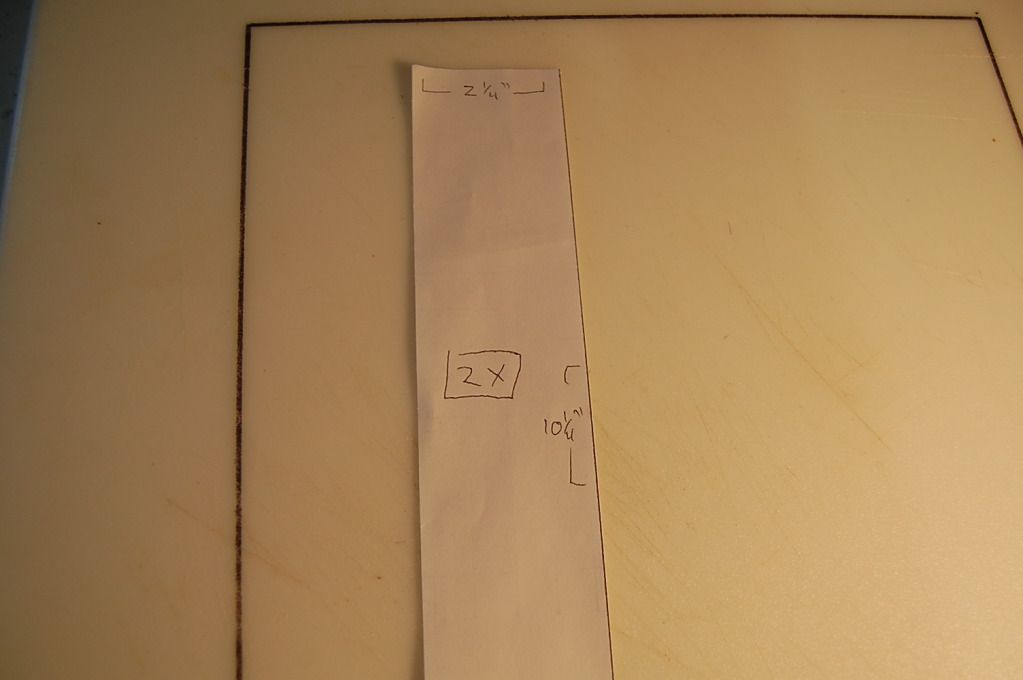

Magazine sides:

make two of these

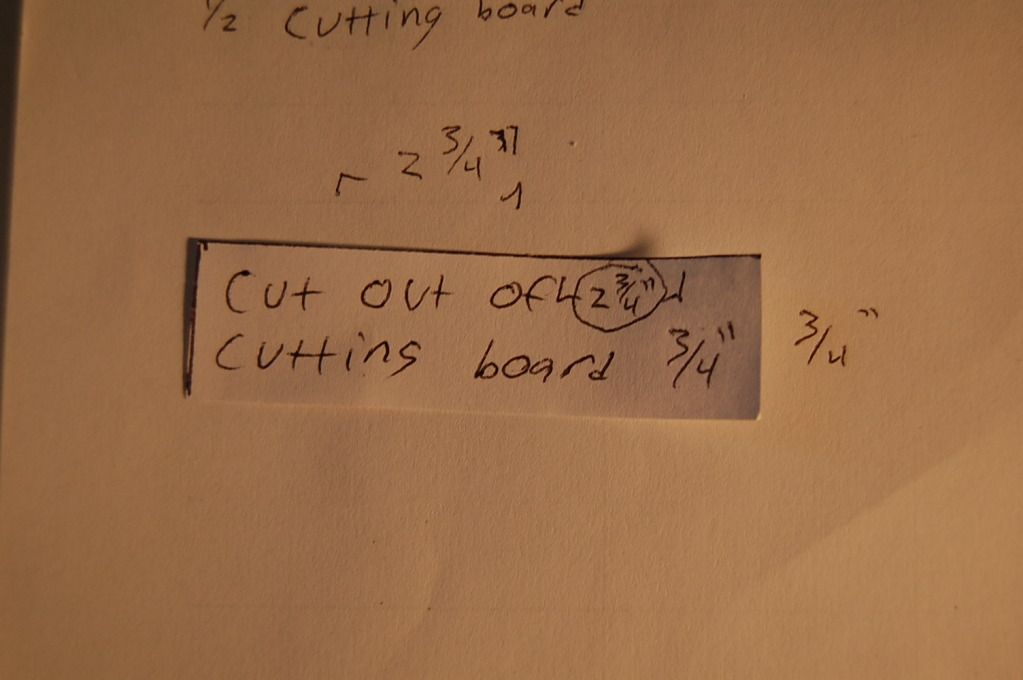

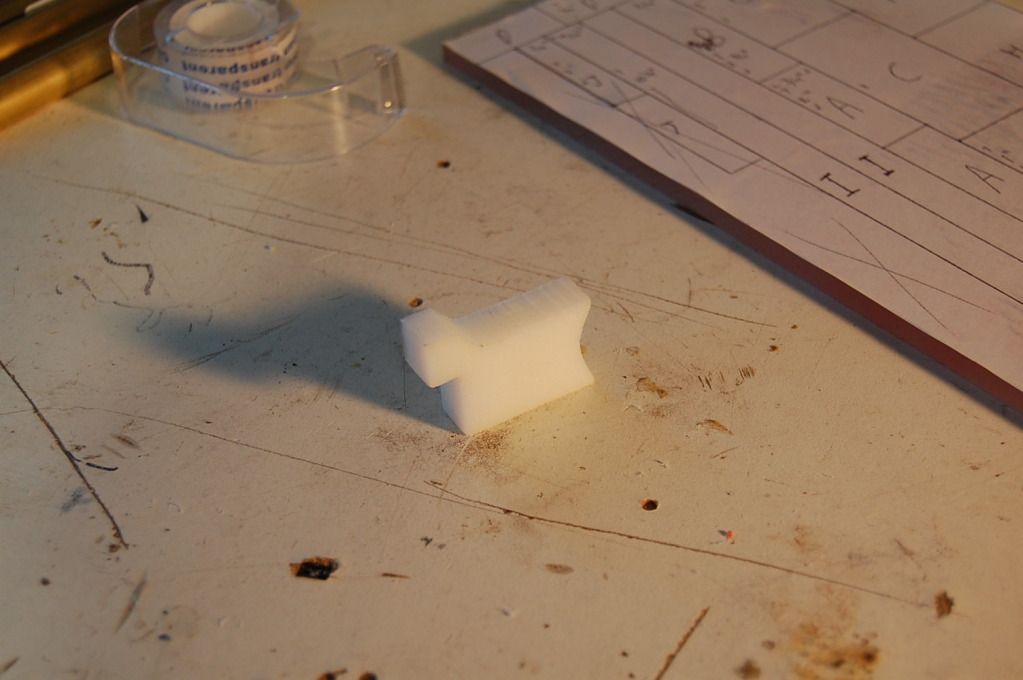

Parts made from cutting board:

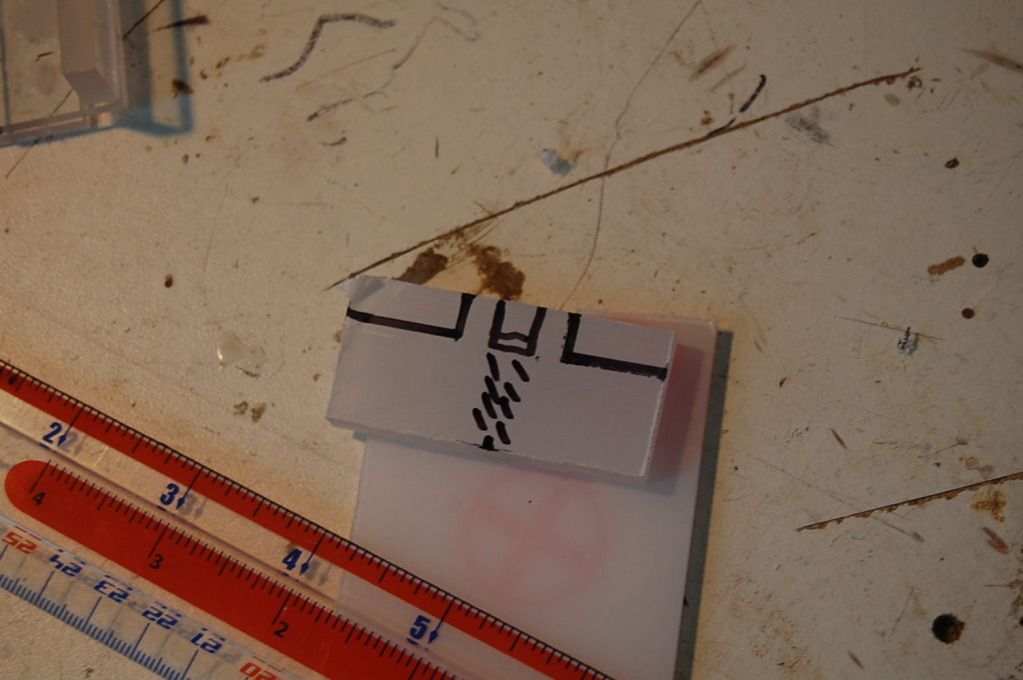

Trigger;

Make one of these

Stock mount:

