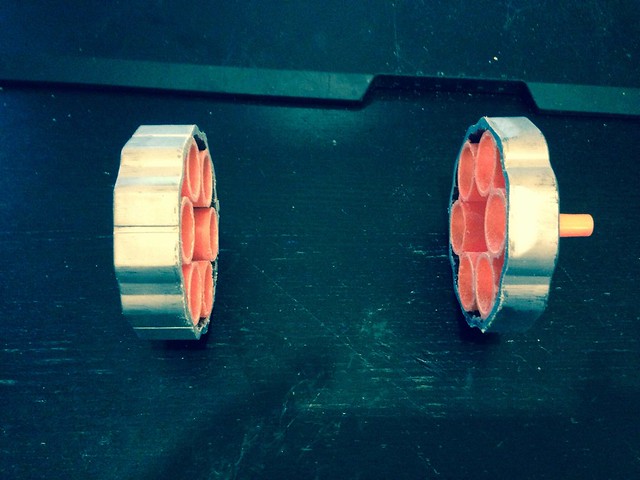

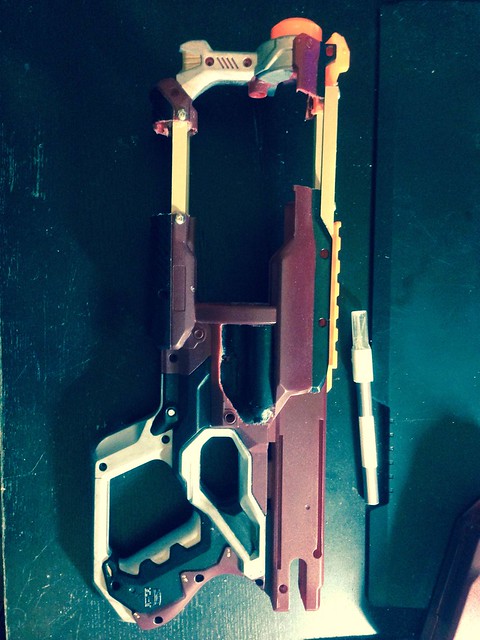

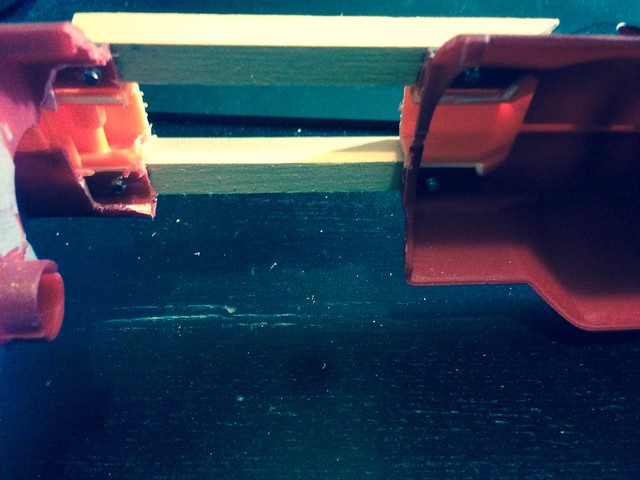

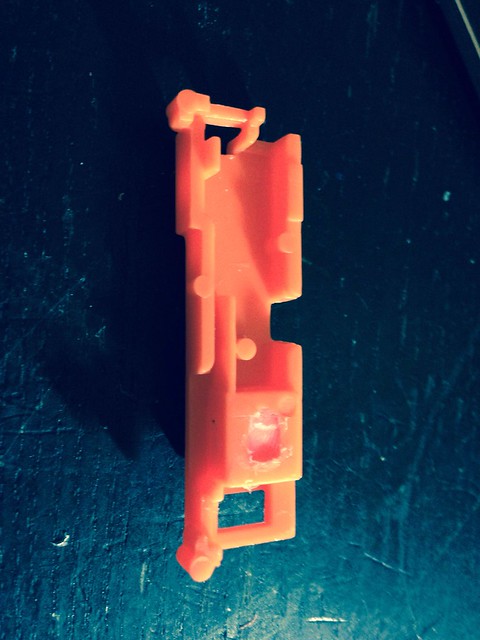

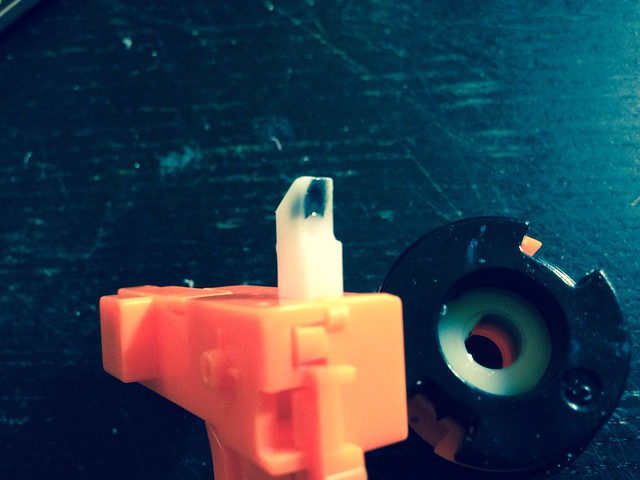

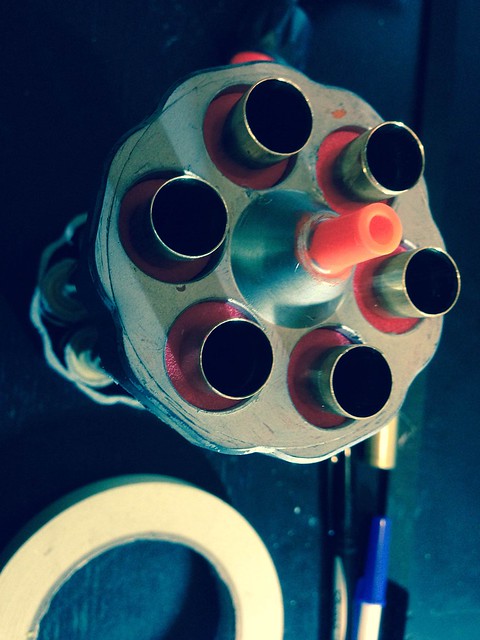

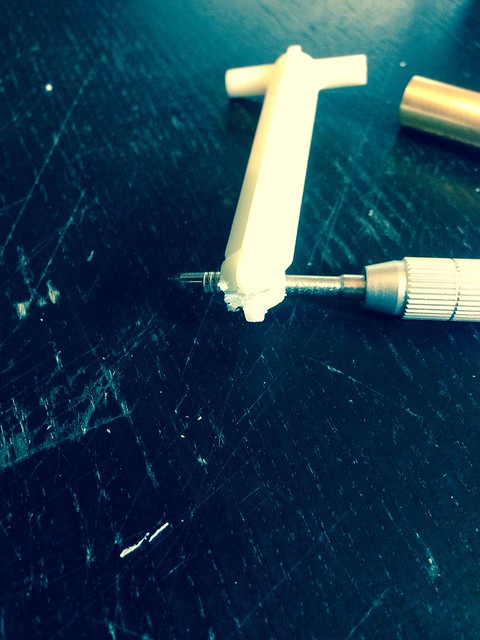

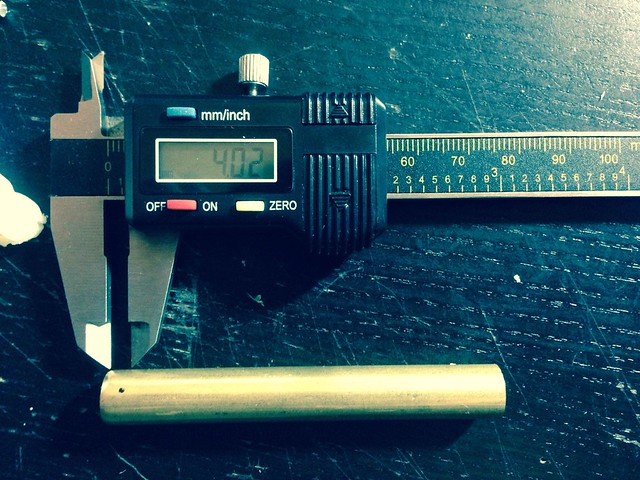

Almost complete minus some logos and minor work on the stock and front end of the gun, Borderlands 2 shotgun inspired Sledgefire:

There have been 1000 items by ompa (Search limited from 20-January 97)

Posted by

ompa

on 31 August 2015 - 01:13 PM

in

Modifications

Posted by

ompa

on 31 August 2015 - 01:13 PM

in

Modifications

Posted by

ompa

on 21 July 2015 - 10:20 PM

in

Modifications

Posted by

ompa

on 21 July 2015 - 10:20 PM

in

Modifications

Posted by

ompa

on 24 June 2015 - 08:37 PM

in

Modifications

Posted by

ompa

on 24 June 2015 - 08:37 PM

in

Modifications

Posted by

ompa

on 23 June 2015 - 04:59 PM

in

Modifications

Posted by

ompa

on 23 June 2015 - 04:59 PM

