Burn off the Christmas cookies and New Year's booze with children's toys and nerdy dudes. This is the third annual installment of the infamous (and only?) winter nerf battle, be sure to dress warm to stave off the frigid Long Island tundra. Note: Must be 13 or older to participate.

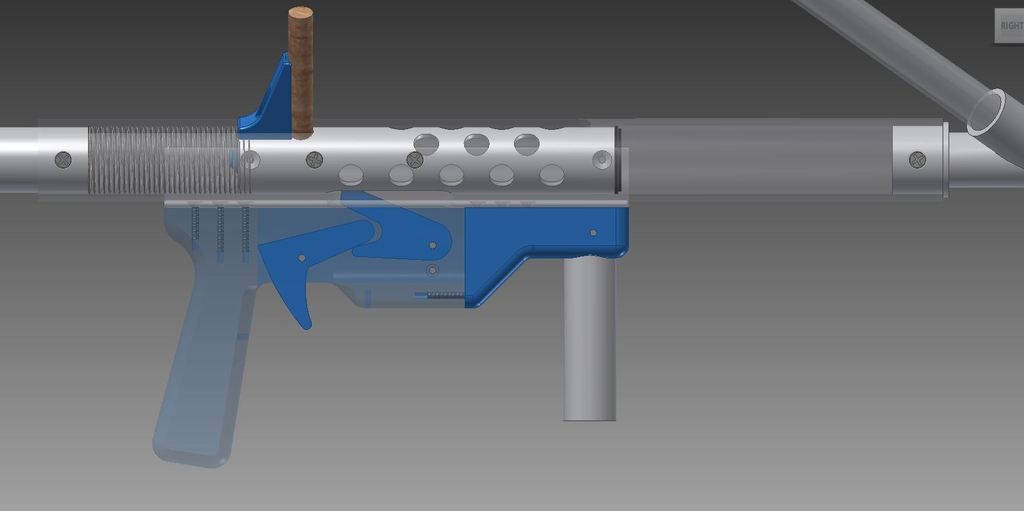

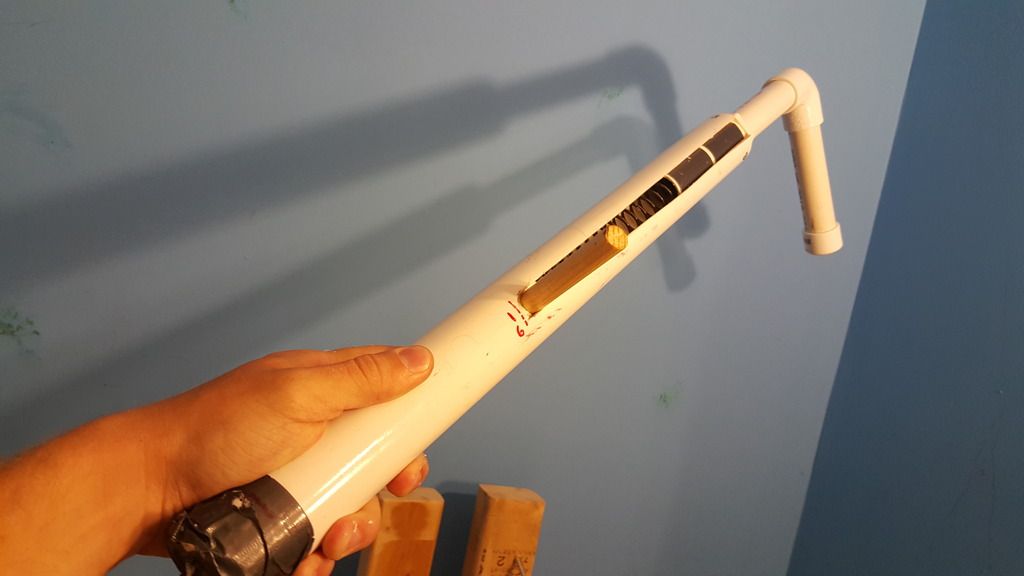

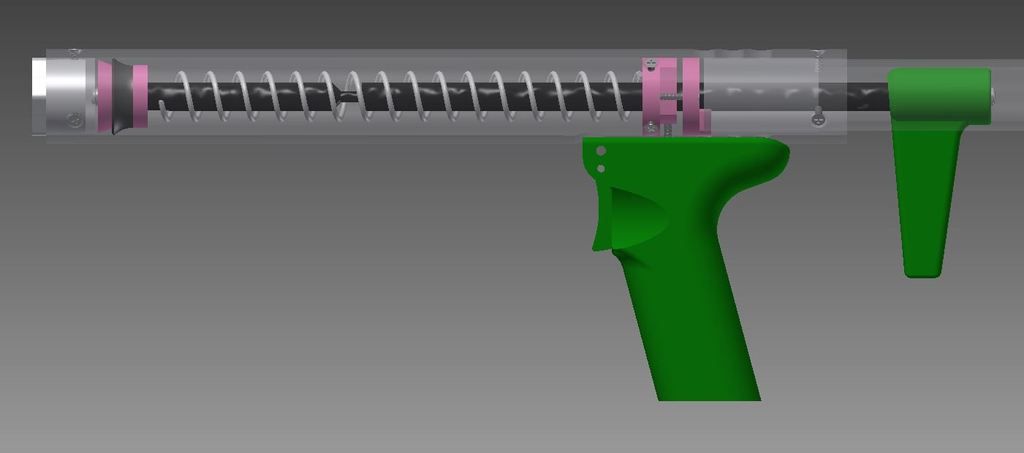

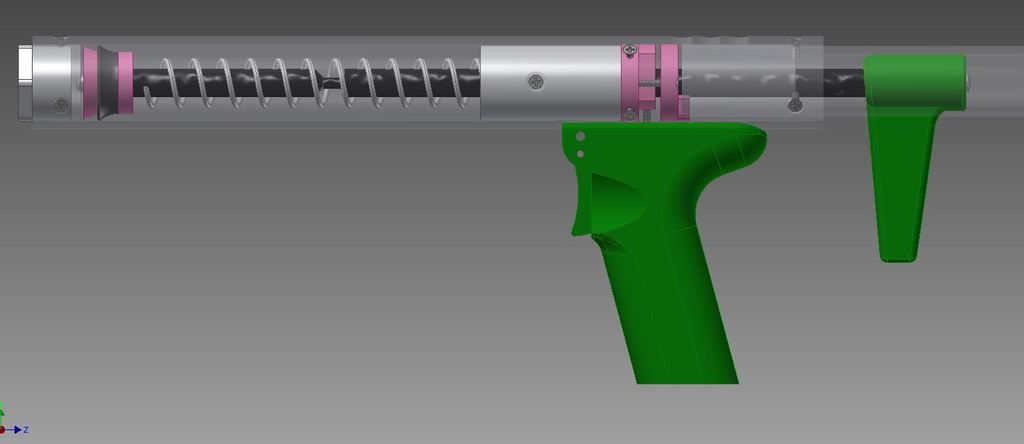

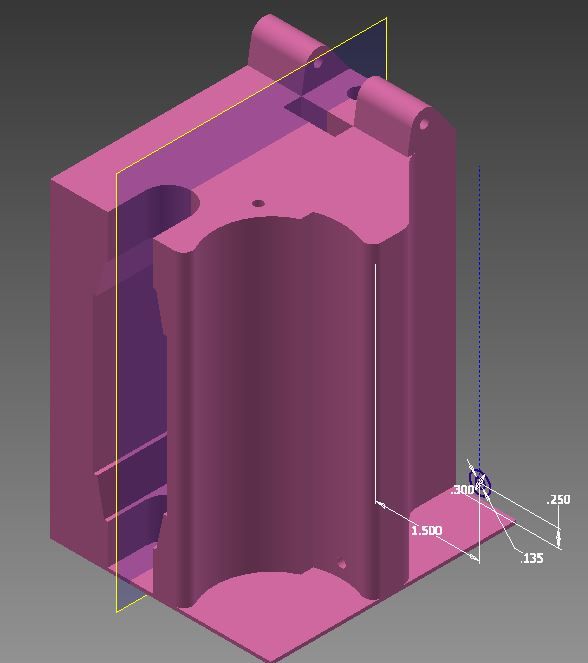

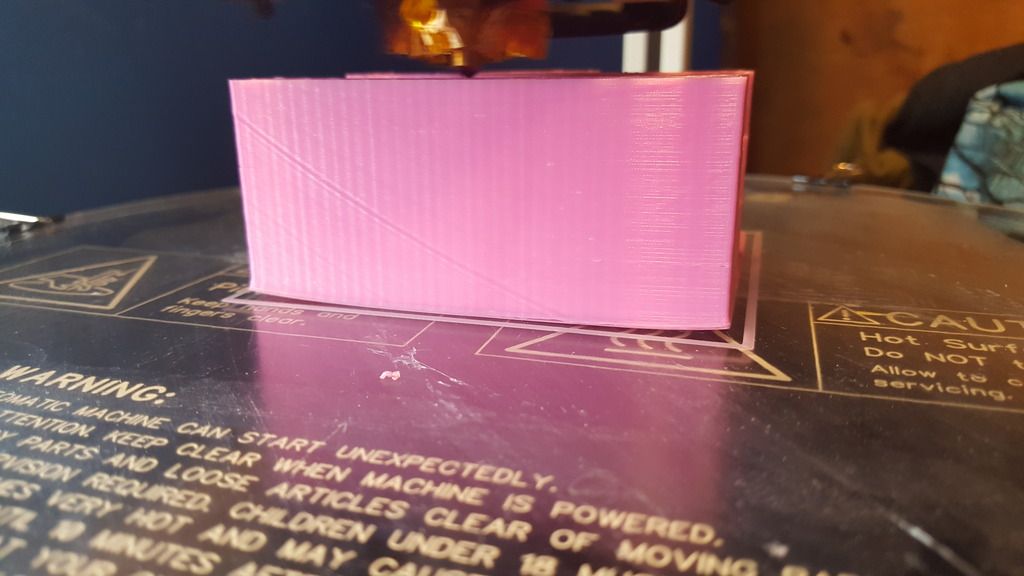

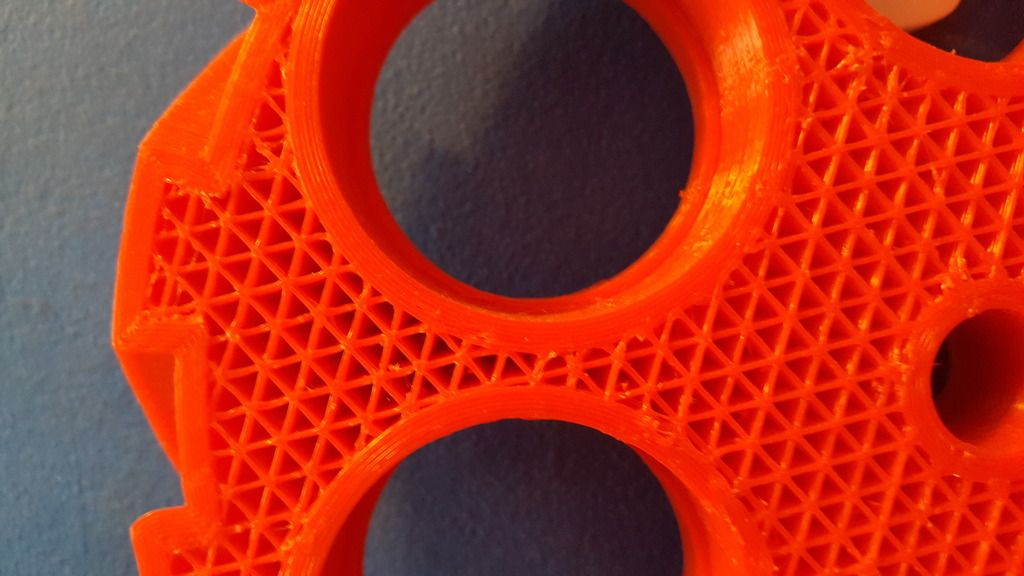

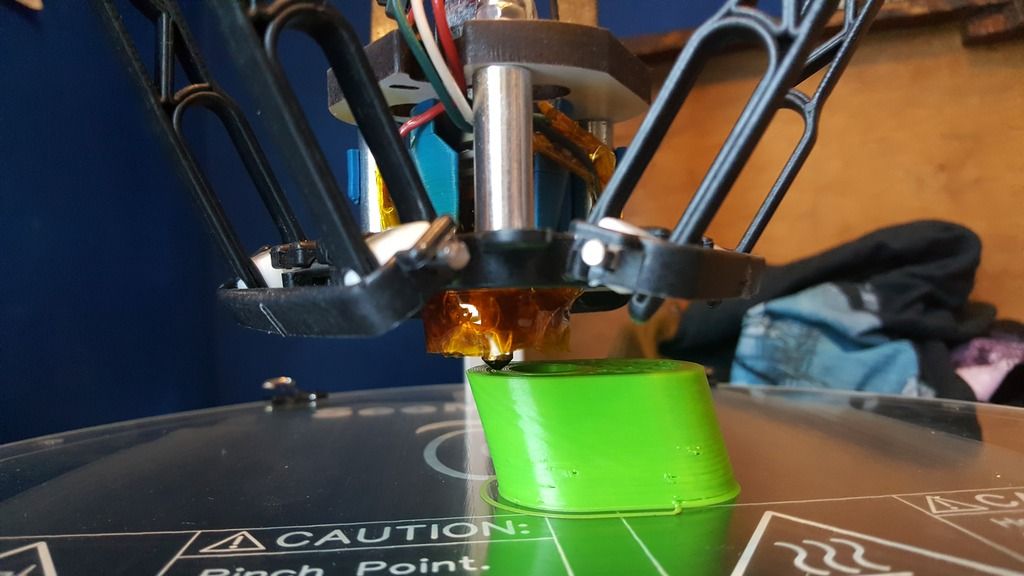

This is an event where high energy foam blasters, essentially homemade piston mechanisms, are going to be used by participants. There is no supervision of minors, this is not a day care activity. Play at your own risk.

When and Where

Saturday January 7th, 2017

10AM - 5PM

Eisenhower Park, Field 2

East Meadow, NY 11554

GPS COORDINATES: 40.725080, -73.568716

Eisenhower Park Field 2, In the "crotch" of Hempstead Turnpike and Park Boulevard. It's the South side of the park that borders Hempstead Turnpike, near the Friendly's. I don't know how I can be more