#27

Posted 28 March 2006 - 06:08 PM

Pic!

That plate next to it is from an air chamber (large diaphragm valve) which is about 5" in diameter. The springs are 11" and 12" long.

To make relevant to the grip situation, if I used these springs and held on to the grip while cocking, the bond would break before it reached half-cock. Not only that, the force (if it did get fully cocked) would probable break the piston head when it slams into the cylinder head...

I'm gonna look through Lowes' supply ans see if I can't find a 1" I.D. spring or a 2" O.D. spring. One or the other, or one for each gun since I have to make a few of these before June...

#28

Posted 25 August 2006 - 04:52 PM

Edited by forest_sharpshooter, 10 September 2006 - 12:52 PM.

><~NERF~><

#29

Posted 25 August 2006 - 10:30 PM

Edited by NiteWalker, 30 August 2006 - 09:22 AM.

Click here

Credit to Carrtoon for the mod.

"The mother of invention is need... Who doesn't have to pelt people with foam?"

#30

Posted 29 August 2006 - 10:11 PM

| QUOTE (Talio) |

| Catagory 5 hurricanes are the mighty dick of God. You don't mess with that! You don't mess with Gods dick! |

#31

Posted 30 August 2006 - 09:26 AM

Edit- Sorry, I forgot this isn't the place for this kind of thing.

Edited by NiteWalker, 30 August 2006 - 12:56 PM.

Click here

Credit to Carrtoon for the mod.

"The mother of invention is need... Who doesn't have to pelt people with foam?"

#32

Posted 15 June 2008 - 08:14 PM

1) Improved construction methods

2) Measurements (!)

3) Notes on previously suggested methods

Improved Construction Methods

For the longest time, one of the worst parts of building a SNAP was grinding down the rear endcap catchface so the nail could slide over it. Well, today I just experimented with using a rounded endcap, and it works like a charm. These are the caps that Home Depot seems to sell, rather than the square edge caps.

So, now you can build a full-function SNAP with a drill, a saw, and some sandpaper...no Dremel required.

Still need a way to make easier handles...eh, that's another day.

Measurements

Many people have asked me for specific measurements. Since I've been building these things in bulk, I've had to finally specify my dimensions. So, here's a set of measurements that I've been using for construction. Variations will work, of course, but I've gotten very consistent results, as well as these being the measurements that worked with the rounded endcap.

Plunger body section: 2 3/8"

Plunger chamber: 2 1/2"

Plunger rod: 9 1/2"

Trigger hole placement: 5" from end

Nail length: 9/16"

Notes on previously suggested methods

Particularly, using roofing nails as the catchpin. Er, forget I said that. From what I've found after using them, the advantaged of using a fatter pin are negated by a weakened clothespin. The larger hole tends to make the jaws snap off, so it's really not worth it. A thinner nail allows for a very smooth catch, and I've only ever had one catchface wear out from use. And now, since catchfaces are a simple drop-in replacement (after drilling one hole), it's really not worth it.

Edited by Carbon, 15 June 2008 - 09:41 PM.

#33

Posted 15 June 2008 - 09:39 PM

#34

Posted 16 June 2008 - 12:56 AM

This guy can see the future!

hasbro in a nerf war!!!!! dude the will cancel it and confinscate are guns

#35

Posted 16 June 2008 - 06:12 AM

I use the curved endcap, works good, but I just need to add the trigger. I have no motivation to finish this thing.

#36

Posted 16 June 2008 - 10:42 AM

#37

Posted 18 June 2008 - 10:09 PM

When I was building my SNAP-1 mk2 I originally got those round endcaps, but I later got the flat ones because they are easier to drill. I still have the round ones, so maybe I could switch them. I still have to put the grip and trigger on my SNAP-1 anyway.

Drill em from the inside going out. You can clamp it in a vice and then the drill will rest right in the center.

Venom: Haven't we all?

#38

Posted 18 June 2008 - 10:46 PM

I actually do all mine by hand, but like you said, inside out. I find it easier to hold the endcap in a large pair of pliers for the larger bits, rather than a vice.When I was building my SNAP-1 mk2 I originally got those round endcaps, but I later got the flat ones because they are easier to drill. I still have the round ones, so maybe I could switch them. I still have to put the grip and trigger on my SNAP-1 anyway.

