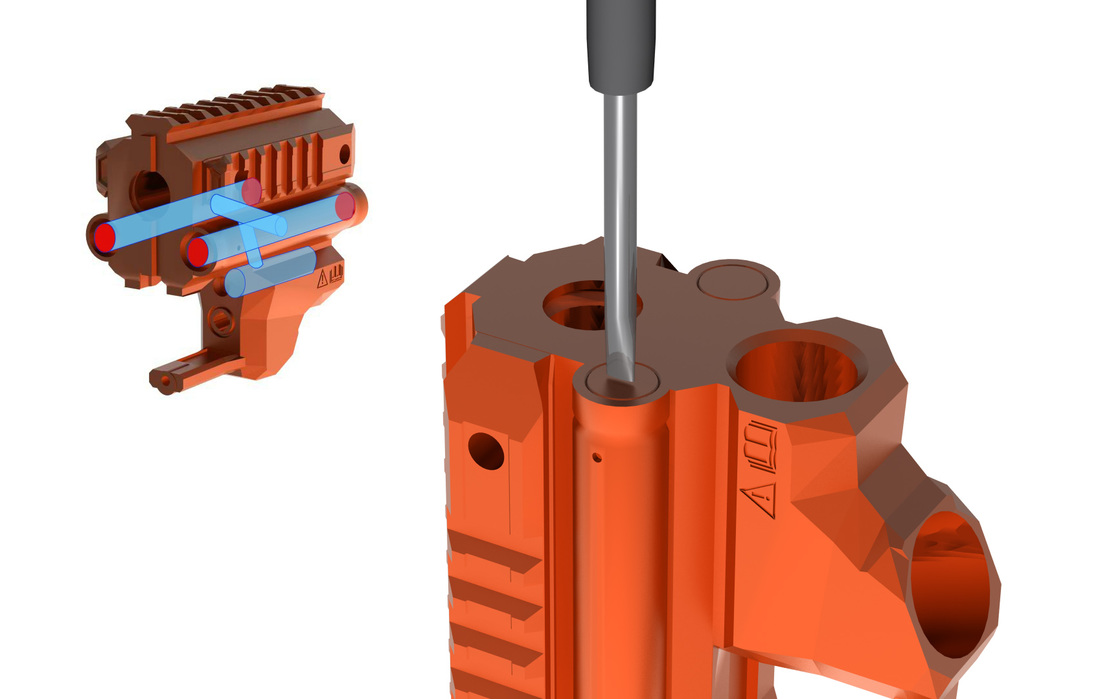

Do you guys have a suggestion for infill percentage requires to have a sturdy enough main block? I accidentally set mine to 100% on this first one, and it is over 350g.

Yikes, I used 20% with .25 layers. It's a little creaky (you can see a split by the grip), but seems ok. It isn't super structural like the catches and stuff in the PSCR that I did do 100%.

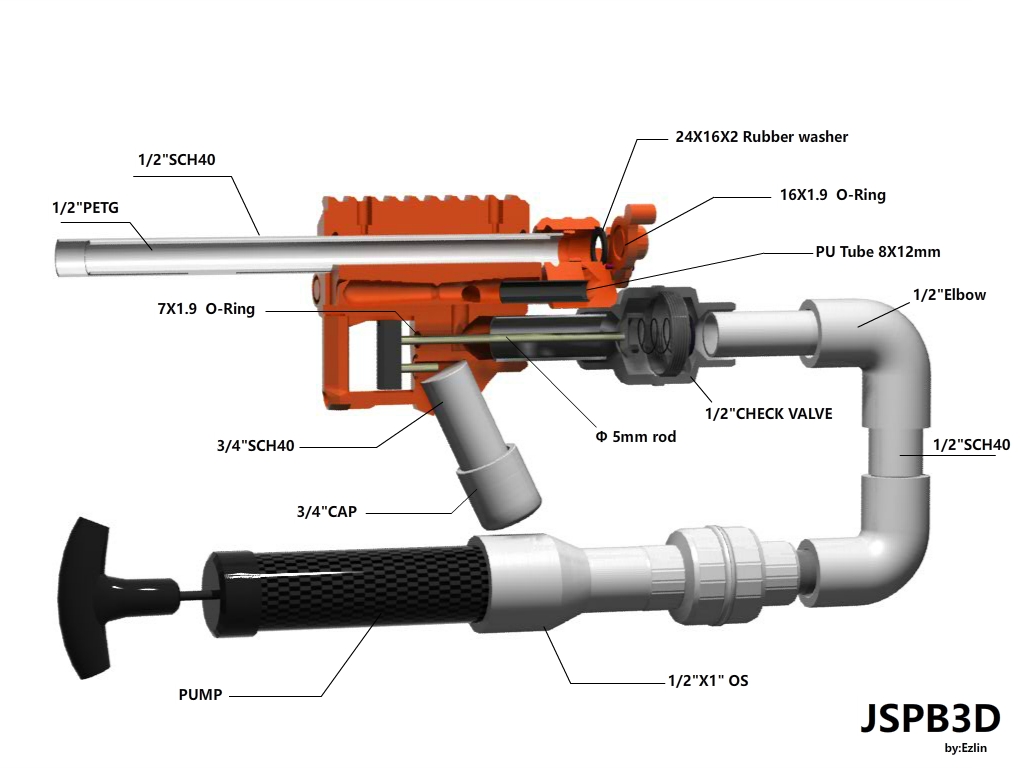

Oh, and I made the RSCB front end myself. It wasn't hard to model, but seeing as JSPB is being kind enough to share the whole file and he's selling an RSCB front end on his site, I won't post mine unless he's ok with it.

