Now there's also a nerfhaven version of those instructions:

http://nerfhaven.com...43

The Aabow.

The Aabow was born after I made the Autobow

http://nerfhaven.com...showtopic=19632

and wished that I had a version for decent range and a hopper. So, I made a pneumatic version with a slightly modified (mostly shortened) snap head.

To make a bow, a cross of some sort is needed to hold the bow arms perpendicular to the plunger. The standard PVC cross is unfortunately not up to the job. The autobow, which uses fairly light tension to fire streamlines mechanically, has broken 2 crosses so far, so the tension I'd want for a SNAPoid needs something special. The first Aabow used a 1 1/4" T as the basis to make a sturdy homemade cross. I didn't like how bulky it was, or how it felt as a handle when I used the bow, so I changed to a different method. But, the T style allows a 5/8" hole (for CPVC) to be drilled through instead of a 1/2" hole (for PEX), so the T potentially has an airflow advantage. So, I'll tell you how to do both.

The T has 1 1/4"--> 1" bushings, where inner tube stop was removed, such that a 1" PVC pipe can fit straight through the T. In order to drill a 5/8" or 1/2" hole through the T, opposite the middle port of the T. In order to ger this straight, you will need a 1 1/4" --> 1/2" coupler. Put some Sch80 pipe in there, and a 1/2" hole can be drilled centered and straight, using the sch80 to guide the drill. Longer drills / segments of sch80 will work better, but even a short segment helps enormously. Centering a 5/8" hole is much more difficult. I did it by wrapping duct tape on the stem of the 5/8" spade, up to the ID of the sch80 (about 1/2"), so that the spade shaft was guided by the sch80 just like the 1/2" drill.

The more compact version reinforces the standard 1/2" cross with steel EMT conduit, which nests inside thinwall PVC. Put short thinwall stubs in the arm ports f your cross (Glue them if you're into that kind of thing), and stick some EMT through the thinwall and cross. Make sure that your piece of EMT is long enough for 1.5" or so to stick out of each side, as this is what the CPVC arms mount to. Then use a sch80 stub in the plunger / output port (they are indistinguishable at this point) to guide a 1/2" drill through the EMT conduit. Clean it up as best you can, then put a short piece of PEX through the hole, and use hot glue to seal around the PEX on one side. If you can do the same on the other side without ruining the port (This will be your coupler), do it, but I found it easier to just stuff hot-glue and wads of paper towel in the EMT on each side instead.

For ergonomics, I like to use a plunger rod guide that keeps the plunger rod from cocking sideways, and also allows me to put a T on the back of the guide for use as a handle. This requires a slotted piece of sch80, which I used a mill to create. I braced the sch80 against a bar of aluminum to prevent it from bending during the slotting process. The bar needs to be on the correct side for the direction of cutting and the rotation of the endmill bit to properly keep the sch80 straight.

The string goes through the slot, and through a hole in the plunger rod. To allow the string to push and rub on the plunger rod without slicing it, I used a ~2" long steel tube, 3/16" OD, ~1/8" ID. I got a 6' long stick of the stuff from mcmaster, and I use it on all of my bows, although early on I had to drill a hole through a piece of solid steel to do this (not fun). Anyways, the string goes through the steel tube, and a piece of straw is used on each side to shield the string from the ends of the tube. Then, the whole assemblage is covered in E-tape to make a nice padded finger-grip. Although the E-tape usually overlaps onto the bare string, the string should still be able to slide back and forth through the tube assemblage.

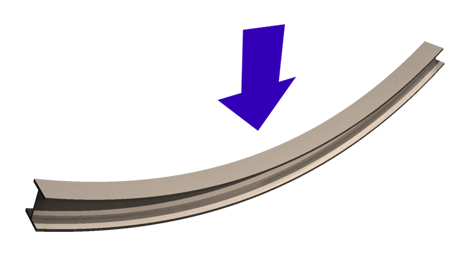

The bow arms are made of 3/4" CPVC, which nests outside the EMT. The CPVC varies from easily sliding over EMT, to being ruinously difficult to press over it. Make sure that you use CPVC from the same batch for both arms, or one arm may bend much more than the other:

Cut V-notches into the CPVC, and put it over the EMT, with the notched on the outside. Then, use a knot on the end of the string to catch it on the V-notch, and wrap a couple of times around the CPVC before putting the final end through the V-notch slot. The V-notch slot should be coplanar with the rest of the bow, such that the string is already pointed in the right direction, and doesnt need to bend around a CPVC edge to get through the plunger and to the other bow arm. Do this on both sides. You can vary the tension without taking the bow apart by changing the number of wraps on the bow ends, although this also changes the neutral point of the bow (the spot where the string would rest if there was nothing in it's way). A neutral point at about the middle of the plunger is ideal for performance, but if you want it to look more like a bow and arrow you can tighten the bow such that it's at the back of the plunger. The relationship between tension, neutral points, and string length depends on the length of the bow arms, so you may need to change this a few times to dial in the tension/shape that you want.

Finally, put a T on the back of the plunger guide. This acts as a handle, which makes it easier to hold the bow when it's drawn, and easier to hold the bow steady when it's being fired. Hopper clips are highly recommended for bows, so you should slap one on.

And here's a pic from my bow family reunion:

Ranges depend on bow tension. I usually keep mine firing about 80-90', but if you want it to do 120' or 60', you can do it with exactly the same method.

Edited by KaneTheMediocre, 18 January 2015 - 01:04 PM.