Note: I did not plan any of this. This war was organized by Dill on Nrev. He wanted me to post it on other forums.

When:

Saturday, August 13, 2011

(or) Monday, August 15, 2011 (depending if weather goes bad)

Both at 12:00 p.m. until we all bust

Where:

(Plug these two places into Google Maps)

Glenwood Park Ave, Erie, PA

Go down the street until you find a play ground.

Fronteir Park, West 6th Street, Erie, PA

Again, find the playground.

What To Bring:

Two primaries (in case one breaks)

Two secondaries (same case)

Eye protection

Water (as much as you can!)

Packed Lunch (fast food is far from both locations)

Money (to buy blasters and darts from other Nerfers)

Bandana (for a surprise)

Darts

A Nerf Nation t-shirt (If you have one, I just want to buy one)

Geusts

Rules:

Stephans are allowed.

No modified Titans in any way (no exceptions.)

No plugged Big Blasts (no exceptions.)

Don't be a jerk.

Have fun!

Games:

1. Team Deathmatch

2. Free-for-all

3. CTF

4. Swords

5. Surprise!

6+. Different gametypes shuffle after round five.

All games have three lives and fifteen second respawns.

Changes could apply.

Hosts and Participants:

Dill (Host)

In need of someone to help me host.

Maybes:

Techshooter+?

DARK NINJA+ ?

- NerfHaven

- → Viewing Profile: Topics: Techshooter

Techshooter

Member Since 18 May 2011Offline Last Active Private

Community Stats

- Group Members

- Active Posts 20

- Profile Views 6,712

- Member Title Member

- Age 28 years old

- Birthday December 16, 1997

User Tools

Latest Visitors

Topics I've Started

Cold War: A New War

30 July 2011 - 01:20 PM

Sonic Bazooka Knockoff + Buzz Bee Hunter

20 June 2011 - 08:23 PM

Note: this modification is a collection of posts, all spaced months apart. Each stage can be done by its self, or you can do all of the mods together.

