Is there any particular reason you needed to make such a complicated breech?

It does not jam and it shotgun loads this way. If this breech is complicated and you guys can think of a simpler method then do it up and show the world. It would be a step forward. Lets see now, who is good at improving my work? Well there is this one character who thinks he can. Nah he probably cannot do it.

You're on. I mean that in an as friendly way as possible.

So, I was under the impression that a lot of people used these kinds of breeches. Apparently I was wrong. Angel would definitely know about them if that was the case. If, and only if, this isn't common practice, I'll name it the Tantum breech. But if not, then this is just another breech write-up. I'm not about to name something that everyone already uses. And it can shotgun load and it doesn't jam. Yay!

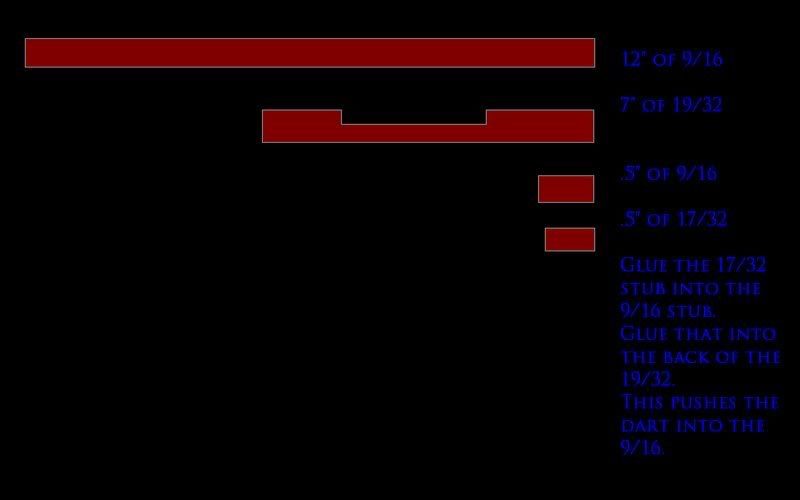

This is more of a collection of pictures then a write up, but I think its pretty self explanatory.

Breech View:

Barrel Sticky-Outy View:

The next part is of a second slot and a little plastic thingy I glued on to prevent the barrel from being able to be pulled out.

Not-Pull-Outable Mech View:

The next set of pics is of the flares that I put on the end of the 19/32 to allow shotgun loading and so the dart is pushed into the barrel as one closes the breech.

Flare View:

Now to answer some questions beforehand that I know will come up:

I'm using thinwall because you can't fit e-tap between regular 1/2" PVC and 19/32 brass. I know some just nest it directly, but there's still some wiggle room if you do it that way, and I'm obsessive compulsive about straight barrels, a la my longshot, if you saw it.

The coupler is there midway through because I didn't have a long enough piece of 1/2" thinwall.

What do y'all think? Especially you, Angel. Do you like it?

Edited by TantumBull, 21 July 2009 - 05:26 PM.