#26

Posted 17 August 2010 - 06:59 AM

#27

Posted 17 August 2010 - 07:31 AM

Hat's off to your awesomeness.

#28

Posted 17 August 2010 - 08:41 AM

You're not likely to be able to cut out the parts with just a dremel. And if you do it's going to take WAY more time to get them right.but I daresay that I could actually make this in my dorm room with just my drill, file, and dremel (plus whatever I can borrow)...

I still recommend a scroll saw or band saw in order to cut them cleanly enough for them to fit together.

Draft required tool list

+ Drill press or Power drill

+ Scroll saw or Band saw + coping saw

+ UNC #6-32 tapping bit

+ 1/2" OD or larger 90-degree Countersink bit

+ Wood-boring drill bit sizes: 1/2", 5/8", & 3/4"

+ Small round file

+ Flat file

+ Screwdriver

+ X-acto knife

+ Bolt cutters (for cutting spring)

Edited by CaptainSlug, 17 August 2010 - 10:41 AM.

#29

Posted 17 August 2010 - 10:00 AM

I think the aesthetics of the Plusbow are slightly better, but that's the only thing it has over this. Functionality, cost, design, and range are all better or identical.

I don't have really enough knowledge/experience/tools to make this thing, but I'd make this if I could.

Mad props 'yo.

And to the assholes posting write-ups before Slug has posted his; fuck you. If you spent a fucking YEAR designing a work of art, and someone pretty much took credit, you'd be very pissed off. He pretty much gave a sneak peek of it with a few details, and you decided to do what he's working on doing. Sorry if I seem like I'm kissing ass, which this probably looks like, but just use your mind before acting like a douche.

... to be able to get a better burst or sustained fire, rather than blowing the whole load at once.

#30

Posted 17 August 2010 - 10:51 AM

Also which size ring seal did you use that was 1/16" too small?

#31

Posted 17 August 2010 - 11:02 AM

1. Any multi-fluted countersink of a suitable diameter will work. I used one from a bit set and any of the cheap ones you can get at Home Depot will work.1. What would be the McMaster part # of an appropriate counter sink bit that can be used?

2. Also which size ring seal did you use that was 1/16" too small?

http://www.homedepot...catalogId=10053

Otherwise part# 3013A43 should work fine

The countersink bit is only used for one step and that one step can also be accomplished with a small round file. The countersink bit will simply produce a smoother finish and will cut the desired angle.

2. 9562K48, but I'm not going to recommend shaft ring seals or O-Rings in the write-up because they require you to make perfectly circular parts to fairly tight tolerances in order to get a good seal. The part number above requires that you make a 1.55" diameter core piece to stretch it over.

I'm still researching the best way to use that part# as a plunger head seal without requiring such machining accuracy.

One possibility is a stack of fender washers. But that would get expensive.

Edited by CaptainSlug, 17 August 2010 - 11:07 AM.

#32

Posted 17 August 2010 - 11:14 AM

2. 9562K48, but I'm not going to recommend shaft ring seals or O-Rings in the write-up because they require you to make perfectly circular parts to fairly tight tolerances in order to get a good seal. The part number above requires that you make a 1.55" diameter core piece to stretch it over.

I'm still researching the best way to use that part# as a plunger head seal without requiring such machining accuracy.

One possibility is a stack of fender washers. But that would get expensive.

Since 1.55" O.D. washers seem hard to find, I assume it would be possible to get 1.625" washers and decrease the O.D. by either using a bench grinder, lathe, or drill press. I have successfully mounted a washer on a 1" screw and put that in the chuck of my drill press and used a file to make it smaller.

The same method can be used to make perfectly round plastic pieces. For example, you could use a polycarbonate piece that was cut with a bandsaw to 1.6" diameter and "lathe" it down to a perfect circle of the right size.

#33

Posted 17 August 2010 - 11:19 AM

I'll figure that out after the write-up is done, then append the templates to include whatever extra/optional parts I come up with.

Edited by CaptainSlug, 17 August 2010 - 11:21 AM.

#34

Posted 18 August 2010 - 09:27 AM

http://captainslug.com/2-11.html

#35

Posted 18 August 2010 - 09:42 AM

[15:51] <+Rhadamanthys> titties

[15:51] <+jakejagan> titties

[15:51] <+Lucian> boobs

[15:51] <+Gears> titties

[15:51] <@Draconis> Titties.

[15:52] <+Noodle> why is this so hard?

#36

Posted 18 August 2010 - 10:21 AM

Everything else, as usual, is super pimp of course.

Kruger and Dunning (1999)

#37

Posted 18 August 2010 - 10:46 AM

Also the random 1/8" hole at the top of PRIME.

From the positioning, I'd say that port is to facilitate U3 dickwaving.

[15:51] <+Rhadamanthys> titties

[15:51] <+jakejagan> titties

[15:51] <+Lucian> boobs

[15:51] <+Gears> titties

[15:51] <@Draconis> Titties.