make one of these

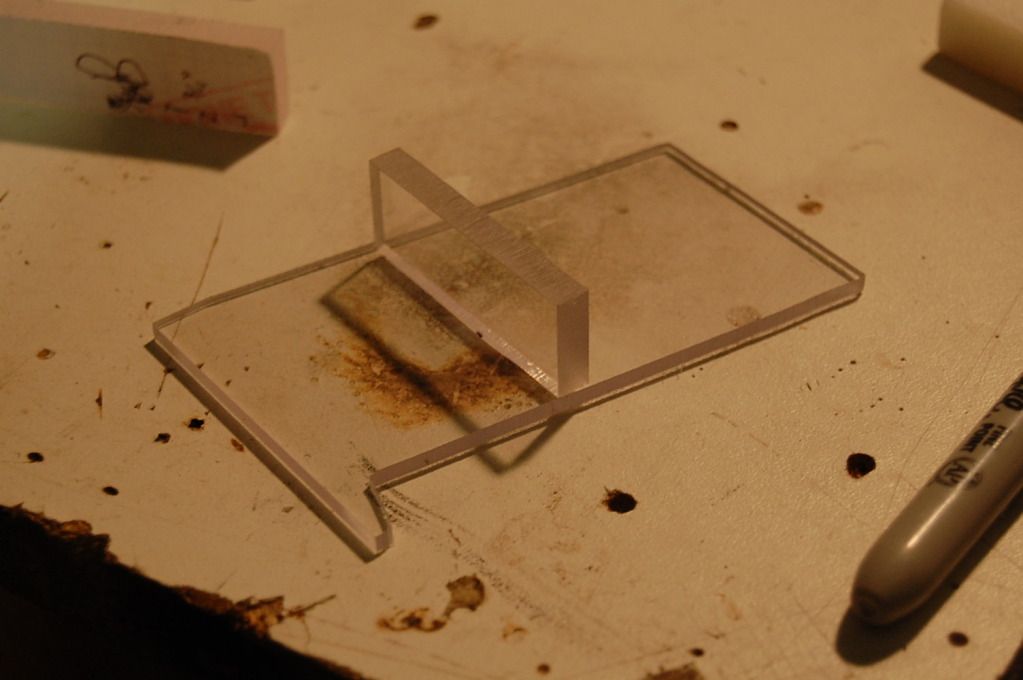

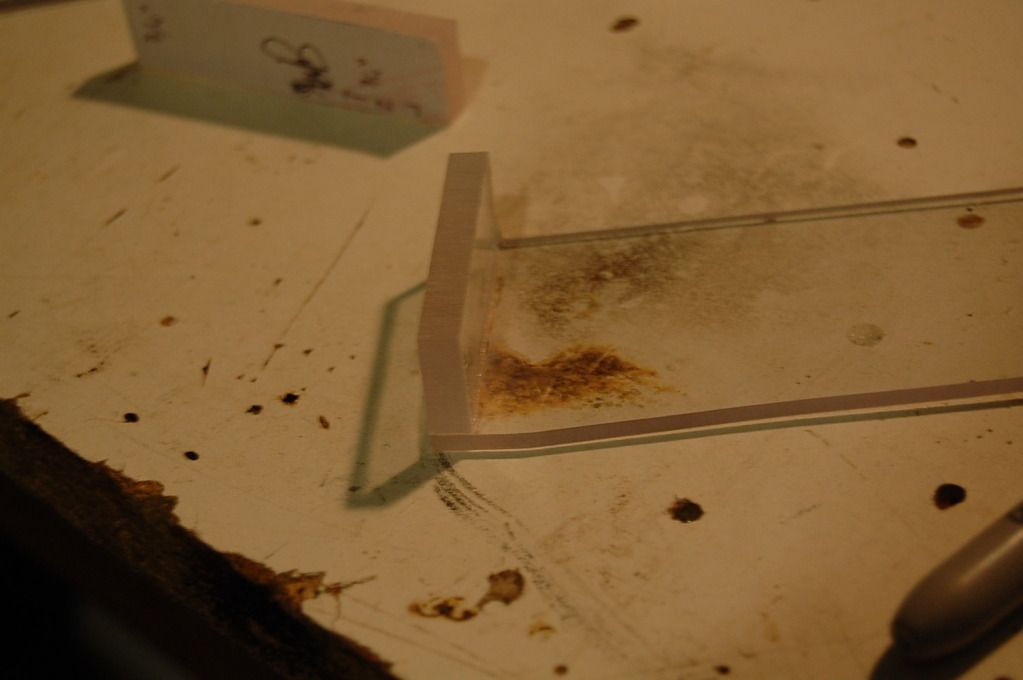

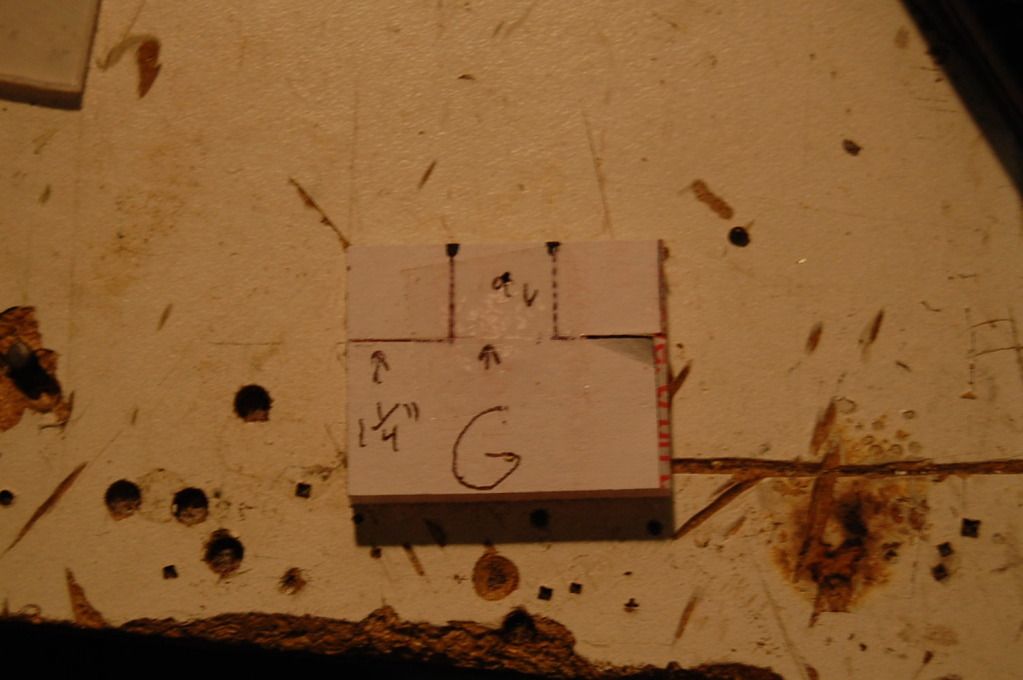

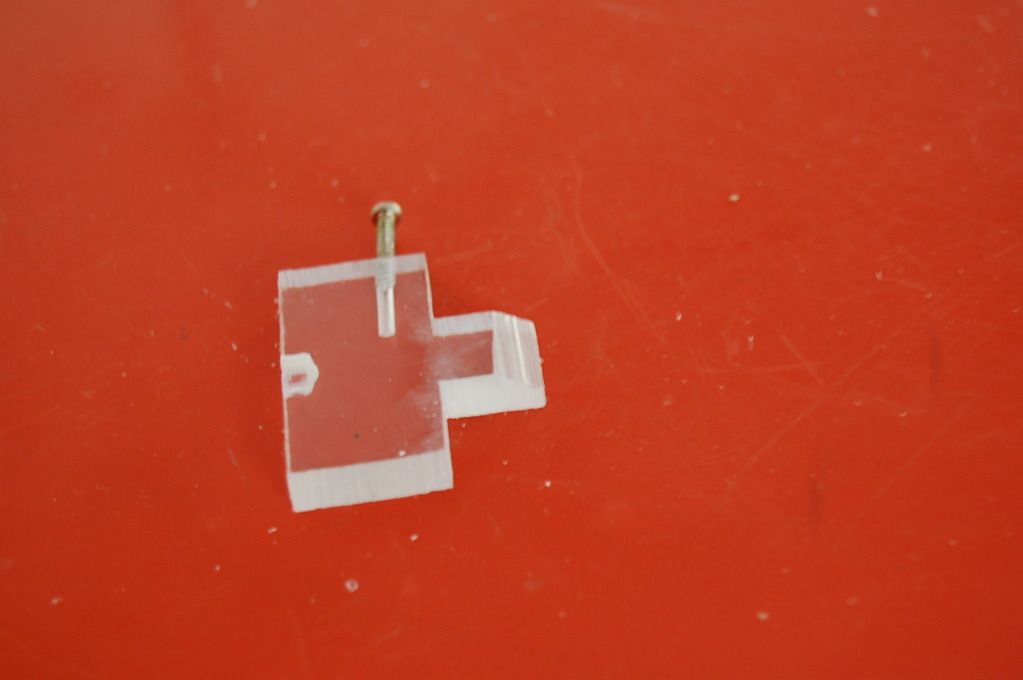

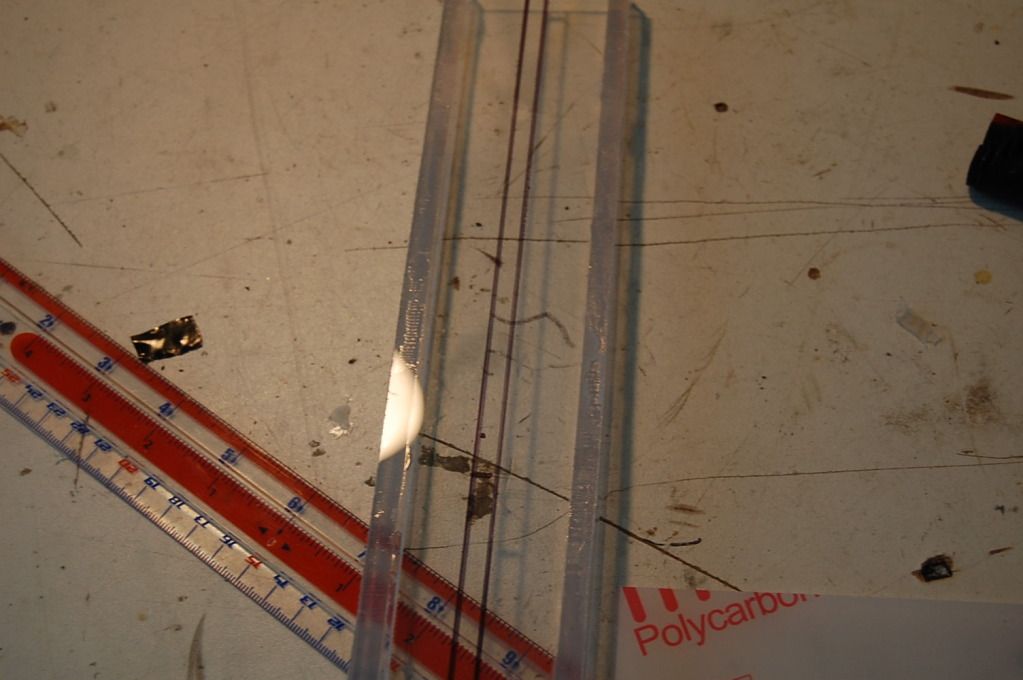

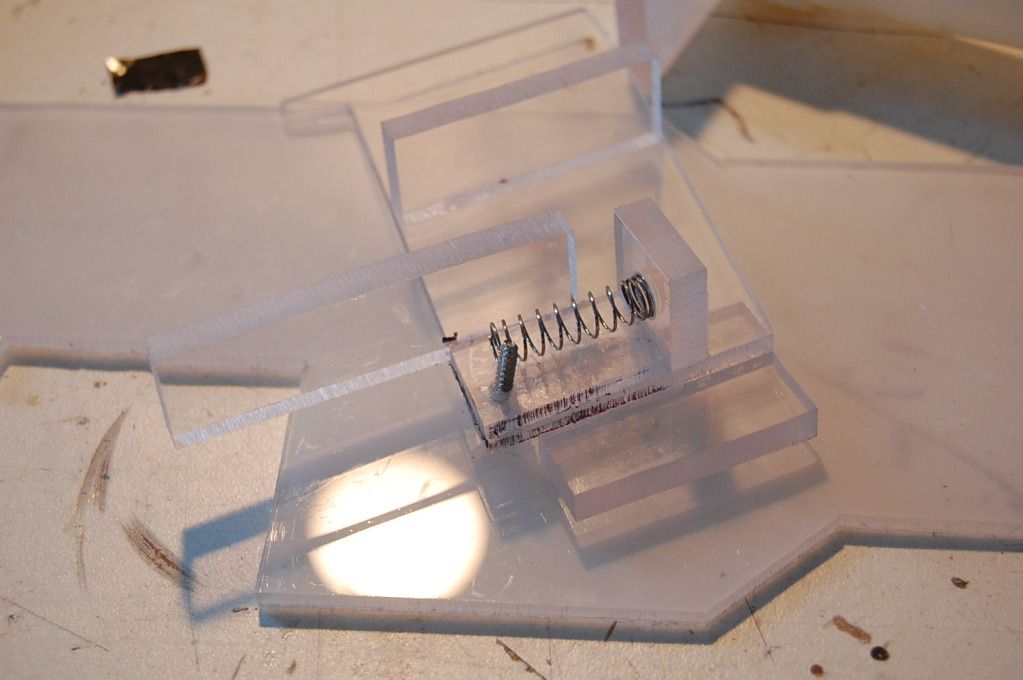

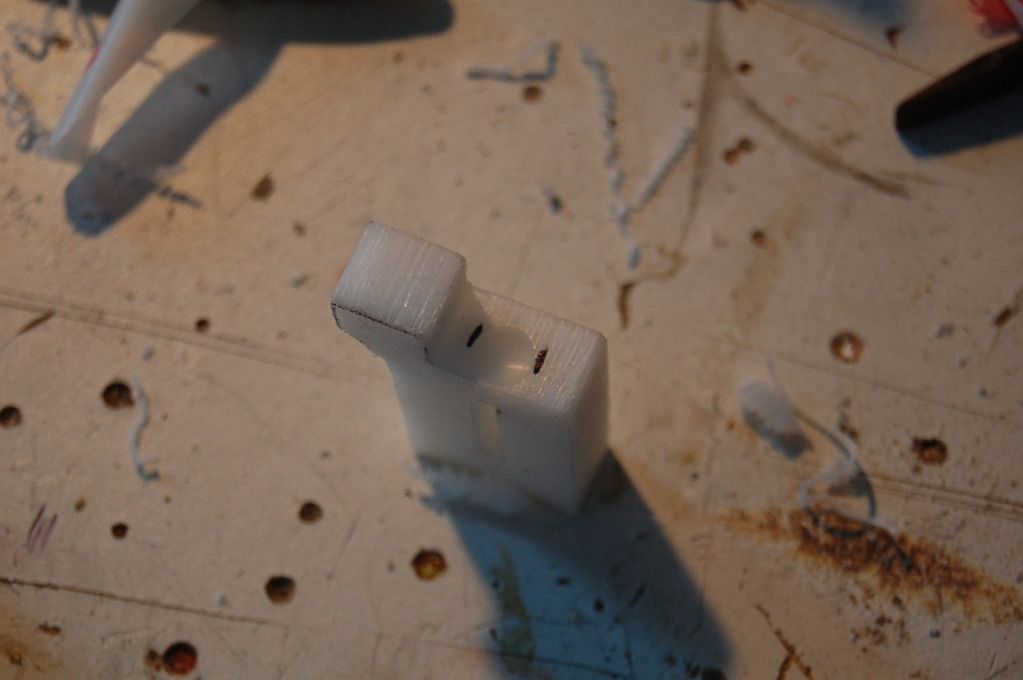

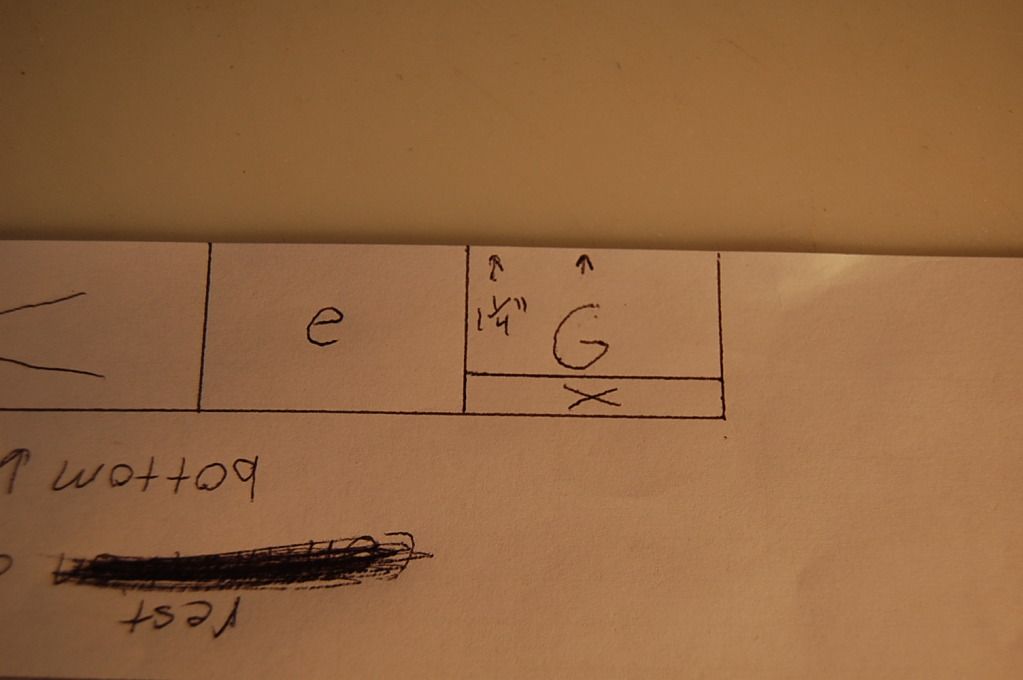

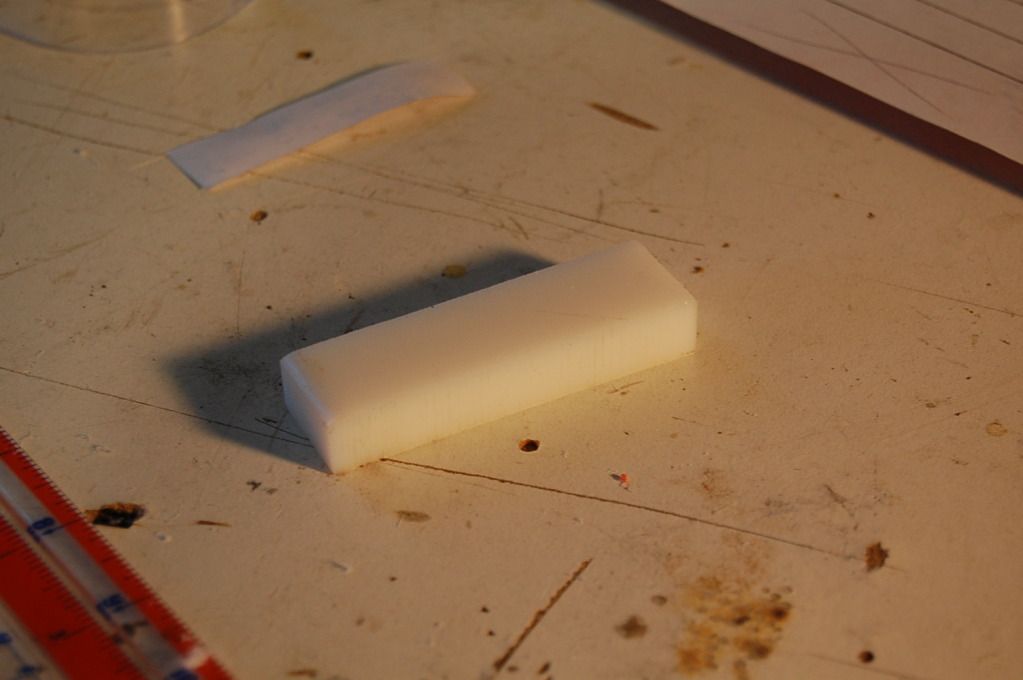

Parts made from ¼” polycarb: (save all the scraps, as you will need them later)

