Items needed:

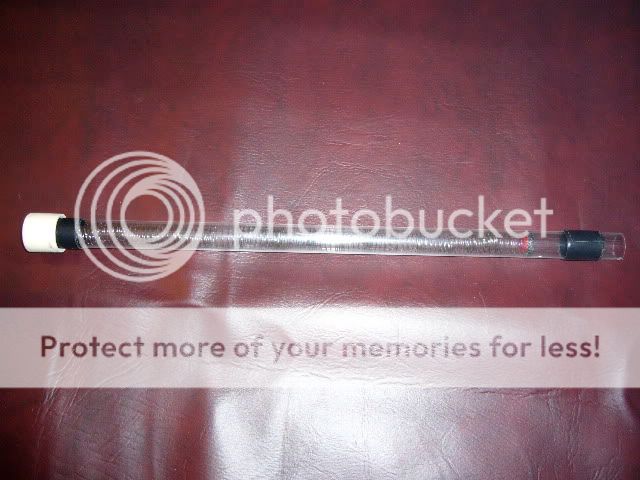

- Reverse Plunger System

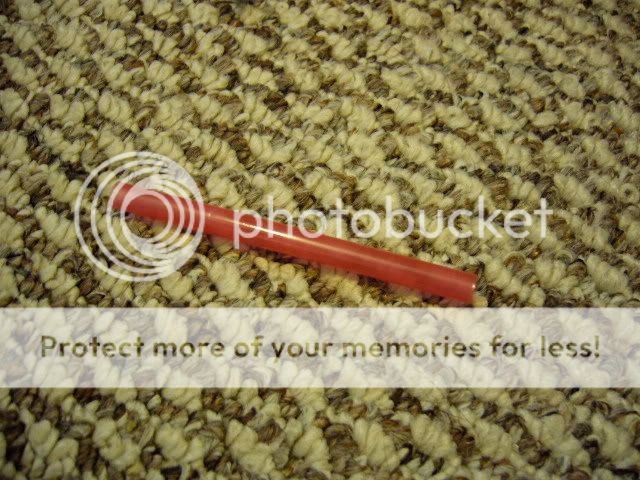

- Foam Backer Rod (FBR) (Either thicker 1/2 inch or 3/4 inch cheap Home Depot/ Lowes foam)

- Longer 1/4 inch drill bit

- Drinking Straw

- Scissors

Find some FBR that fits tightly into the back end of the Reverse Plunger/ Barrel Piece (for lack of a better term I'll just refer to it as the reverse plunger in this writeup)

Measure the length of deadspace in the back or the reverse plunger/ barrel piece. (Longstrike, if I remember correctly was @ 4-3/4 inches)

Cut the FBR and Straw to the Length of the deadspace

Take a 1/4 inch drill bit and drill through the center of the FBR ( I would recommend holding the bit and hand drilling it through as opposed to using a power drill... it's safer and straighter... )

Once you have the FBR Drilled through twist the straw through the hole in the FBR (I would recommend sticking the 1/4 drill bit inside the straw so you don't collapse the straw and you may want to plumbers goop the outside of the straw to help it's air seal)

Once that is done twist the FBR into the back of the reverse plunger and it's done.

I did this with my Longstrike and got an immediate recognizable difference in velocity and impact with the wall as the dart rebounded much further than before the FBR was added even though I started by power drilling so the hole wasn't perfectly straight. I also left about a milimeter of FBR sticking out of the back to act as padding on the plunger head.

Find content

Find content