Yes, the clip system works by taking pressurized air and pressing the next dart down in the reload barrel, just like ambushbug said. Before going on, I'll explain the clip:

This is the old clip, but you'll get the idea:

Materials:

Dremel

1/2'' inside diameter PVC

1/2'' outside diameter CPVC

Electric tape

Start out by cutting about a 3'' piece of PVC.

You need to take your dremel to it and cut completely through it on the sides. Next cut through the top to the other side only once. Cut the opposite side also, not cutting all the way through, but leaving a thin plastic film. Now peel the plastic up like this:

It is a bit confusing, but I hope you will get it with the next few pics...

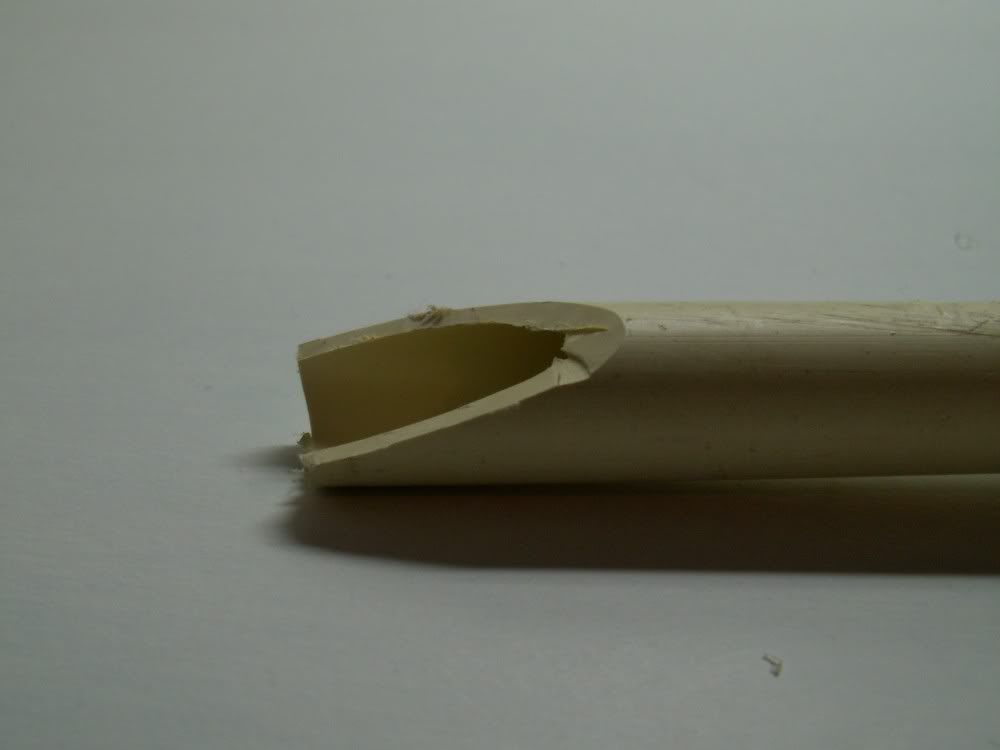

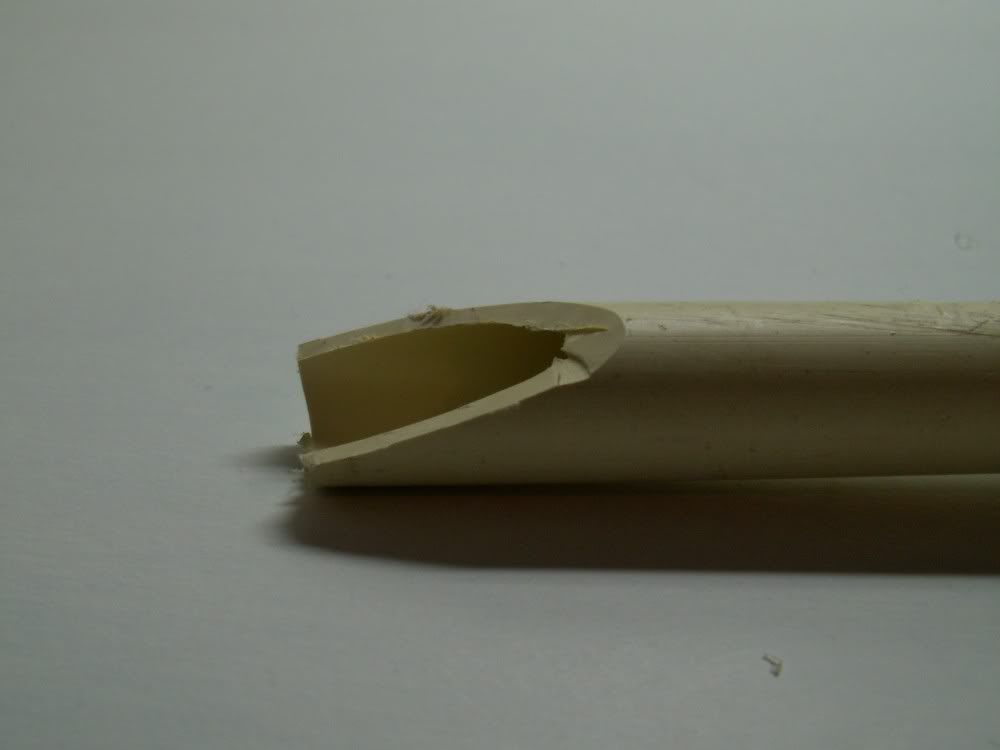

Now, cut a piece of CPVC to about 3''. Slot out about 1/3 of the 3'' piece like this:

Now push the CPVC into the PVC. Look carefully at the placement of the CPVC. I pushed it in, not quite flush with the slot of the PVC. This is essential:

Now, you need to cut another piece of CPVC to around 5''. Cut it to however long you want your reload barrel to be. It has to maximize ROF, but not so much that it fires inconsistently from a lack of pressure. 5'' fits around 10 stefans. Cut the end of the CPVC at around a 30 degree angle to sit flush on the 3'' slotted CPVC:

Fold back the PVC and push the reload barrel in. Make sure to push it into the little gap you left between the slot of the PVC and the CPVC. Here's the next pic:

Now, load that sucker up with electrical tape! Make sure it doesn't leak! I didn't use hot glue because the stefans could possibly get caught on it, but if your careful, you'll be fine. It should look like this:

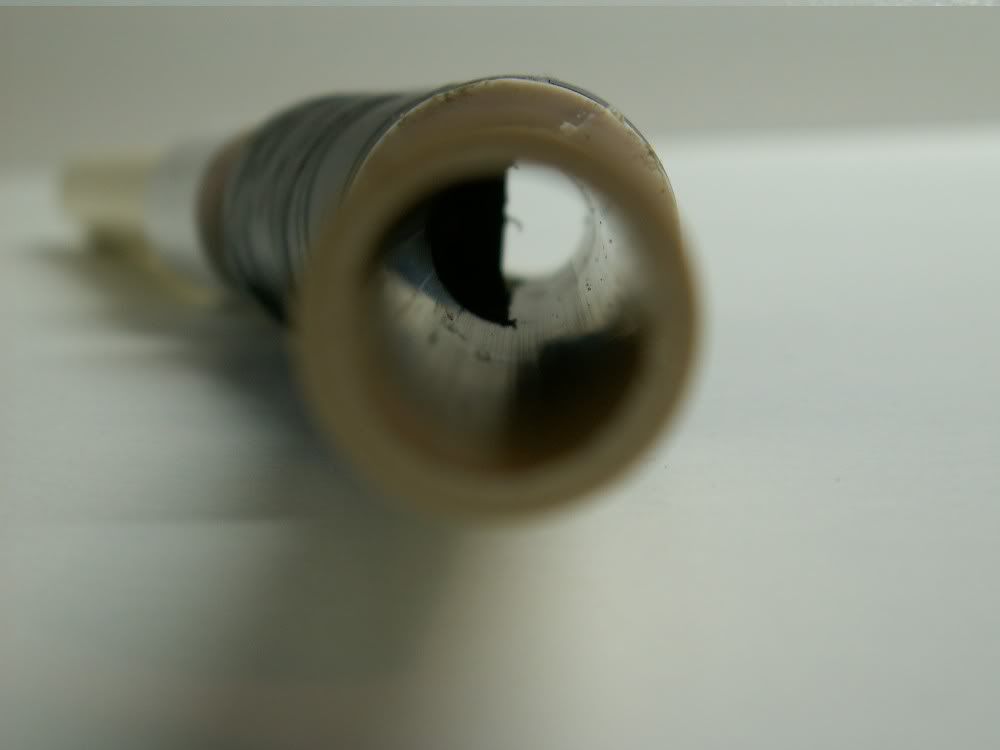

Now here's a finished pic of how it should look when you look down the barrel:

Notice that this reload barrel can be quickly taken off and you have just your cpvced BBB. It's completely removable.

The pump I found was from a Lanard water gun called the Waterbolt. I had to hack it out of its shell, but it fit perfectly inside the BBB.

The needed volume was just guess and check for the pumps. One SSPB didn't quite work, so I slapped another one on the other side. When I finished, it looked down-right ugly. Hence the new encased pump. It seemed to work even better than the SSPBs. I've got no leaks now, and a good air supply.

The Y junction clip system is the same diameter on the inside. The PVC on the outside is merely just a casing. You need to make sure that your darts are making a smooth transaction from the angled barrel to the striaght barrel. On my second clip, I had problems with that smooth transaction. Sanding is key. Also you need to make sure the seal is perfect. Dart size is important also. They need to be 1'' or smaller. Any longer, and they might catch in the process of trading from the angled barrel to the straight barrel.

The ranges are whatever your original BBB could do. It loses no seal, except on the last dart because there are no darts behind it, and works perfectly. One dart is pressed into the straight barrel. It stops when it hits the bottom of the barrel. Now it has made a seal and is in the line of the air. Pressurized air forces it out of the barrel at a good rate and it fires nicely! The next dart is pushed in, and the same thing happens.

Reloading can be very fast, or very time consuming. It all depends on how consistent you want your gun to be. The first reload barrel I made had a coupler where you could replace it with another pre-loaded one. This works fine, but sometimes the darts were hung up on the gap the coupler made. You can see that my new one doesn't have that. I get very consistent results, but it takes about 30 seconds to reload. I find that after the 12 shots, just rip off the reload barrel, and use the cpvced BBB. If you haven't noticed, it can also shoot arrows.

The idea of using a pressurized system to advance the darts came after guessing and checking. First, I made the reload barrel. I needed to advance the dart manually and then plug the top of the barrel. If the top of the barrel isn't sealed off, darts will shoot at you! So then, I thought a spring system would be my next try. This turned out to be too complicated. Jamming is an issue, and it'd be a pain to reload. Hence, the air. I had SSPBs lying around and serving no purpose. I saw that the action of the cocking on the BBB was perfect for the pumps, so I tried it. It works nicely and I couldn't be more happy!

I hope that answers everything so far... Any more questions? Maybe I should write a book!