in

Modifications

Posted by

ompa

on 23 June 2015 - 06:58 AM

in

Modifications

Posted by

ompa

on 23 June 2015 - 06:58 AM

in

Modifications

Posted by

ompa

on 22 June 2015 - 10:00 PM

in

Modifications

Posted by

ompa

on 22 June 2015 - 10:00 PM

in

Modifications

Posted by

ompa

on 12 June 2015 - 01:08 AM

in

General Nerf

Posted by

ompa

on 12 June 2015 - 01:08 AM

in

General Nerf

Posted by

ompa

on 12 June 2015 - 12:58 AM

in

Modifications

Posted by

ompa

on 12 June 2015 - 12:58 AM

in

Modifications

Posted by

ompa

on 11 June 2015 - 02:43 AM

in

Modifications

Posted by

ompa

on 11 June 2015 - 02:43 AM

in

Modifications

Posted by

ompa

on 11 June 2015 - 02:36 AM

in

Modifications

Posted by

ompa

on 11 June 2015 - 02:36 AM

in

Modifications

Posted by

ompa

on 11 June 2015 - 02:30 AM

in

Modifications

Posted by

ompa

on 11 June 2015 - 02:30 AM

in

Modifications

Posted by

ompa

on 05 June 2015 - 01:24 AM

in

Modifications

Posted by

ompa

on 05 June 2015 - 01:24 AM

in

Modifications

So I bought an extreme air max one a couple of days ago, and I want to make a brass breech for it. I want to know if I use a 3/4" to 1/2" pvc reducer, will it be air tight with 9/16" brass pipe? Here is the reducer and here is the brass pipe if it makes a difference. As an inner barrel, I wanted to use this. Is this an effective barrel setup? Is there anything I'm doing wrong?

Thanks a lot,

Mattakers

Posted by

ompa

on 28 May 2015 - 09:13 PM

in

General Nerf

Posted by

ompa

on 28 May 2015 - 09:13 PM

in

General Nerf

Posted by

ompa

on 24 May 2015 - 03:44 PM

in

General Nerf

Posted by

ompa

on 24 May 2015 - 03:44 PM

in

General Nerf

Posted by

ompa

on 21 May 2015 - 06:14 PM

in

Modifications

Posted by

ompa

on 21 May 2015 - 06:14 PM

in

Modifications

Posted by

ompa

on 22 April 2015 - 07:50 AM

in

General Nerf

Posted by

ompa

on 22 April 2015 - 07:50 AM

in

General Nerf

I can hit that speed with a Mountain Dew and half an hour. But I can only ever fire that blaster /from the hips/.

