2009-STYLE

Where:

Tincher Preparatory School

1701 Petaluma Ave.

Long Beach, CA 90815

When:

Saturday, August 10th 13th

10~4

Fuck yeah, nerfing like it's 2009!

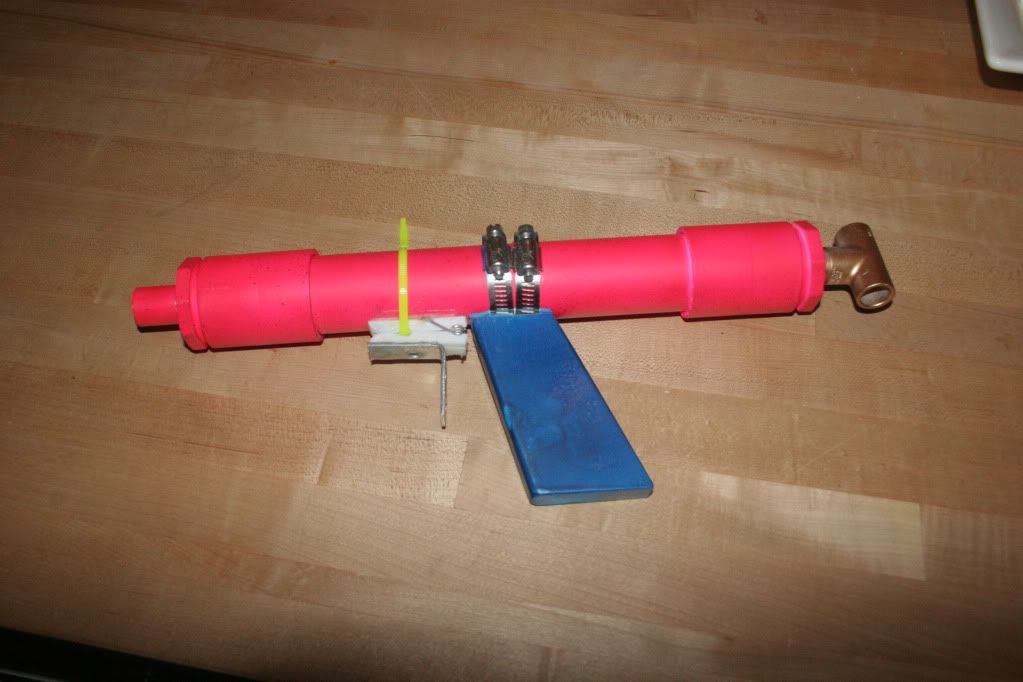

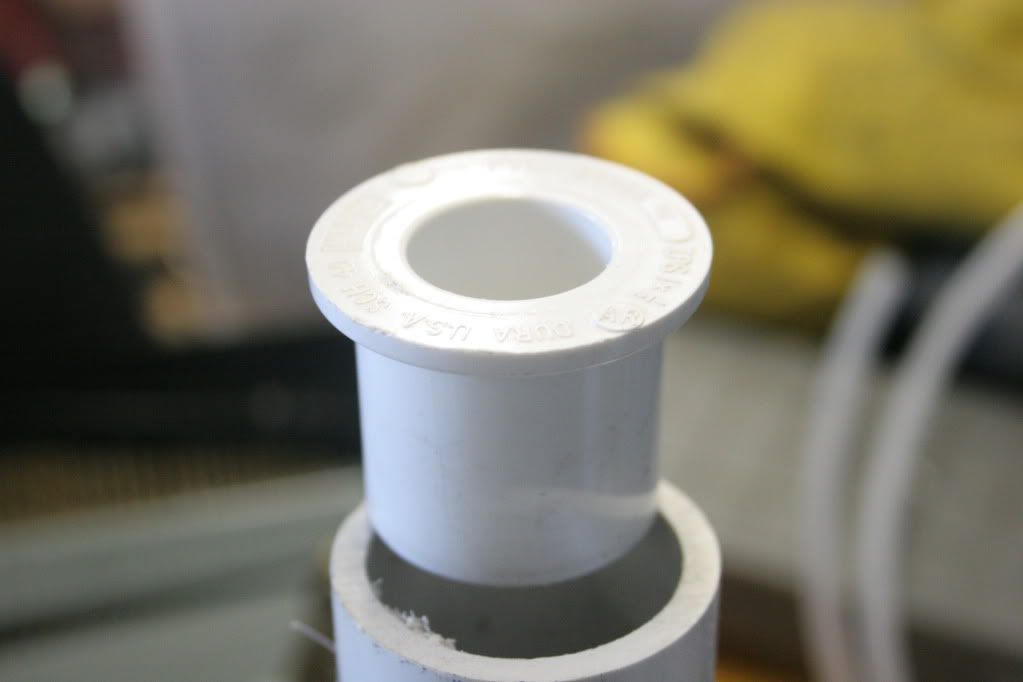

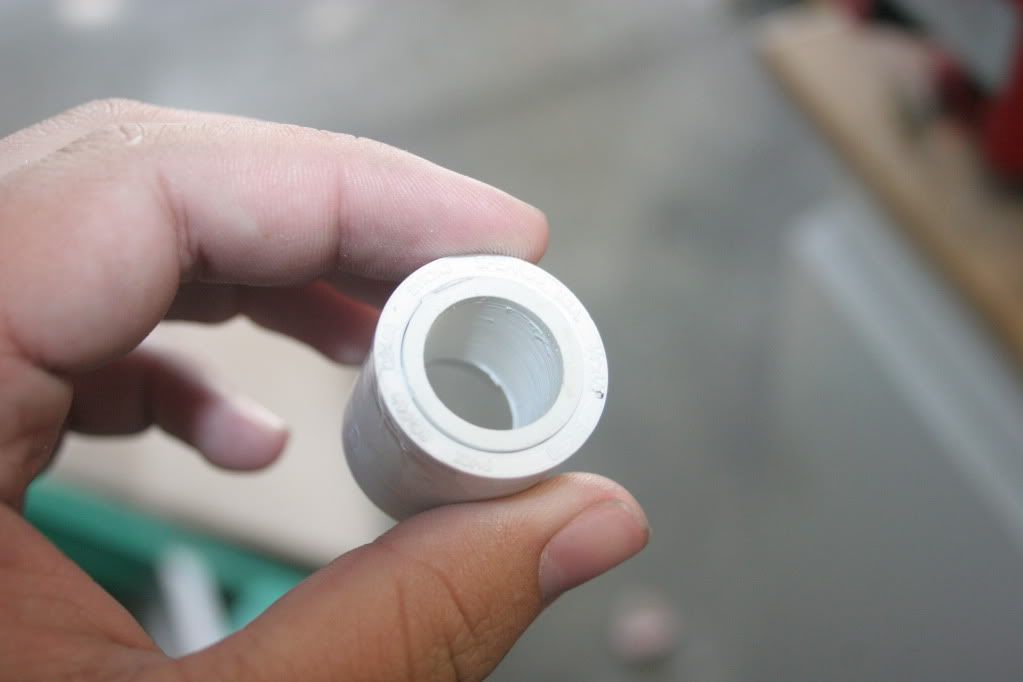

Rules are fairly typical for SCUN events. This location is awesome. This is the August SCUN war. All darts, excluding 'super domes' are allowed. Regarding blaster bans - basically, don't be a dick. If it's too powerful, we'll ask you to stop using it, and if you have any concerns, feel free to PM me. Singled 4Bs are not allowed unless they have a hopper and OPRV. Titans must have an absolver. Homemade airguns are allowed if they aren't stupidly powerful. It is not recommended that anyone under 13 shows up, and if you are under 13 and you show up without a parent that stays the whole time, you'll be kindly asked to leave. Hopefully we won't get rained out like last year.

You are allowed to block anything 5/8" in diameter and under with your blaster. Large ammo (arrows, balls) counts as a shield breaker.

I'm allowing glue domes (not 'super' domes) again unless a large majority of people don't want that to happen. Feel free to PM me if you have any questions or concerns about darts you plan on using.

Find content

Find content