I apologize for the lack of assembly and completed gun photos. Most of these were taken in-progress during mod parties, which is great for the writeup; however, photos and a video of the final product were lost somewhere. This blaster was done as a contract and already shipped, so it is up to the client to post final pictures to help convey what words cannot. Also in this vein, a lot of my pictures will be misleading, as they were indeed taken before final refinements. Pay attention to the captions.

Materials

- 12" section of 1-1/2" sink drain extension pipe

- 1-1/2" OD rubber washer

- 1-1/4" OD steel washer

- 1/8" plastic sheet (I used PVC) #8747k112

- 1/16" plastic sheet (I used PVC) #8747111

- 12"+ of 7/16" square plastic rod (I used 1/2" square polyethylene rod and shaved it down...) #8732K14

- 6-32 machine screws (various lengths)

- 6-32 threaded rod (4" piece or longer)

- 1/2" 6-32 set screws #94025a400 or #92311A148

- 6-32 nuts and wingnuts

- stronger catch spring #96565K36

- #9637K25

Preparing the Shell

Sand down all the ridges in the rear portion of shell up to the very large ridges that hold the vertical fins of the plunger rod.

You want your 1.5" sink drain to be able to fit nicely within the rear section when assembled.

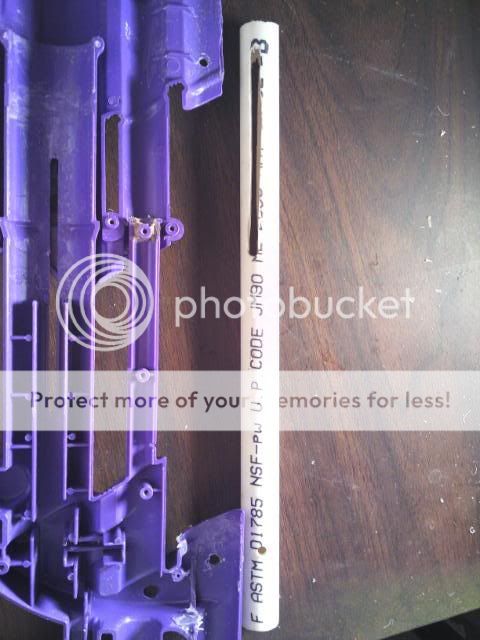

Constructing the Plunger Tube

Start by cutting yourself 6.5" of sink drain pipe, starting from the front.

Build a spring rest by cutting a (1-1/4"?) circle out of 1/8" plastic sheet. In the picture I used 1/2" plastic sheet. 1/2" plastic sheet is complete overkill. Before you have completely detached the circle out of the plastic sheet, drill a 1/2" hole in the center. then finish cutting out the circle. This is easier than completely cutting out the disc and then drilling a hole in it, and I prefer it to pre-drilling the hole and cutting out the circle in case you cut your circle crooked/off-center. Err on the side of a larger disc than a smaller one; you can take a sanding drum to the disc later to get it to fit perfectly inside the sink drain. Dry fit the pieces together, and secure with a few dabs of superglue, and then drill + tap 4 1/2" deep 6-32 holes equally spaced around for your set screws.

You'll notice that I have also taken the liberty of solvent-welding the spring rest into the plunger tube. This is also excessive, as the set screws will be enough to hold the spring rest against any reasonable amount of springs put in there. However, as the front bushing is removable, there is no harm in doing so. However, you may want to make your front bushing permanent for whatever reason, in which case you will want your spring rest to be removable.

The front bushing is constructed out of a 3/4" to 1/2" slip reducing bushing, solvent-welded inside the rear piece of 1/2" sink drain tail (fron the scrap piece you cut off when you shortened the plunger tube). Sink drain extension is designed to be fluted so the rear end can fit into the front end of the next piece. Depending on the specifics of the tube you buy, you may need to sand down the bushing to get it to fit. You want a long enough piece of scrap sink tail to fit snugly into the plunger tube and also enclose your bushing. Also, add padding at this point for your plunger head.