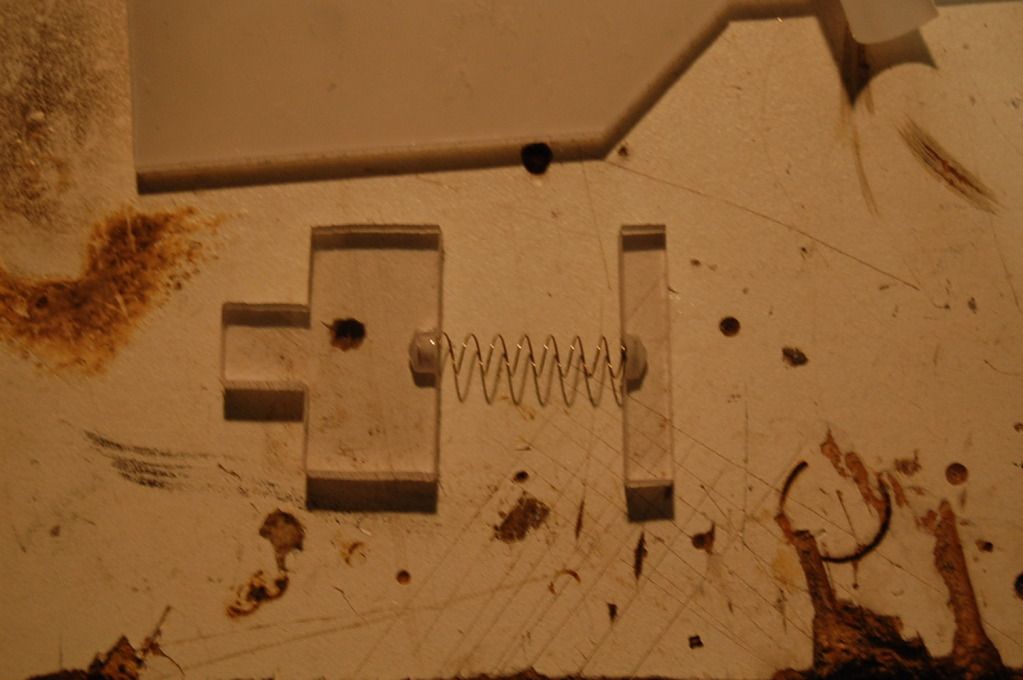

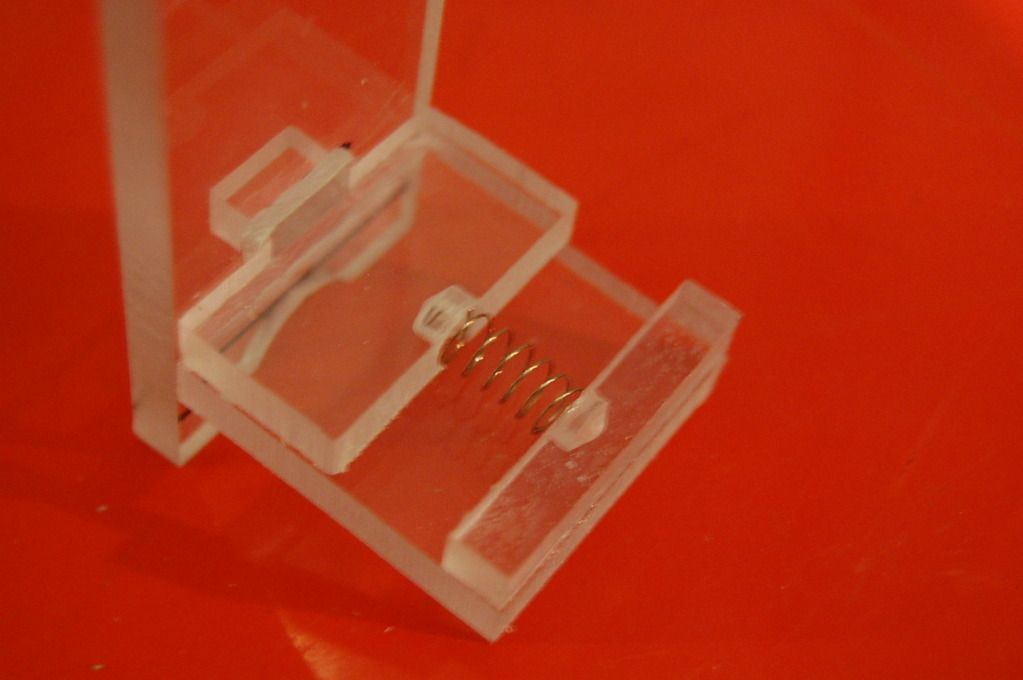

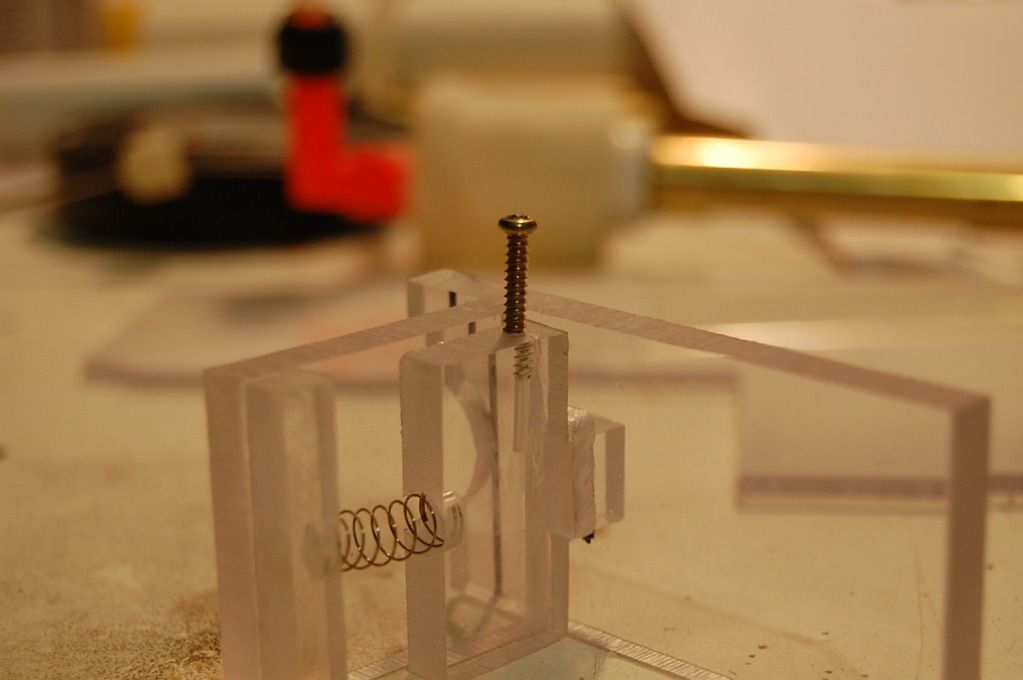

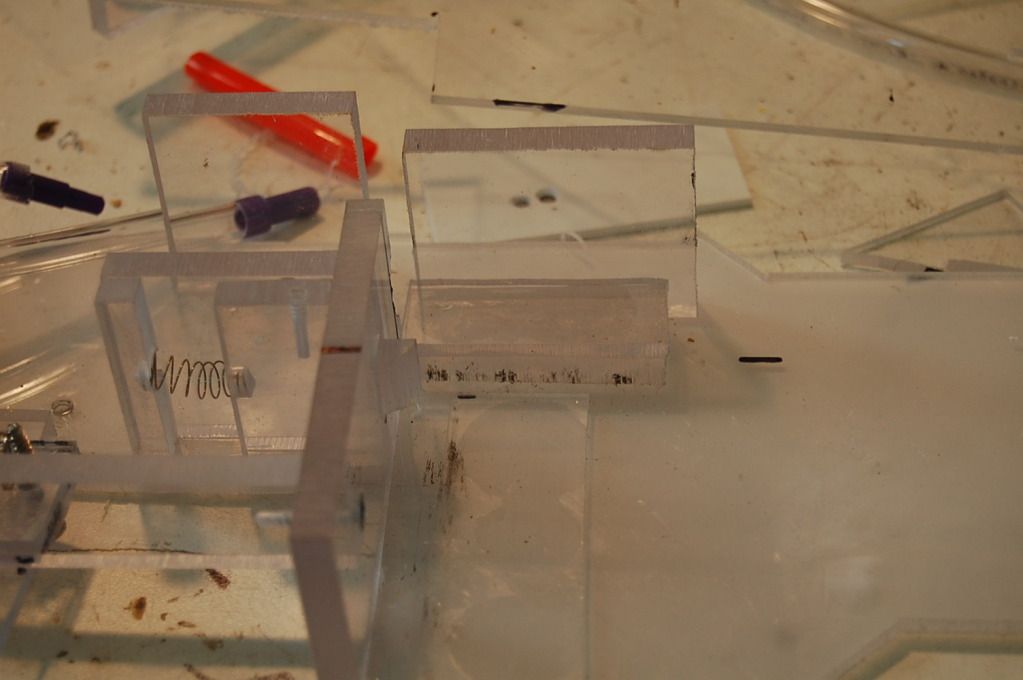

All the standoffs:

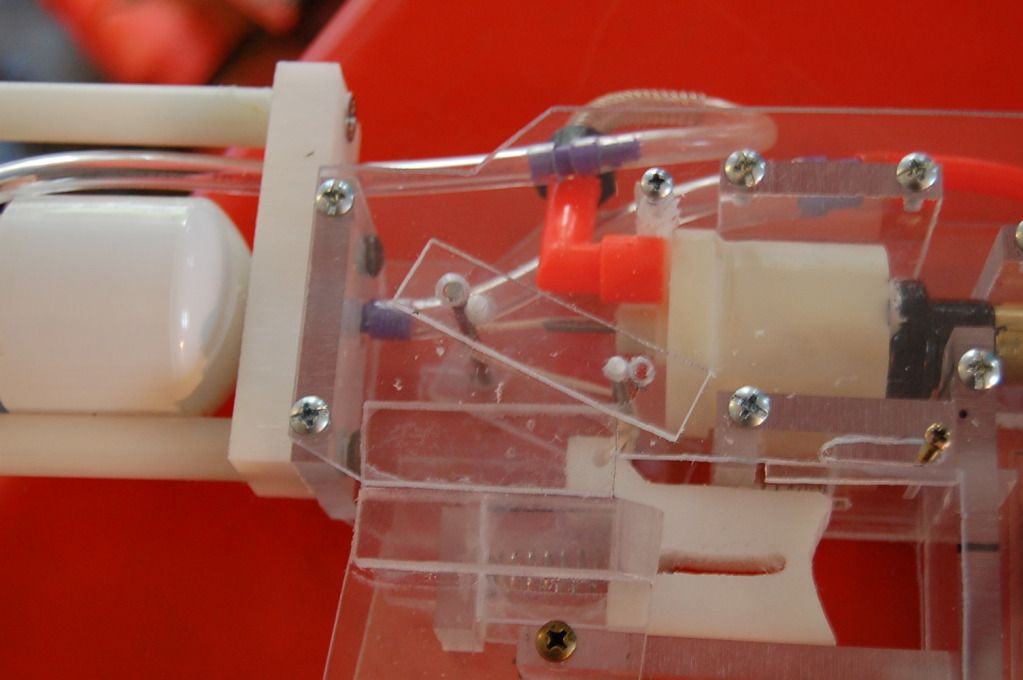

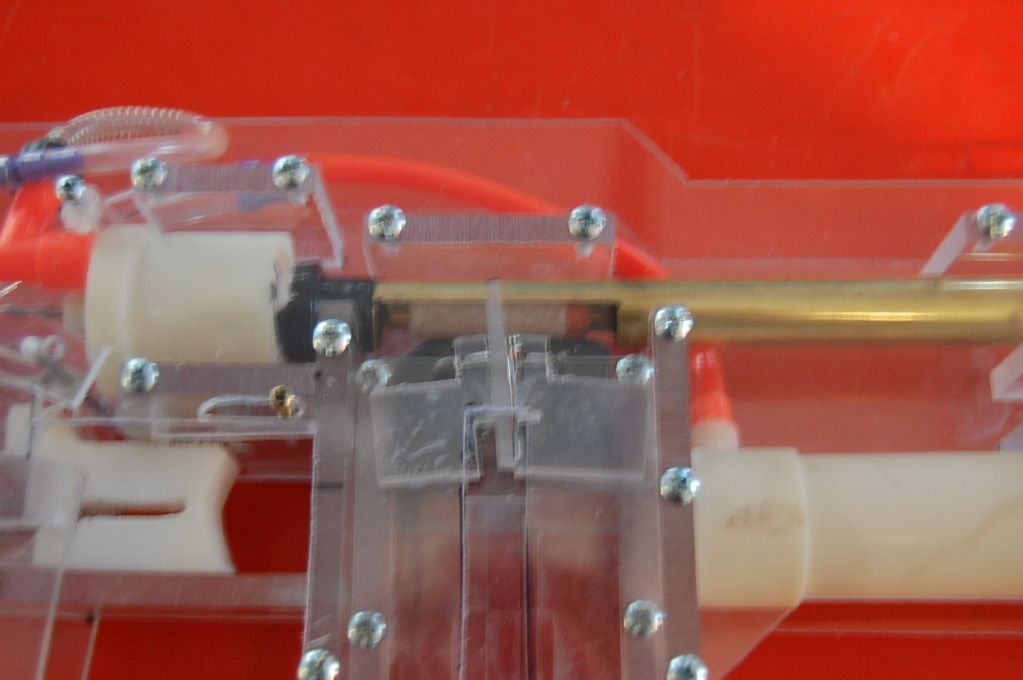

A few zoomed shots:

Continuation of bottom of sheet. Tape this to the bottom of the main template.

Random stuff:

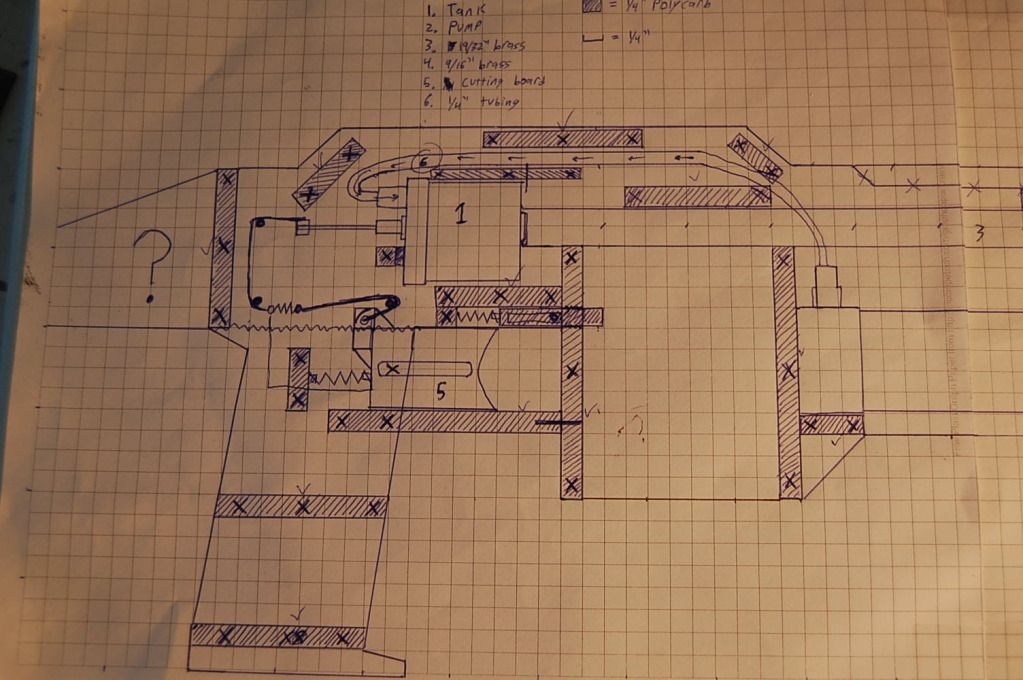

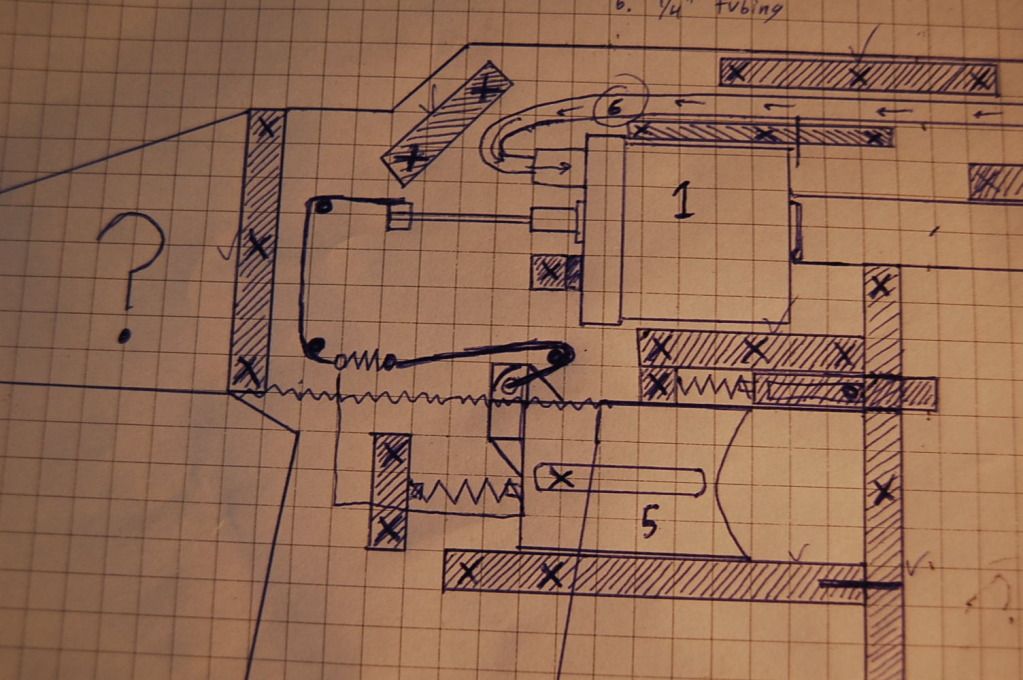

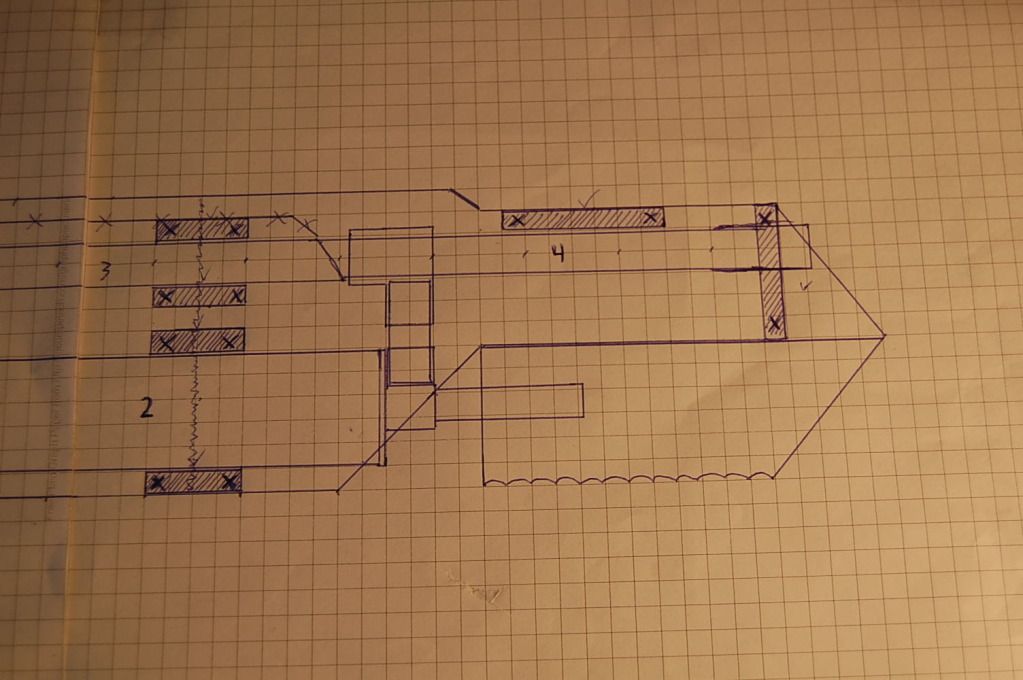

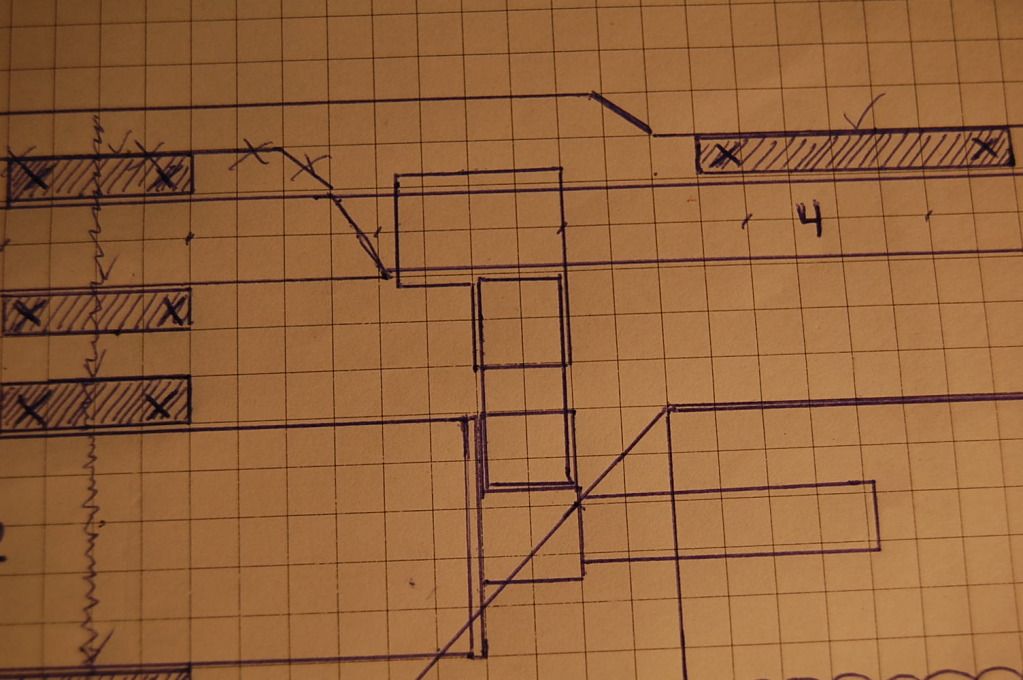

Finally, here is the master plan. Each square represents 1/4” by 1/4”.