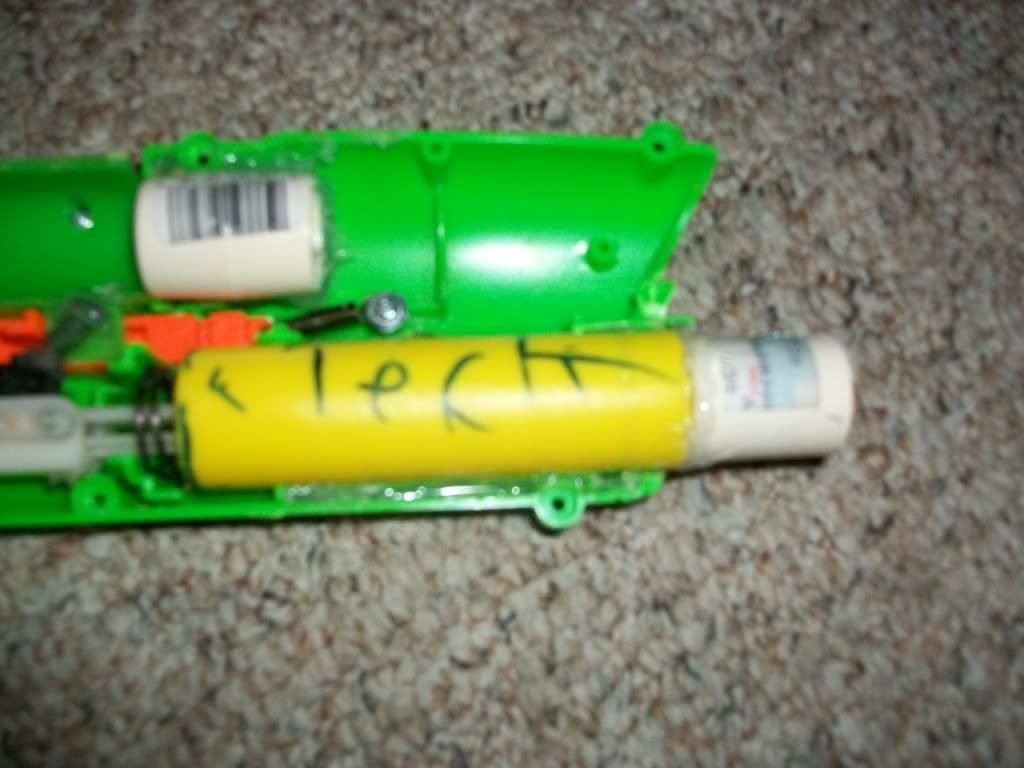

I got this gun a couple months back, opened it up and was depressed. The plunger tube it has is smaller than a night finder plunger tube. I did a mod and got 20 ft. ranges. Now I did a different mod and got 50-60 ft. ranges.

Materials needed

dremel/pipe cutters

your choice of glue

cpvc coupler.

First open up your hunter and don't pass out because the plunger tube is so small. Take out you plunger tube and cut off the tubing leading to the bolt-action part and glue on your coupler.

(I got board a month back and wrote Tech in it since it was ope for the 2 months)

Now cut the front of the gun off that is in front of the plunger tube and dremel it out until your coupler can fit inside it.

(Now that I think of it I should have got a side view but hopefully you will understand what I mean at the end)

I added an extremely weak catch spring to the catch because mine had trouble catching and I did not replace the plunger spring.

(Wow that picture is really blurry)

If you planned to do the whole breach thing that was on nerfhaven and then your bolt broke you will have to sand out the back a little where the bolt goes.

(Hmm I don't have anything to put as a caption for this picture)

Do an air seal improvement and now you are done!

With a 5 1/2 inch barrel I got between 50-60 ft. but it didn't make that nice pop noise that lets you now you have the right barrel length. For half an hour work and no spring replacement I'm happy with this gun and its ranges.

Okay, I know this thread is old, but I feel that these modifications to the blaster are very important.

Part 2

Materials

A screw

1/2in. Wooden Dowel

tools

Dremel

1/2in. Drill bit

A drill bit slightly smaller than your srew

A drill

The first thing I would like to say is that you can't replace the spring because the plastic used on this gun is extremely week (including the shell) and the compression rate of the stock spring is very low, so it would be hard to find a spring with the correct compression rate.

First, you will want to either dremel or brake off the handle peice (mine broke from a stronger spring).

Next, you are going to want to drill a small hole in the second half of the plunger rod (the part that slides).

Now, you are going to want to drill the same sized hole in your 1/2in. wooden dowle:

Fourth, scew the plunger rod and handle together. Now, you are going to want to sand down the screw so that it is almost flush with the second half of the plunger rod:

(Note, you are going to want to put some lube on the second half of the plunger rod)

You are going to want to drill a 1/2in. hole in your plunger tube where the hole is:

(It is small and blurry because I took it with my cellphone. I'll get a better one up later).

Cut a hole in the bottom of you gun for the handle put your blaster together and you're finished with part 2! This blaster is a ton of fun, but can't function well with an rscb. I typically use a polypipe breach on it. Part 3 will be up as soon as the snow outside melts so that I can use PVC cement. I'll get a picture of the finished product up later. I now name it the Predator V1.

If you followed all the modifications that I have done so far, your hunter is pum-action and shoots a little over 50ft. flat, but I wanted something that would shoot a little farther.

Part 3: Predator Missle

Materials Needed

A hunter with all the mods done to it so far

Sonic Bazooka Knockoff or a BBBB

Hot glue

Goop/epoxy puddy

JB weld/Epoxy

1/2in. PVC coupler

E-tape

First, this is what the SBK looks like out of the box.

Now an internal shot.

Now cut off the original barrel so that you have just about 1/2in. of the barrel left and wrap it in E-tape until the coupler fits on tight and goop it on with a nice layer of Epoxy around it.

The original barrel fits 1/2in. CPVC air-tightly, and the coupler allows you to se 1/2in. PVC barrels. Double couplering is so easy with this blaster.

While thats drying, cut up your hunter so that it looks like this:

Now cut the trigger guard off of the SBK.

Now test fit your pieces so that they fit like a puzzle:

Now sand every piece of plastic that any form of glue will be touching. Firts, hot glue the two blasters together on the forgrip (but not on the sides). Next, put JB weld or epoxy on the side of the two blasters and tie them together. after that dries, put goop on it or epxy puddy. Do the same to the other side.

