Materials Needed:

Dremel with cutting bit

Some elastic material (I used an elastic knee brace, but those stretchy bandages work)

Epoxy

Padding materials (I used some pull-and-stick on shoe insole things)

Here's a pic of the stock shell below. Basically I cut along the red lines. I removed the handle completely, and X's mean I tossed those pieces. The yellow/gray part where the yellow shell doesn't cover is saved for later, which I did for one side, but you can do for both if you need a bigger hole. I cut the little target thing to get more room for my hand.

This is how I planned it to fit, though it's slightly different since I couldn't put my thumb all the way up there, which you'll see later. The trigger should be on the battery cover, which is shown in the next 2 pictures.

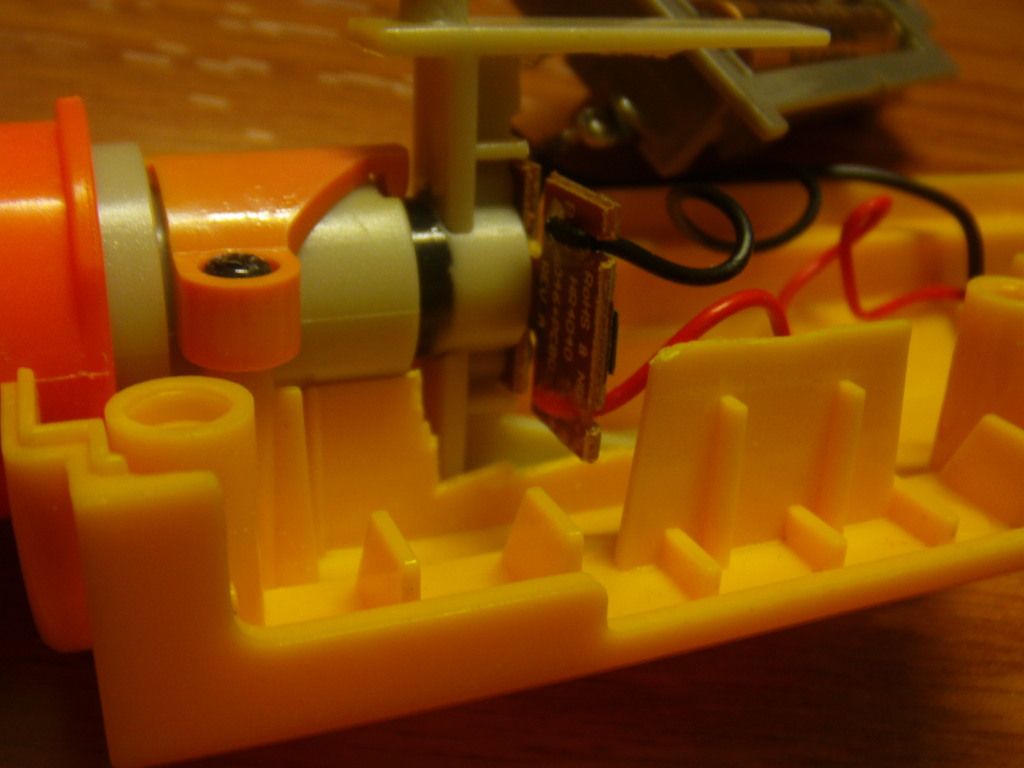

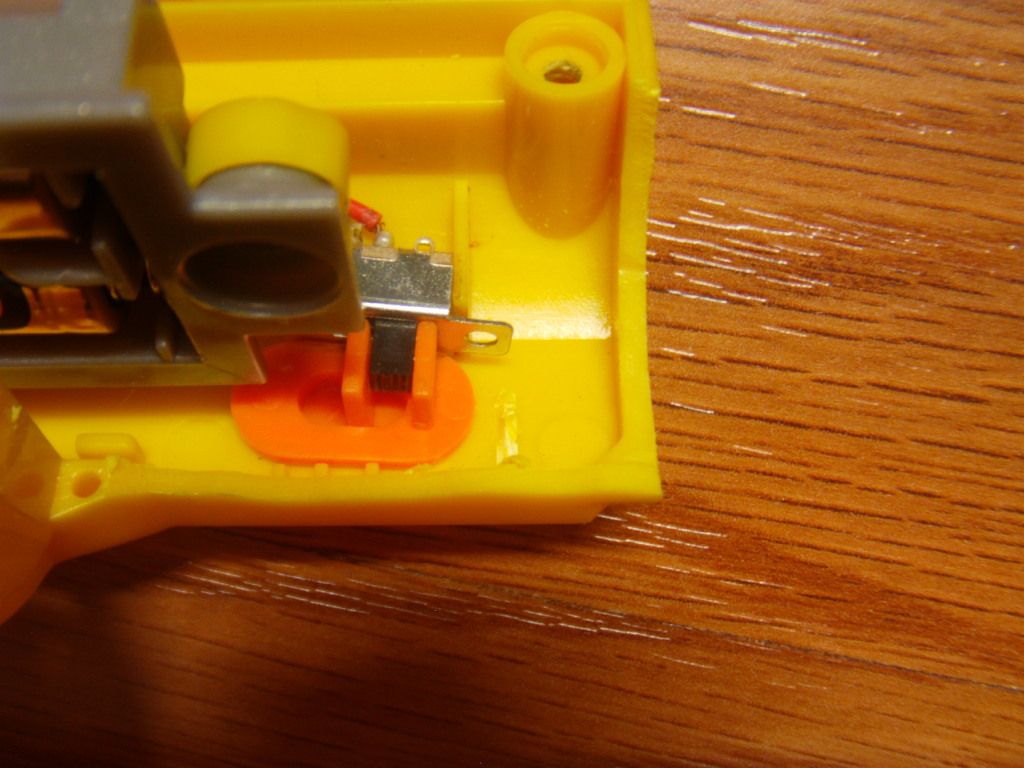

I took off the trigger components and drilled a hole to fit the trigger button on the battery cover. Tested to fit, making sure the hole wasn't too big.

Next I got some hot glue and glued that sucker in. Make sure you do not get glue on the spring or anywhere near the button of the trigger components or else it'll screw it up. I put electrical tape over everything so I don't get shocked or pricked.

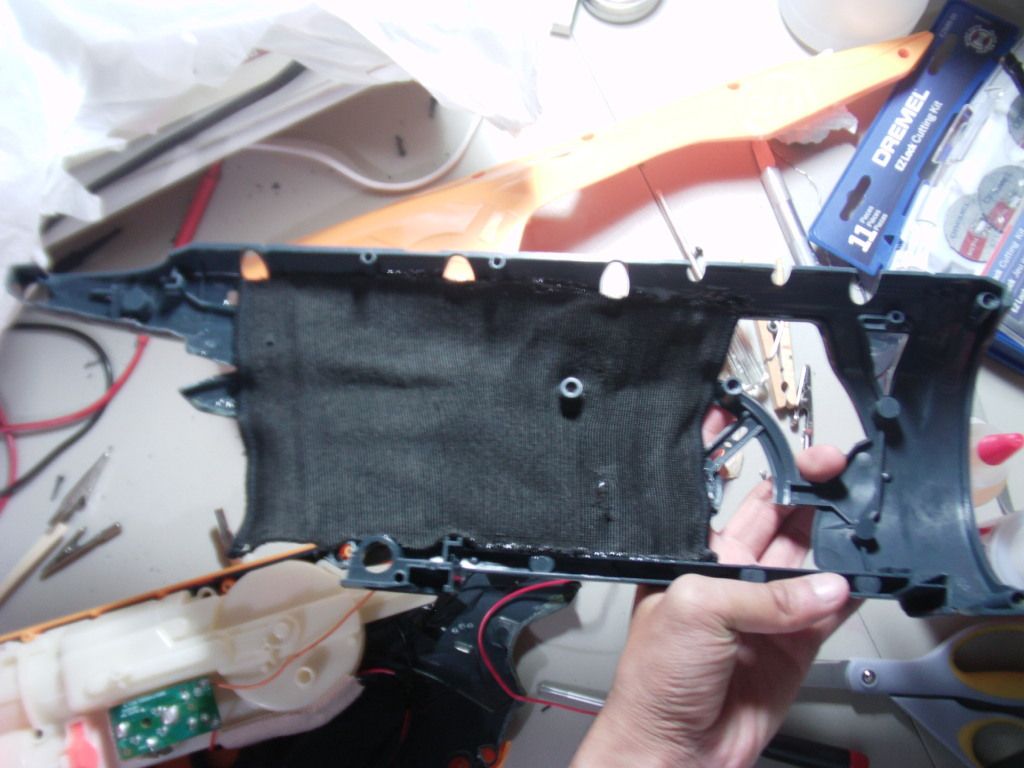

I cut the knee brace to a size I wanted and epoxied to all the points it can connect to the shell, again I only did this for one side, but you can do it for both.