Shaded parts are made of ¼” polycarb. In the write-up, I changed a few things, so don’t make the gun directly from this schematic.

Rear of gun:

Front of gun:

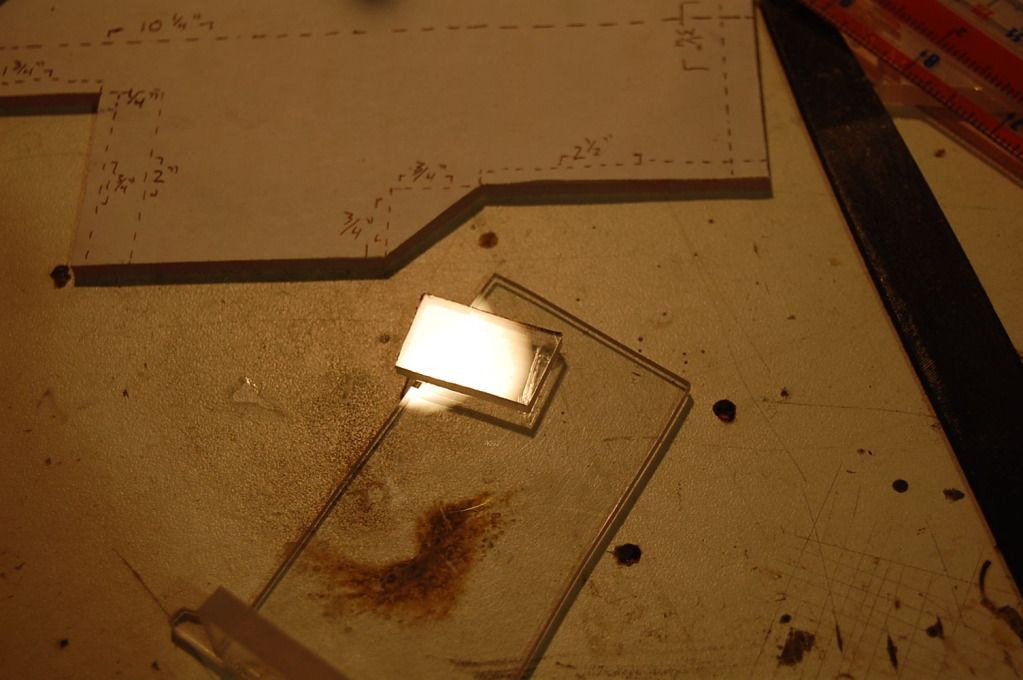

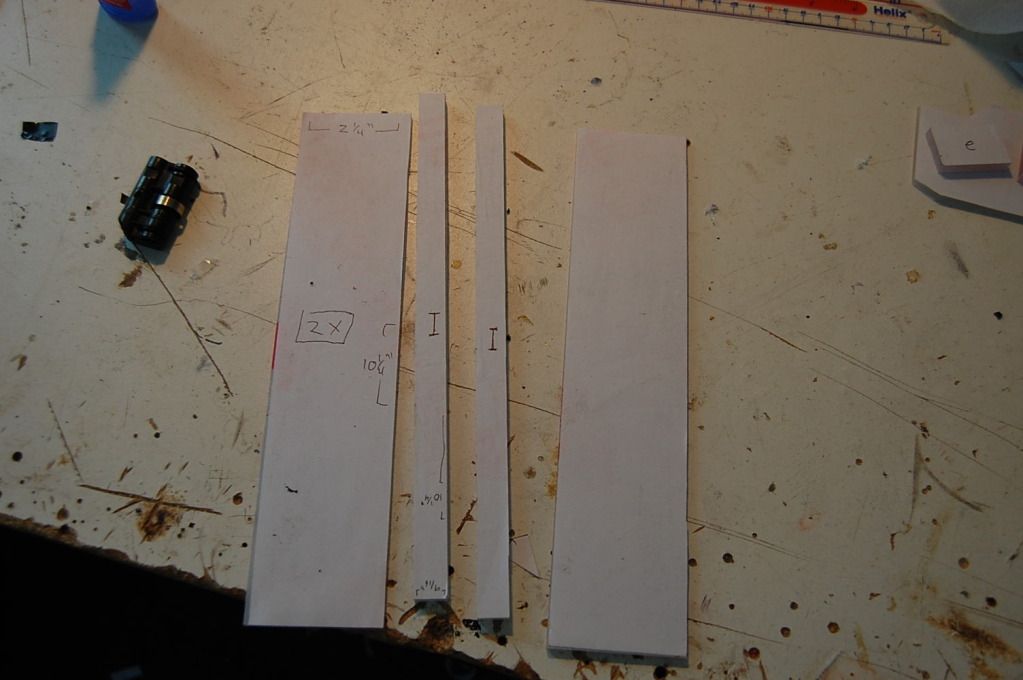

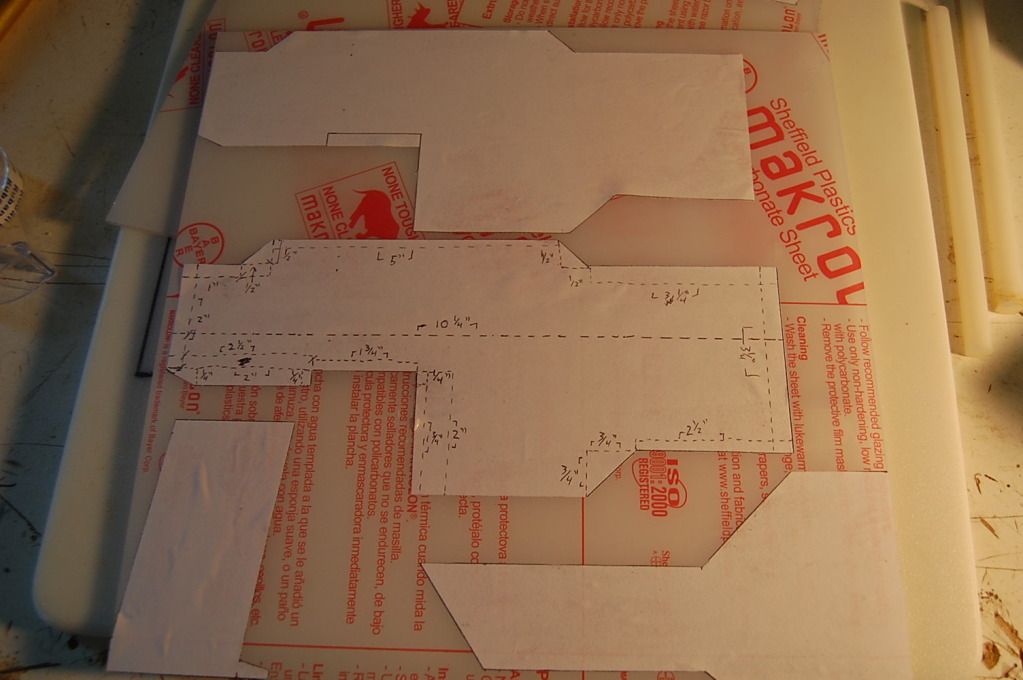

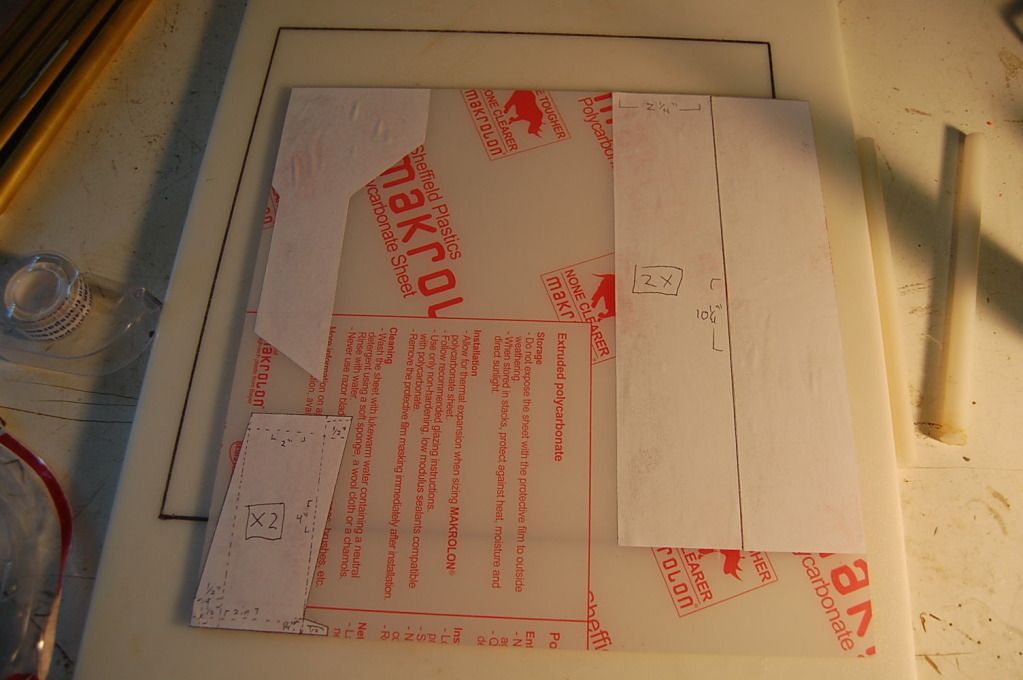

Here’s how the templates are laid out on the polycarb:

Sheet number one:

Sheet number two:

¼” sheet:

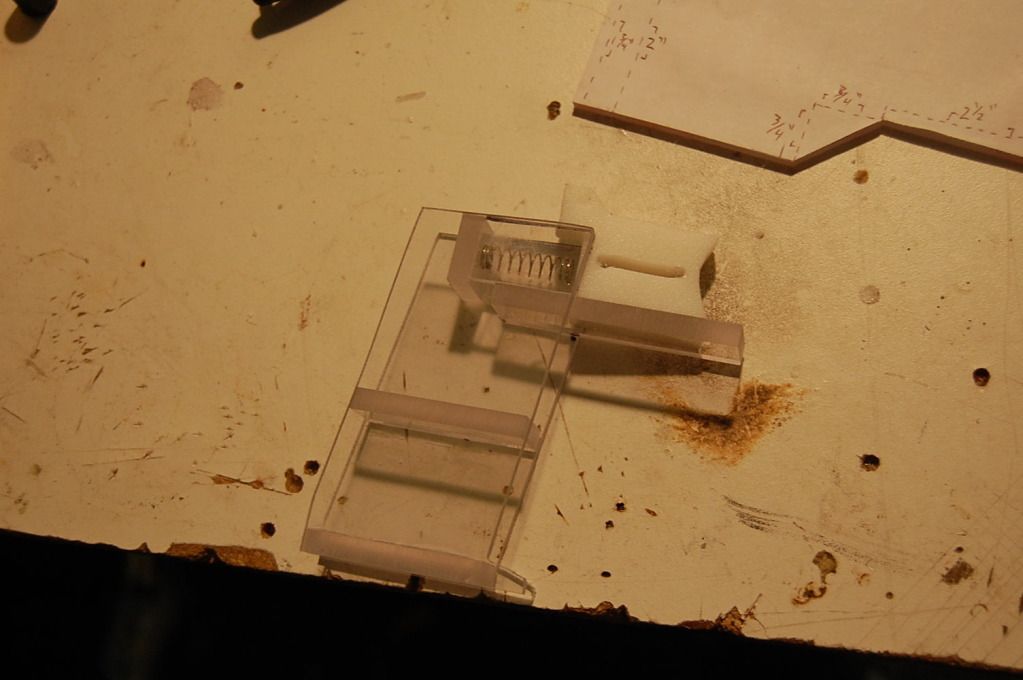

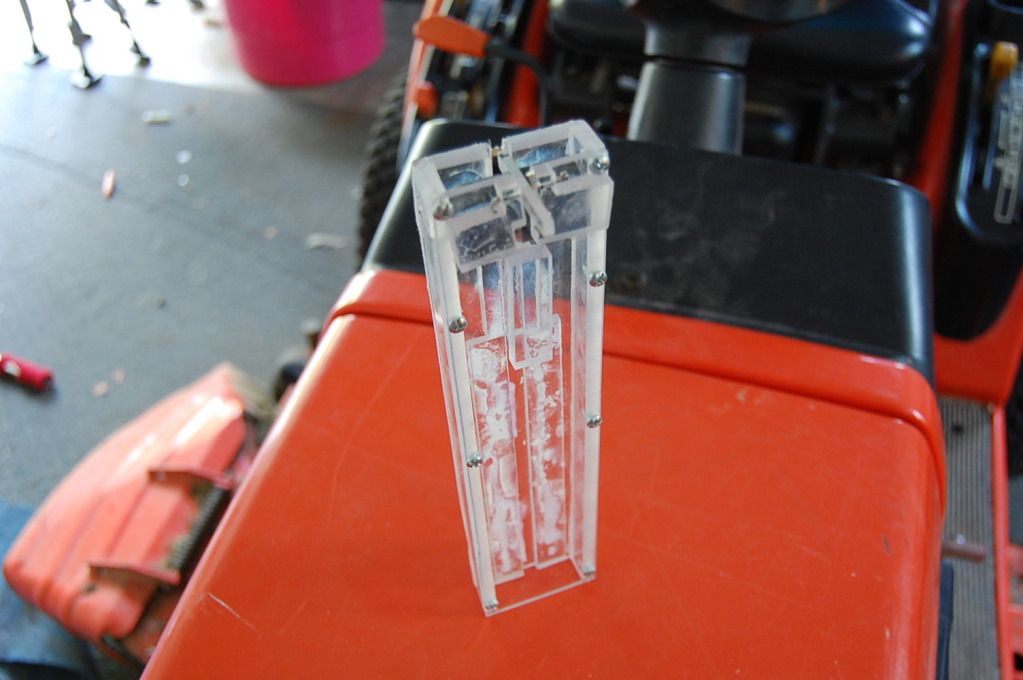

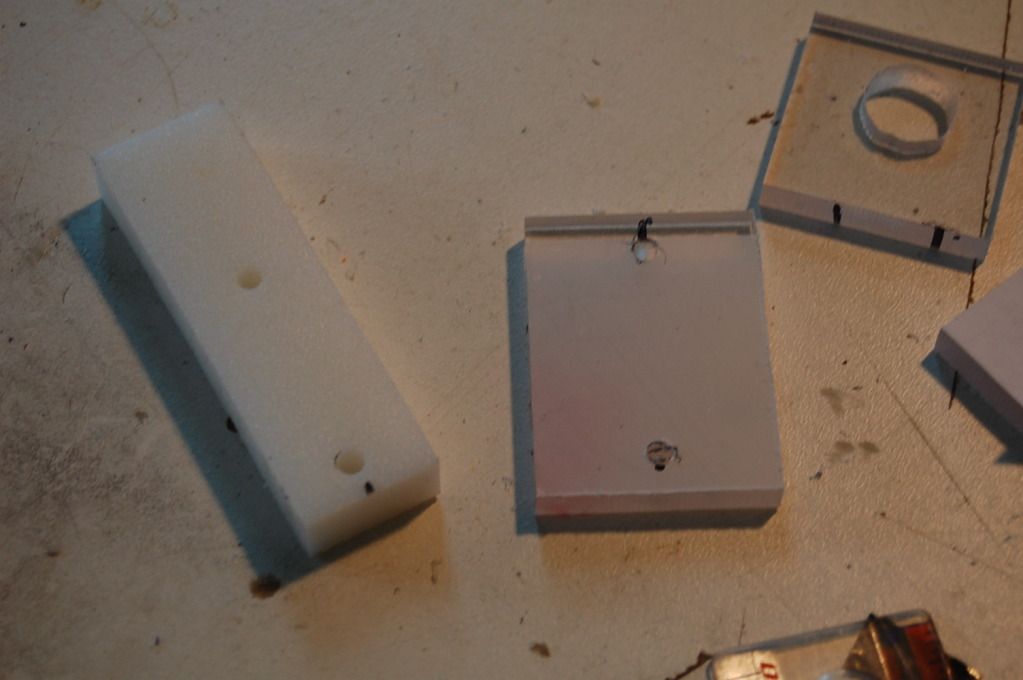

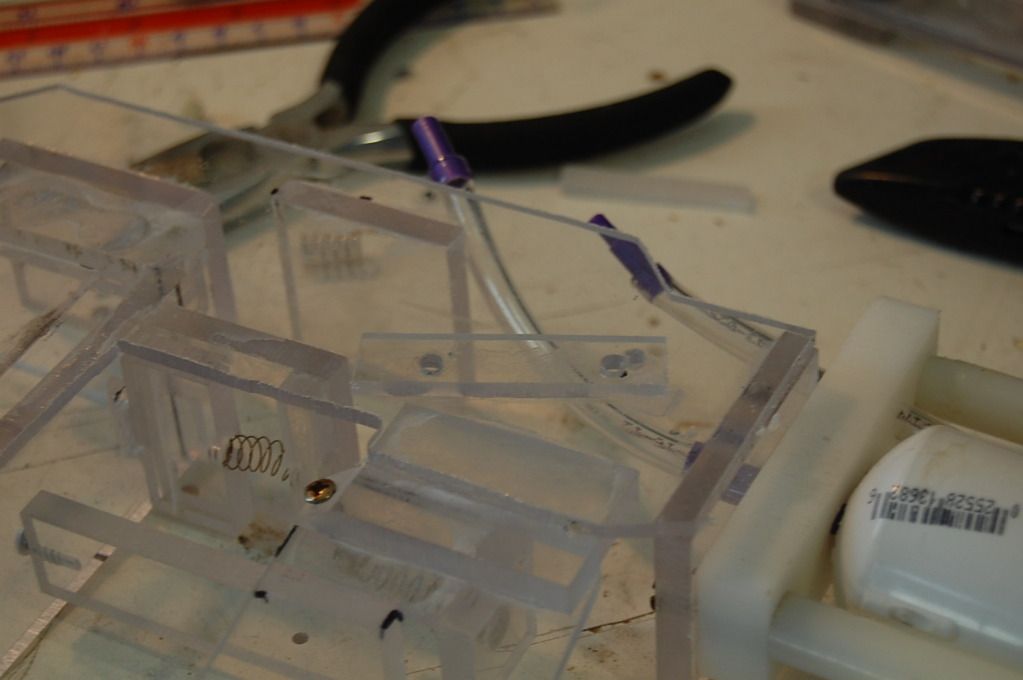

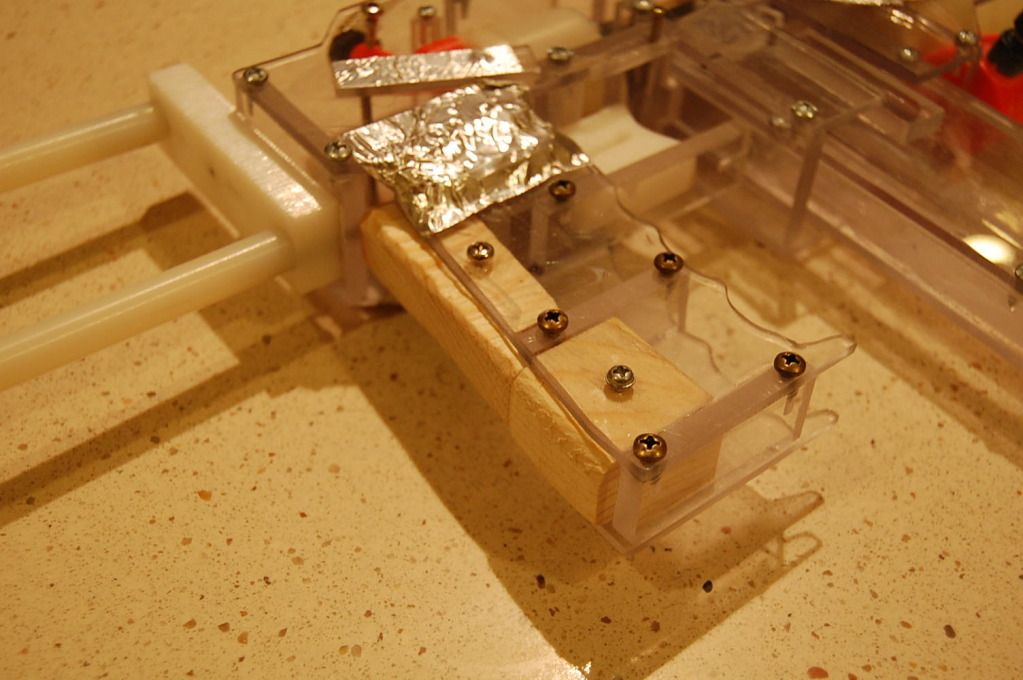

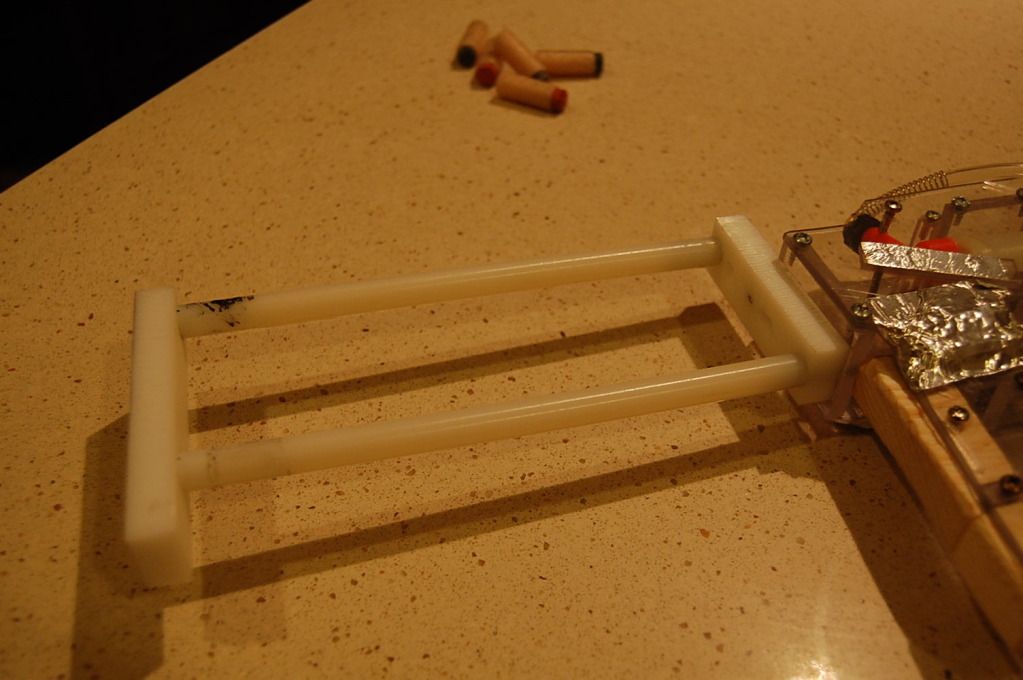

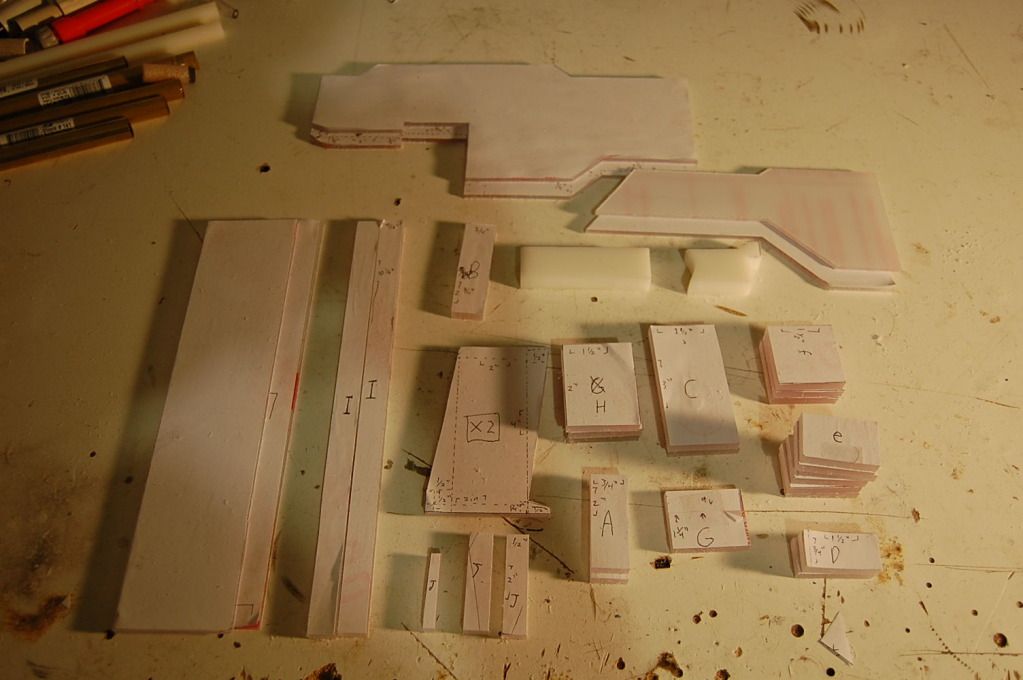

Here’s all the parts cut out:

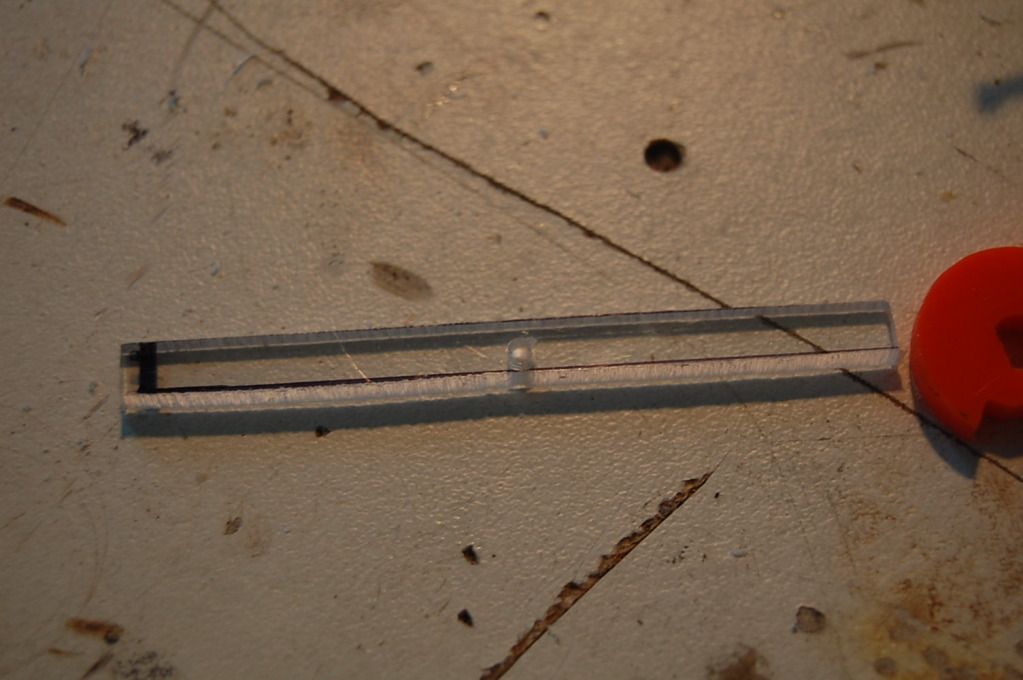

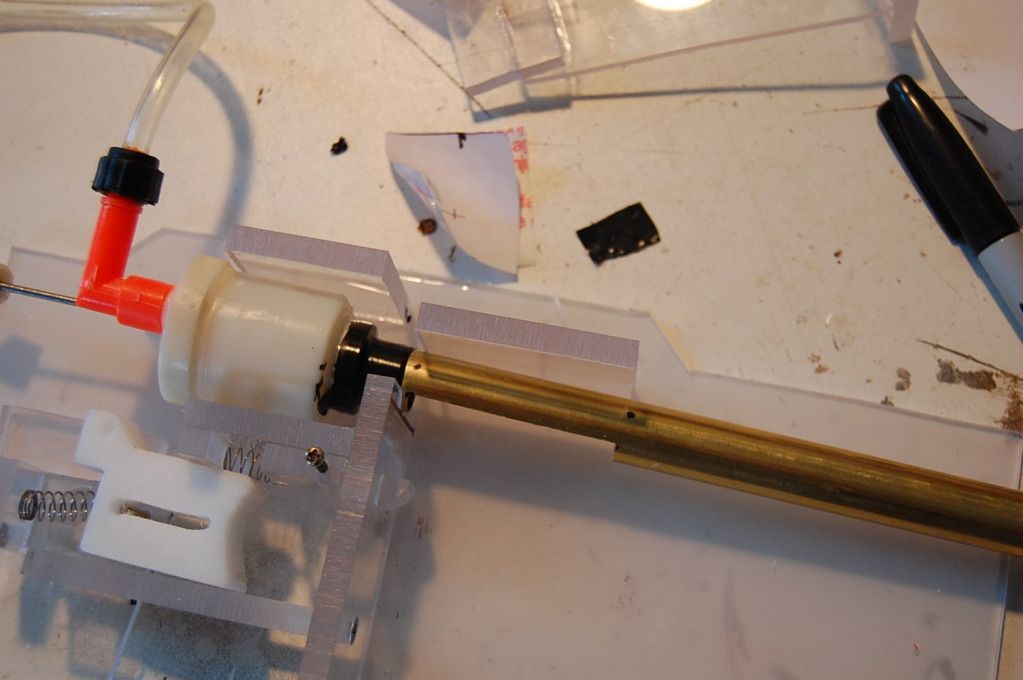

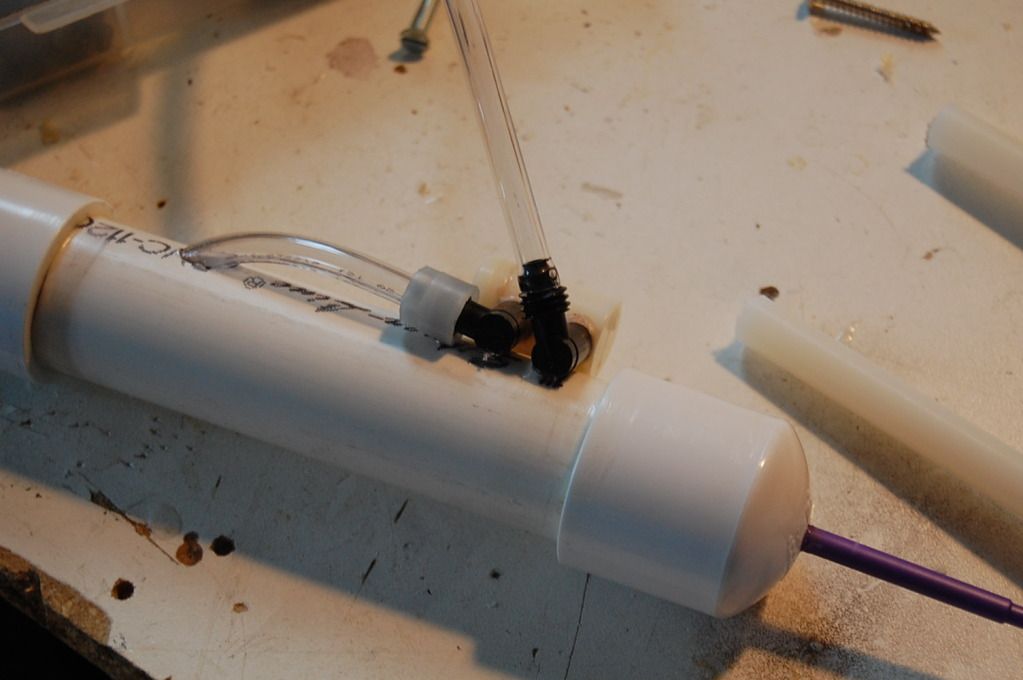

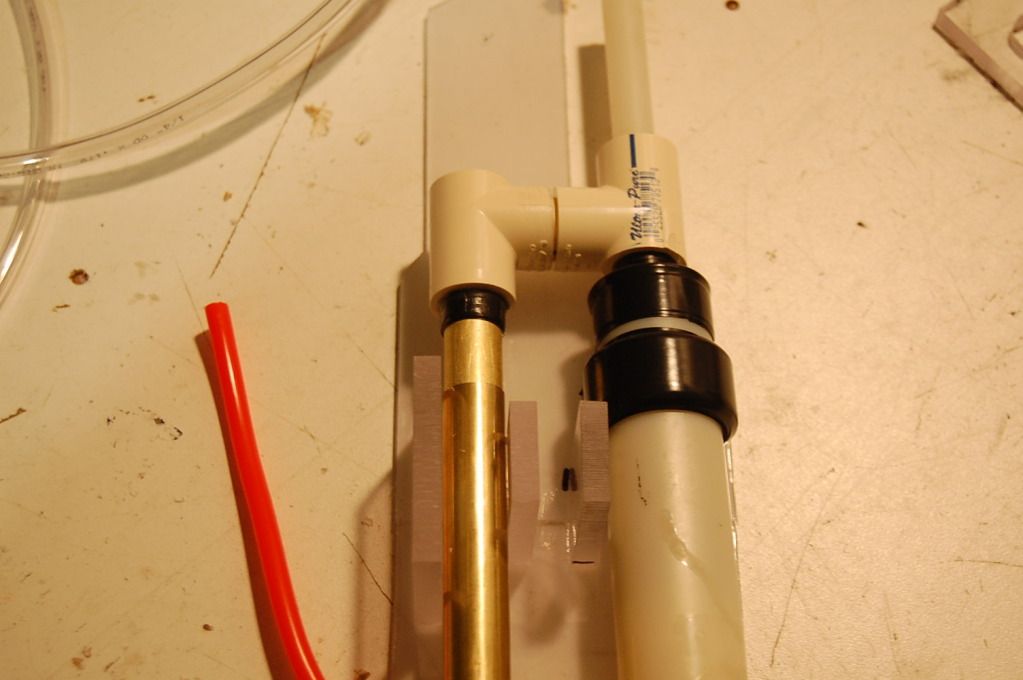

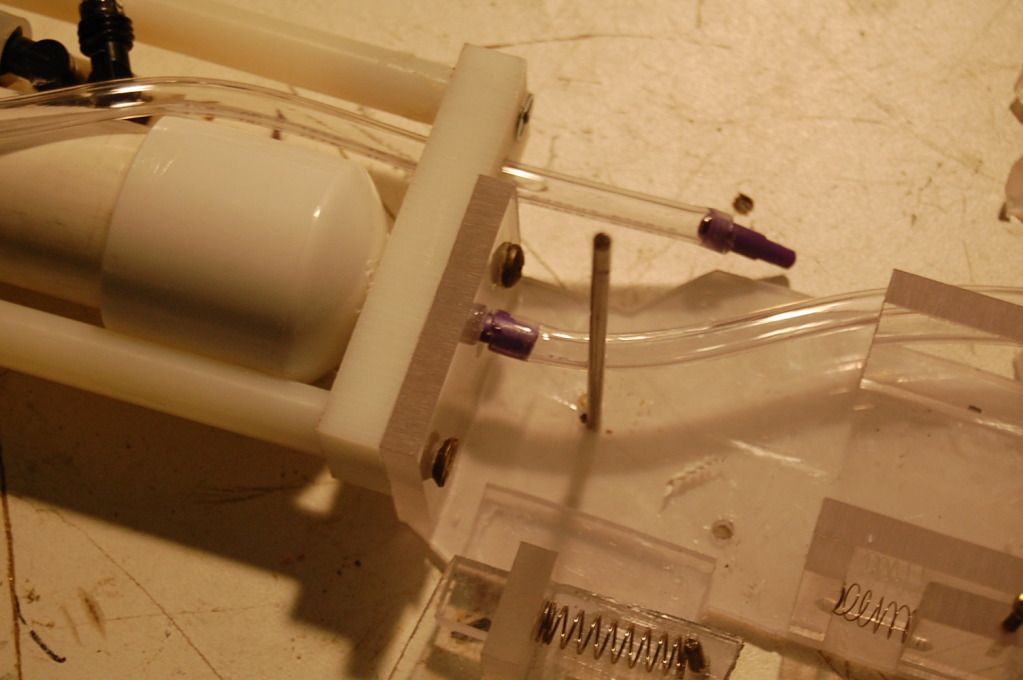

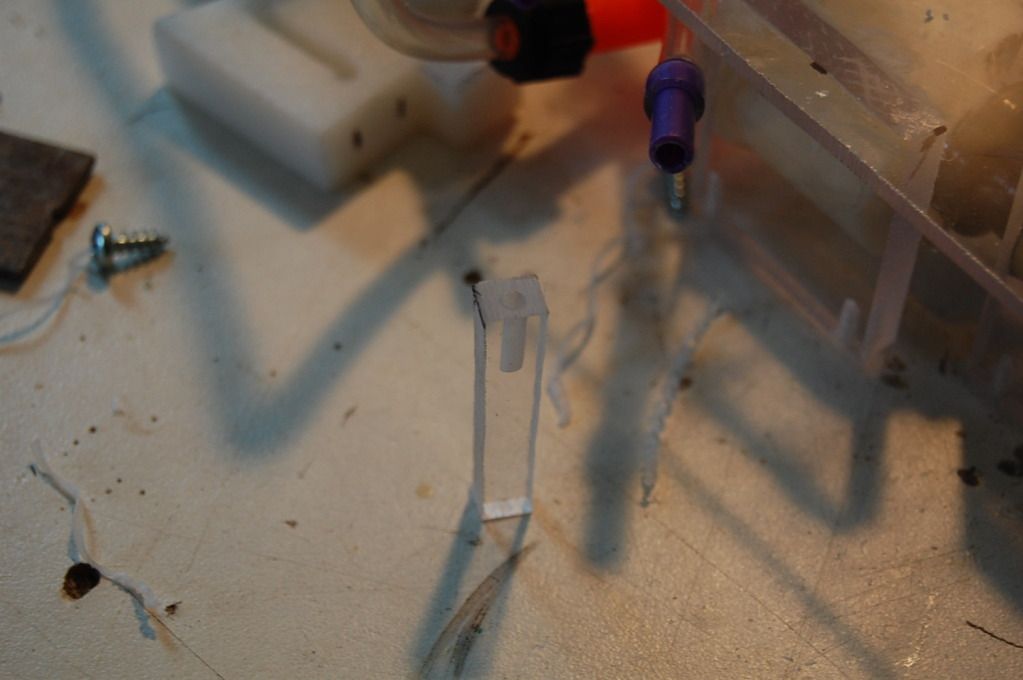

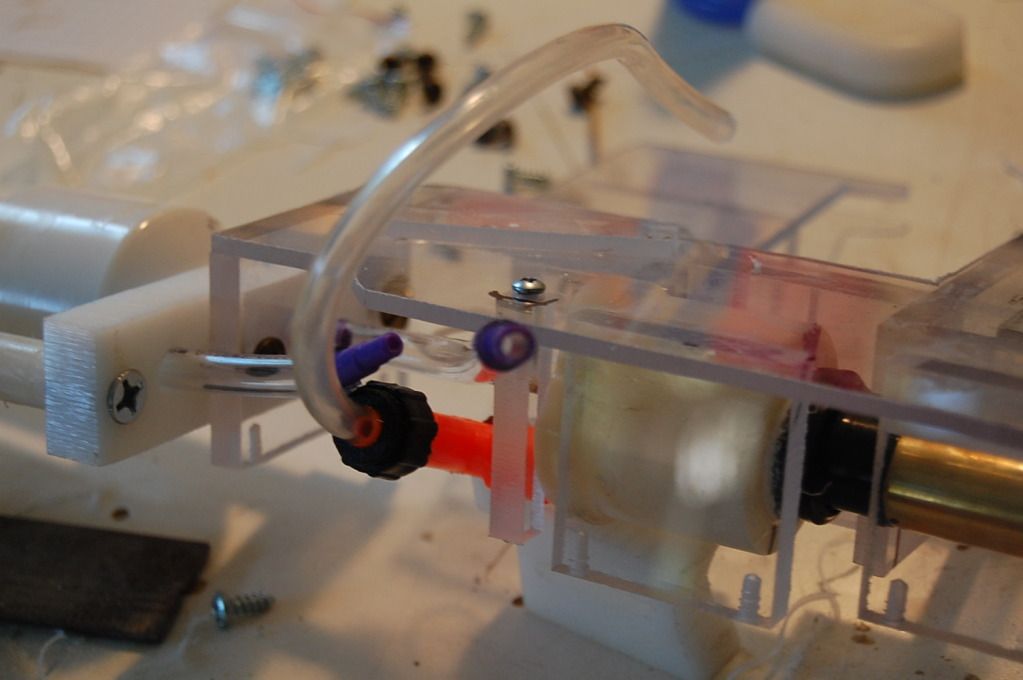

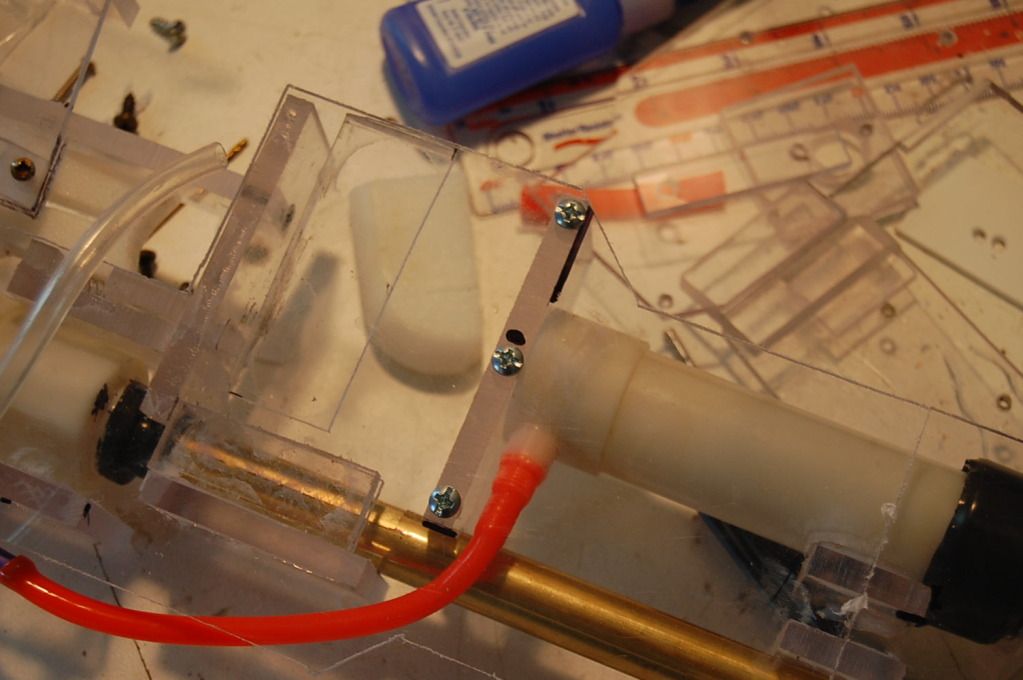

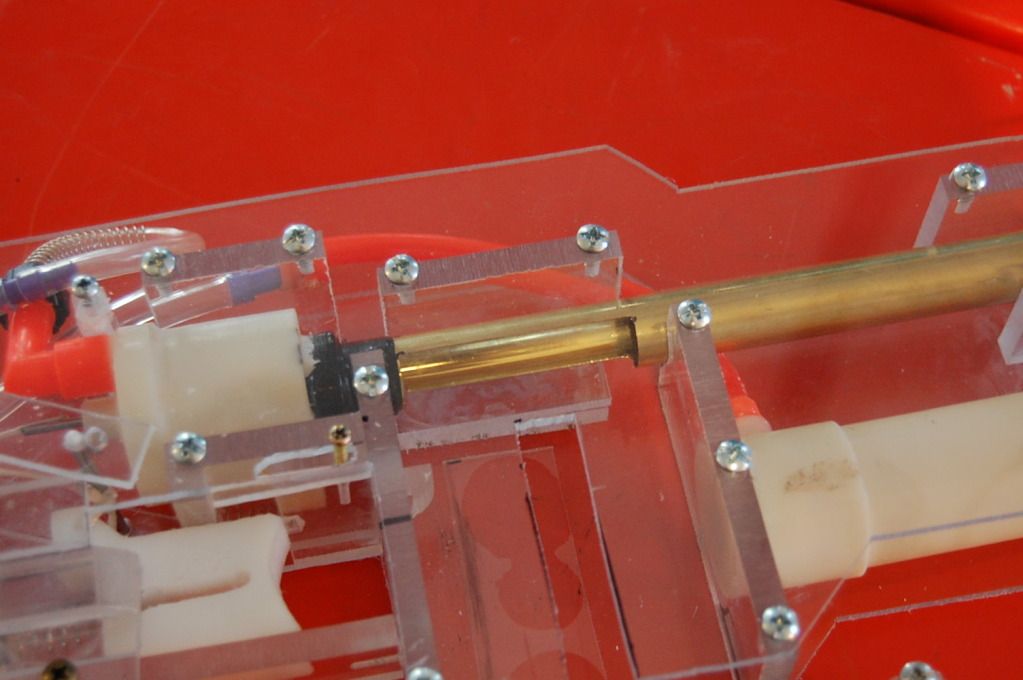

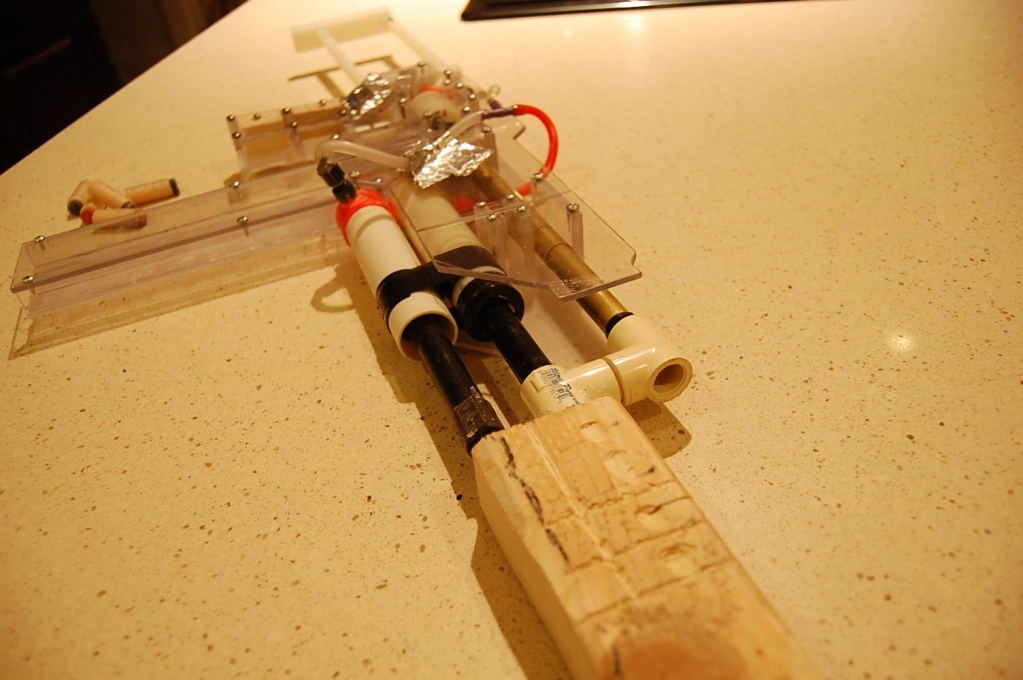

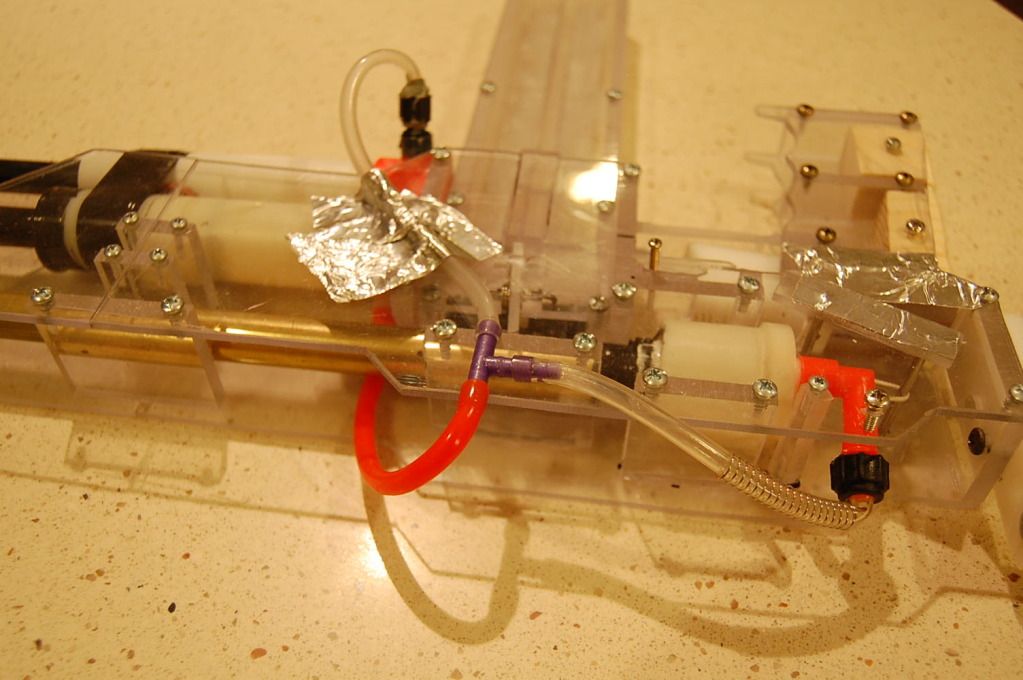

Now, cut 7 ½” of 19/32” brass and wrap the end with a bit of electrical tape.

Cut a ¼” thick sliver of ½” PVC, and glue it the brass.