(Note, I only hotglued it in this picture the wrong way. It lasted one day. DO THE WAY I DESCRIBE IT)

You may think that this looks uncomfortable to hold, but it's not:

I figured I should show the breach that I use on the hunter, so here it is.

As much as I hated to do it, the SBK couldn't operate a hopper with the stock OPV in place so I had to plug the pump, but there is a bright side to it. If you pump the blaster eight times it takes about 5 seconds for the air to release becase it is a back-pressure blaster.

Finished internal shot:

(I had to cut a slot in the shell for a hopper)

Put the blaster back together and your done!

(It doesn't work well with the RSCB, I don't even know why I put it on).

The ranges of the SBK are around 70-80 with glue domes and and a 6in, CPVC barrel. It doesn't work well with a hopper. I added a LSFG spring to the hunter and I'm getting around 60-70ft. flat with glue domes and a 4in. CPVC barrel.

I got this gun a couple months back, opened it up and was depressed. The plunger tube it has is smaller than a night finder plunger tube. I did a mod and got 20 ft. ranges. Now I did a different mod and got 50-60 ft. ranges.

Materials needed

dremel/pipe cutters

your choice of glue

cpvc coupler.

First open up your hunter and don't pass out because the plunger tube is so small. Take out you plunger tube and cut off the tubing leading to the bolt-action part and glue on your coupler.

(I got board a month back and wrote Tech in it since it was ope for the 2 months)

Now cut the front of the gun off that is in front of the plunger tube and dremel it out until your coupler can fit inside it.

(Now that I think of it I should have got a side view but hopefully you will understand what I mean at the end)

I added an extremely weak catch spring to the catch because mine had trouble catching and I did not replace the plunger spring.

(Wow that picture is really blurry)

If you planned to do the whole breach thing that was on nerfhaven and then your bolt broke you will have to sand out the back a little where the bolt goes.

(Hmm I don't have anything to put as a caption for this picture)

Do an air seal improvement and now you are done!

With a 5 1/2 inch barrel I got between 50-60 ft. but it didn't make that nice pop noise that lets you now you have the right barrel length. For half an hour work and no spring replacement I'm happy with this gun and its ranges.

Okay, I know this thread is old, but I feel that these modifications to the blaster are very important.

Part 2

Materials

A screw

1/2in. Wooden Dowel

tools

Dremel

1/2in. Drill bit

A drill bit slightly smaller than your srew

A drill

The first thing I would like to say is that you can't replace the spring because the plastic used on this gun is extremely week (including the shell) and the compression rate of the stock spring is very low, so it would be hard to find a spring with the correct compression rate.

