The initial goal of this home made was to create a compact pump action blaster that retained the performance made familiar by it's popular contemporaries. It's of a Bull Pup design with a familiar 7" draw and more importantly, incorporates a unique pump action system that allows for the familiar and more ergonomic shotgun style prime, without the use of a pully. In fact the only thing different about this system from a 'RainBow Pump' is it's configuration. It is, in essence, a Reverse/Inverse RainbowFire Pup.

I'd like to begin by explaining that the materials I chose to use are what were available to me. Many of you know that I live in Canada and I don't have access to many of the popular materials commonly used for homemades or McMaster Carr. The majority of my materials were sourced from Home Depot, Lowe's, Walmart, the Dollar Store and Pet Smart. I'm sure this can be converted using the popular materials available to most of you ('Merikans).

The name, "Multiple Orgasm", was chosen mainly because it incorporates so many sexy goodies. Namely, the unique priming system configuration I deemed, the G-Spot . And like Zorn's FAL, I felt like adding some estrogen to the database.

So let's begin...

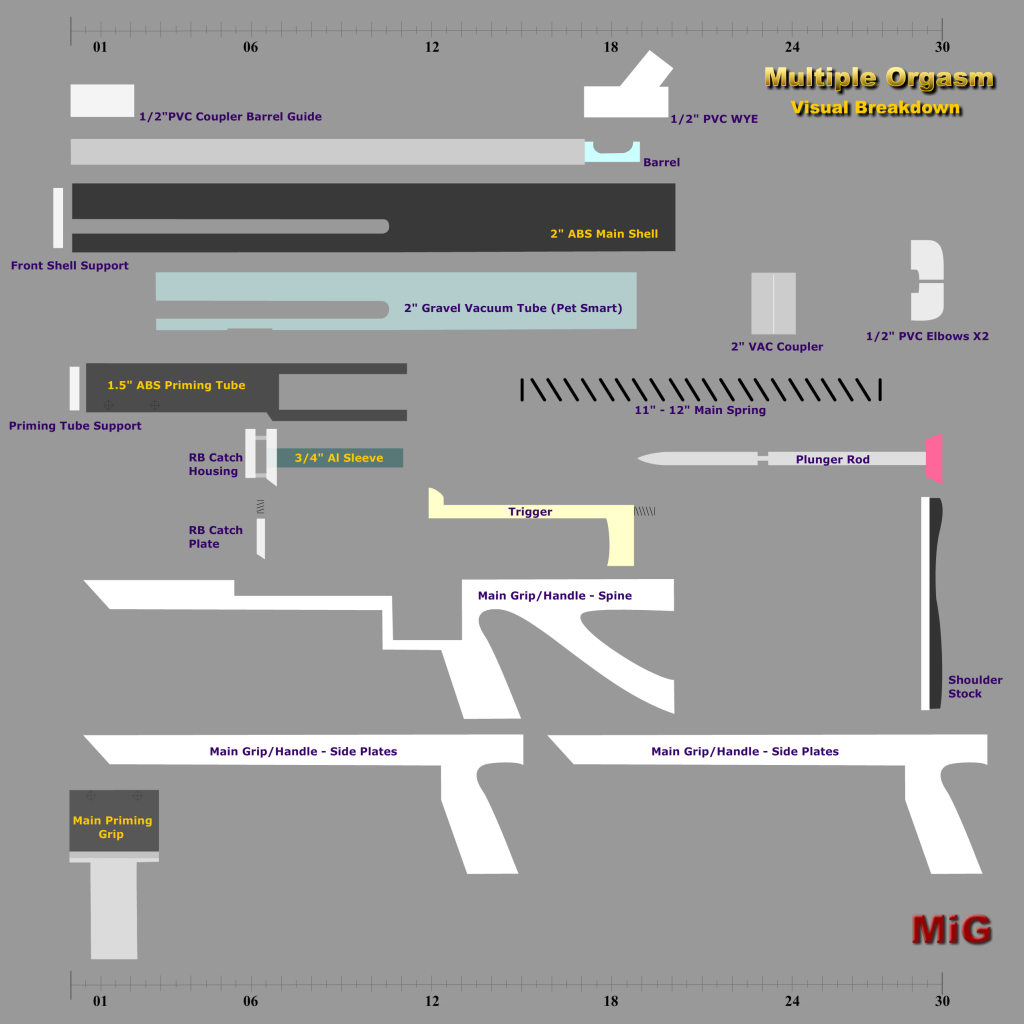

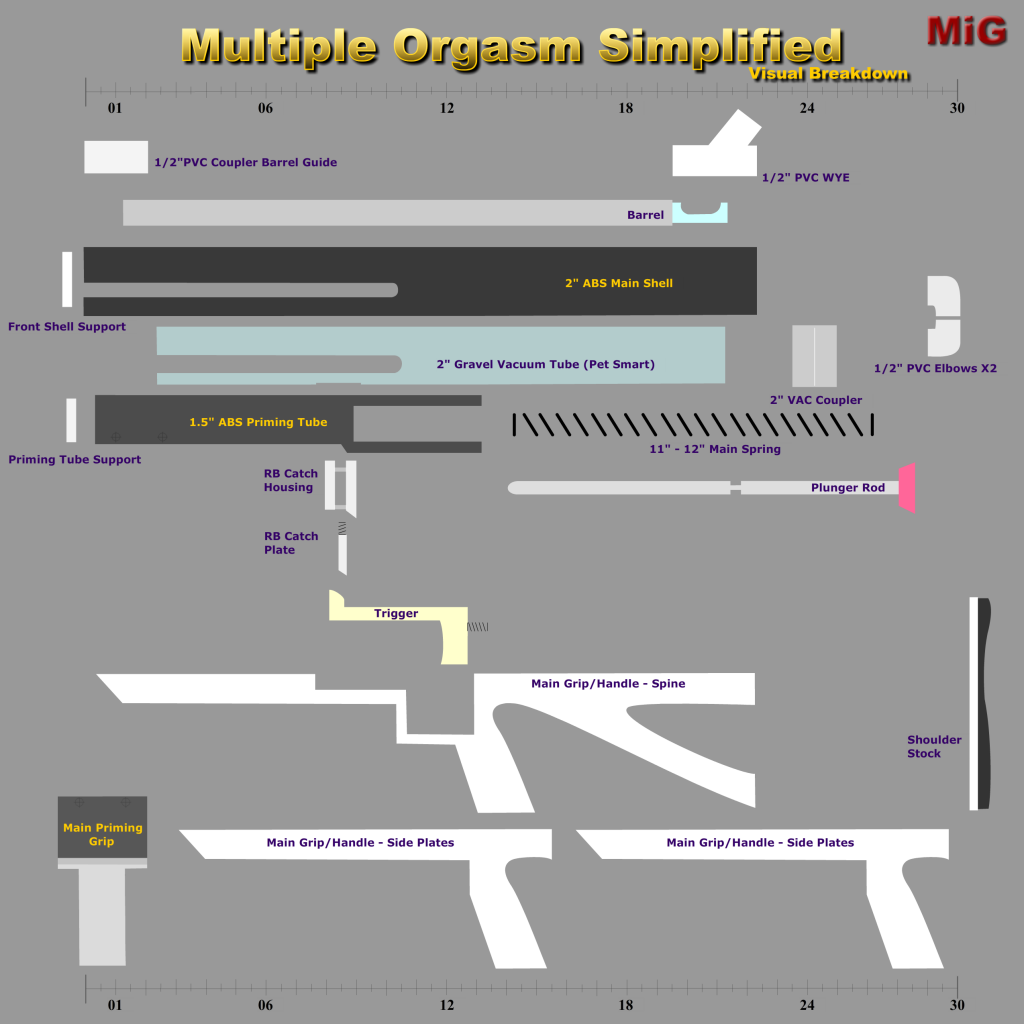

The main things you'll need are three different sized tubes/piping that sheath nicely into each other. In my case I chose:

- 1.5" ABS as my main priming bar

- a 2" gravel vacuum tube (meant for aquariums) for the main plunger tube

- 2" ABS for the shell.