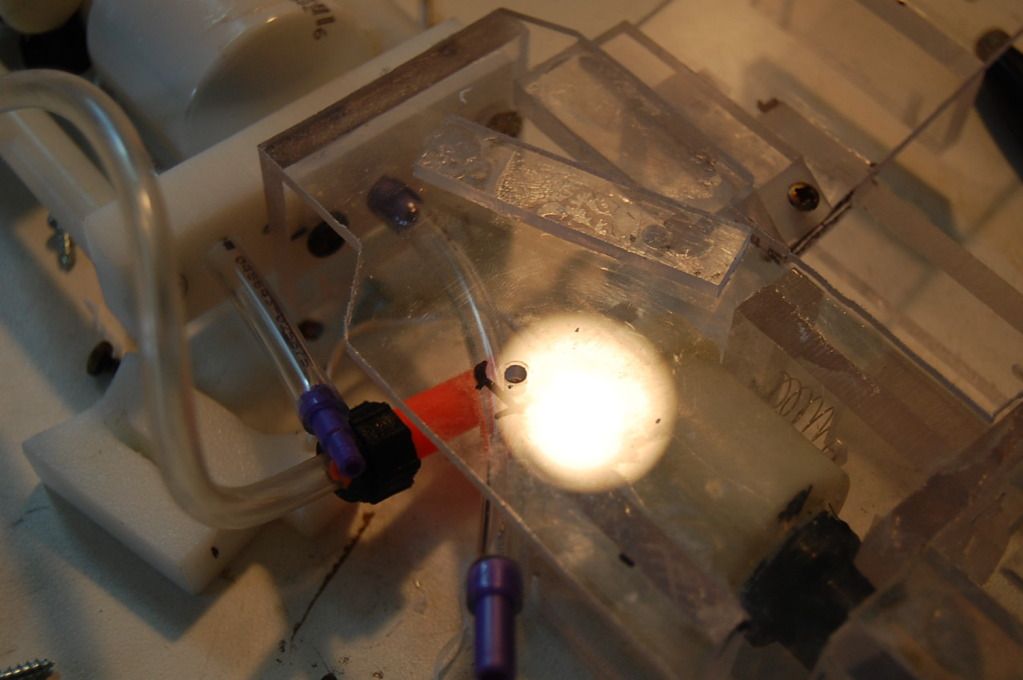

Then glue that to the tank.

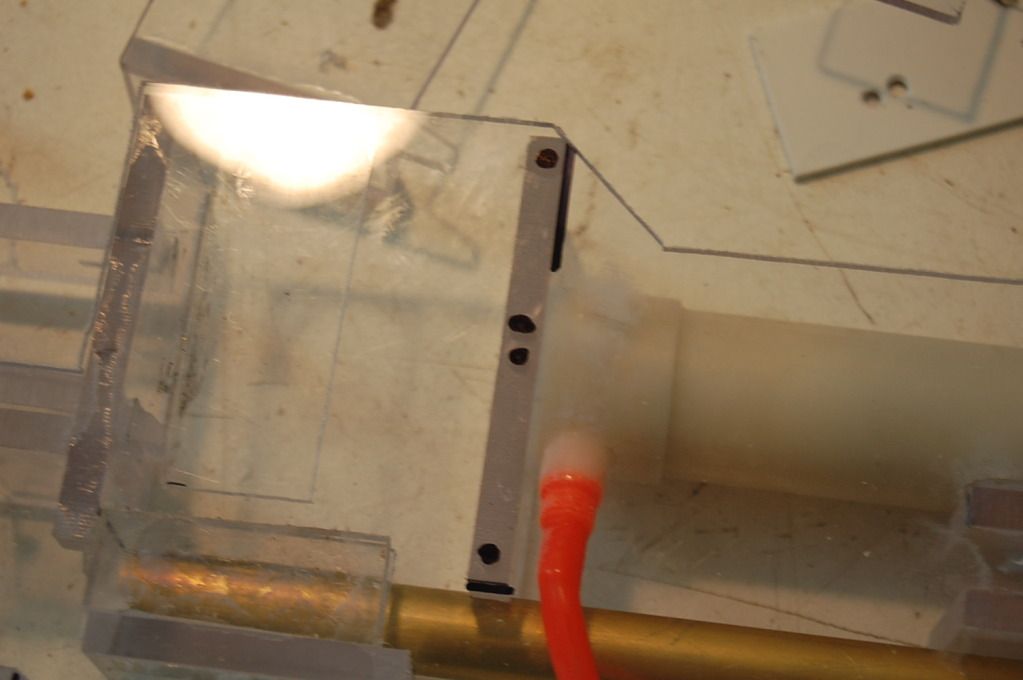

Cut a 2” long slot in the brass, ¾” from the tank.

