A design I have been refining over the past month. I did one a few years ago when I saw the FAR, but the Caliburn and the rapid improvements in 3d printing inspired me to give it another shot. Obvious comparisons will be made to the Caliburn because that seems to be the standard and although this started differently I converged on some of the same design decisions (trigger group was a place where I iterated a few times and came back to the dual lever).

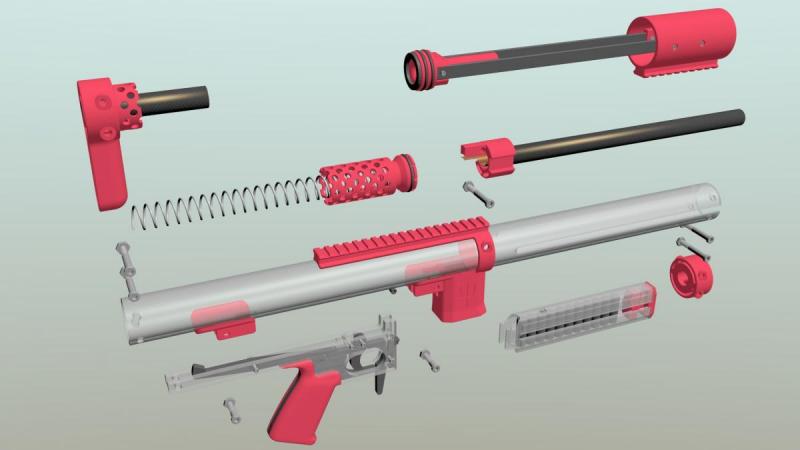

The drivers for this design that would set it apart from other homemades is the ease of servicing, low deadspace and durability. For servicing there are 7 M6 bolts or push pins to field strip. The durbabilty is there with no threading of 3d printed parts, metal strips or the receiver and the monocoque receiver. Receiver is a 1-3/4"x1-1/2" polycarbonate tube, like the transparency and material properties. Will fit a [k25]/[k26]/K13 spring. 1.5" of pre-compression and 6.25" of compression with a 1.5" OD plunger chamber. I copied the spring compression scheme of the Caliburn as I haven't experimented with [k26] springers before, just going to assume it has got it right. O-ring seals for plunger, double on bolt, and trunnion has one to cushion the front of the bolt.

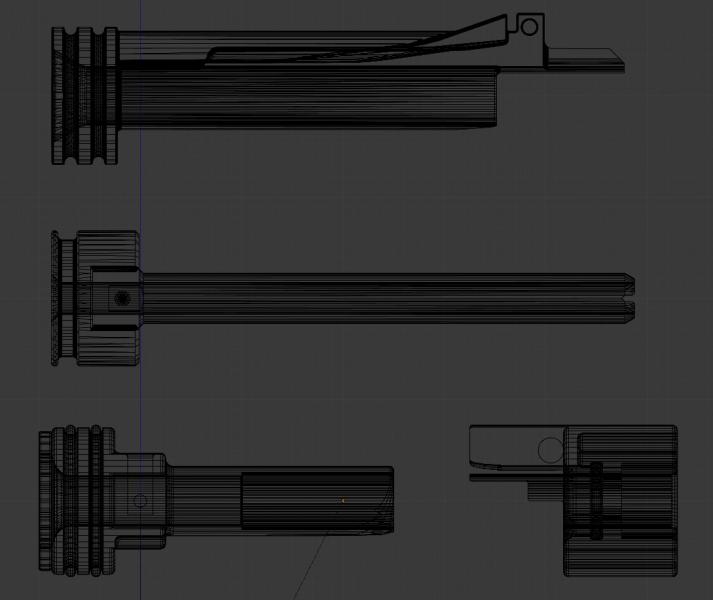

There is only 2" of dead space and a 0.5" bore in the bolt. The bolt seals with a 9/16" brass over the 17/32" breech. It is a sort of reverse sleeper breech, can not have the dart finger on the bolt, so it is instead on the breech. The idea is the dart will slide into the 9/16" as it pushes forward, halving the deadspace over a pusher design. The bolt could be used as a pusher simply by putting brass that will sleeve inside 17/32" in the rear section.

The barrel and breech are separate pieces, allowing for easy barrel swaps depending on the darts, spring or desired muzzle device. The breech is secured with a bolt/pin to lock in the correct head spacing. The barrel could be 9/16", 17/32" or any combination of the two. The only requirement is that there is a ~1/2" collar of 9/16" to seal around the front of the 17/32" breech. outer barrel should be <0.75". In my renders it is shown with 18mm carbon fiber tubing to support the brass.

The priming arms to connect the bolt and foregrip are exactly 12". This simplifies part sourcing. You could even use carbon fiber strips meant to reinforce musical instruments. The receiver will require mostly simple machining, the only difficult part is the long slot. Doable with a drill and coping saw.

Magazine is a bit of a difficulty. It is sized for a katana mag, I used the bumper STL to make sure I had the profile correct. However the catch is much lower, really the catch on the katana mags is very high compared to nerf mags. I could make it work with the katana catch location by reducing the length of pull, going for a button catch with cross bar (most likely one I would try), or putting the mag release on the front of the mag well, but didn't want to make that compromise. Not sure If it is acceptable to expect a modification on the magazine to use and also don't have a katana mag on hand for exact measurements (would need position and dimensions of catch retaliative to the bore axis). I have designed a 12 dart version of the mag, feed lip profile is different (scale-able).

For ergonamics, 11.25" length of pull (but plate to trigger, about 1" longer than Caliburn). ~28" overall length with a 12" barrel. Furthest part of foregrip is 25.75" from the buttplate and 4" long. Pistol grip is modeled after a magpul moe for ar, cross check dimensions with my paintball marker (Tippmann A5).

Magenta parts are to be 3d printed. The clear components are polycarbonate (other than magazine). The controls could be either.

Another idea I had was to use a brass liner for the plunger tube (resizing plunger and bolt appropriately) to reduce seal drag. Didn't see any examples of this being tried, might be very similar to aluminium tube performance.