After a lot of thought and experimentation over a few weeks I decided on a combination of two off the shelf valves for semi-auto functionality. The advantages of this assembly are that it's efficient, powerful, relatively small, and very easy to build. The main disadvantage is the cost. I spent probably $45 alone on the assembly, which isn't too bad but more than I'd prefer.

The gun I built is for test purposes and will be recycled later. I don't have any stefans at the moment so I have tested with streamline darts. The range test was inconclusive because the streamline darts crap out after about 15 to 20 feet due to drag. It shoots streamline darts through cardboard at close range. If anything it's too powerful and I'll have to tone down the pressure from its current 40 PSI, reduce the pressure chamber volume, and start using weighted stefans to get use of the system.

To understand how the assembly works I'll link to guides explaining the individual components first. Spudfiles' page on QEVs explains their use and CaptainSlug had previously explained directional control valves. Read those pages and have a good idea of how those valves work before trying to understand how the assembly works.

The above image shows the entire test gun. I am using an HPA tank as the pressure source.

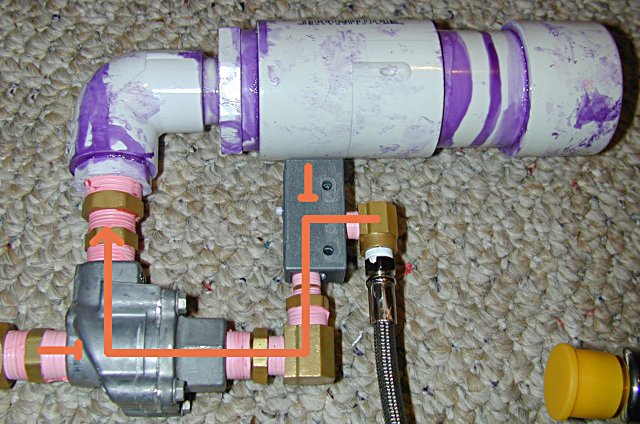

This image and the one below use the same symbols CaptainSlug used in his directional control valve thread. The flat portion indicates flow stops there. I added arrows to show what direction the flow will be going in.

When the button on the directional control valve is not pressed the flow from the HPA tank goes through the QEV and into the air chamber. No air is leaving through the barrel or the exhaust port of the directional control valve.

When the button is pressed a few things happen. The system stops accepting air from the HPA tank. The air in the tubing between the QEV and the directional control valve is vented through the directional control valve's exhaust and that causes the QEV to exhaust its air out the barrel.

Basically, the chamber is filled when the trigger is not pressed and the chamber is emptied when it is depressed.

I'll be looking to get a video up to show how quickly the system works... it's really quite impressive. I can get through perhaps two cycles per second with this assembly. I was a little worried that the directional control valve I had wouldn't pilot the system well enough because they're designed for low flow but I think it's nearly perfect for the system.

I'll also get a parts list for the valve I have above soon too... to get you started the QEV and directional control valve are both available from McMaster-Carr and are part numbers 6646K11 and 6464K11 respectively.

Any questions, comments, hate speech, etc., are welcome. Normally I'd wait until I finished a gun to post about a development but I thought this valve assembly is too valuable to keep secret. Hopefully this will spark more development in air pressure guns.

Edit: To those who want to point out that my teflon tape looks excessive, that's what happens when you use the pink tape. It's only two layers if even that. The color and thickness of the tape is what makes it look obnoxious.

Edited by Doom, 09 March 2013 - 02:44 PM.

Added a link to replace an old broken one.