Usually around this time of year, we have a thread or two pop up and get closed for some silly reason, so he's everyone's chance!

GROUND RULES

-This topic will be open and pinned for one week, for everyone to wish everyone a lovely holiday and festive new year and all that.

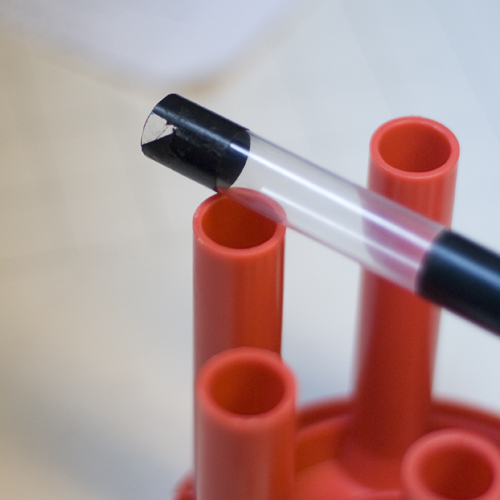

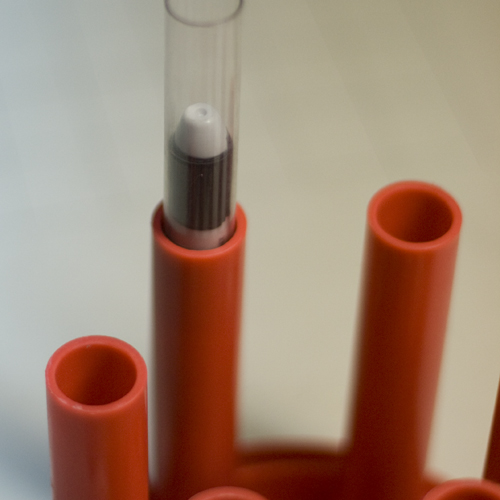

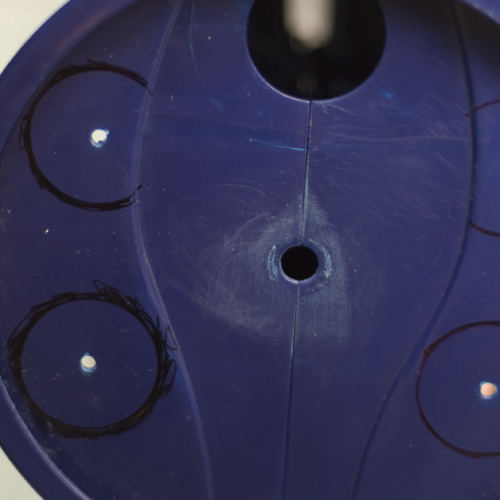

-This topic is also for the inevitable boasting of Nerf and modding related gifts.

Past that? NOBODY CARES. Don't be that guy, blasters and modding tools ONLY.

Annnnnyway, I do hope everyone has had a wonderful go of this holiday season and I hope we'll be seeing you all just as much as ever in 2013.

Find content

Find content