Write-up V1.0

Mirrored at Instructables

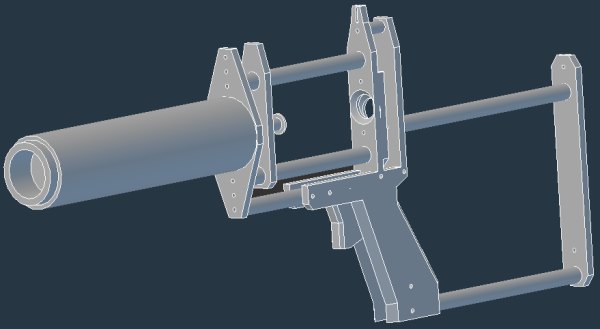

Plunger draw: 4.5 inches

Plunger volume: 14.5 cu in

Plunger tube length: 8.5 inches

Spring load when primed: 30 lb

Main project goals

+ Half the machining time of a +bow

+ Half the material cost of a +bow ($40 or less)

+ Reduced plunger stroke length

+ Increased and variable plunger tube volume

+ Fewer parts

+ No "face rape"

+ Made from less than one square foot of a single thickness of polycarbonate

+ Easier to disassemble

+ One or fewer internal cuts required for completion

+ Easily upgraded with an optional pump-action foregrip

+ Stock is optional

+ Wider machining tolerances for most of the parts

Essentially I wanted to improve upon what has made the +bow so venerable, but up the stakes while starting on a clean sheet of paper.

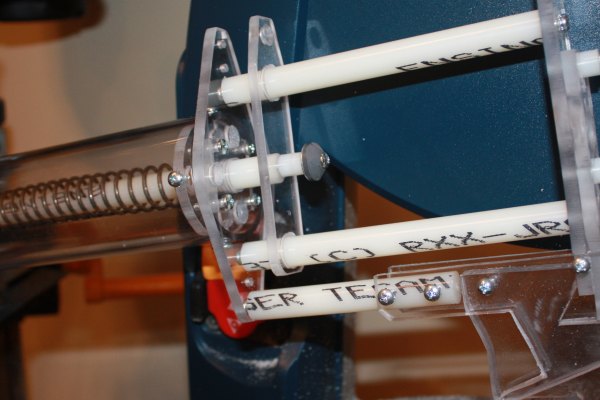

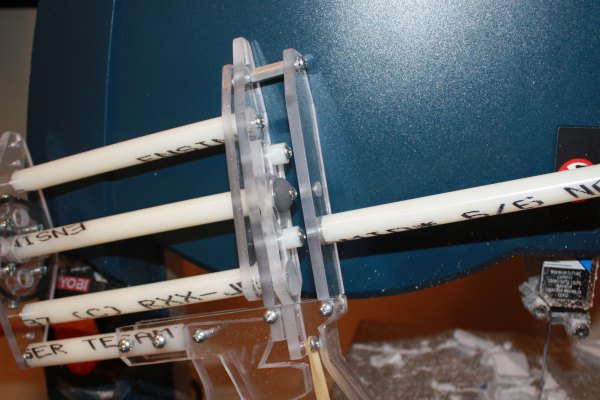

The plunger tube has an inner diameter of 2 inches with 1/8" thick walls allowing it to be structurally independent.

The catch on this homemade is at the end of the plunger rod, rather than being notched into the plunger rod itself. This not only makes machining the whole thing easier, but it also means that there is no top or bottom side to the plunger rod.

The plunger rod, catch, and priming handle are in an enclosed area. The plunger tube and plunger head can be removed by unfastening 5 screws.

Because of the configuration of the parts, the plunger tube and plunger head can be replaced with a smaller or larger diameter set of parts. The plunger stroke can also be lengthened or shortened by equally increasing the length of the plunger tube, 1/2" frame rods, and plunger rod.

Rather than being capped off by a bushing, the end of the plunger tube is capped off by half of a 1-1/4 coupler wrapped in 3 or 4 layers of e-tape. This allows several different bushings to be used for single 1/2 barrels, 3/4 pipe breeches, or large shotgun attachments.

It may take me a week or two to make a duplicate working example in order to compile a complete write-up. I've had a very busy year and little time to devote to this.

I would also like to point out that I was unable to find any ring shaft seals that would fit this size of polycarbonate tubing. The two nearest sizes are either a 16th too big or too small.

Edited by CaptainSlug, 24 August 2010 - 02:26 PM.