The only improvement that I made over his design is that no lathe work is necessary; all you need is a a rotary (dremel) tool, a few cutting and sanding bits for said tool, a hack saw, and (maybe) some drill bits and a power drill.

This isn't a full writeup, but it's pretty simple so you shouldn't really need one anyway.

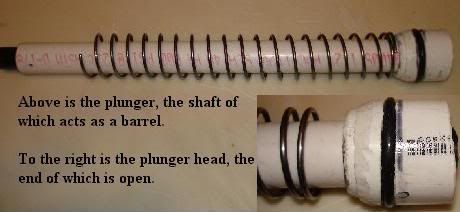

First up is the plunger/barrel:

The shaft is made out of 0.5" Sch. 40 PVC. On one end is a 0.5" to 0.75" bushing, as well as (approximately) half of a 3/4" coupler. I used a #18 O-ring.

To make the plunger head, I first cut off a ring from the end of the coupler and put it on the bushing. Then, I put the O-ring on, followed by the rest of the (half of the) coupler. The O-ring was too smal (even though it was the largest they had), so I wrapped some narrow strips of electrical tape around the bushing (underneath the O-ring). This pushed the O-ring out far enough to seal against the plunger chamber.

Also, one can nest whatever barrel material one wishes inside the 0.5" PVC. I used nested 17/32" and 9/16" brass.

As a side note, the spring pushes against the bushing, so it would be a good idea to solvent weld the bushing to the shaft.

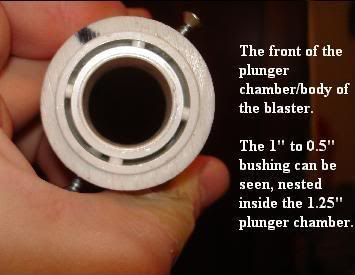

The plunger chamber itself is made out of 1.25" Sch. 40 PVC. I've found that a 1" to 0.5" bushing fits very well in the 1.25" PVC.

I dremeled out the 0.5" fitting of the bushing, so that the 0.5" PVC could slide effortlessly through it, and the front of the spring presses against it.

I wrapped some electrical tape around the narrower part of the bushing to add to the friction, and used two screws to keep the bushing from moving.

PS: I'll cut the screws down eventually.

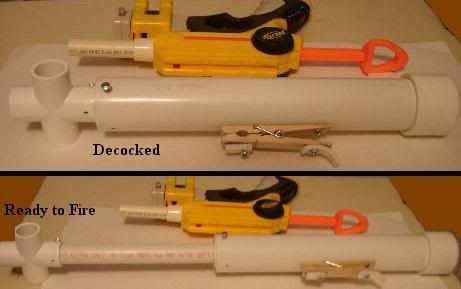

The trigger is a pretty basic clothespin trigger, but I used 1/8" music wire instead of a Carbon's customary nail.

The "top" of the clothespin is screwed to the outside of the plunger chamber, and has an oversized hole through it to allow the music wire catch into the plunger chamber's hole (which is also over sized, for smooth operation).

The "bottom" of the clothespin holds the music wire catch. The flat piece of PVC keeps the music wire from falling out of the clothespin, and the curved piece provides a more comfortable trigger.

Final additions were a 0.5" 4-way coupler (not sure if that's the right name) on the front end of the plunger/barrel, and a removable 1.25" endcap to seal the back of the plunger chamber just before firing.

The final product (for now, at least):

I was going to add a pistol grip and more proper trigger, but I kind of like the "boom stick" style of holding this thing and, well, I have other things I need to do.

As you can see, when de-cocked it's about the same length as a cocked NF. Cocked, it's several inches longer.

Ranges were a little disappointing for something with a plunger chamber that is that big, but by no means horrible. It got about the same range as the NF that you see pictured there (which has a spring replacement in addition to the obvious CPVC barrel replacement), which is to say about 50 feet in cold weather.

By the way, PANTS doesn't really mean anything. I considered calling it the "PANS" (for a backwards SNAP, like the Wob+) or "Toon Stick" (Carrtoon + boom stick) but I figure Carbon and Carrtoon have rights to those. PANTS, on the other hand, just sounded funny...so I went with it.

However, just to follow the tradition, let's say that PANTS stands for "Pretty Adequate Nerf Thingy Shooter."

Thanks go to Carbon and Carrtoon, for their designs.

Also to whoever came up with the idea to put an O-ring on like that (Hilt, maybe?)

And finally to Captain Slug, whose Wob+ thread got my rear in gear (oh, his Wob+ will be infinitely better, but I was still first.

EDIT 4/1/08: In the intervening weeks, I've realized that the bad ranges may be because there is a large amount of dead space between the back of the barrel and the endcap. I am working on a solution for this.

Edited by jwasko, 01 April 2008 - 09:01 PM.