Drill em from the inside going out. You can clamp it in a vice and then the drill will rest right in the center.

#39

Posted 18 June 2008 - 10:49 PM

I actually do all mine by hand, but like you said, inside out. I find it easier to hold the endcap in a large pair of pliers for the larger bits, rather than a vice.When I was building my SNAP-1 mk2 I originally got those round endcaps, but I later got the flat ones because they are easier to drill. I still have the round ones, so maybe I could switch them. I still have to put the grip and trigger on my SNAP-1 anyway.

Drill em from the inside going out. You can clamp it in a vice and then the drill will rest right in the center.

Makes sense. I need to make me a SNAP sometime. Can I maybe get some pointers at SPANO?

Venom: Haven't we all?

#40

Posted 19 June 2008 - 01:34 PM

Yeah, I will answer any questions I can about it. I probably won't want to use mine a whole lot, since I'll have my beastly big blast, so you could use it all you want. This reminded me to go finish building it.....Makes sense. I need to make me a SNAP sometime. Can I maybe get some pointers at SPANO?

#41

Posted 19 June 2008 - 02:52 PM

And if he can't answer it, I probably can.Yeah, I will answer any questions I can about it.

Makes sense. I need to make me a SNAP sometime. Can I maybe get some pointers at SPANO?

EDIT: Just realized I wasn't in the SPANO thread.

Edited by Carbon, 19 June 2008 - 02:55 PM.

#42

Posted 19 June 2008 - 06:14 PM

And if he can't answer it, I probably can.Yeah, I will answer any questions I can about it.

Makes sense. I need to make me a SNAP sometime. Can I maybe get some pointers at SPANO?

EDIT: Just realized I wasn't in the SPANO thread.

I thought I remembered seeing something about you going to SPANO. Maybe not, I haven't been all there recently as I am tired, but thank you venom.

Venom: Haven't we all?

#43

Posted 19 June 2008 - 07:10 PM

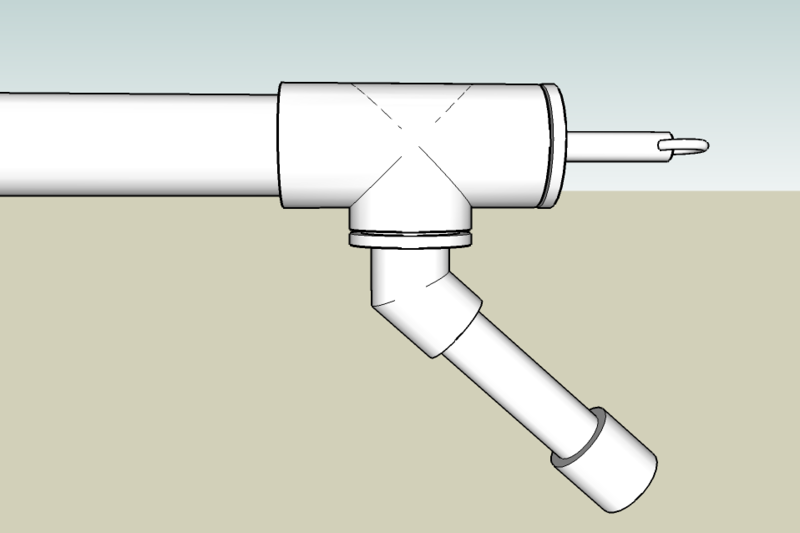

Have you ever considered a tee and a 45 degree elbow?Still need a way to make easier handles...eh, that's another day.

#44

Posted 20 June 2008 - 06:17 AM

Have you ever considered a tee and a 45 degree elbow?Still need a way to make easier handles...eh, that's another day.

The Tee looks significantly cut down in your picture. I'd be worried about it snapping off.

Edit: I thought about it some more. My diagram may not be that significant for this case. I was probably thinking about using a huge 2" tee.

Edited by quiet asian man, 20 June 2008 - 06:30 AM.

#45

Posted 20 June 2008 - 01:48 PM

I don't think that the gun would rotate as much as you say it would in real life. Flexor tendons in the wrist should be able to overcome most of that force.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users