Check this thread for more details.

Edited by cheesypiza001, 19 April 2010 - 10:03 PM.

Posted 09 August 2010 - 07:11 PM

Edited by jubjub517, 09 August 2010 - 07:51 PM.

Posted 04 December 2010 - 09:46 PM

Edited by Darksircam, 04 December 2010 - 09:53 PM.

Posted 24 February 2011 - 12:43 PM

![]()

Posted 22 July 2011 - 11:17 PM

Edited by KaneTheMediocre, 22 July 2011 - 11:21 PM.

Posted 29 July 2011 - 01:38 AM

Edited by KaneTheMediocre, 29 July 2011 - 01:40 AM.

Posted 31 December 1969 - 07:00 PM

Edited by Zorn's Lemma, 11 August 2012 - 08:43 PM.

Posted 25 August 2012 - 07:47 AM

Edited by Phoenix66, 25 August 2012 - 07:53 AM.

The more the merrier (except if you're a 10 year old with a foam sword. In which case - the fewer the better)

Posted 25 August 2012 - 07:20 PM

Posted 20 September 2012 - 10:43 PM

Edited by BOSS9, 22 September 2012 - 07:33 PM.

Posted 21 September 2012 - 12:46 AM

If two powerful is a problem then just go with one powerful. I guess this style of hopper will work even beyond three powerful..

Posted 26 September 2012 - 02:13 AM

Posted 20 January 2013 - 04:19 AM

Edited by KaneTheMediocre, 20 January 2013 - 04:21 AM.

Posted 25 January 2013 - 07:33 PM

Posted 04 February 2013 - 11:34 PM

Posted 05 February 2013 - 10:27 PM

Edited by Hammy, 09 February 2013 - 05:58 AM.

Posted 17 February 2013 - 03:31 PM

Posted 24 February 2013 - 07:53 PM

Posted 03 March 2013 - 07:06 PM

Edited by Birch, 03 March 2013 - 08:34 PM.

It's like a Hurricane ate a Tornado and shat out a Monsoon!!

Posted 03 March 2013 - 10:12 PM

Edit don't know why this is not working. Link: https://docs.google....AzKYH6y7Eo/edit

Posted 01 August 2013 - 12:06 AM

Everyone hates engineers because they listen to what you say and then think about it.

Check out my YouTube!

