#26

Posted 22 March 2006 - 07:56 PM

#27

Posted 22 March 2006 - 08:02 PM

#28

Posted 22 March 2006 - 08:44 PM

CaptainSlug, you essentially want to make a Dr. Gatling design, only using these syringes instead of bolts...interesting. The RoF would be limited by how fast it would load, not really the motor speed. However, with any decent fire rate, 120VAC would be necessary to have firing commence for more than five minutes. Trust me on that. Even with the lowest-watt motors I have access to, none have the power to drive the barrels fast enough or have enough speed if geared down via drive belt(s). A 12VDC starter motor would be able to without too much of a drop in speed, but that would not last very long. Cooling, luckily, would not be a problem due to the life of the battery...

If you have access to a washing machine or a garage door opener, the motors from these are superior to anything I have yet to see used or use personally for a project such as this where there probably is a budget to deal with. Good luck, though.

#29

Posted 22 March 2006 - 08:47 PM

Yeah, I (or whoever wants to try the design first) might have to look at cutting the seal down or replacing it with a single O-ring.I think the syringe head needs some surgery...

I'll have a design sometime in the next 24-hours.

I had a small 13RPM 12V turn-table motor assembly that would be perfect. That or something similar in the 10-50RPM range.Even with the lowest-watt motors I have access to, none have the power to drive the barrels fast enough or have enough speed if geared down via drive belt(s).

We're not talking alot of torque here and I have enough experience shopping for motors to know what I'm looking for.

But the simplest design for starters will be designed with a crank instead of a motor. Not aonly simpler, but authentic "gatling" to boot.

Edited by CaptainSlug, 22 March 2006 - 10:39 PM.

#30

Posted 22 March 2006 - 09:23 PM

Sounds awsome.

Yes, I'm the Cliff Claven of the Internet.

#31

Posted 23 March 2006 - 12:04 AM

For triggering, I'm currently holding down the pullrod with my thumb, resting teh notch against the hole in the endcap. To fire, I let go.

#32

Posted 23 March 2006 - 02:48 AM

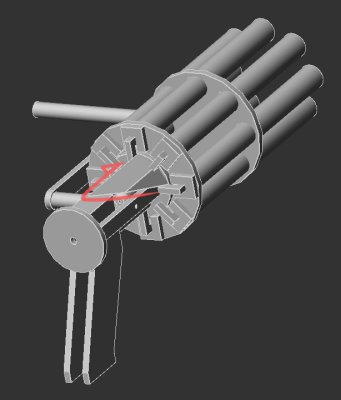

And here's the really basic workup of mechanics of what my mental plan was. The drum might have to have a larger diameter than shown here to make the advancing ramp at a shallower angle.

It uses a miter gear set inside so that you turn the crank counter-clockwise and in turn the drum rotates clockwise at the same speed. I made sure all of the parts in the design are both cheap, and accurate dimensionally.

Edit: If I can find the right electric motor or a donor cordless drill I may have found a much simply way of making the motorized version with a different trigger system. I'll start a new thread for that later.

Edited by CaptainSlug, 23 March 2006 - 03:29 AM.

#33

Posted 23 March 2006 - 05:15 AM

This might be easier with less barrels; there would be less spring tension to fight against. Also, I worry about the 1:1 ratio. A slight advantage would be nice to allow less user fatique. It all depends on how stiff those springs are though...

#34

Posted 23 March 2006 - 12:19 PM

#35

Posted 23 March 2006 - 11:55 PM

It's definitely cool, and definitely possible, but my concern is whether you will store enough ammo to keep up with a high ROF.

#36

Posted 24 March 2006 - 12:07 AM

Like say in an LnL, I took a syringe, that has an AMAZING seal, and put that in place of the tube where pressure is built up.

I think this might add an entirely new aspect of modding spring guns.

If someone had this idea earlier I couldnt find it.

Edited by bizket12, 24 March 2006 - 12:08 AM.

#37

Posted 24 March 2006 - 12:16 AM

You summed up EVERYTHING I was thinking about while working on the motorized version.It seems like it would be easier to just attach a rod in place of the gear on the drum, and chuck it in a cordless drill, making sure to set it as slow as possible.

It's definitely cool, and definitely possible, but my concern is whether you will store enough ammo to keep up with a high ROF.

I'm not sure if I should post that design or not because I don't know when I'll get around to making it.

Edited by CaptainSlug, 24 March 2006 - 12:17 AM.

#38

Posted 23 April 2006 - 09:12 AM

#39

Posted 23 April 2006 - 10:44 AM

#40

Posted 23 April 2006 - 07:13 PM

But that's based on glycerin which won't last terribly long in open air. Just use silicone spray lubricant

Silicone doesn't work, though...binds up the plunger heads like crazy. You're right, though, alex...KY is water based (at least I think it is), so that should work with this particular kind of rubber. Good call.

#41

Posted 02 May 2006 - 03:17 PM

Ingredients: Chlorhexidine Gluconate, Glucono Delta Lactone, Glycerin, Hydroxyethylcellulose, Methylparaben, Purified Water, Sodium HydroxideYou're right, though, alex...KY is water based (at least I think it is), so that should work with this particular kind of rubber. Good call.

The Glucose and Glycerin ingredients will slowly evaporate or congeal out over the course of a week or so and your oil wil change from a lubricant to a sticky resistant. You could try it and it will work for a while. If what I'm predicting will happen happens it will be easy to just clean it out of the gun.

You might want to try vegetable oil.

Edited by CaptainSlug, 02 May 2006 - 03:18 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users