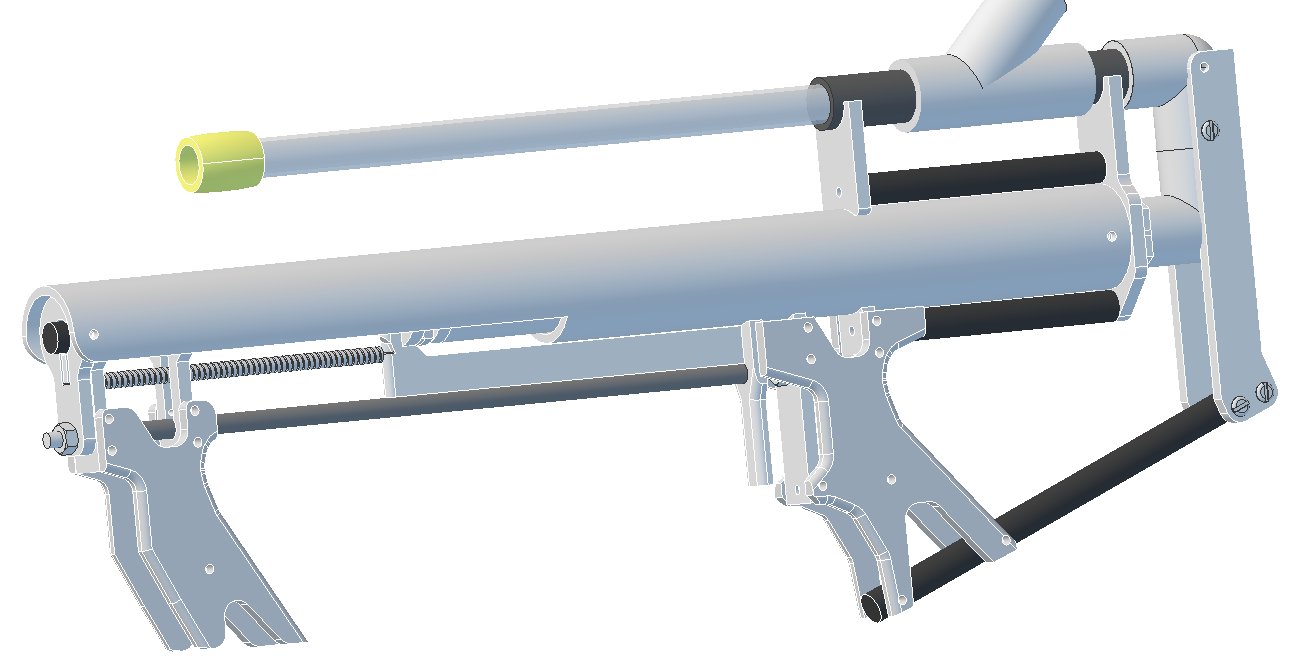

So I just moved into my college dorm and was unable to finish this blaster. Sincere apologies to Slug.

I cut out all the essential parts and got a pretty good feel for how it would eventually come together. My notes/suggestions are listed here.

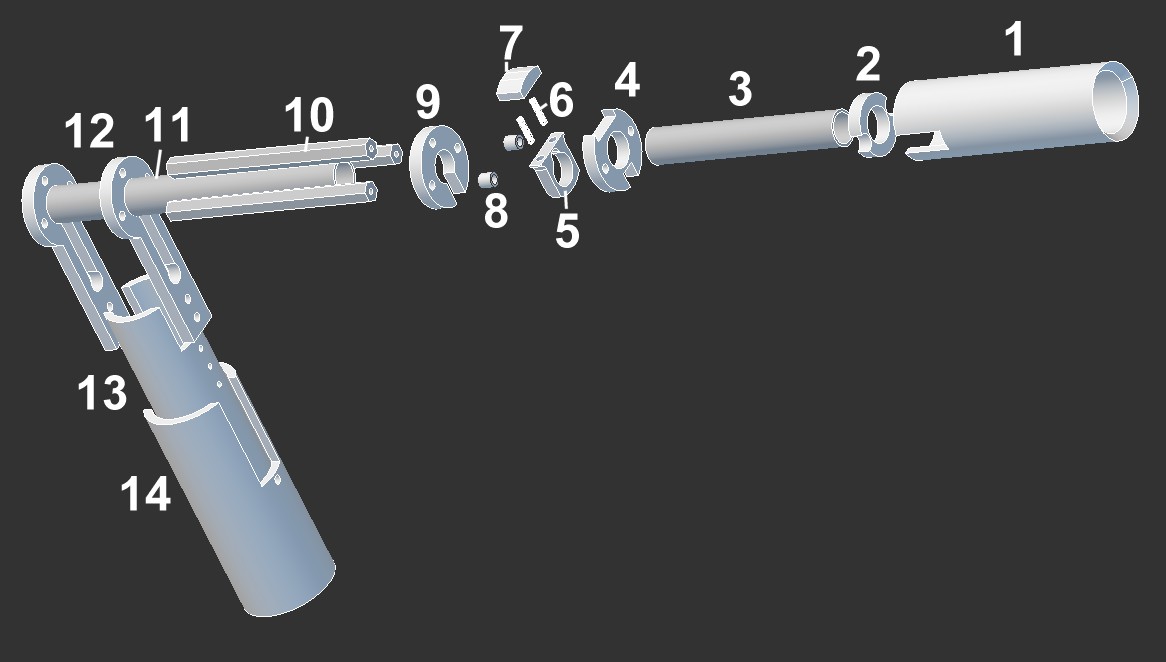

- The spacer designated "FRAME3" should be fitted over the 1/2" pvc stub connecting the bushing to the bottom elbow. The original (or at least how I interpreted it) is designed to be fitted between the 1.25" pvc body tube and the hexagon protrusion of the front bushing (thus riding on the 1" insert of the bushing). For modulability (removal) and adaptability to differing versions of bushings, the center hole should be the OD of 1/2" pvc. That said, FRAME3 needs to be SUPER STABLE and very difficult to move as a the handle and trigger are held up by it in the back.

- I took the liberty of dicking around with the assembly of the inner catchplate and shuttle. I used really long bolts to attach SHUTTLE1 and SHUTTLE2 with a nuts inbetween to secure them. Those bolts then attached to the standoffs that connected to the catch.

- The bottom metal threaded rod is super sturdy and It really holds everything together. Very cool.

- I ran a ziptie through the handle and around the body tube because I want shit to stay together. This is probably a reflection of my mediocre machining skills over the design and I also like to over-engineer things.

- I filed the shit out of the trigger as it gets some interference with the shuttle pieces and the catchplate. All points of friction were filed. The strength of the trigger spring is also key to making sure the trigger stays aligned. Stronger is better. That said, I worry about it.

- I used countersunk screws to attach the 1" spring anti-kinking pipe to the first 1" catch circle. I believe slug suggested using epoxy or some adhesive to attach it (as it theoretically wouldn't have much/any force to deal with), but I don't want it fucking up.

- I really dislike the open-plate handles. I realize it wouldn't be a huge hassle to put in wood or something between them, but fuck they are just killin' me. I sanded and filed the hell out of them, but damn.