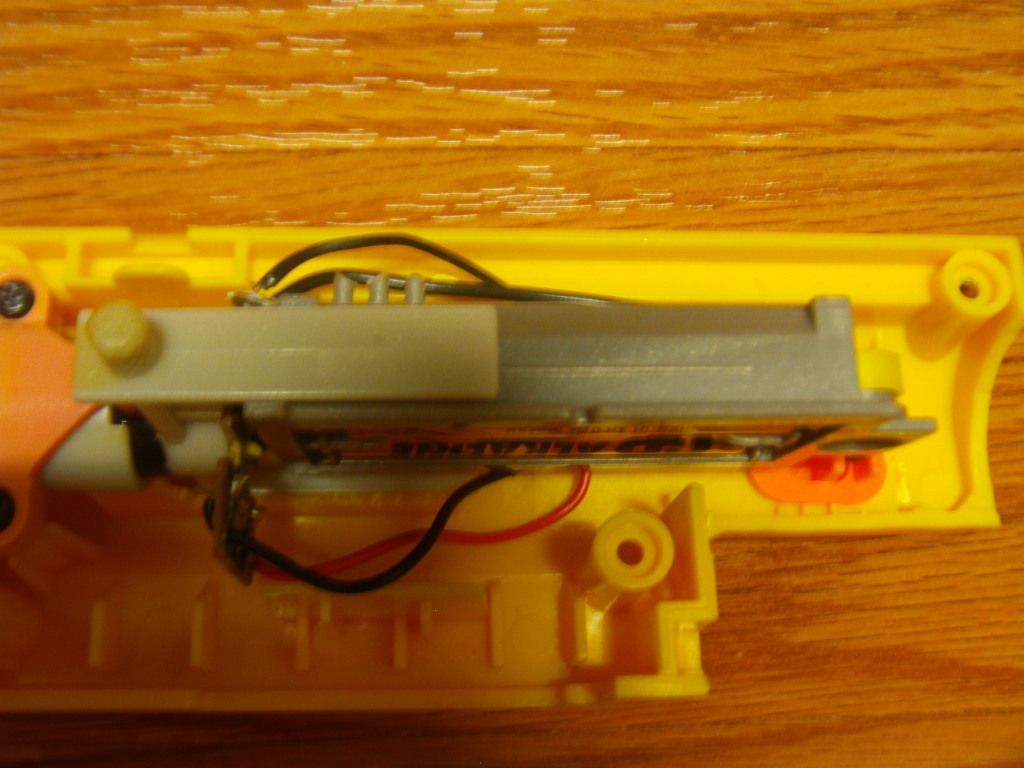

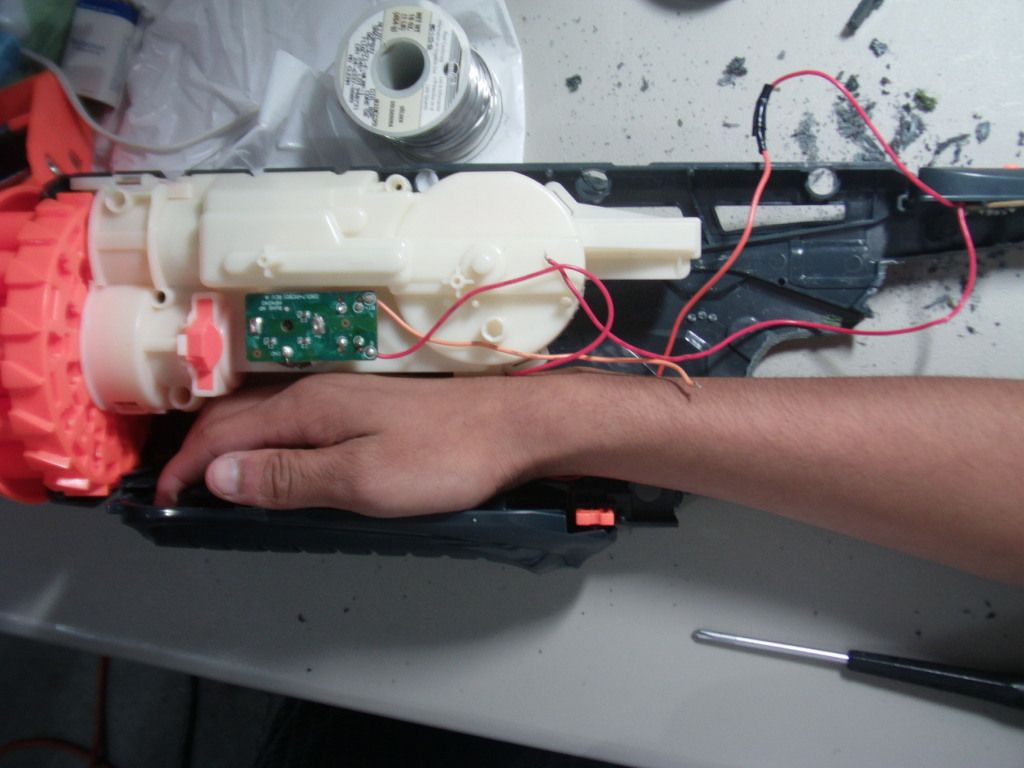

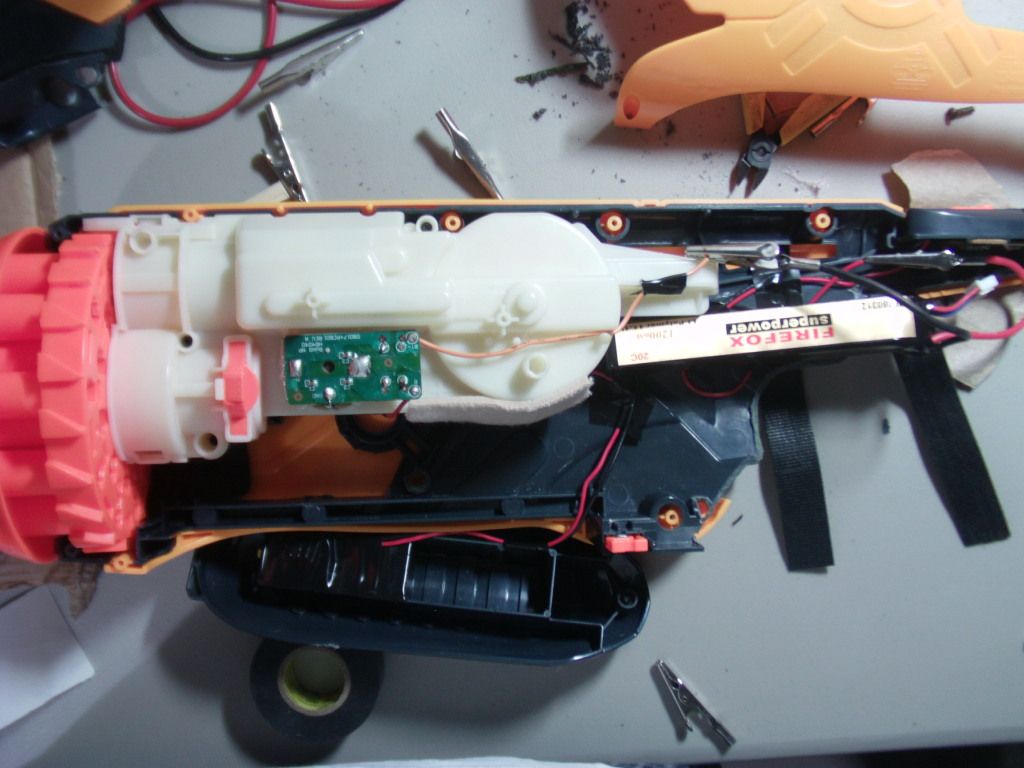

BAM two days later, here's what I got on the insides. Just replaced some wires to make some longer/shorter and padded some areas where it was uncomfortable. The strips near the battery (which I accidentally fried when testing because the positive and negative clips touched...super dangerous, always keep them apart, I was lucky I got it out before it blew up) are Velcro which I used to keep the battery inside. The battery is the same I used in my Quachity Stampede Loadout.

And finally...Here's the finished product. I fried my battery like I said, so I couldn't make a battery, but it SHOULD work. It's not super comfortable, but it's not too uncomfortable either. I epoxied the yellow/gray piece from the beginning back on to the knee brace material just for looks. Make sure you round out those edges on the shell so you don't cut yourself. I also had to cut a little hole for my thumb to pop out, but it can still look extremely cool if I can make some sort of claw thumb from a glove to match the blaster.

Video:

Find content

Find content