Because I lost my original piece of sink drain, I had to substitute, which is why in the following pictures, you will see that my front bushing is severely sanded in, and is not fully enclosed in sink drain tail.

Fit the bushing into the plunger tube and drill/tap a hole straight through. You should place this hole about 1/8" further back than I did.

The fit is supposed to be like this

but you can see that sink I drilled my hole too far forward, the bolt that is supposed to run through the shell and the plunger tube and the bushing, securing everything together, is not going to have enough plastic to latch on to. Thus, I had to move everything in my assembly 1/8" back, which puts additional constraints on spring compression, and also reduces draw length slightly.

This is how the plunger tube is supposed to look with the front bushing attached.

Notice that my bolt use is way too short as it is supposed to extend out long enough to be visible (and thus securable through nuts) on the outside of the front portion of shell.

Preparing the Shell, 2.0

Make the front portion of your shell look like so

The rear ridge is dremeled out completely so that the rear section of shell can push forward as much as possible (increasing draw). The front ridges are dremeld down to fit the OD of 1.5" sink drain. The green dot is the hole to fit the bolt that secures the plunger rod. To drill this hole, I place the plunger tube into one side of the shell and drill down through the visible portion of the plunger tube into the shell. Then I run a bolt through this half of the shell and the PT, add super glue to the other side of the PT, and press down the other section of shell. I remove the bolt, remove the already drilled section of shell, and then run the drill through the plunger tube and the other section of shell. This ensures that your holes in the shell match up with the holes in the plunger tube so that your bolt will fit nicely through. Also, drill these holes with a larger bit as you won't be tapping them.

Constructing the Plunger Rod

Start with 13" of the square rod. 12" may do if you are buying 7/16" square nylon from McMaster rather than 1" square rod or 7/16" square rod from a different plastic supplier. Notice that in the picture the square rod is less than 12"; this is because of mistakes in previous steps that required me to cut it down to size. However, you want more starting material than less, which is why 13" is preferred.

Shave down the height of your square rod if needed. One of the cross-sectional dimensions must be 7/16" or slightly less; the other doesn't really matter, though it should probably be 7/16" or greater. Cut a catch notch in your square rod. You can use the picture for reference, but it is best to measure carefully against the stock plunger rod. Measure from the back (the end opposite the arrow, in the direction of the arrow), as you will have to slowly cut down the front to get everything to fit in the end.

Also cut a 1/16" wide slit for the horizontal fin. Again, you can use the picture for reference, but carefully compare with the stock plunger rod, and measure from the back. Getting the spacing right here is crucial. To cut the slit, I drilled successive holes and then connected them all together with a cutting disc. Depending on what material you use, your mileage may vary. Polycarbonate and PVC rod will be easy to machine: you can just drill the endpoint holes and cut the slit out with a saw. Nylon and polyethylene will be annoying to machine, if you want to cut the slit with a saw, you will have to be extremely patient.

Next, cut a fin out of 1/16" plastic sheet. Use the picture for reference in dimensions, but again, compare frequently with the fin of the stock plunger rod.

Drill and tap two holes to secure the fin.

The fin will be secured with two sections of 6-32 threaded rod, which will double as the vertical support. You are probably better off repeating this process to cut out a vertical fin as well and solvent-welding it together. I was both lazy, and chose to go with ease of disassembly, so as reassembly is also easier.

Finally, drill and tap a hole in the business end of the plunger rod to secure your plunger head.

The plunger head is constructed from a 1.25" steel washer as the spring compression piece, a 1.5" rubber washer to seal, and a 1" washer cut from 1/8" plastic to help form the seal. The sides of the plastic washer are beveled to help the rubber washer form a cup shape.

The plunger rod is assembled like so. Notice the stubs of threaded rod securing the fin. Also, notice the lack of a lock washer on the front. You would do well to add one. You can also see the beveling on the plastic washer.

Edited by Zorn's Lemma, 27 January 2010 - 04:52 AM.