You'll also need:

- 3 cutting boards for the catch, supports, trigger, grip/handle and stock. In my case I chose 2 thinner boards and one relatively thick board. - 2 1/2" elbows (I eventually swapped out one of the elbows for a T)

- 2 stubs of 1/2" PVC

Since this does utilize a slightly modified Rainbow catch, a slotted omni-directional plunger rod will also be required. There are many variations on this but in my case I made mine out of PEX, nylon drywall anchors and a 2.5" 8-32 screw.

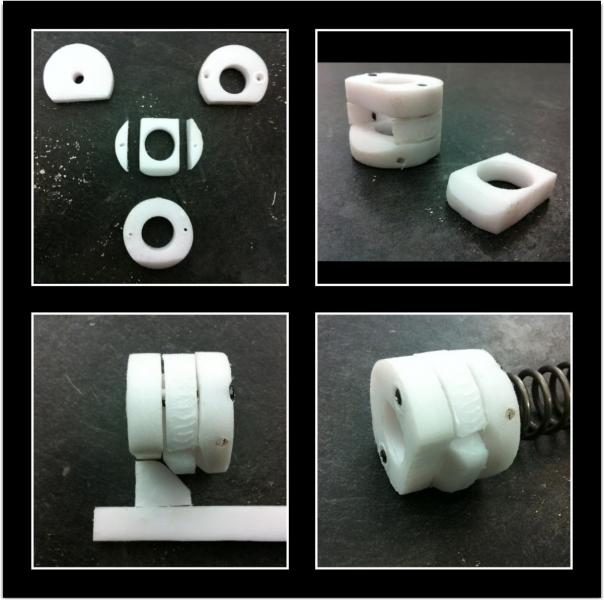

Using the thicker of the cutting boards, I cut out the 2 main supports, my catch, and what I needed to create my bushing/coupler. I used a 2 1/8" (54mm) hole saw bit for the larger disks and a 1 3/4" (44mm) hole saw bit for the smaller disks.

*Note that one of the bushing rings is made with the thinner cutting board.

SinceI knew I would be using PEX as my plunger rod, I cut out the appropriate sized holes using a 5/8" stepped drill bit, widening it just slightly after using a Dremel/rotary tool.

You'll note that in creating the catch plate, I cut off the two sides which are used as the guide and spacers. Please notice that the entire catch assembly has been cut with a 'slope' to accommodate the triggering system.

Let's move on to the plunger rod next. We'll come back the catch assembly as the creation of the plunger rod will make the rest of the catch assembly make more sense once it's created.

I used a 1 7/8" drain stopper as my plunger head as it fits perfectly into the 2" gravel vacuum tube. I cut both parts of the plunger rod out of PEX who's respective lengths were determined by my spring and it's fully compressed length. The length of the piece closest to the plunger head is 0.25" longer than the length of my spring fully compressed. The latter half is the rest of the length of the spring leading into the catch. Nylon Drywall anchors were screwed into the illustrated ends. The anchors must be new and unused as they need to 'bite' into the interior walls of the PEX. Both lengths are connected via a 2.5", 8-32 screw. Once it was screwed into one end, the head of the screw was sawed off. A 0.75" length of 1/4" vinyl tubing was slipped on to the screw as protection for the catch plate. Then the other length was manually screwed in by hand. This will actually require a bit of wrist strength to get it down so the notch is only 0.75". The pointed end at the tail of the plunger rod was made out of a scrap piece of nylon but it can be fabricated out of epoxy putty. It's secured via super glue and a set screw. It's purpose is to guide the plunger rod through the catch plate. However, this is optional. You could lengthen the end of the plunger rod to already exist through the catch plate. It will become clearer as you read on.