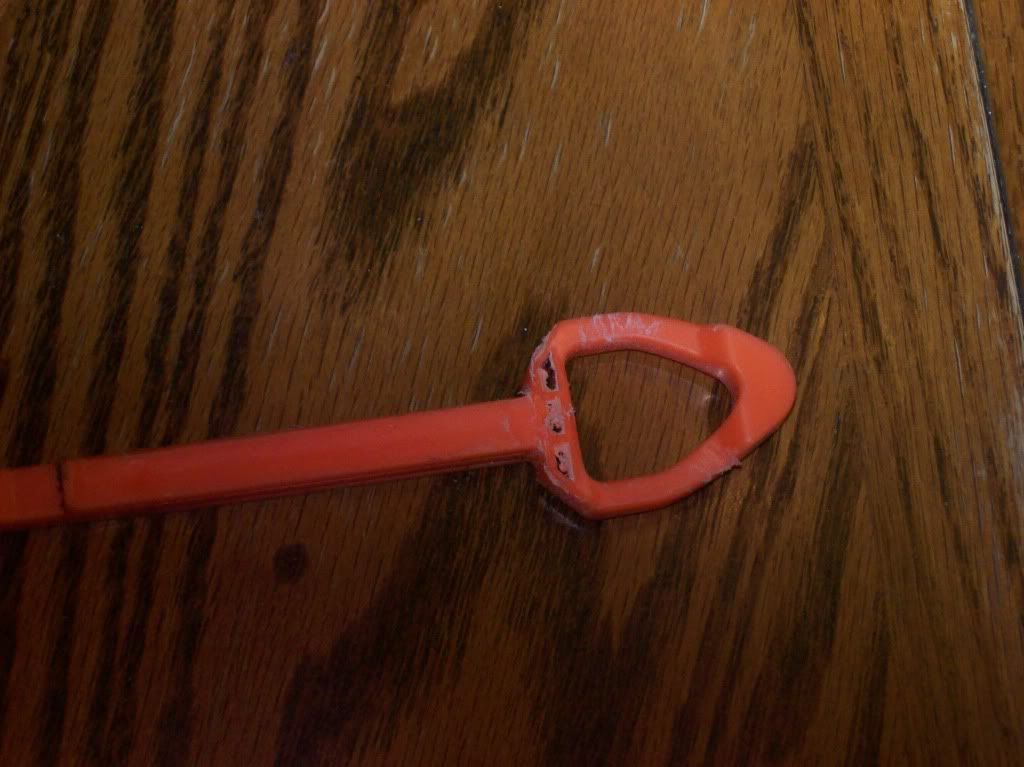

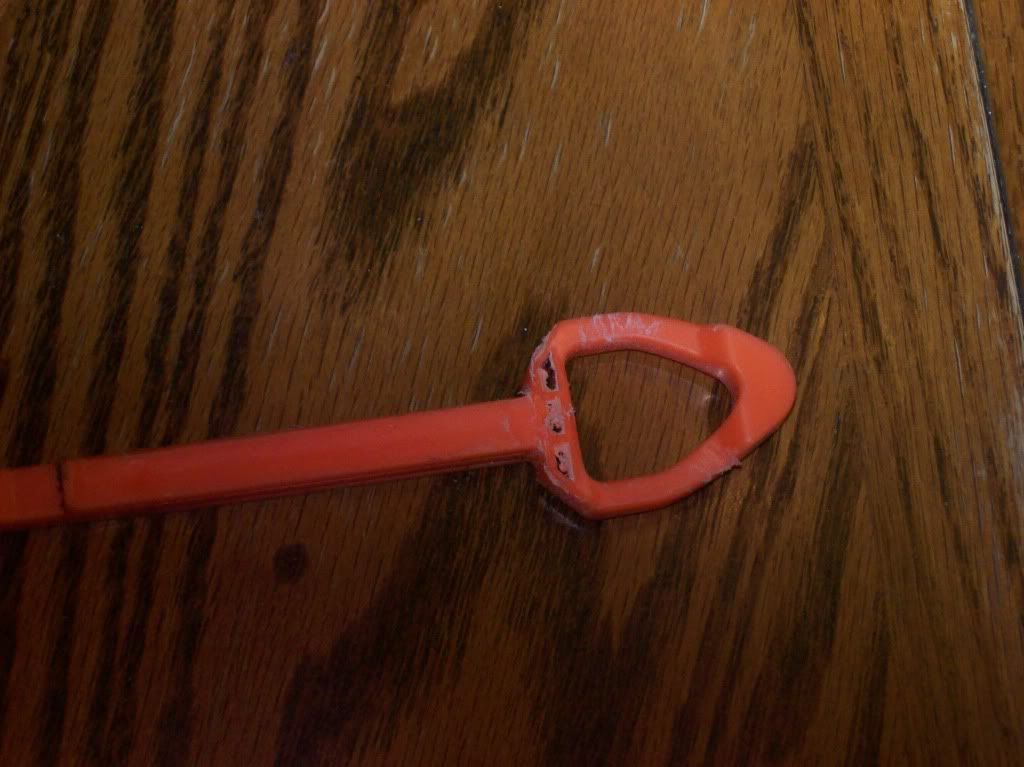

First, you will want to either dremel or brake off the handle peice (mine broke from a stronger spring).

Next, you are going to want to drill a small hole in the second half of the plunger rod (the part that slides).

