Hi everyone, I am 3DBBQ . ![]()

I want to show you my latest project.

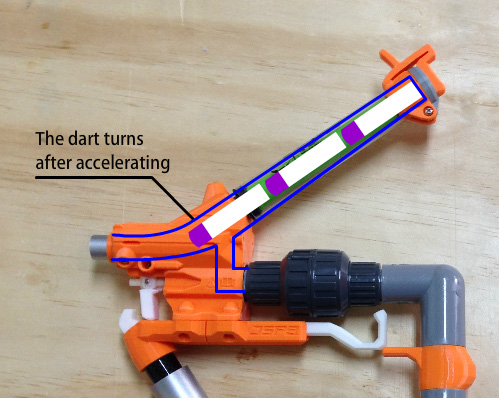

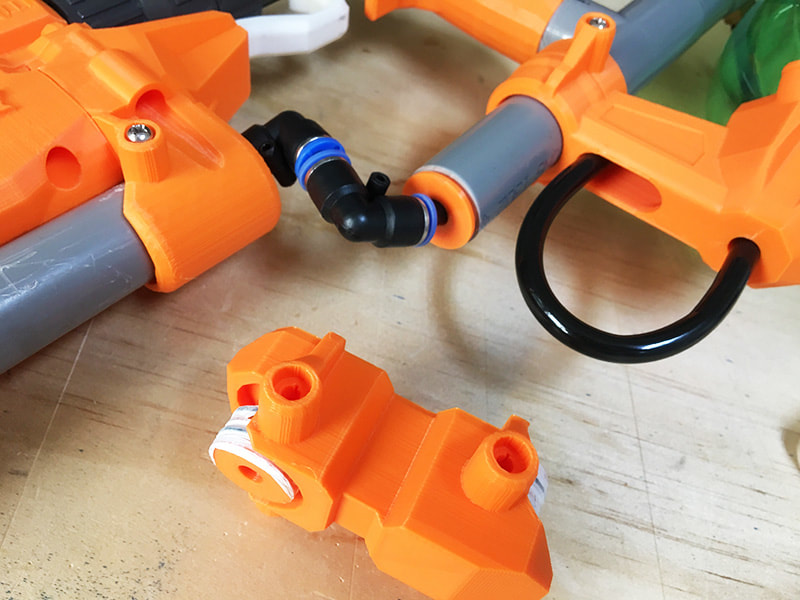

This is the hopper clip design. This is a mechanism that I have never made before because there weren’t any Pipe Wyes where I lived.

When prototyping, I used 3D printing to make the Pipe Wyes models. These are the areas where I have fixed the hopper clip:

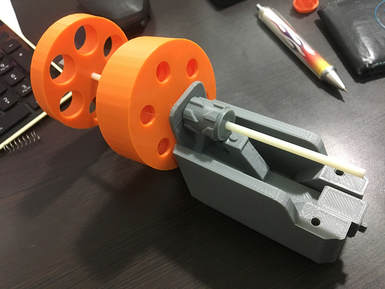

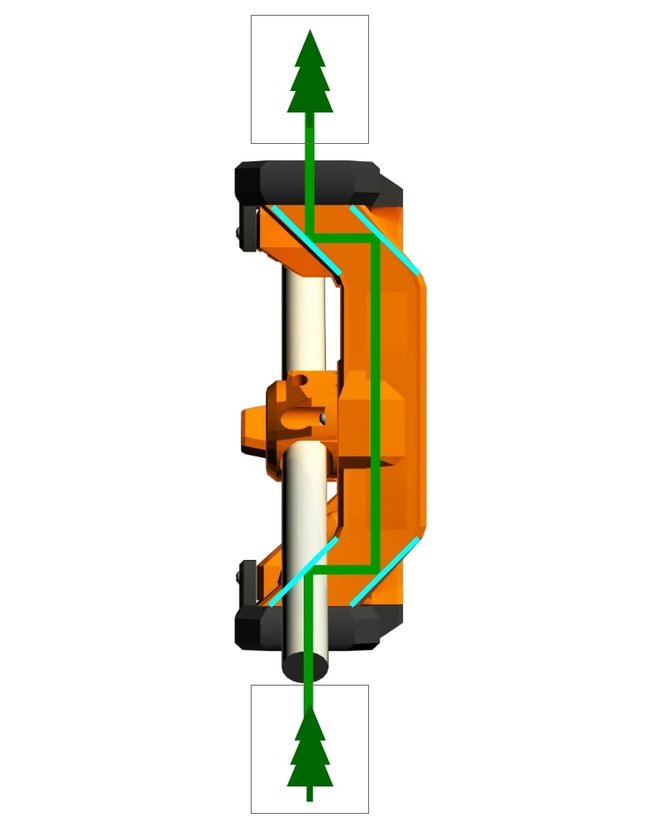

1. The darts now start to turn after it accelerates instead of turning while it accelerates. This allows the darts to really go through every step without getting stuck or shooting blanks.