...Now back to the catch assembly.

Much like Zorn's Fal catch setup, I shortened the the rear end of the plunger rod by applying that length to the catch via a length of 3/4" aluminium. The length is also the approximate length of the spring fully compressed. *Again, this is optional. The purpose here is to shorten the overall length of the blaster as a whole. Otherwise, a full length plunger rod is all that's required.

I VERY carefully sized the hole in the spring rest to be a very tight friction fit with the 3/4" aluminium. Just as an extra measure, I also used Super glue.

With quite a bit of sanding, I was able to get the PEX plunger rod to sheath almost frictionlessly inside the 3/4" aluminium. It's important that the spring you use fits over the plunger rod AND the plunger rod sheath. It's also important to make sure that there is very little to no 'wobble' in this set up to avoid the spring 'kinking' and causing problems with the draw.

Above, you can see that this setup shortens the overall length by at least 4". The 4 extra inches that would have stuck out the other side of the catch has been integrated into the primed portion of the plunger rod.

*The spring I'm using is not a [k26]. It's a spring I found locally that is 12" long, has a full compression length of 4.5" and has a max load weight of 28kg (~62lbs.)

And now we move on to the "G-Spot"!

This is where things become reversed and inverted. Normally, what would normally be used as the plunger tube, now becomes the priming bar/tube (1.5" ABS). Instead of the plunger rod facing in, it faces out. By taking the catch out of its normal position, held static inside the plunger tube, and placing it in the priming bar, it becomes mobile. Integrating the catch in this manner solves the riddle of keeping a shotgun style pump action prime with in a compact Bull Pup configuration!

I know it seems complicated, but if you have or have made a Rainbow Pump, this will be easier to understand. If you take your RBP apart, simply turn the catch and plunger rod the other way. Bingo! It's that simple. Your 1.25" plunger tube becomes the priming bar/tube and the 1.5" thin wall most of you use as the priming sheath would now become the plunger tube. The only thing you need now is the shell.... more on that later on.

As you can see above, slots have been cut out of my 1.5" ABS. The main slot (the larger one) is there to allow the trigger room to travel along the priming bar without getting in the way. It's made just wide enough for the catch to 'drop'. The extra slots are purely aesthetic. The added length towards the plunger head, which is also the approximate length of the spring compressed, is not all that necessary but does offer assistance in guiding the G-Spot assembly along the plunger canal.

Below are more examples to help you understand the G-Spot better.

I used set screws to secure everything down. Since this will travel inside the plunger tube, you don't want screws protruding that can potentially scratch up the plunger tube walls. A good sanding to eliminate sharp edges and burrs is highly recommended.

The 2 most bottom pictures illustrate how the assembly looks primed.

Before we can insert this into the plunger tube, we need to create the bushing/coupler.

If you're using 1.5" thin wall as your plunger tube, a 1.5" coupler would make this a lot easier. However, since I do not have access to 1.5" thin wall, I used a 2" gravel vacuum tube. Which fits very snugly into a 2" VAC coupler.

*note - Even though I'm using a 2" VAC coupler, I could not use 2" VAC tubing for my plunger tube because 1.5" ABS does not sheath into it. But 1.5" ABS does sheath perfectly into the 2" gravel vacuum tube.

Shown below, the three disks I cut earlier, form the bushing plates for my make shift coupler assembly. I cut down my PVC elbows and wye to appropriate lengths to minimize dead space and so that the barrel could rest flush with the shell, once it's all put together.

The natural lip inside the 2" VAC coupler acts the perfect separator for the plates and ensures that they remain centred and square.

The elbow nests very snugly into the centre disk (top right) and is super glued and gooped in. Goop is used in great excess here to ensure a perfect seal. Since the disks war cut with a 2 1/8" hole saw, they have a very snug fit inside the 2" VAC. Once the whole thing was goofed and sandwiched together. I use set screws to secure the last plate.