clear about this. The park is huge and every year people get lost, so just follow the GPS coordinates.This location is really good especially with a couple of mobstacles, which we will probably have available. There are a couple "lanes" of trees along with ample open field and a good staging area immediately next to the parking lot.

Weather Here --> https://weather.com/...ay/l/3966:19:US

Looks like it's going to be 20/30 degrees F and partly cloudy that day, so dress nice and warm.

What to Bring

-Eye Protection. I am big on this. Everybody wears eye pro, preferably impact resistant safety glasses/goggles. There are no exceptions to this rule.

-Blasters and darts. This should be obvious. It is a Nerf war. See below.

-Beverages. Bring extra water. There are bathrooms a short walk from the play field, and you'd be surprised how dehydrated you can get even in such cold environments.

-Food. We will provide bagels and coffee for breakfast/lunch/snack. There will be 30 minutes set aside for lunch so bringing a packed lunch would be wise, or there are some fast food joints right on the road.

-Warm Attire. Last year it was relatively warm, like 45 degrees, but FF1 had temperatures sink to like 25 degrees. Hats, scarves, gloves, jackets, waterproof boots, maybe even water resistant pants depending on the levels of snow of the ground. You can always strip off a jacket if it gets too warm but you'd be hard pressed to find someone willing to give up theirs for your cold ass.

-Sportsmanship. If you get tagged out, another game will resume within five minutes. If your blasters are underpowered, tough shit, you adapt. There are enough trees that short range blitz attacks are actually pretty effective when we play objective games. The no-asshattery rule applies here as always.

Blasters and Foam Darts

-ABSOLUTELY NO BLACK OR CAMO PAINTED BLASTERS

-Do not count on others to supply you with a homemade if you only brought a single shot pistol. That bring said, we always have people that bring super-stock and you'd be surprised how effective an overhauled Rapidstrike can be against even the most daunting of 4Bs.

-No homemade compressed air powered blasters. All compressed-air powered blasters must have an OPRV. No HPA, this isn't paintball. All other homemade spring powered blasters, and modified or stock store-bought blasters are sweet. Bring extra homemades if you got 'em, expect to be pelted with high energy homemade foam blasters should you attend.

-#6 washer weighed slugs ONLY for homemades. No slingshot weighted darts, no exposed metal darts, no glue-dome darts. This is your only warning. All store-bought darts of any kind are permitted so long as they are not further weighted.

-Bring extra blasters that you are OK with others using. We need as many extra as we can get.

Other Notes About the Cold

Batteries tend to discharge at a slower rate in the cold, so if you have a battery powered blaster, test it out and make sure it works after you stick it in the freezer for an hour. Dart fit on homemades is also affected due to the low humidity and low temperature, the foam tends to change it's material properties just a bit and likes to shrink just enough to fuck up every perfect fit in your barrel at room temperature.

Confirmed Attendees

Aeromech +3

Alphatrooper

David

XDevilX

SnoopDoggyDoge

Edmund

DX

EvilBunnyo

Gabe NYDZ

Jax

Nerfgeek

Dusty +?

ASGrocks

Ronald

Blitz

Zackthemack

augamemerald

Borvickos

Facebook Link: https://www.facebook...19246895097210/

Find content

Find content