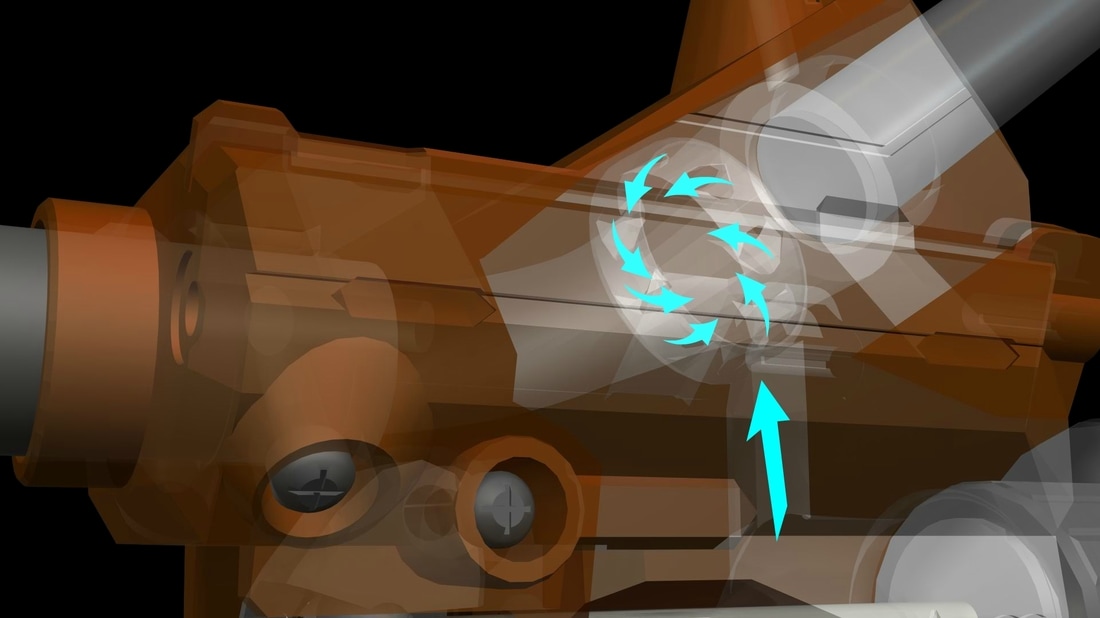

2. Using a spiral airflow to allow turning while accelerating.

3. 35 degrees is a good angle.