[15:52] <+Noodle> why is this so hard?

#38

Posted 18 August 2010 - 10:55 AM

1. I assume the two trigger pieces can be replaced with a 1/2" piece of polycarbonate?

2. Also was the coupler for the foregrip in the parts list? Is it just a normal 3" coupler?

3. If I may ask, where does the name 2-11 come from?

By the way, the video seems to link to the video on the +bow.

Thanks for the design, can't wait to build mine.

Edited by Lt. Stefan, 18 August 2010 - 02:14 PM.

#39

Posted 18 August 2010 - 11:49 AM

Also the random 1/8" hole at the top of PRIME.

From the positioning, I'd say that port is to facilitate U3 dickwaving.

No that's the one at ... oh that's the plunger tube? I wonder why people dump lube in there then...

Kruger and Dunning (1999)

#40

Posted 18 August 2010 - 03:20 PM

What's the 5/8" hole on CATCH for? Ease of assembly? Also the random 1/8" hole at the top of PRIME.

Everything else, as usual, is super pimp of course.

The screw that attaches FRAME1 to the 5-1/2" rod is right there, so the 5/8" hole is so that the CATCH piece clears it.

The 1/4" hole at the top of the PRIME piece is clearance for the head of the screw in the top of the FRAME1 piece.

1. Yes, if you have some. You could also just cut one 1/4" thickness trigger and use spacers/washers with it. But the extra width of the completed trigger feels better.1. I assume the two trigger pieces can be replaced with a 1/2" piece of polycarbonate?

2. Also was the coupler for the foregrip in the parts list? Is it just a normal 3" coupler?

3. If I may ask, where does the name 2-11 come from?

2. It's in the "optional" sub-section of the part list. It's a gravity-feed coupler rather than a SCHedule rated one so the ID is slightly smaller, as is the wall thickness.

3. Because this design goes to 11

Edited by CaptainSlug, 18 August 2010 - 03:47 PM.

#41

Posted 21 August 2010 - 03:29 AM

#42

Posted 21 August 2010 - 06:35 AM

After I acquire the money, I am going to make one.

Again, Good Show Old Boy.

Venom: Haven't we all?

#43

Posted 23 August 2010 - 09:01 PM

For those of you with

BIG MEATY CLAWS

The GRIP-SPACER piece can either be lengthened by 3/4" or just flipped around to give you more space on the back of the grip.

I left plenty of room for adjustment of the stock by providing several ways for it to be attached and adjusted.

Fore-going the trigger guard and step in the GRIP halves also improved this issue that a couple people had with the +bow grip. I wanted to make the grip as minimalistic as possible to make it easier to machine, but could only go so far without compromising its function.

Customizing the GRIP halves on this blaster will be significantly easier since it involves fewer parts. The only requirements on the GRIP halves are the placement of the drilled holes.

Edited by CaptainSlug, 24 August 2010 - 08:40 AM.

#44

Posted 26 August 2010 - 08:57 PM

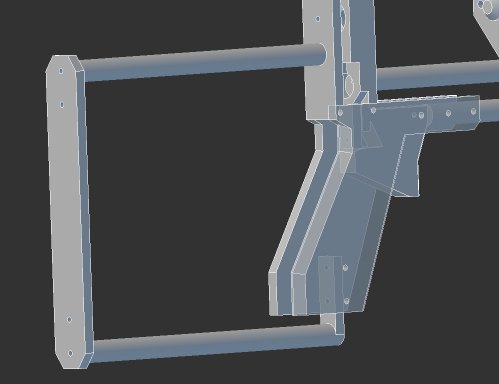

How tight is the FOREGRIP piece supposed to be around the plunger? The ones I cut out fit only when stretched, and do not slide very easily. Is this okay?

#45

Posted 27 August 2010 - 09:53 AM

I've gotten to building some, and as of now only have one question.

How tight is the FOREGRIP piece supposed to be around the plunger? The ones I cut out fit only when stretched, and do not slide very easily. Is this okay?

The pump handle on mine slides freely with no friction. The only resistance is created by the spring and return band.

#46

Posted 27 August 2010 - 09:59 AM

The pump handle on mine slides freely with no friction. The only resistance is created by the spring and return band.

Then I guess that piece needs to be cut inside the lines to fit on the plunger tube. Thanks.

#47

Posted 27 August 2010 - 04:50 PM

The inside line on the Foregrip frame piece is the only place where I would recommend centering your blade on the line when cutting it. Yes it should be able to slide freely on the outside of the plunger tube.The pump handle on mine slides freely with no friction. The only resistance is created by the spring and return band.

Then I guess that piece needs to be cut inside the lines to fit on the plunger tube. Thanks.

Edited by CaptainSlug, 27 August 2010 - 04:51 PM.

#48

Posted 10 September 2010 - 02:16 AM

#49

Posted 15 October 2010 - 10:13 PM

-foregrip addition

-needs bobbin and spring

#50

Posted 16 November 2010 - 06:46 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users