Note how I carved both the disks and the coupler to be fitted around the elbow.

Now that we have the bushing/coupler assembly made, we can move on to the main plunger tube.

You've seen some of the pictures below before but here they are again because I know you don't want to scroll all the way up.

The only new picture is the one on the bottom right. It's just there to give you an idea of where we're going.

Although the plunger tube has already been cut, you can see the necessary slots that need to be made to allow for the priming assembly to function.

In the first picture, you can see how the assembly sits within the plunger tube in its relaxed state.

In the second picture, you can see how the priming assembly is seated in its initial state of prime.

In the third photo, you can see how the entire primed assembly is drawn back to its initial position, ready to fire.

The larger slots are to allow for the travel of the priming handle once it's attached to the priming bar. The drilled holes illustrate the positioning of the priming handle.

Important to recognize; the positioning of the priming handle must NOT be placed too close! I placed it as close as I could to the catch without having to cut slots that would interfere with the active portion of the plunger tube. You can see in the third picture that the plunger head rests just before the slots.

The only other slot that needs to be made is the one for the trigger slide so it can hook up inside the plunger tube to flick the catch. The G-Spot, if you will

.... If you haven't guessed by now, holding the trigger down while priming, you rub the G-spot in rapid succession allowing for 'slam firing'!

Above is just some more images of the main plunger tube with the necessary slots.

And now we move on to the shell.

For my Shell, I used 2" ABS. This is where those who are aesthetically inclined, can get as creative as they want. The main purpose of the shell is to house everything we have just created. It also gives a place to attach the main grip/handle. The only necessary slots to make in the shell are for the priming handle so it can attach to the priming bar and travel its necessary length (7"). And one for the trigger slide.

The extended slots I made are completely unnecessary and only serve to show off the internals. In fact, the priming slots don't need to be as wide as I made them. They only need to be as wide as the area that connects the priming handle to the priming bar. 1/2" at most I would say.

Your shell should be at least 1.5" longer than your internals so you can attach the 'stop' at the front of the shell that keeps the priming bar from shooting out the front. Think of it as the priming rest.

In order for the 2" VAC coupler to fit inside the 2" ABS, I needed to use my 2 1/8" hole saw to bore out the business end so it would fit inside. This made that area relatively weak so I solvent welded four strips of ABS as structural support.

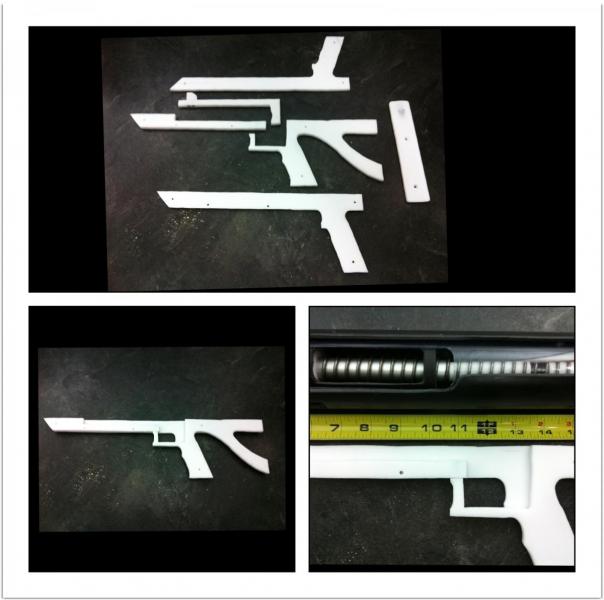

The main grip/handle, trigger and stock.

The main grip/handle, trigger and stock are made from cutting boards. The centre spine of the grip is made from the thicker cutting board (Kitchenade). While the two outer halves and shoulder plate are made from the thinner cutting boards (Walmart).