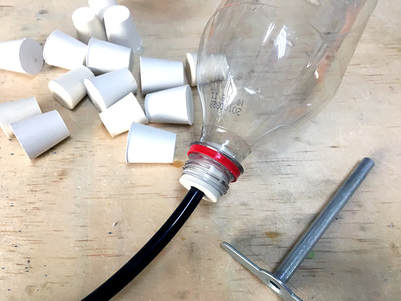

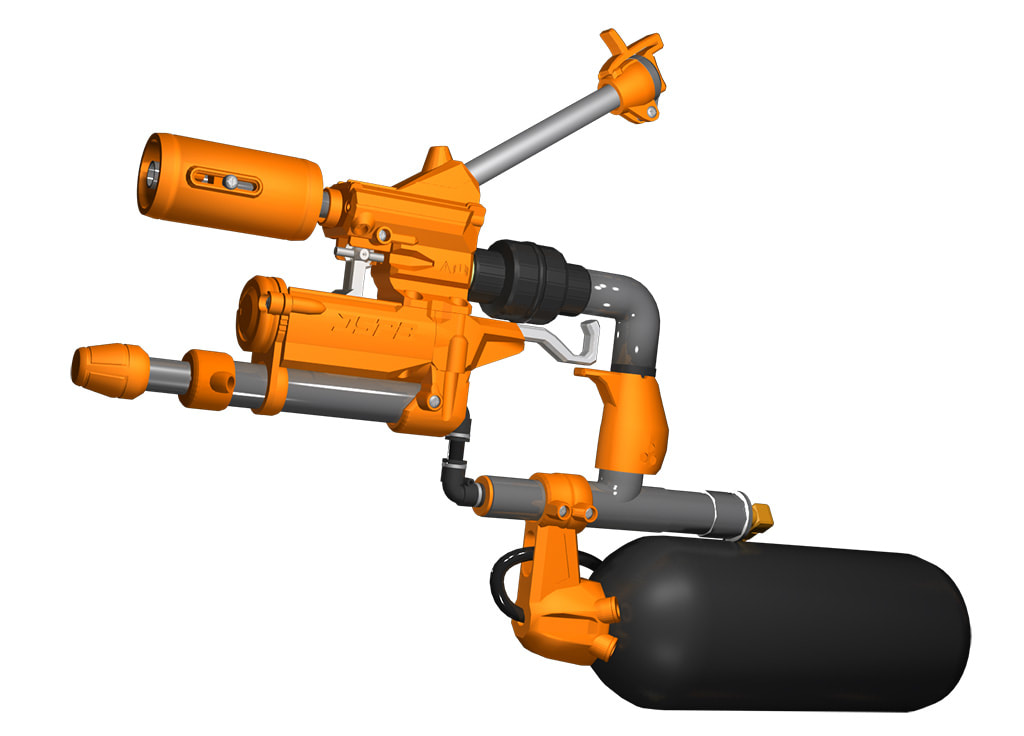

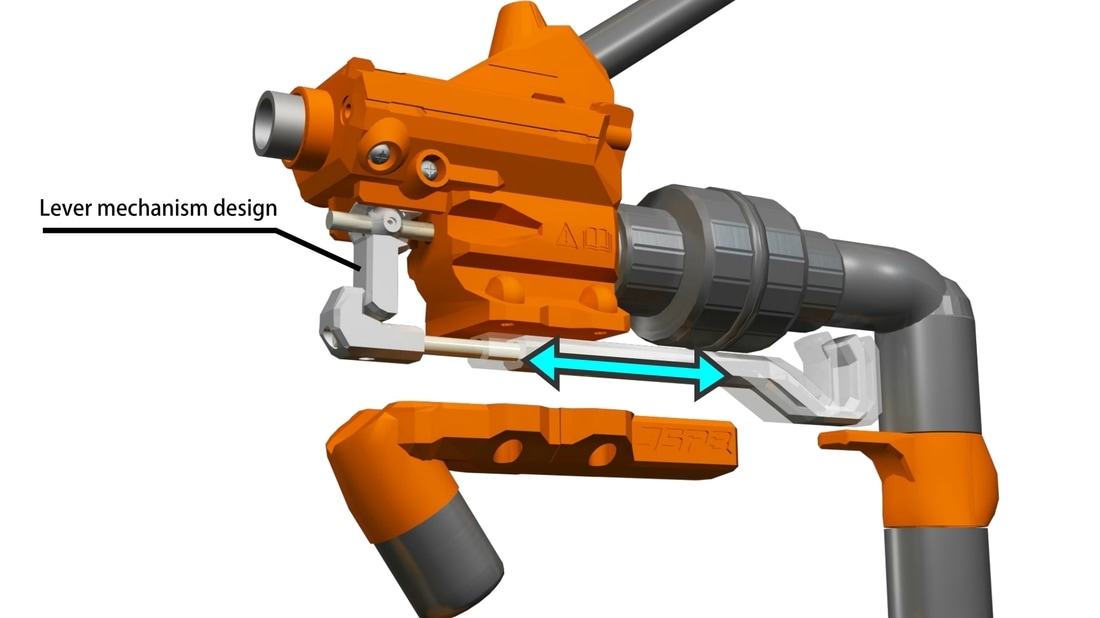

I use a bigger check valve instead of a mini valve for larger ones have greater pump force and power.

However, there is a problem with shooting compared to the mini valve, which is why I’ve designed a lever mechanism that can make you press easily and shoot with a strong force.

The hopper clip’s aiming scope is made of four mirrors to form a reflex sight that prevents the magazine from blocking the line of sight.

Conclusion: The hopper clip is a design that allows speed and high efficiency. It also solves the problem of an obscure line of sight thanks to the sighting device.

-------------------------------------------------------------------

This is the version of the big air tank I’m fixing now.

The big air tank can be used in many places, but I recommend to use it with an air tank big enough for better results.

