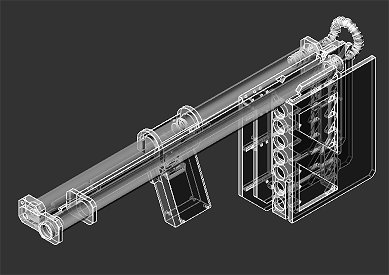

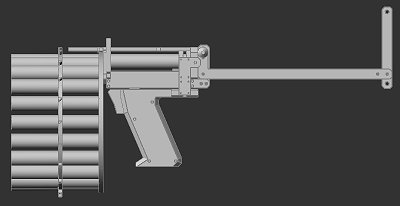

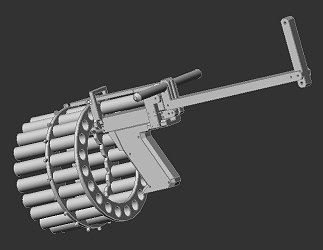

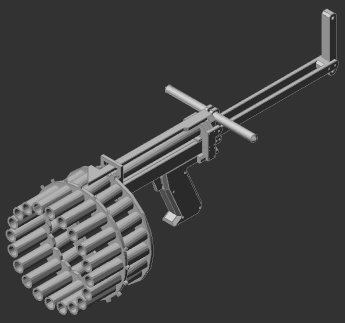

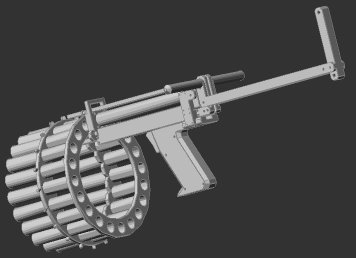

As boltsniper pointed out my earlier designs were a bit more complicated than they needed to be.

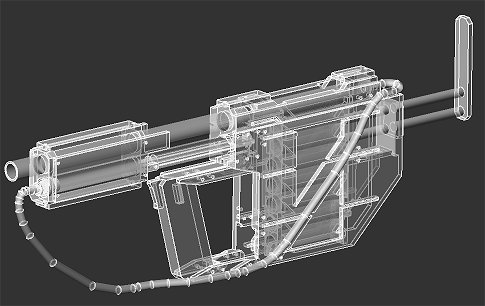

So I started over trying to put myself in the mind-set of having to make a gun with limited tools and a limited budget. I ended up with a VERY simple (machining-wise anyways) design that I'm quite pleased with.

$25 worth of polyester, a scrollsaw, power drill, some solvent, and a #6-32 tap wrench are all that would be needed to make this design which includes the following features.

- 14 inch barrel length

- Made completely out of PETG

- 5 inch travel spring-loaded plunger

- Removable/Stowable stock

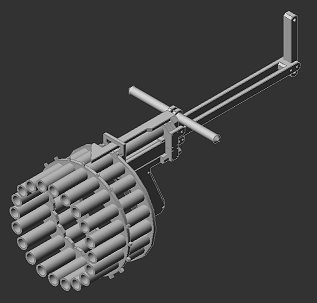

- 8 round clip that feeds during each priming cycle

- Front reloading of the 5 lower chambers on the clip

- The ability to preload a second clip (or just a larger one) after two darts have been fired

- Ease of disassembly and replaceable barrel

What I would eventually like to do is do a complete instruction manual of how to make your own including power tool specific usage tips and general plastics machining advice. I've been primarily making computer cases out of plastic but this would be an interesting change from that.

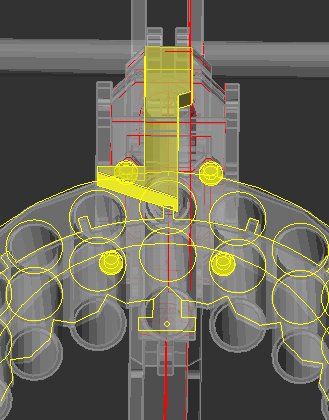

I need to make an image outlining the priming and round advancing cycle...

Edited by CaptainSlug, 22 February 2006 - 11:29 PM.

This topic is locked

This topic is locked