Posted by

ompa

on 22 April 2015 - 07:23 AM

in

Modifications

Posted by

ompa

on 22 April 2015 - 07:23 AM

in

Modifications

Posted by

ompa

on 21 April 2015 - 08:31 AM

in

Modifications

Posted by

ompa

on 21 April 2015 - 08:31 AM

in

Modifications

Posted by

ompa

on 21 April 2015 - 08:25 AM

in

Darts and Barrels

Posted by

ompa

on 21 April 2015 - 08:25 AM

in

Darts and Barrels

Posted by

ompa

on 21 April 2015 - 08:19 AM

in

Modifications

Posted by

ompa

on 21 April 2015 - 08:19 AM

in

Modifications

Posted by

ompa

on 21 April 2015 - 08:03 AM

in

Modifications

Posted by

ompa

on 21 April 2015 - 08:03 AM

in

Modifications

Posted by

ompa

on 21 April 2015 - 12:54 AM

in

Modifications

Posted by

ompa

on 21 April 2015 - 12:54 AM

in

Modifications

Posted by

ompa

on 20 April 2015 - 11:46 PM

in

Modifications

Posted by

ompa

on 20 April 2015 - 11:46 PM

in

Modifications

Posted by

ompa

on 20 April 2015 - 11:21 PM

in

Modifications

Posted by

ompa

on 20 April 2015 - 11:21 PM

in

Modifications

Posted by

ompa

on 15 April 2015 - 08:20 PM

in

Darts and Barrels

Posted by

ompa

on 15 April 2015 - 08:20 PM

in

Darts and Barrels

Posted by

ompa

on 15 April 2015 - 08:00 PM

in

Darts and Barrels

Posted by

ompa

on 15 April 2015 - 08:00 PM

in

Darts and Barrels

Posted by

ompa

on 15 April 2015 - 03:19 PM

in

Darts and Barrels

Posted by

ompa

on 15 April 2015 - 03:19 PM

in

Darts and Barrels

Posted by

ompa

on 13 April 2015 - 11:01 PM

in

Modifications

Posted by

ompa

on 13 April 2015 - 11:01 PM

in

Modifications

Posted by

ompa

on 13 April 2015 - 10:49 PM

in

Modifications

Posted by

ompa

on 13 April 2015 - 10:49 PM

in

Modifications

Posted by

ompa

on 04 April 2015 - 11:21 PM

in

Modifications

Posted by

ompa

on 04 April 2015 - 11:21 PM

in

Modifications

Posted by

ompa

on 01 April 2009 - 12:50 AM

in

Nerf Wars

Posted by

ompa

on 01 April 2009 - 12:50 AM

in

Nerf Wars

Posted by

ompa

on 31 May 2008 - 05:31 PM

in

Modifications

Posted by

ompa

on 31 May 2008 - 05:31 PM

in

Modifications

Posted by

ompa

on 30 May 2008 - 11:03 PM

in

Modifications

Posted by

ompa

on 30 May 2008 - 11:03 PM

in

Modifications

Posted by

ompa

on 28 May 2008 - 09:11 AM

in

Modifications

Posted by

ompa

on 28 May 2008 - 09:11 AM

in

Modifications

Posted by

ompa

on 28 May 2008 - 12:16 AM

in

General Nerf

Posted by

ompa

on 28 May 2008 - 12:16 AM

in

General Nerf

Posted by

ompa

on 28 May 2008 - 12:14 AM

in

Modifications

Posted by

ompa

on 28 May 2008 - 12:14 AM

in

Modifications

Posted by

ompa

on 28 May 2008 - 12:09 AM

in

Modifications

Posted by

ompa

on 28 May 2008 - 12:09 AM

in

Modifications

Posted by

ompa

on 27 May 2008 - 11:59 PM

in

Modifications

Posted by

ompa

on 27 May 2008 - 11:59 PM

in

Modifications