- NerfHaven

- → Viewing Profile: Topics: balisticjoe

balisticjoe

Member Since 03 Apr 2008Offline Last Active Jan 22 2024 09:00 PM

Community Stats

- Group Members

- Active Posts 311

- Profile Views 10,647

- Member Title Member

- Age Age Unknown

- Birthday Birthday Unknown

User Tools

Latest Visitors

Topics I've Started

APOC pre-war shakedown

12 July 2017 - 09:55 PM

When: Saturday 7-22-17

Where: Babbage Park, 2 Edison Avenue, North Brunswick Township, NJ 08902

Backup location (if picnic area occupied) John Adams elementary

Time: 10 - someone passes out

What to bring: food, lets not lose momentum to lunch if possible

Rules: The usual shit, don't be a dick. I reserve the right to shoot you with your own blaster if it's hitting too hard, or kick you out, whatever I feel like.

Round types: This is NJ, we do 3-15. Might do some no hopper rounds or pistol rounds if people want.

The Balistic Blast

15 July 2014 - 11:46 PM

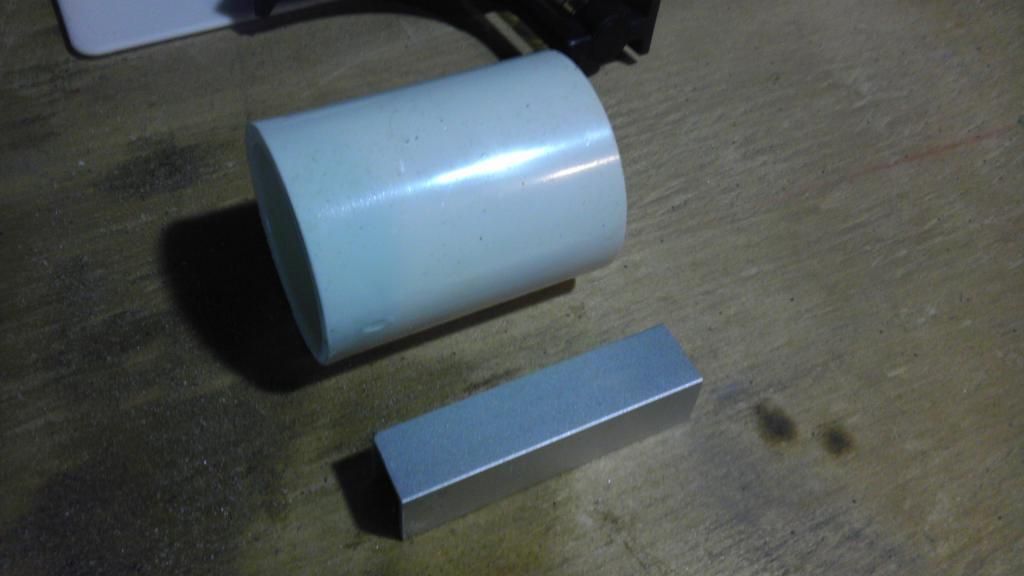

For a while now I have been experimenting with the use of 1/2" aluminum u-channel as a means of a catch mechanism for a nerf blaster. After several revisions I have come up with a system that is based on the SNAP catch, but is much more repeatable with the elimination of the clothespin part of the mechanism. I believe that this new design offers a strong reliable system that applies to blasters of all types, while still being machinable from ordinary tools.

Materials

1/2" aluminum u-channel

-can be found at most home depot's/lowes, the first one needs 1 1/2', but

less than 3" for each subsequent blaster (the extra is for tool use)

2' of 1 1/4" PVC pipe

-Yes, the 2' sections from home depot are perfect

1"x2" lumber

-you only need about 9", but a very fine handle material

an assortment of machine screws

-I prefer 8-32, but 6-32 are popular around these parts, you will need one 6-32 machine screw, you will need a tap that matches, so plan ahead

a cutting board

-Dont use your mom's, she will be very upset with you

-a good thick one from wal-mart, about $7.50, or use polycarbonate (preferred)

1/2" nylon rod

-you can get this from McMaster, if not you can use a wooden dowel from a big box store, anything 1/2", round, and reasonably strong should work

1" to 1/2" PVC reducer

-only if you want to fire darts

1 1/4" PVC coupler

-trigger mechanism mount

1 1/4" PVC tee

-Used for shoulder rest (I didn't becasue I wanted to be fancy, don't let that stop you)

1 1/2" fender washer x2

Your standard homemade blaster rubber washer

-McMaster 9562K46 you may want more than 1, just in case, or for your second one

[k26] spring

-This is nerfhaven, they get used for everything McMaster 9637K26, but I will show steps to use any reasonable sized spring

Tools

Dremel

Hand drill

Coping saw

Sandpaper

Tap for your preferred screw

Round micro file (The cheap wal-mart file set is worth its cost)

Pliers, screwdrivers, etc...