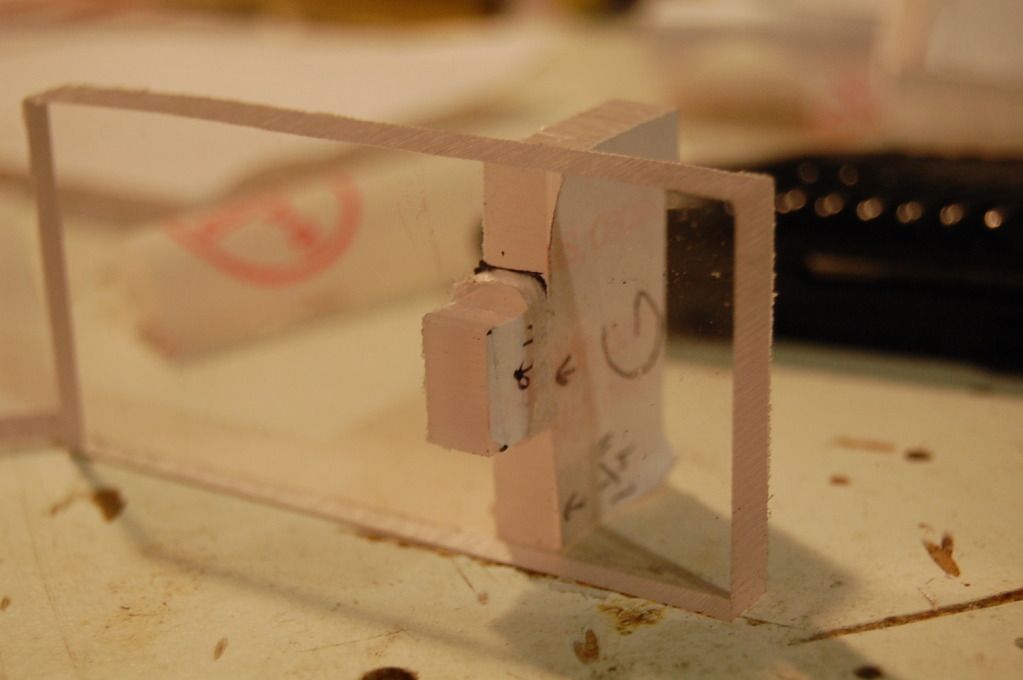

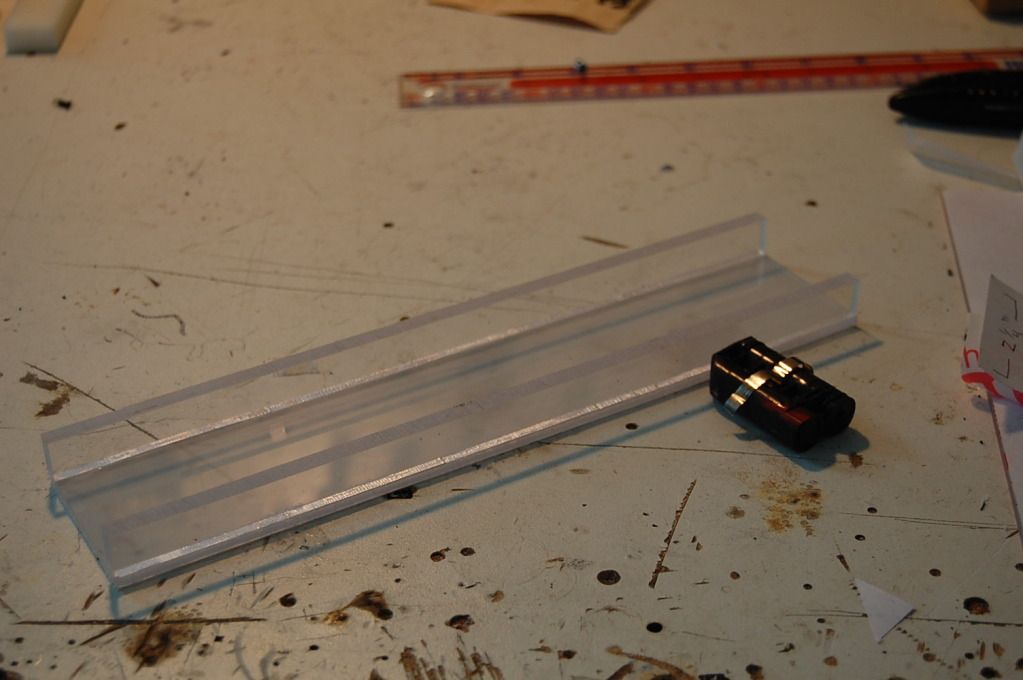

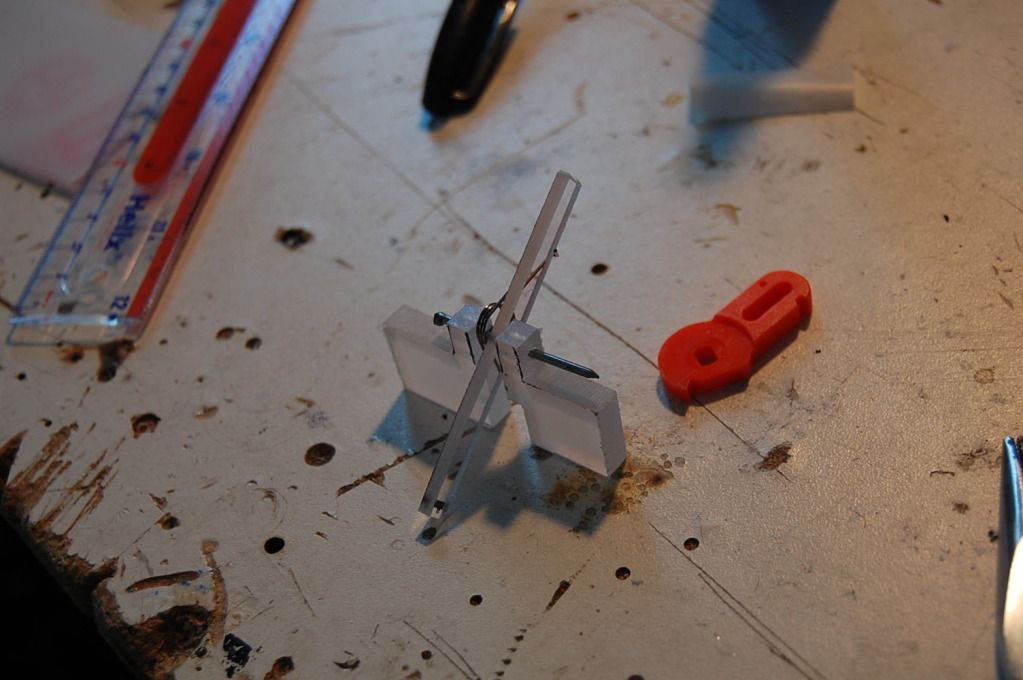

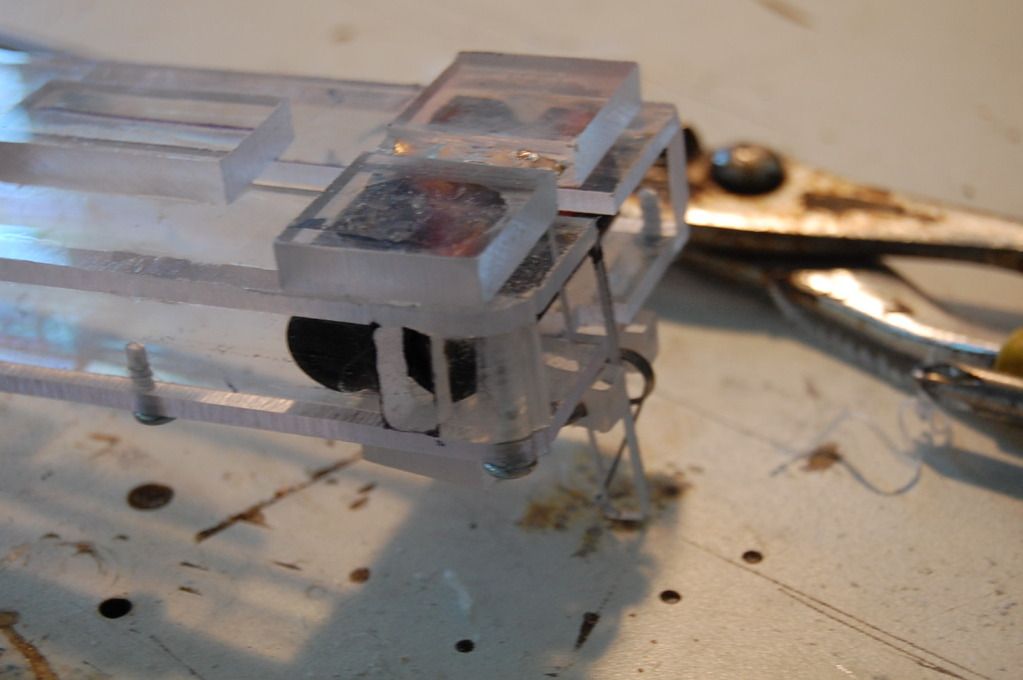

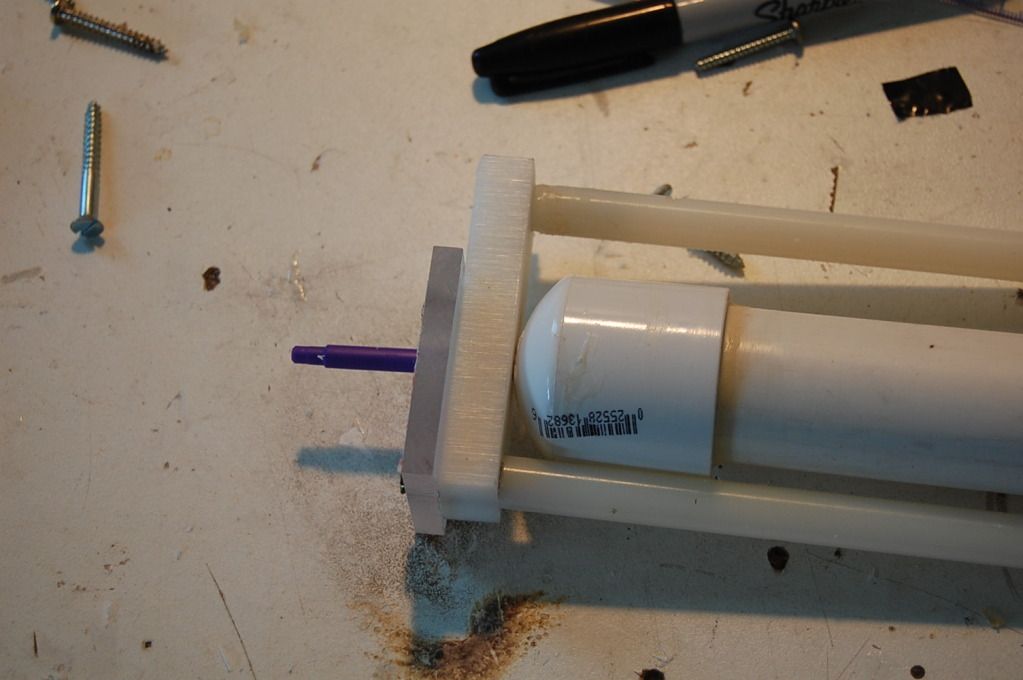

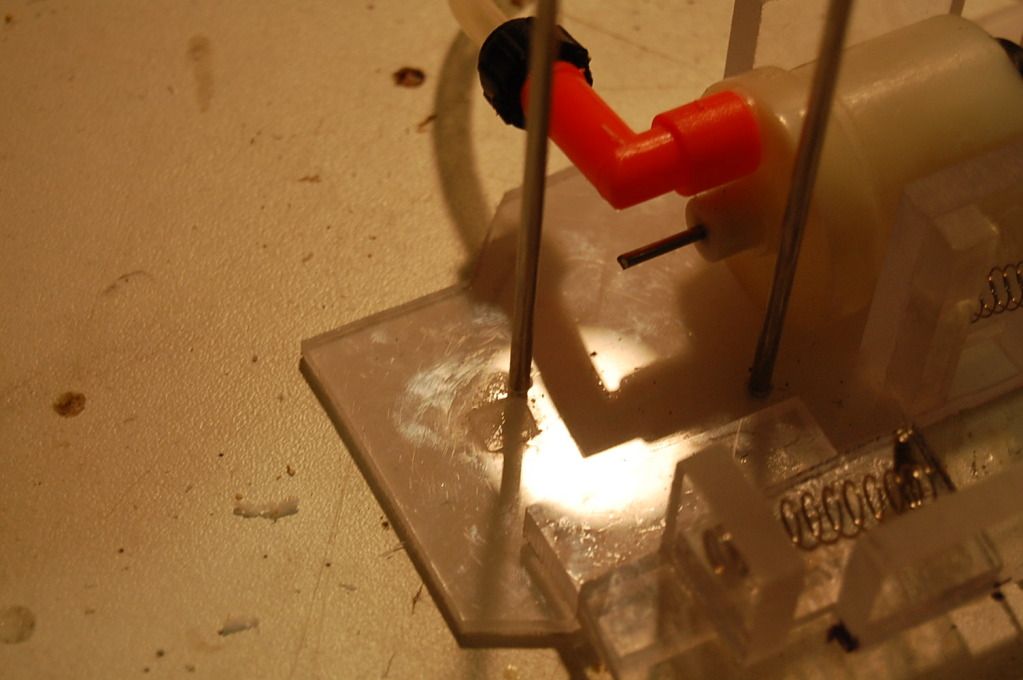

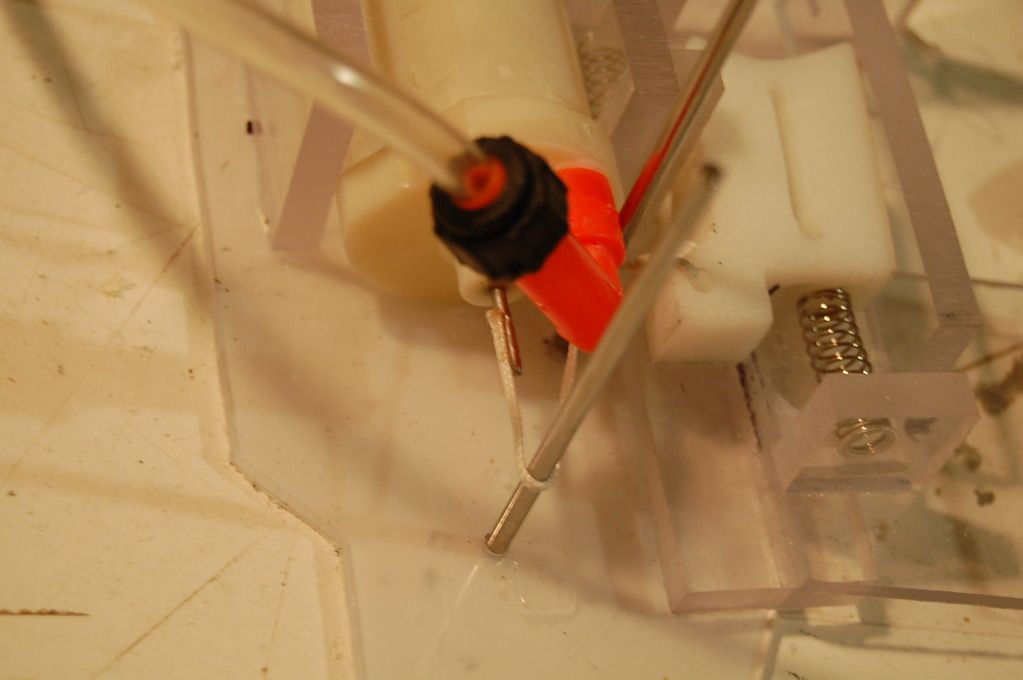

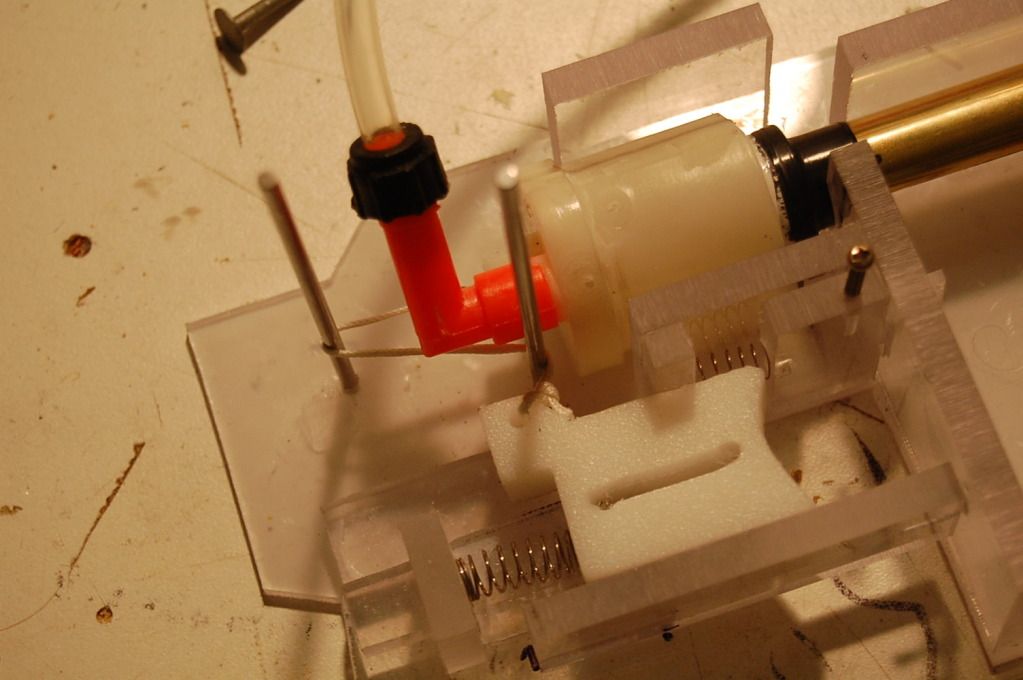

Now take ¼” polycarb piece C, and glue the pump to the center:

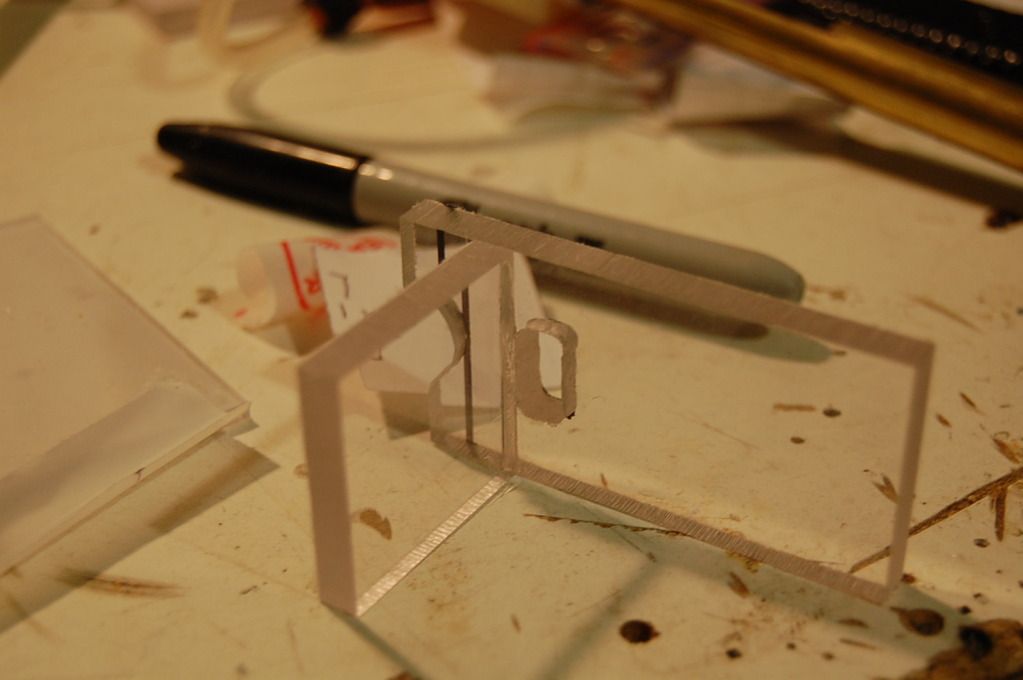

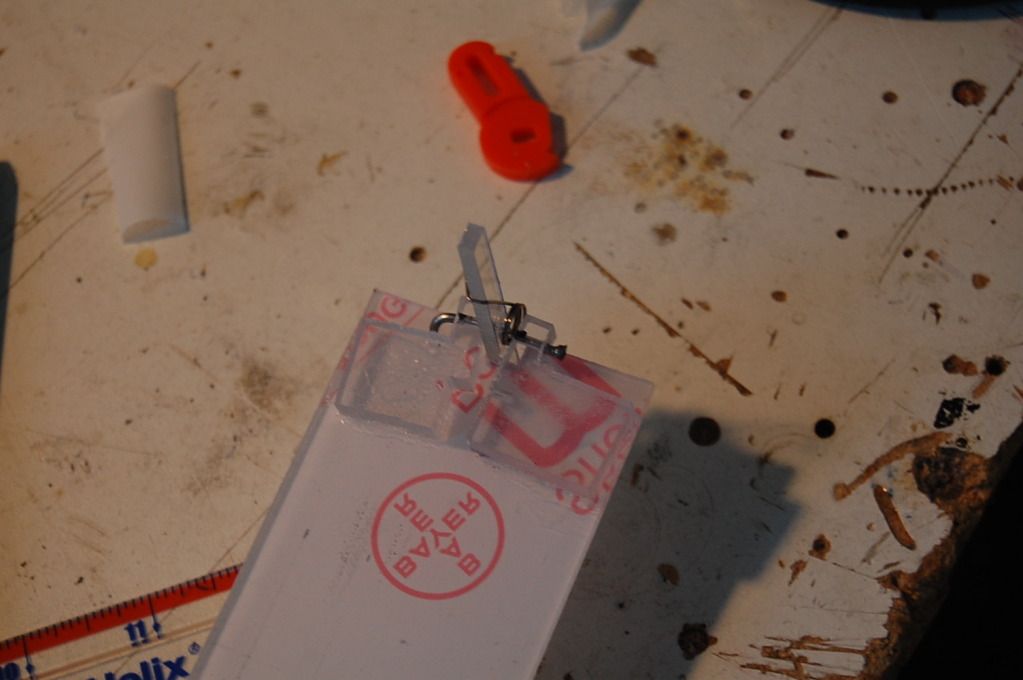

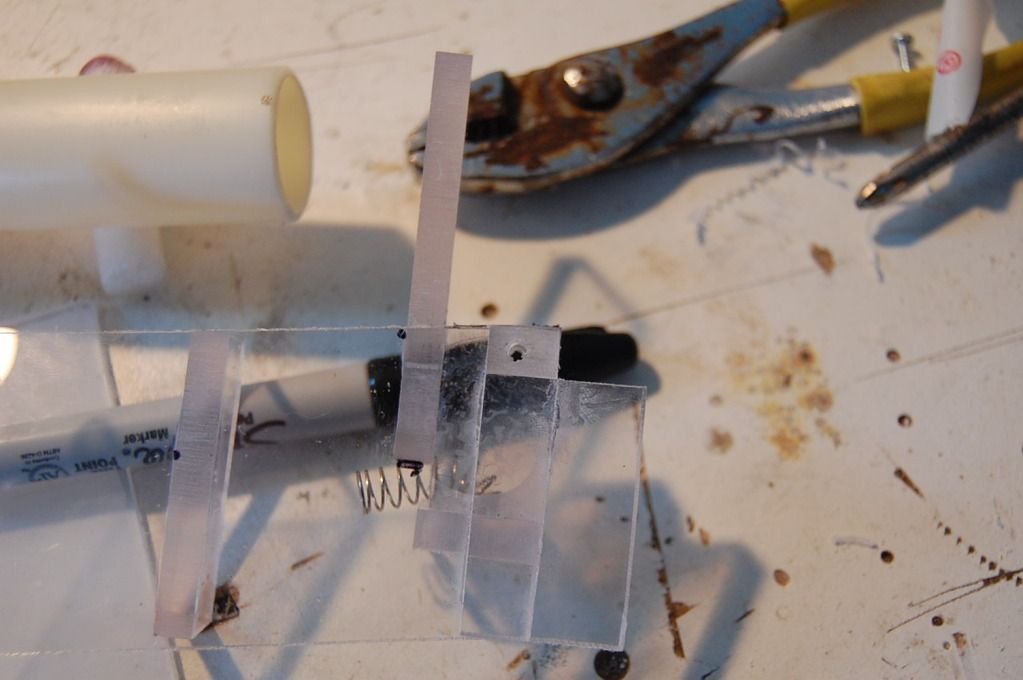

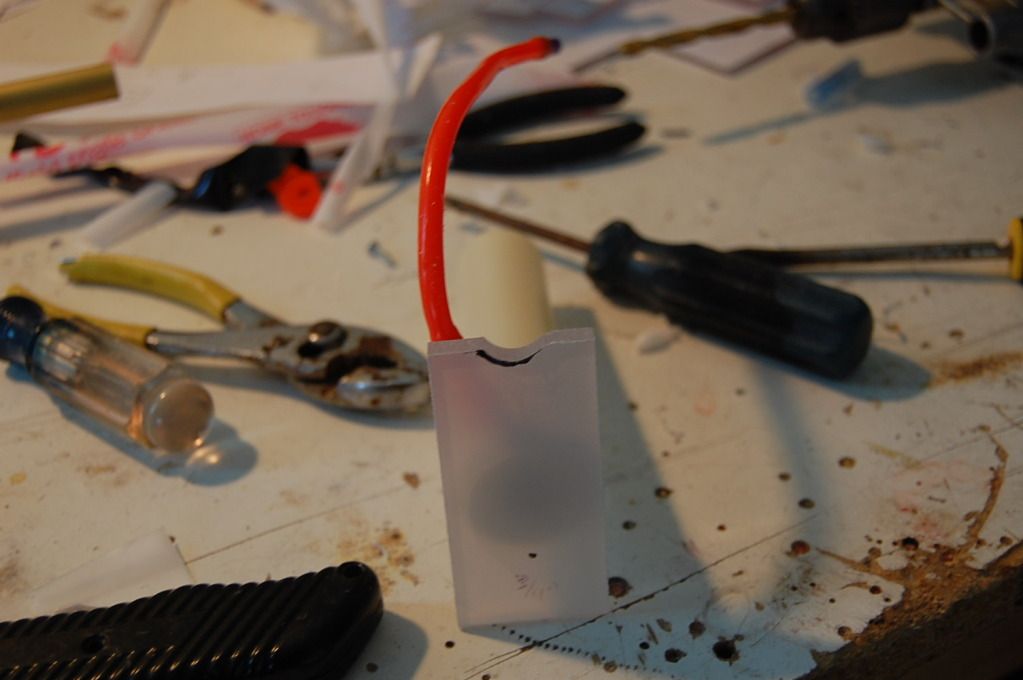

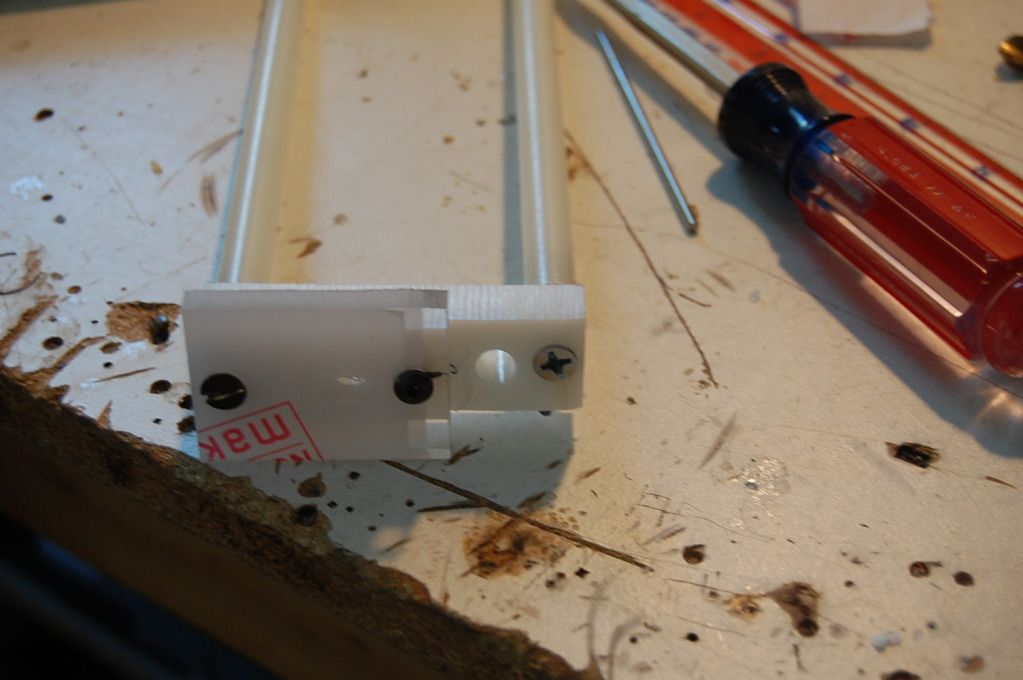

Cut out the 1/8” in 1” slot in the trigger.

As well as drilling a 1/8” hole in the back:

Edited by hamoidar, 15 October 2012 - 04:17 PM.