Posted 03 August 2013 - 08:07 AM

See you on the field, Alfatrooper My YouTube

Posted 03 August 2013 - 12:28 PM

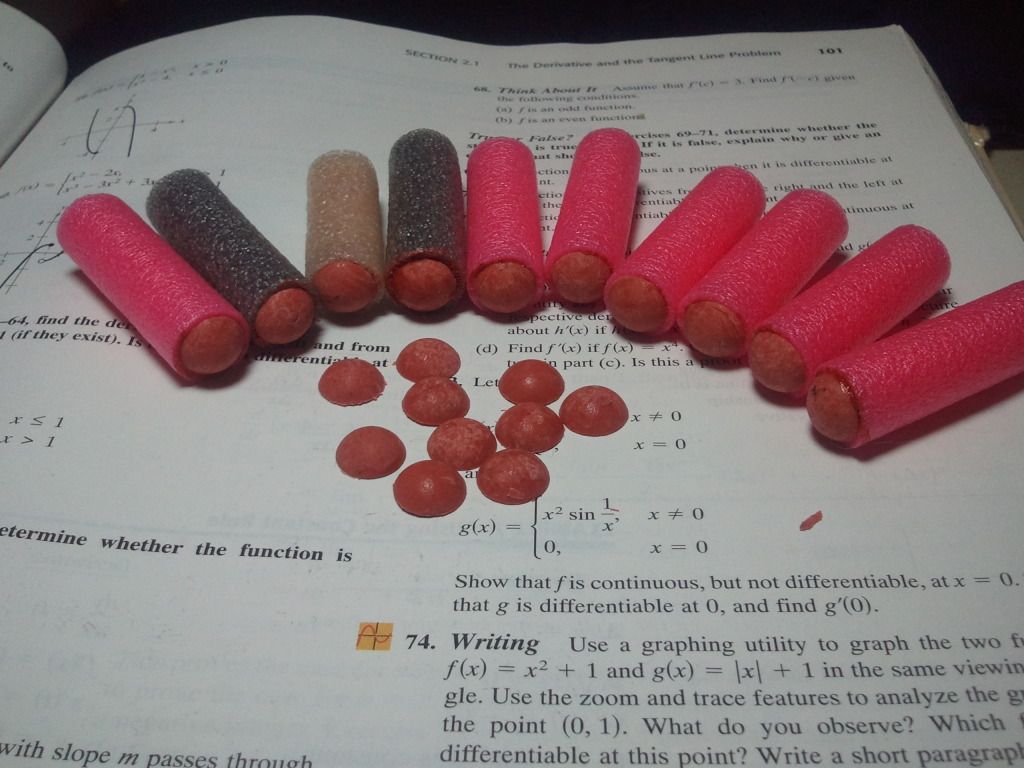

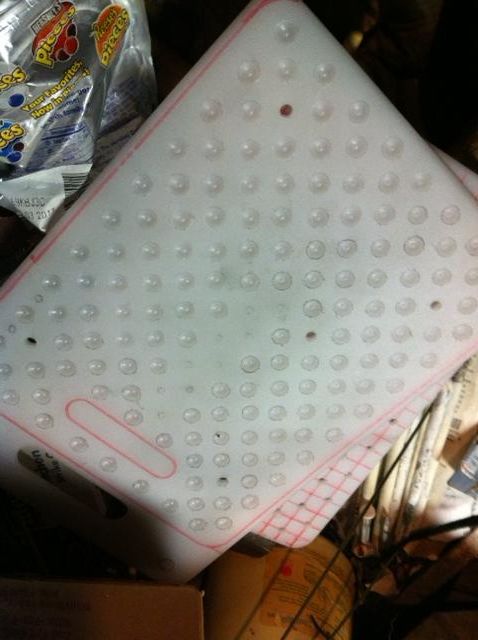

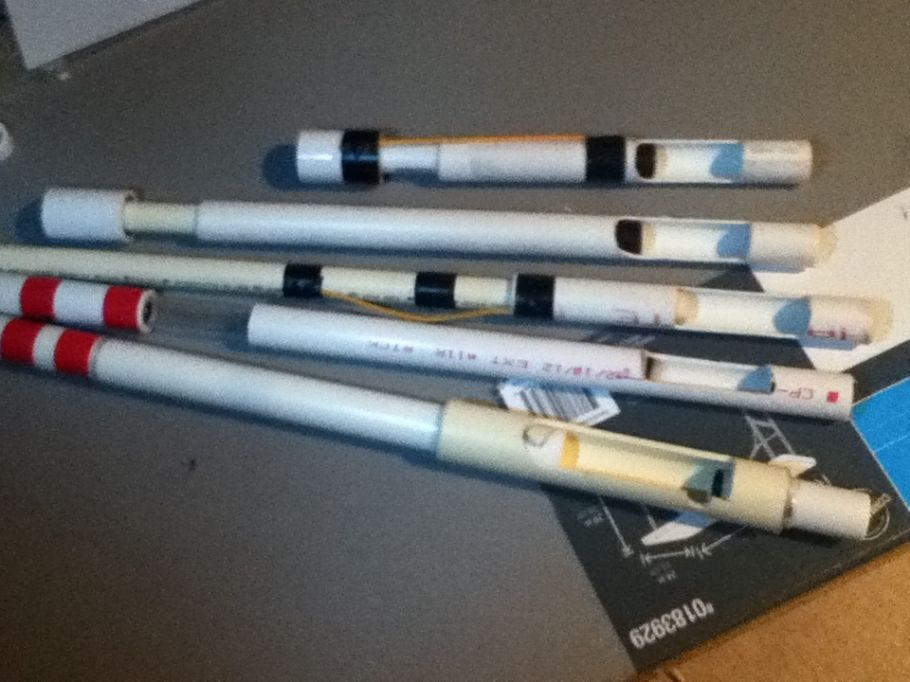

Use this thread for pictures of your dart or barrel designs/concepts that aren't yet ready to have a thread dedicated to them.

Do not use this thread to take pictures of your recreations of existing designs (e.g. "look at how pretty my slugs are!"), unless there was something unique to the smithing process.

0 members, 1 guests, 0 anonymous users