That said, power tools will make your life easier and the process faster, go on craigslist, a decent drill press, a scroll and/or band saw, and especially a belt/disk sander are easy to find for pretty cheap, I got all three of mine for $100.

The trigger mechanism

I'm bad at measuring things, so to get most of the sizes right I derive them from measurements, you may notice this in the write-up. Adam Savage of mythbusters fame talks about saving time by knowing when you do and don't need to be precise, so when a sharpie is a valid method of marking cuts, don't be afraid of eyeballing stuff, it is so much easier.

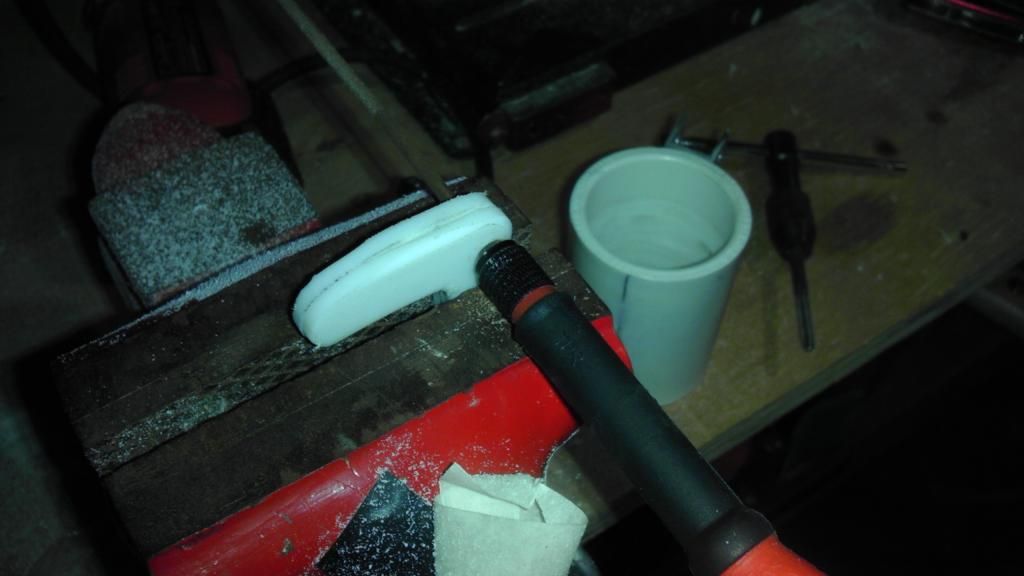

Start off with cutting a section of aluminum channel to the length of the coupler.

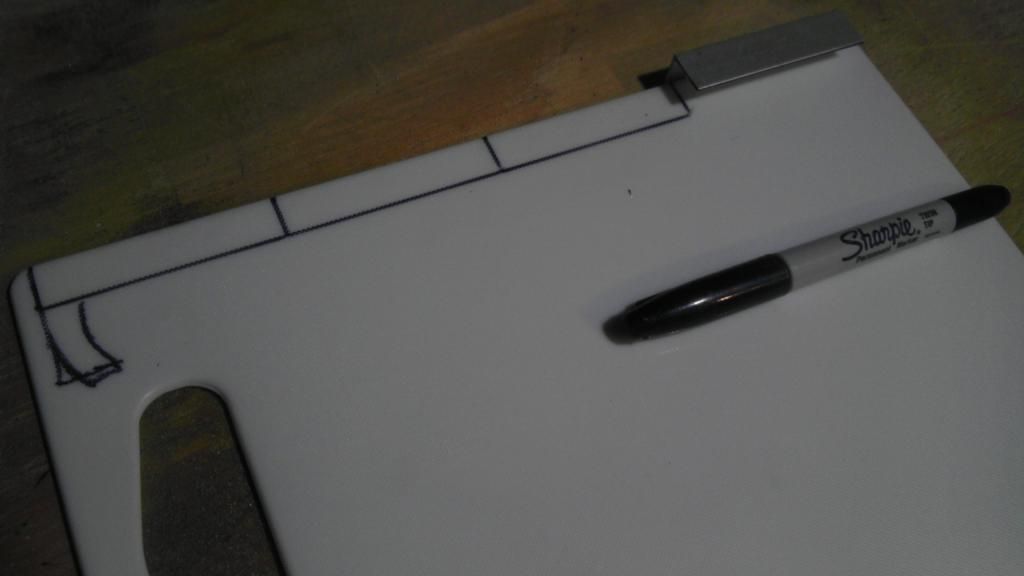

Then, insert your cutting board or polycarbonate into the slot of the u channel, and trace around the edge. Then doodle a trigger onto one end. Don't worry about the other rectangles in the picture, that was only for a test.