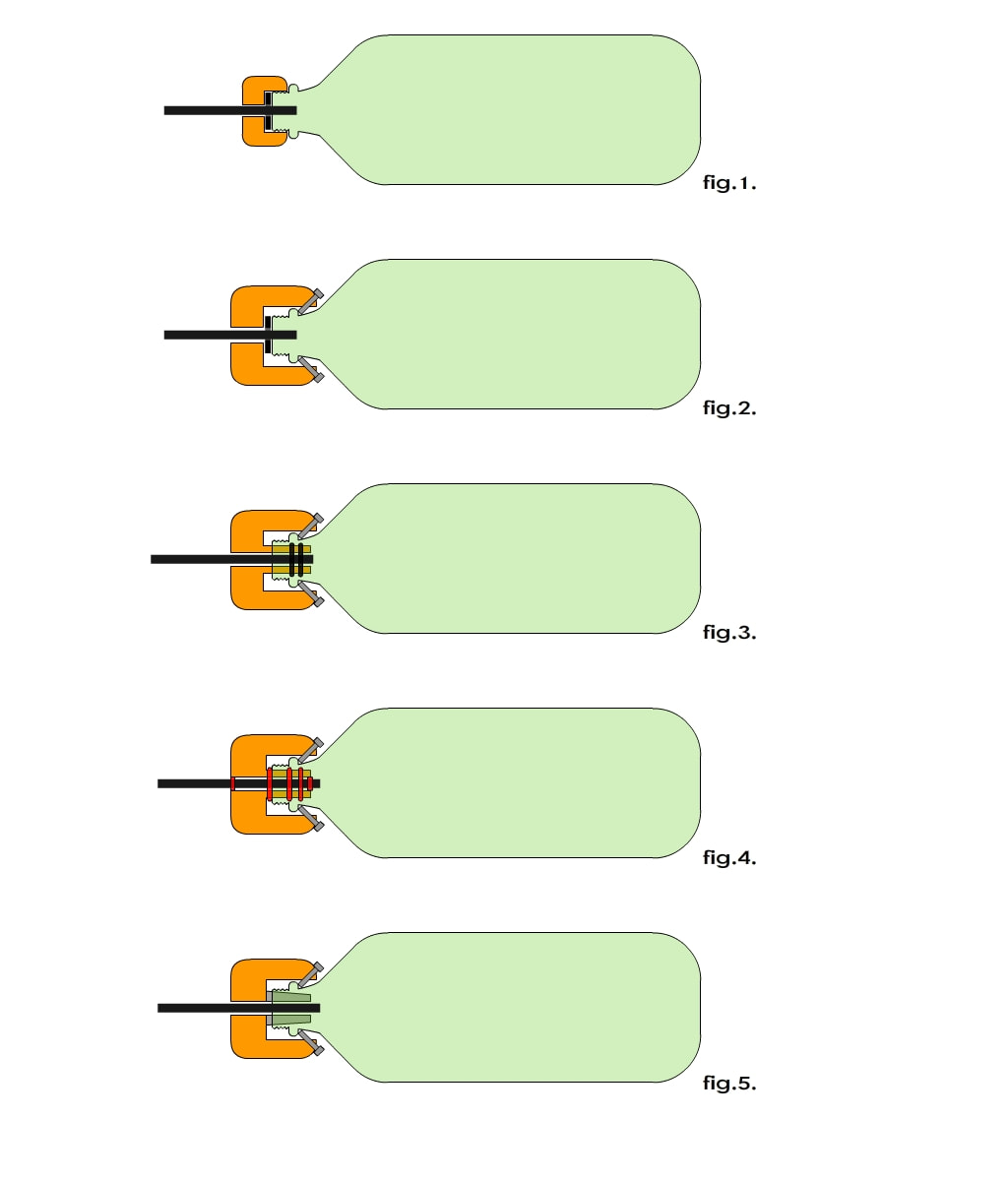

This is how it works:

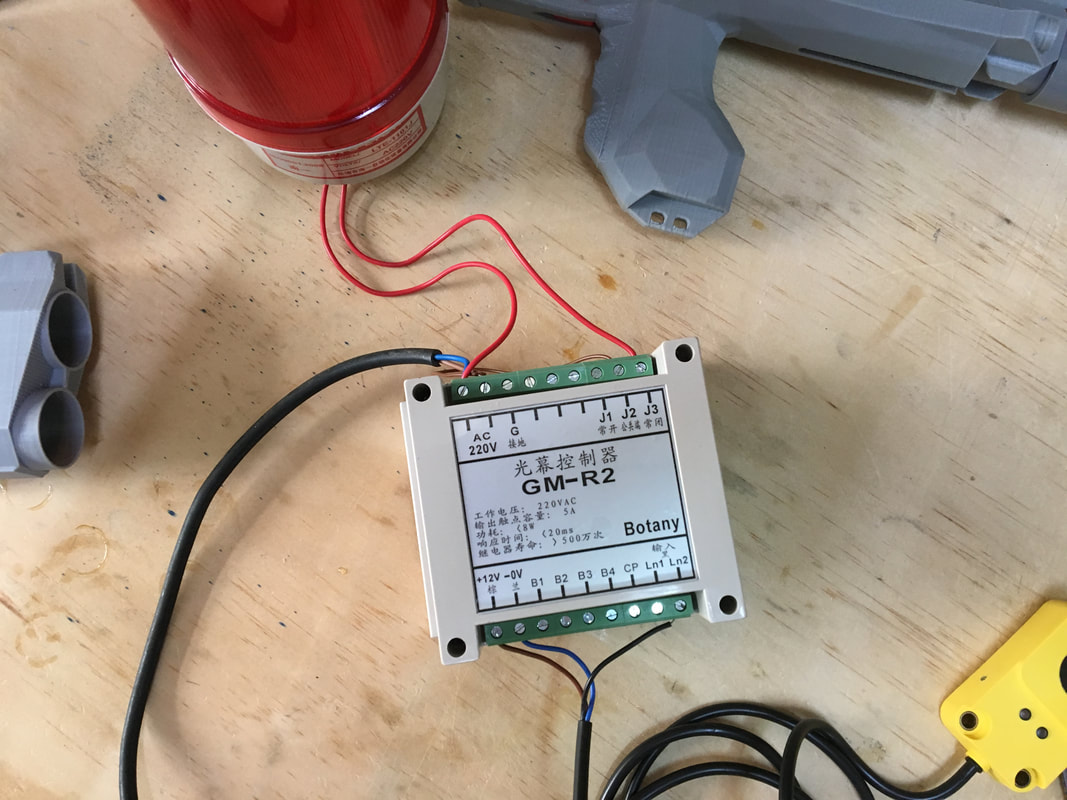

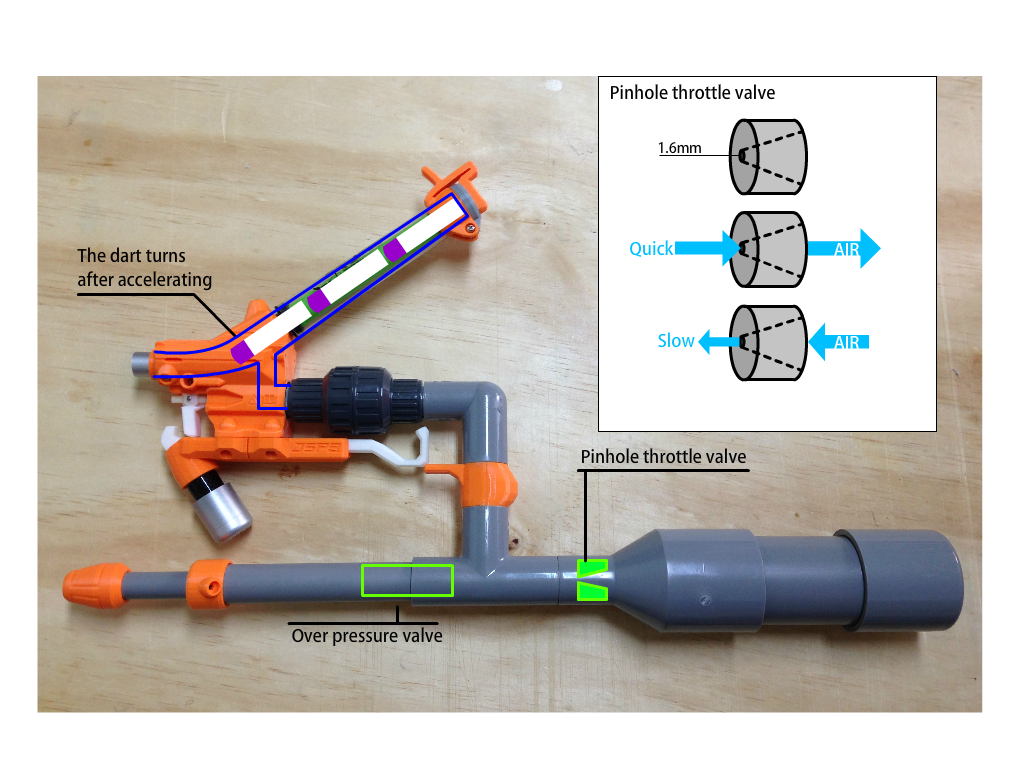

Using a tiny cone to prevent the air from shooting out at once. The cone allows the air to enter the spacious air tank quickly, and leave the spacious air tank slowly. During the shooting process, do not press the trigger for too long so that you don’t consume and waste the air.

This is a design that is easy to make and it can allow firing shots in rapid succession.