Every one has pondered a way to determine whether or not they or others are actually firing flat. Of course placing an actual level from the tool box is obvious but as we all know, impractical. Especially, if you want to do a test quickly and with various blasters. I know people have duct taped or rubber banded levels to Nerf accessories before but those don't fit well on to home mades which tend to not have Nerf tacticool rails.

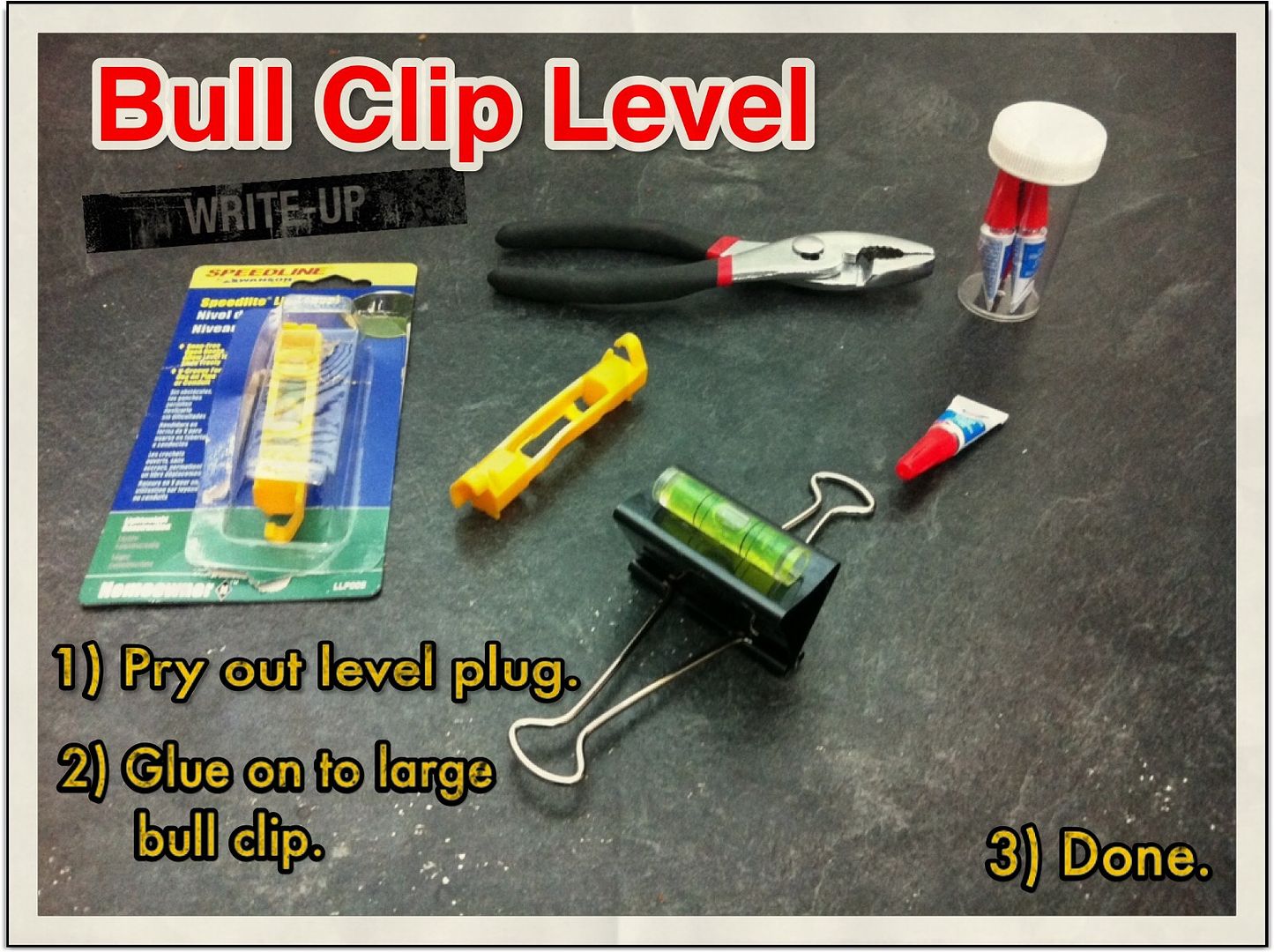

Here's a cheap and practical solution: It takes all of 3 minutes (or less) to do and costs about $3.00.

The levels and bull clip were sourced from Dollorama. The levels come in a pack of 2 and the clip came in a bunch of assorted sizes. In fact, everything you see on the counter was bought at Dollarama.

The first thing that you need to do is separate the level from its housing. I just used a set of pliers. Next, just super glue it on to the wide part of the bull clip. There's usually a slight groove along the middle which should help to align it center. ...and you're done!

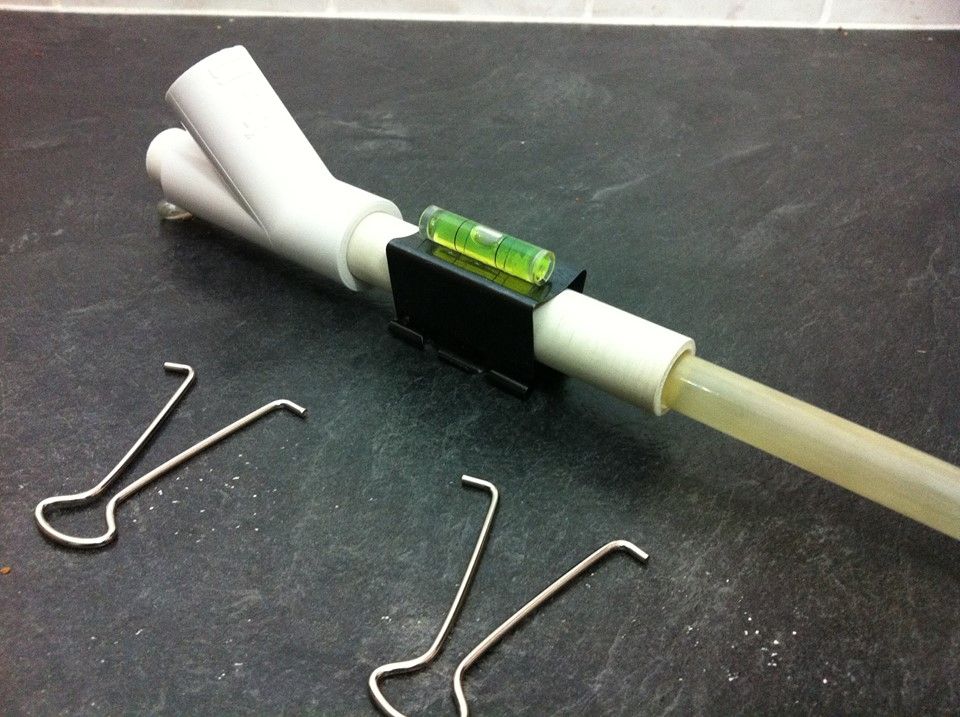

You now have a level that can be mounted and dis-mounted quickly, virtually anywhere on your blaster. It clips nicely on to the Nerf rails and on to most barrels.

When mounted on the rails, it can double as a pseudo scope.

If you don't like the clip arms, they can easily be removed.

Now, firing level and FLAT can be proved to yourself and to everyone else.

Find content

Find content