Now you need to drill a hole in the u channel, this will act as the pivot for the trigger. You will want to make it halfway between the gap and the back plate, and about the same distance from one side. The pictures will help guide you. As you can see, mine is a little lopsided, it still works fine. Tap it for your screw size.

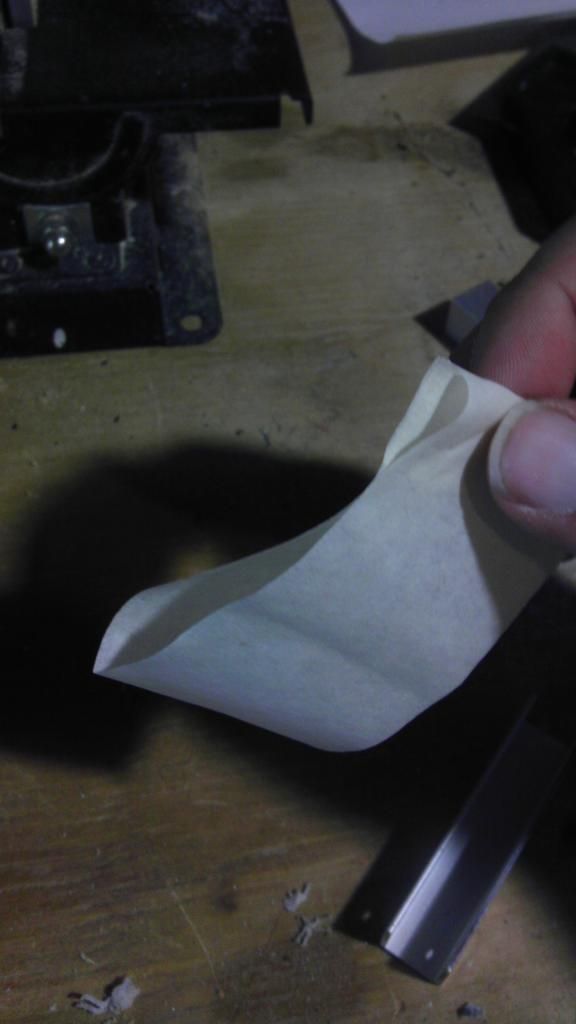

Next, we will use one of my favorite tricks, and quarter our coupler. Start by covering the coupler with one wrap of masking tape. WITH ALL THE MASKING TAPE TRICKS THE ENDS NEED TO BE IN LINE WITH EACH OTHER. That is, the tape forms a perfect cylinder around the piece.

Then, cut off a 1' piece of aluminum u channel, this is now your favorite tool. Caress it if you like. Hold up the sloted end of the u channel to the coupler, with one "leg" over the seam of the tape. Because of 3 dimensional trigonometry, it turns out that where the u channel meets the coupler (or pipe) is a perfect line down the side of the cylinder. This is why it is a nerfers favorite tool.

Use a knife to cut through the seam of the tape, remove the excess.

The tape, when removed from the coupler will have a length exactly equal to the diameter of the coupler. So we will remove the tape, and fold it in half non-sticky side to not-sticky side to create a seam.

Then, use the seam to fold the sticky sides together, the tape is now equal to exactly half of the diameter of the piece.

Now, fold the tape in half again. This can now be used to quarter the coupler.

To quarter the coupler, first put a line on the coupler using the u channel.

Then use the folded tape to mark each quarter along the outside of the coupler. Where the fourth the mark would go, you should line up with the line you made first, this is how you know the marks you made are exactly on quarter around the circumference of the coupler.

