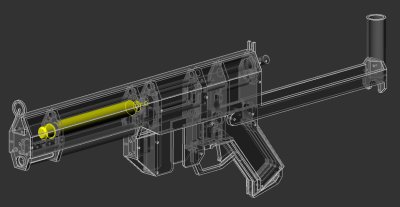

Aim: To make a fully semi-automatic magazine-fed Nerf weapon. One trigger pull fires one dart, and the cycle is self operating with no operator input aside from the trigger. Gun is powered from a pressurized external tank and operates at 30-40psi.

The mechanism is as follows.

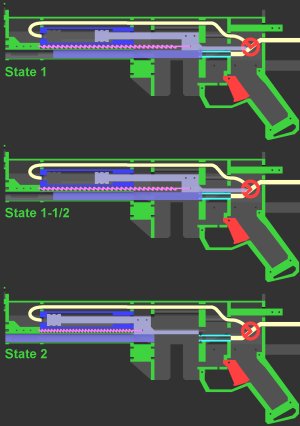

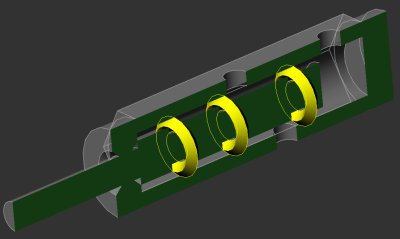

State 1: Trigger neutral. Supply input pressurizes air cylinder (breech actuator)

State 1-1/2: Trigger is held down. This inbetween state only lasts around half of a second. The directional control valve connects the air cylinder to the output and closes off the tank supply line.

The barrel is sealed against the output while the air cylinder is depressurizing into the barrel to exhaust to atmosphere (and thusly shoot the dart).

State 2: Trigger is still held down. Air cylinder has completely depressurized and weak spring return can now overcome the pressure level of the air cylinder in order to return it to the forward position and open the breech.

Cycle returns to State 1 when the trigger is released. Time duration of State 1-1/2" is dependent upon the load added with the spring return. Hence the decision to use an extension type spring which is easier to adjust. The return spring really only needs to overcome the friction of the o-rings.

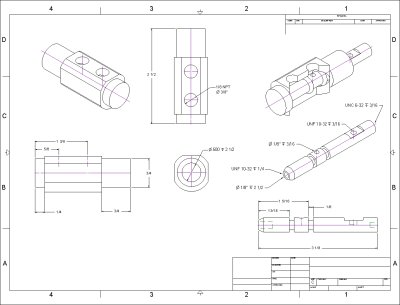

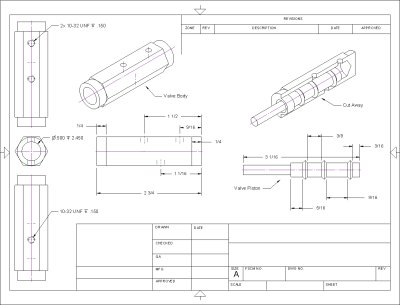

I realized that the air cylinder did not have to be made custom because a wide range of bore sizes are available, so based on some very easy math I figured out what size I needed, and altered the CAD model to accommodate the off-the-shelf part.

Tomorrow I will do the lathe work on the high flow rate directional control trigger valve.

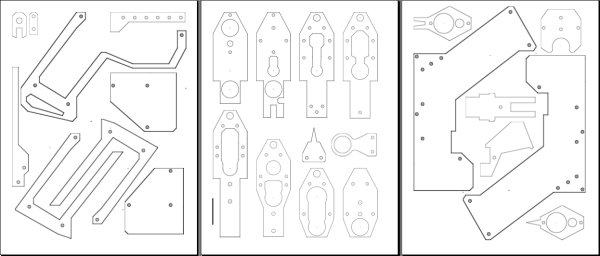

And this weekend I will start on cutting all of the raw materials to size and applying the templates I have made from the CAD model.

Edited by CaptainSlug, 11 September 2007 - 08:16 PM.

This topic is locked

This topic is locked