But wait! Notice the clear part of the clip is facing the right side?

Its fine for left-handed users... but for right-handed users it means they cannot see how much ammo is in the clip, instead all their opponents can see the ammo count clearly!

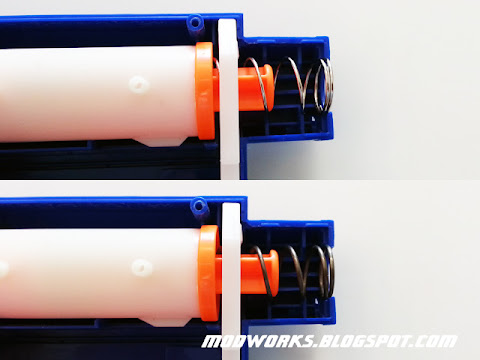

Here is an example of the Elite 18-dart clip in a Longshot:

Right-handed users cannot see their ammo count...

...but their opponents can see it clearly!

Studies suggest that up to 80-90% of the world population is right-handed, which means alot of users (like me!) will have this common issue with their Elite clips.

So here is how to solve it, with some simple modding steps.

Step 1:

Cut or sand down the raised clip restriction areas at the top part of the clip.

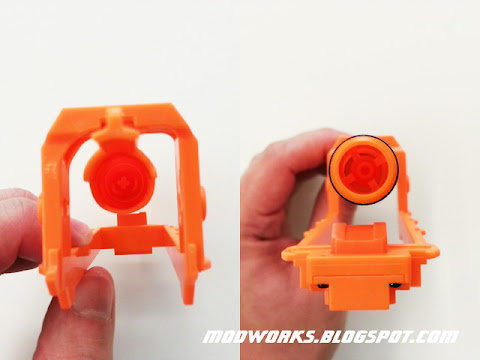

Original clip (left) vs modded clip (right).

Make sure the raised areas are properly flattened and smooth.

Step 2:

Use a dremel or hobby knife to cut a clip-lock notch on the side of the clip. Mirror the exact notch position from the other side.

Ensure that the new clip-lock notch is cut at the correct position.

Final Step:

Clean up the notch cuts and test load it into blasters. Its done!

Original Elite 18-dart clip (left) vs Modded Elite 18-dart clip (right).

:: Results ::

Here is the modded Elite 18-dart clip loaded into a Longshot.

Right-handed users can now see their ammo count...

...but their opponents cannot!

Enjoy your improved Elite Clips!

Note: This mod can be done on any N-Strike clips or drum magazine too.

--

Additional Note:

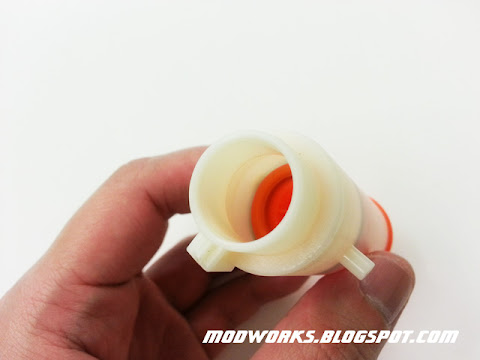

For blasters like the Nerf Retaliator or Recon, modded clips will get blocked by the casing part in front of the clip well (as shown below).

Therefore you'll need to also cut off the raised section on the clip, then it can fit into those particular blasters.

- Update! -

For blasters like the Nerf Stampede or Rayven, their clip detection pressure switches are in a position that will be affected by the unused notch, hence the system will "think" that there is no clip loaded. (Thanks to harpuia for this tip!)

Therefore modders will have to either tape down or bypass those pressure switches, or just use tape to seal the unused notch.

Find content

Find content