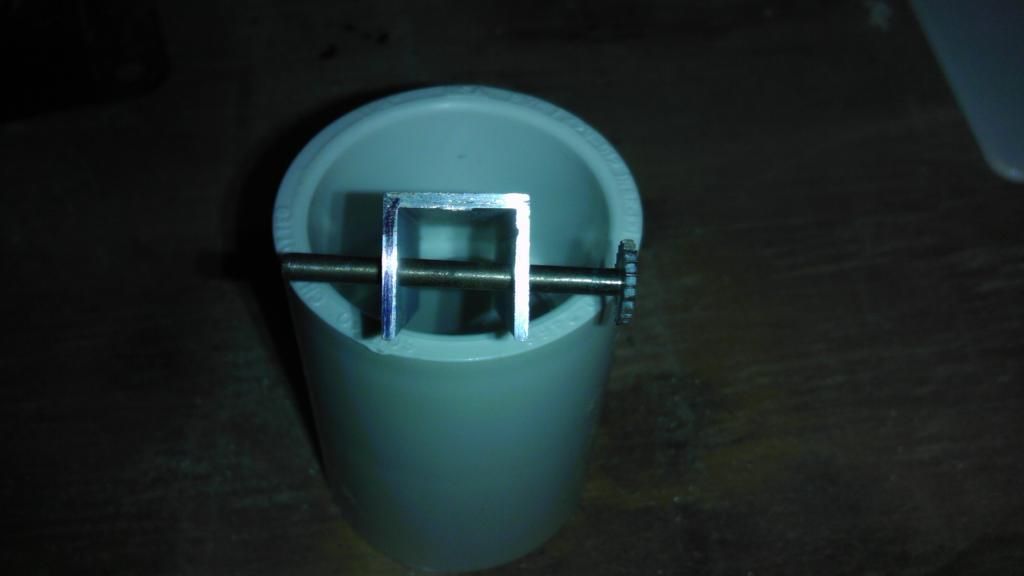

Now that we have the coupler quartered, we can attach the u channel.

Try to line it up with one of the lines, it doesn't need to be perfect, just somewhat straight. Reinforce it with putty, and any other super adhesives you may have.

Then, you are going to want to remove this lip from inside of the coupler, just enough to slide relatively easily on the 1 1/4" PVC pipe.

Now we are going to work on the trigger. Take the piece you traced out before, and cut it out. Hold it into the u channel, and mark where the pivot hole is, drill out the hole.

Use a small round file to open up the hole so a screw can slide through it easily.

Now on the part of the trigger that meets up with the top of the u channel, make a line down the center, and drill straight down about 2 inched away from the actual trigger.

Temporarily mount the trigger in the u channel, make sure it is centered, then drill a hole through the u channel and coupler.

Since this hole will house the catch pin, we will need to clear some space for the pin to move freely. Do this with a small round file.

Now we will make the band rest for the catch pin. Just take a small piece of scrap plastic, and cut a small v out of a rectangle, refer to the picture for help. Be sure to round off all of the edges, you want to create a minimal amount of stress on the rubber band, shearing it will break the mechanism.

Now drill and tap a hole at the bottom of the v. Use a 6-32 here, as it will easily fit into the side of a 1/4" piece of material, with enough space for you to fudge it up a little bit.

Now we will make the catch pin. To do this take a 6-32 machine screw, about 2.5" - 3" long, put a single nut on it. Using a pair of pliers to hold the nut, use a screwdriver to spin the screw while holding it against some sort of grinder, I used my belt sander. CAUTION, IT WILL GET VERY HOT. Using the screwdriver to spin it in the nut helps to create a more round profile on the screw.

When finished, you should not be able to see any threads, and the head should be rounded off to prevent wear.

After it cools, remove the nut, and screw it into the band rest.

Now you can place the catch assembly into the bottom hole of the trigger. Then put on a rubber band to act as a trigger spring. This will complete the trigger mechanism.

I will update this thread as soon as I can (tomorrow?) with the rest of the build. Until then I leave you with this trigger mechanism to think about. A little bit more work than a SNAP, but with notable upsides. It is fairly easy to make, and super cheap to build.

Please wait for a few minutes while I reserve Space for the rest of the posts.

Sm3k Mod

26 August 2009 - 12:17 AM

Tools needed:

• Screwdriver (Phillips and flathead)

• Dremel and a fair amount of bits

• Something to cut pvc

• Neddle node pliars

• Diagonal cutters

• A fully functioning brain (recommended)

Materials needed:

• Petg (4 ft.)

• ½” pvc (16 in.)

• E-tape-lots of e-tape

First is first-here is your blaster:

After doing this to two turrets-this step will help a lot-drill a small hole in the center of the turret. Widen it to allow access to the screw.

This is what it will look like after you take this part off.