Now, you are going to want to drill the same sized hole in your 1/2in. wooden dowle:

Fourth, scew the plunger rod and handle together. Now, you are going to want to sand down the screw so that it is almost flush with the second half of the plunger rod:

(Note, you are going to want to put some lube on the second half of the plunger rod)

You are going to want to drill a 1/2in. hole in your plunger tube where the hole is:

(It is small and blurry because I took it with my cellphone. I'll get a better one up later).

Cut a hole in the bottom of you gun for the handle put your blaster together and you're finished with part 2! This blaster is a ton of fun, but can't function well with an rscb. I typically use a polypipe breach on it. Part 3 will be up as soon as the snow outside melts so that I can use PVC cement. I'll get a picture of the finished product up later. I now name it the Predator V1.

If you followed all the modifications that I have done so far, your hunter is pum-action and shoots a little over 50ft. flat, but I wanted something that would shoot a little farther.

Part 3: Predator Missle

Materials Needed

A hunter with all the mods done to it so far

Sonic Bazooka Knockoff or a BBBB

Hot glue

Goop/epoxy puddy

JB weld/Epoxy

1/2in. PVC coupler

E-tape

First, this is what the SBK looks like out of the box.

Now an internal shot.

Now cut off the original barrel so that you have just about 1/2in. of the barrel left and wrap it in E-tape until the coupler fits on tight and goop it on with a nice layer of Epoxy around it.

The original barrel fits 1/2in. CPVC air-tightly, and the coupler allows you to se 1/2in. PVC barrels. Double couplering is so easy with this blaster.

While thats drying, cut up your hunter so that it looks like this:

Now cut the trigger guard off of the SBK.

Now test fit your pieces so that they fit like a puzzle:

Now sand every piece of plastic that any form of glue will be touching. Firts, hot glue the two blasters together on the forgrip (but not on the sides). Next, put JB weld or epoxy on the side of the two blasters and tie them together. after that dries, put goop on it or epxy puddy. Do the same to the other side.

(Note, I only hotglued it in this picture the wrong way. It lasted one day. DO THE WAY I DESCRIBE IT)

You may think that this looks uncomfortable to hold, but it's not:

I figured I should show the breach that I use on the hunter, so here it is.

As much as I hated to do it, the SBK couldn't operate a hopper with the stock OPV in place so I had to plug the pump, but there is a bright side to it. If you pump the blaster eight times it takes about 5 seconds for the air to release becase it is a back-pressure blaster.

Finished internal shot:

(I had to cut a slot in the shell for a hopper)

Put the blaster back together and your done!

(It doesn't work well with the RSCB, I don't even know why I put it on).

The ranges of the SBK are around 70-80 with glue domes and and a 6in, CPVC barrel. It doesn't work well with a hopper. I added a LSFG spring to the hunter and I'm getting around 60-70ft. flat with glue domes and a 4in. CPVC barrel.

Nite'n Load

27 May 2011 - 10:31 AM

Writeup on Nerfmania

First off, credit goes to A.C.E. for making the original one. He created it WAY before me. Also, this is only cosmetics, it WILL NOT cover anything for range

Materials

3B handle

Nite Finder

Epoxy Putty

Hot glue

First, get your 3B handle and cut it here:

Put your 3B handle aside for a while and get your Nite Finder. Take out all of the internals and cut it here:

(You may want to sand away the curve left from the handle)

(You may want to sand away the curve left from the handle)

Now take your handle and hot glue it onto your Nite Finder shell (make sure that you can still open the gun up)

Now try your best to get it level by sanding. (You CAN'T cut off the NERF symbol, it won't work)

Now, to save Epoxy Putty, try to level it out with hot glue.

(I got it around the symbol)

(I got it around the symbol)

Now, it's time to give your handle some strength and make more things level. Get your Epoxy Putty and glue down the handle and make everything smooth.

I don't have a picture of this, but the trigger won't actually work until you Dremel a hole in the handle fot it to slide through, but even after that it won't work! cut down your trigger to make it fit and them curve it with yout dremel (or create a new, smaller trigger).

Now, screw down the trigger and glue the trigger spring to the shell.

Put your internals in and it should look very strange.

Close the gun up and... your still not done. Fill those holes in the shell that let you see the plunger tube with hot glue

Paint it and your done!

Fireing VideoAgain, credit goes to A.C.E. for making the original.