I measured out the length so the stock would be flush with the back of the blaster assembly. The grip/handle was measured out so that the trigger guard met up with the priming handle. For all intents and purposes, the trigger guard only goes as far as the plunger head after it has been primed. You can see below that the trigger guard lines up with the priming slot.

Here you can see how the spine is attached to the shell. Access ports were made to help secure the shell to the grip spine. *Note how the screws are counter sunk and flush so as not to injure the plunger tube. There are 2 screws in the front and 3 in the back.

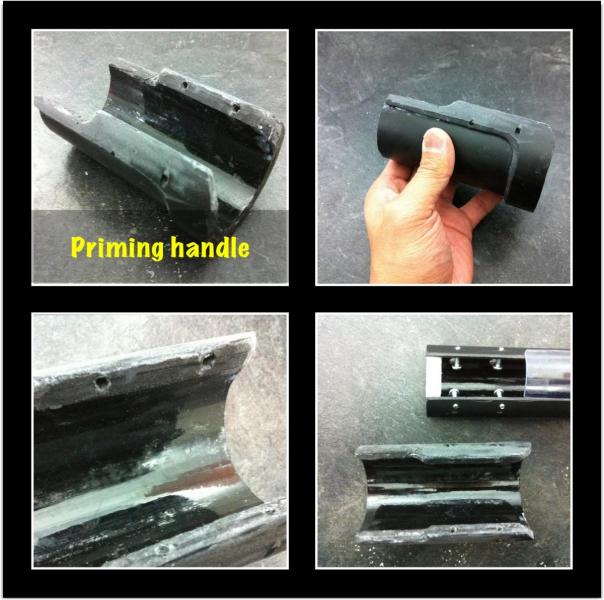

The priming grip/handle.

My priming grip/handle was made with 2 pieces of 2" ABS solvent welded together. I used 2 because I needed to create a wide enough surface to create screw ports so I could secure it to the main priming bar.

Once you put it all together, it looks like this:

Here it is against a Crossbow to show a relative size comparison.

Pros: All the criteria I set out for were fulfilled.

- Compact design under 24"

- Full 7" draw

- Regular shotgun style pump action prime

- Ranges well over 100'

- Looks bad a$$

- IS bad a$$

Cons:

- It's a little heavy by Nerf standards. But I'm pretty strong so I could deal.

- It can't be de-primed as one would normally de-prime a blaster except by blocking the barrel. Not really a problem since it's so compact.

- The cost. Since this took a lot of trial and error to get it right, I must have spent over $100 to build this. But if I were to do it again, I think the hard costs would still be around $70. However, I do live in Canada so these parts may be a lot cheap for most. Especially those in 'Merika.

- It took a loooong time and a lot of patience and elbow grease. Those of you with actual workshops, I envy you. My workshop is my kitchen and I only have basic hand tools. I have a rotary tool, hack saw, a palm sander, screw drivers and an X-acto knife.... and safety glasses.

POST MORTUM

After doing a lot of testing, I found that the 16" barrel I had initially designed this for, was too short. This obviously has to do with the plunger tube volume. I'm sure if this were down sized to 1.5" PVC thin wall. A 16" barrel would be just the right length, keeping this design under 22". Theoretically, with a full length [k26], this design could be kept under 20"!

I decided to make this a vertical grip since my spring is so strong.

I also added some very tactical elements like a cheek rest and padding for the shoulder stock.

Here you can also see how the VAC assembly is bolted to the shell.

...but I couldn't stop there. I also swithched out the top elbow for a T and added Blue LEDs.

As you can see, it lights up internally. Both within the barrel and the plunger tube. No air leaks and no loss of range or power.

...Ohh but wait. I made the cheek rest even more ergonomic. and improved the LEDs.

When the lights are off, it's even more impressive!

....AND

...since this is a feminine themed blaster, why not make it more pleasurable for her with the proper lube.

Sploooosh!!!!

Yes. I do use this as lube.

Firing Demo

LED Demo

Edited by makeitgo, 29 December 2017 - 01:40 PM.