Take off the pump handle and then unscrew the rest of the gun. The internals.

Take note of the tank setup-it will help you later on. You may want to pump it to see how the whole thing works.

Now take off the one screw holding the tank setup in place. And focus your attention to the back.

Gently hold the white piece as you unscrew it. Once you have it undone-lift it up slowly-you don’t want to lose the spring. Place it in a safe place with the rest of the parts that come along with it. Until you get to this.

Now gently turn it over so that the turret if facing up and slowly take the turret off slowly for the same reasons as above.

Now take the parts and put them in the same safe place.

Time to start working on the turret. First-use your diagonal cutters and cut the prongs in the front of the turret. Now unscrew the back of the turret.

If you are lucky you will be able to take the blue turret casing off. If you are like me- it’s time to take the original barrels off. To do this you just need to pull them away from the rest of the turret. Sometimes the ar will stay glued in.

The best way I have found to fix this is to take a drill bit and extend the hole to the ar peg. Then you need to take a flathead screw driver and pry it out.

Time to re-barrel this thing. Grab your 4 ft. of PETG and cut it into 8-6 in. sections. Now add a lot of e-tape to the bottom of the sections to the point where it fits right into the stubs of the turret.

I had trouble with getting them to be perfectly straight. So I added some more e-tape about an inch from the bottom.

Now put the barrels into the turret (glue them if you want). And put your PVC onto the barrels.

Wrap some e-tape on the turret and be glad the hardest part is done.

Now-you need to improve the seal to the tank. To do this take a small oring-or as I did here cut up neoprene washer-and glue it to original seal.

NOTE: by doing this you will need to manually advance the turret. But the seal is worth it.

Make sure you reinforce the pump handle. To do this you need to drill through the original peg and replace it with a bolt. I used a 8-32 bolt.

Quick Question

01 March 2009 - 10:09 PM

1. What is the id and OD of the tubing n a hornet?

2. Dose this tubing work with most other air guns(at3k specifically)?

3. Mcmaster Carr numbers for it.

4. I know I need silicone based-but what type of lube specifically?

5. The sizes of "o"rings for the ls.

6. Are there ball/check valves for the tubing?

7. Fittings fr the tubing(t connector).

8. any product numbers will also help

9. what size brass fits frost king foam well?

thank you in advance.

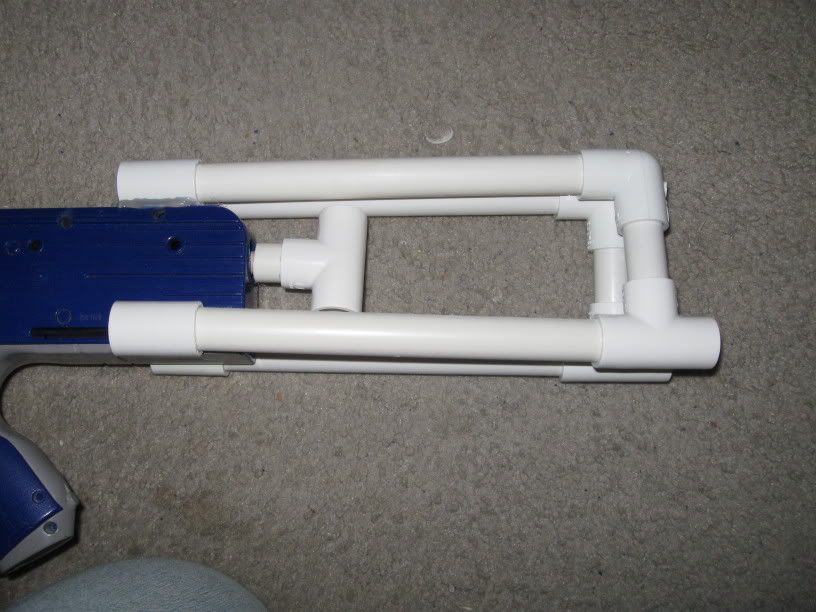

Longbow

02 February 2009 - 10:23 PM

pre-cut

former internals

cut down to size

you will see

the primer

could you call it a fore grip

general side shot

The stock

this is its current state, you can see that i tried to replicate a x-bow a little with the design. it seems very bulky but it is very comfortable. Remember this is a prototype and there is plenty of room for improvement. there will be a write-up some time this weekend. What do you think?sorry for the large pics.

- NerfHaven

- → Viewing Profile: Topics: balisticjoe

- Terms of Service and Privacy Policy

- Code of Conduct ·

Find content

Find content