The Vague Plan:

A valve inspired by Dr. Nerf and his valve and CaptainSlug's A.B.P.

I had first hoped that the barrel's back-and-forth motion would correspond directly with the trigger pull and return. Unfortunately, my first iteration proved that this would require a trigger pull of several inches: the dart length + dead space between dart and valve + valve travel.

Which brings me to...

The Failed Attempt:

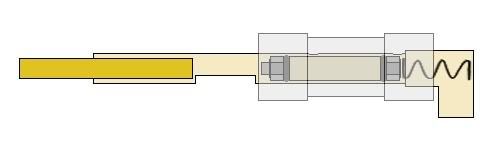

My first iteration went undocumented, as I abandoned the project after hitting some problems. I can, however, give a description and illustration.

1.

-The "Outer Barrel" is the long beige rectangle, with the right angle at the end, made of 3/4" CPVC

-The "Reservoir" is the grey rectangle, made of 1" PVC

-The "Connection" between the Outer Barrel and Reservoir is 1/4" Vinyl Tubing

The "Valve" is the more complex part, descibed further in (2.)

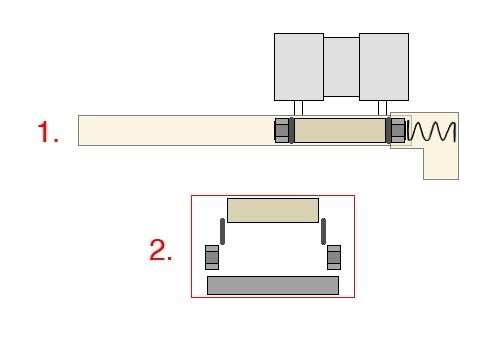

2.

-The Valve consists of two O-Rings on a section of Threaded Rod, spaced by 1/2" CPVC and kept in place by two Nuts that have been ground down to fit inside the Outer Barrel.

This model failed because of bad seals between:

-The "Air Source" (not pictured) and the Outer Barrel

-The Reservoir and the Outer Barrel, at the Connection

Mistakes/Problems To Be Solved:

-I sealed the Connection with only hot glue, and expected it to be airtight.

-I didn't use a one-way valve between my Air Source (a hand pump) and the Outer Barrel.

-Where the Connection met the Outer Barrel, there was too much obstruction, keeping the Valve from sliding freely.

That should sum up what I've done so far. I've now been motivated to take another crack at it, but I'd like to run few ideas past the NIC. First, the Connection between the Outer Barrel and Reservoir. The "two crappy bits of tube and hot glue" approach was a bad one. Hot glue isn't durable, so I got some PVC cement, which means no more vinyl tubing. I need a Reservoir and Connection that's airtight and makes no protrusion into the Outer Barrel, so as to keep the Valve's movement unimpeded, yet allow maximum airflow when open. Second, I've realized I need a one way valve between the Air Supply and the Outer Barrel, as the pump isn't enough to hold back the pressure needed. I bought a couple Schraeder valves, but I need to find the best way to mount them. The valves are encased in rubber... and I kind of lost the little documentation they came with...has anyone used these before?

The Schraeder Valve:

The last problem, one which I haven't played with yet, is the best way to trigger the valve. If plain trigger pull is insufficient, then there needs to be a different way to cycle the action. I, of course, am leaning towards lever action. I'm shying away from a pneumatic ram (like in the A.B.P.) due to complexity issues. Ideas?

I hope I've explained the situation perspicuously, If you have questions, ask away.

Edited by Gyrvalcon, 22 July 2007 - 12:13 AM.