First off, credit goes to A.C.E. for making the original one. He created it WAY before me. Also, this is only cosmetics, it WILL NOT cover anything for range

Materials

3B handle

Nite Finder

Epoxy Putty

Hot glue

First, get your 3B handle and cut it here:

Put your 3B handle aside for a while and get your Nite Finder. Take out all of the internals and cut it here:

(You may want to sand away the curve left from the handle)

(You may want to sand away the curve left from the handle)Now take your handle and hot glue it onto your Nite Finder shell (make sure that you can still open the gun up)

Now try your best to get it level by sanding. (You CAN'T cut off the NERF symbol, it won't work)

Now, to save Epoxy Putty, try to level it out with hot glue.

(I got it around the symbol)

(I got it around the symbol)Now, it's time to give your handle some strength and make more things level. Get your Epoxy Putty and glue down the handle and make everything smooth.

I don't have a picture of this, but the trigger won't actually work until you Dremel a hole in the handle fot it to slide through, but even after that it won't work! cut down your trigger to make it fit and them curve it with yout dremel (or create a new, smaller trigger).

Now, screw down the trigger and glue the trigger spring to the shell.

Put your internals in and it should look very strange.

Close the gun up and... your still not done. Fill those holes in the shell that let you see the plunger tube with hot glue

Paint it and your done!

Fireing VideoAgain, credit goes to A.C.E. for making the original.

Nitefinder overhaul: BigFinder

24 May 2011 - 05:04 PM

Writeup on Nerfmania

So, I decided I wan't an insanely awesome secondary, so I was going to make a super extended draw NiteFinder, but it evolved into this. The writeup with be divided into two parts, super extened draw and plunger tube replacement.

Super Extended Draw

Tools/Materials

Dremel

Nitefinder

Hot glue

So, first take out your plunger tube and cut off those little screw holes that hold the plunger tube down. Next, cut slots in the back of the Nitefinder in between the two screw ports and make it go up to the catch holder:

Chop off that nub on the plunger rod:

Now, you are going to want to minimize your Nitefinder:

(If you did it how I minimized it (like Rogue) then you should have most of the screw ports left.)

Set the plunger tube forward and glue it down.

Plunger Tube Replacement

Materials

1/2in. CPVC coupler

Super Glue

Goop

Electrical Tape

Lube

BBBB Pump tube and head

Hot glue

A screw

[k25] spring

3/4in. screws*3

E-putty (maybe)

Tools

Dremel

Hot glue gun

Ruler

First, you are going to want to cut your BBBB pump tube to a length of about 4 1/2 in.

Now, get your 1/2 in. CPVC coupler and cut it in half:

Now rap it several time in electical tape until it fits tight in BBBB pump tube:

Super glue it into your BBBB pump tube (make sure the coupler is all the way in). After it dries, put lubricate a piece of CPVC and put in your coupler. Put Plumber's Goop around it and the coupler and let it dry:

(This does not have the goop around it yet)

While that's drying, gut your BBBB pump head like this:

Put a screw in the hole and fill the face with hot glue:

The screw doesn't have to stay in the hot glue, it just makes the plunger head stay on better, and it adds more pre-cumpreshion and allows you to use a shorter spring.

Also, add three wraps on teflon tape or 1 wrap electrical tape under the o-ring to get a perfect seal:

(Note: In one this picture, it has teflon tape, but in another picture it has E-tape. I switched the teflon tape out for E-tape.)

Now, you are either going to want to fill in the back of you plunger rod with hot glue or E-putty. I used hot glue, but would recomend E-putty:

Now your going to want to cut your [k25] spring to a length of about 5 in.

[img]http://http://www.mediafire.com/imgbnc.php/d06e552db340db179d65e847de98c4e1f7ef7441c536ffc2b039abfac48824d94g.jpg[/img]

Here's a spring comparison. The [k25] on the right, the home depot spring in the middle, and the stock spring farthest to the right:

[img]http://http://www.mediafire.com/imgbnc.php/2617e263518fd7bf2805d611437c42c744caebe42d4f44181a1c67fd2e0a35194g.jpg[/img]

After the BBBB pump tube is finished drying, glue it in with all your internals in like this:

[img]http://i789.photobucket.com/albums/yy173/techshooter7082/100_5532.jpg?t=1302046827[/img]

(You will have to do Dremeling to make it fit)

Put it back together and your not done!