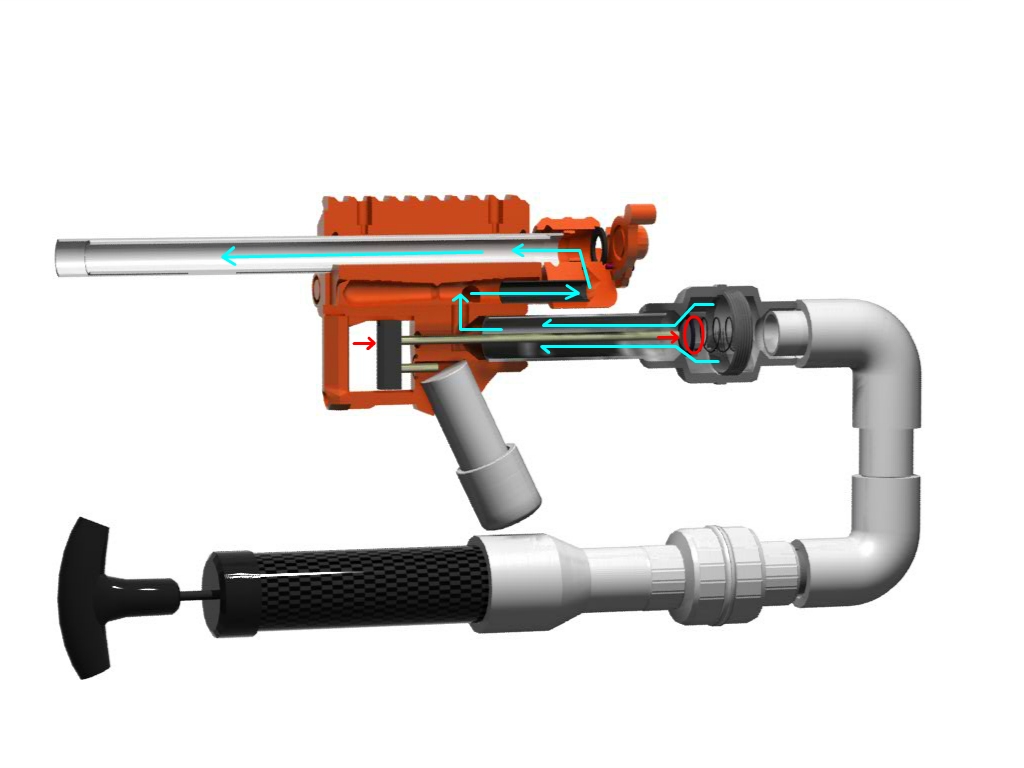

Your trigger valve to stopped working,is the valve itself the problem?

Yes, the valve itself stopped up. I'll maybe try washing it now that it's a fresh day and I've thought about the problem, and try rebuilding my custom valve with glue and maybe a spring.

Where do you get valves? Online or locally? Yours look like they'd unscrew so you can examine them, which would be better than mine which are welded-together.

Trigger guard is a bit close, I will modify it.

While you're looking at it, the 3/4" handle is a *tad* tight and fragile. Maybe beef up the sides (especially toward the opening) and increase the opening 0.01" or so. Also, there are a *ton* of holes in the blaster, presumably for mounting stuff to the pic (NERF?) rails. If you sealed those up - maybe put a tight-fitting cylinder in there that would punch out if you drive a screw into it - it'd be easier to construct.

The trigger is also pretty fickle for me. It's grabbing the printed lines in the body and not wanting to pull or reset very well. A lever-trigger would probably work better.

Expect you to finish it!

Hopefully it'll work for me today. If not, it may remain in this state indefinitely

Ed: Right, so tried washing the valve, pushing it from either direction, pumping air throught it; nothing. The valve is totally dead, but I'll take it back to see if I can swap it out for a not-dead one.

My homemade valve kind-of works, kind-of doesn't. It is a *much* easier trigger pull than the bought valve was, but it leaks air no matter what I do to it. Because it leaks some air, I've been hesitant to weld it in place as I should, so I'm getting residual leaks all around it. Also because it leaks, I've been hesitant to firmly attach the pump, which keeps popping off. So... Benched, for now. I might try again tomorrow if I can return the valve - those things are super expensive comparatively.

Which is one of the biggest reasons I had the parts to try making my own - a valve at Lowes, where I got mine, was ~$6. The oring and poly ball were like $0.10 each (or rather, a few bucks for 100), and they fit in a section of 1/2" PVC with 1/2" CPVC nested at either end to retain everything. I added a spring and a pin to hold it, but I'm not 100% convinced they're necessary (the ball should be light enough to get blown closed just by pumping). The whole thing costs like $0.75, plus minimal time to make it.

Edited by Meaker VI, 18 October 2016 - 04:10 PM.