In the process of making room for the new PT, I knocked out the front swrew ports and messed up another. To fix this I added some 3/4in. screw there.

[img]http://i789.photobucket.com/albums/yy173/techshooter7082/100_5534.jpg?t=1302046919[/img]

I am incredible pleased with this blaster. It puts out a good amount of air and is pretty powerful. Shadow has already asked this question, so I figured I should answer it: the reason I am using a [k25] spring is because the [k26] had to high of a compression rate to work in this blaster.

So, I decided I wan't an insanely awesome secondary, so I was going to make a super extended draw NiteFinder, but it evolved into this. The writeup with be divided into two parts, super extened draw and plunger tube replacement.

Super Extended Draw

Tools/Materials

Dremel

Nitefinder

Hot glue

So, first take out your plunger tube and cut off those little screw holes that hold the plunger tube down. Next, cut slots in the back of the Nitefinder in between the two screw ports and make it go up to the catch holder:

Chop off that nub on the plunger rod:

Now, you are going to want to minimize your Nitefinder:

(If you did it how I minimized it (like Rogue) then you should have most of the screw ports left.)

Set the plunger tube forward and glue it down.

Plunger Tube Replacement

Materials

1/2in. CPVC coupler

Super Glue

Goop

Electrical Tape

Lube

BBBB Pump tube and head

Hot glue

A screw

[k25] spring

3/4in. screws*3

E-putty (maybe)

Tools

Dremel

Hot glue gun

Ruler

First, you are going to want to cut your BBBB pump tube to a length of about 4 1/2 in.

Now, get your 1/2 in. CPVC coupler and cut it in half:

Now rap it several time in electical tape until it fits tight in BBBB pump tube:

Super glue it into your BBBB pump tube (make sure the coupler is all the way in). After it dries, put lubricate a piece of CPVC and put in your coupler. Put Plumber's Goop around it and the coupler and let it dry:

(This does not have the goop around it yet)

While that's drying, gut your BBBB pump head like this:

Put a screw in the hole and fill the face with hot glue:

The screw doesn't have to stay in the hot glue, it just makes the plunger head stay on better, and it adds more pre-cumpreshion and allows you to use a shorter spring.

Also, add three wraps on teflon tape or 1 wrap electrical tape under the o-ring to get a perfect seal:

(Note: In one this picture, it has teflon tape, but in another picture it has E-tape. I switched the teflon tape out for E-tape.)

Now, you are either going to want to fill in the back of you plunger rod with hot glue or E-putty. I used hot glue, but would recomend E-putty:

Now your going to want to cut your [k25] spring to a length of about 5 in.

[img]http://http://www.mediafire.com/imgbnc.php/d06e552db340db179d65e847de98c4e1f7ef7441c536ffc2b039abfac48824d94g.jpg[/img]

Here's a spring comparison. The [k25] on the right, the home depot spring in the middle, and the stock spring farthest to the right:

[img]http://http://www.mediafire.com/imgbnc.php/2617e263518fd7bf2805d611437c42c744caebe42d4f44181a1c67fd2e0a35194g.jpg[/img]

After the BBBB pump tube is finished drying, glue it in with all your internals in like this:

[img]http://i789.photobucket.com/albums/yy173/techshooter7082/100_5532.jpg?t=1302046827[/img]

(You will have to do Dremeling to make it fit)

Put it back together and your not done!

In the process of making room for the new PT, I knocked out the front swrew ports and messed up another. To fix this I added some 3/4in. screw there.

[img]http://i789.photobucket.com/albums/yy173/techshooter7082/100_5534.jpg?t=1302046919[/img]

I am incredible pleased with this blaster. It puts out a good amount of air and is pretty powerful. Shadow has already asked this question, so I figured I should answer it: the reason I am using a [k25] spring is because the [k26] had to high of a compression rate to work in this blaster.

- NerfHaven

- → Viewing Profile: Topics: Techshooter

- Terms of Service and Privacy Policy

- Code of Conduct ·

Find content

Find content