- 16-inch barrel made from schedule 80 PVC and polyethylene tubing

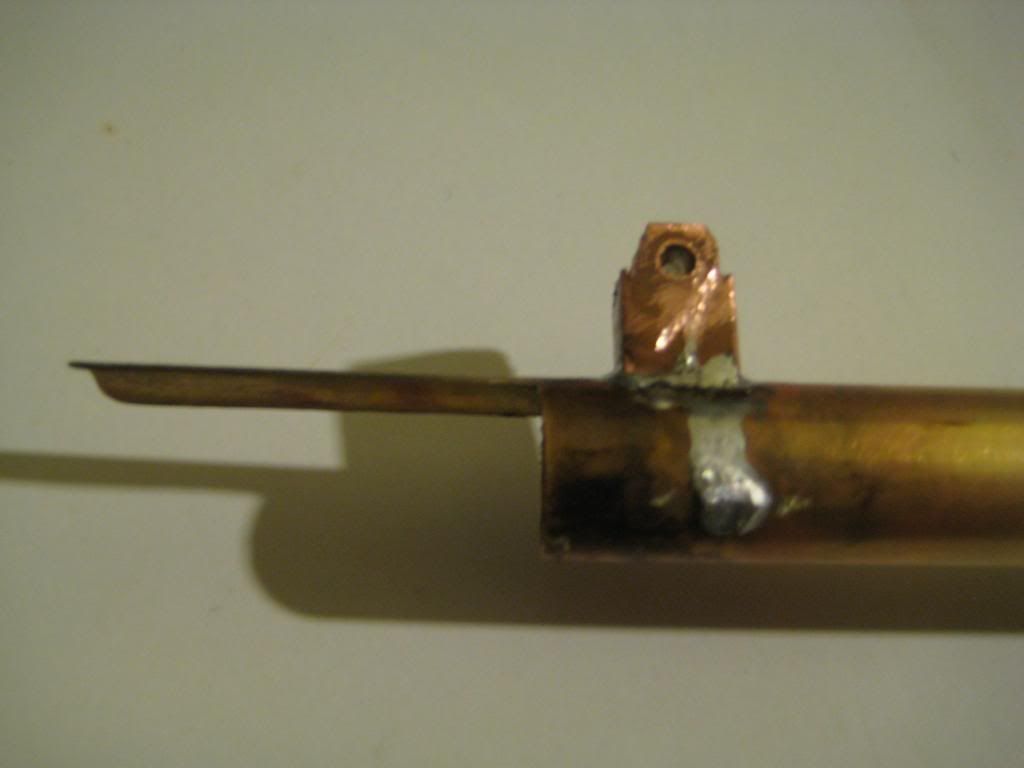

- Plugged pump

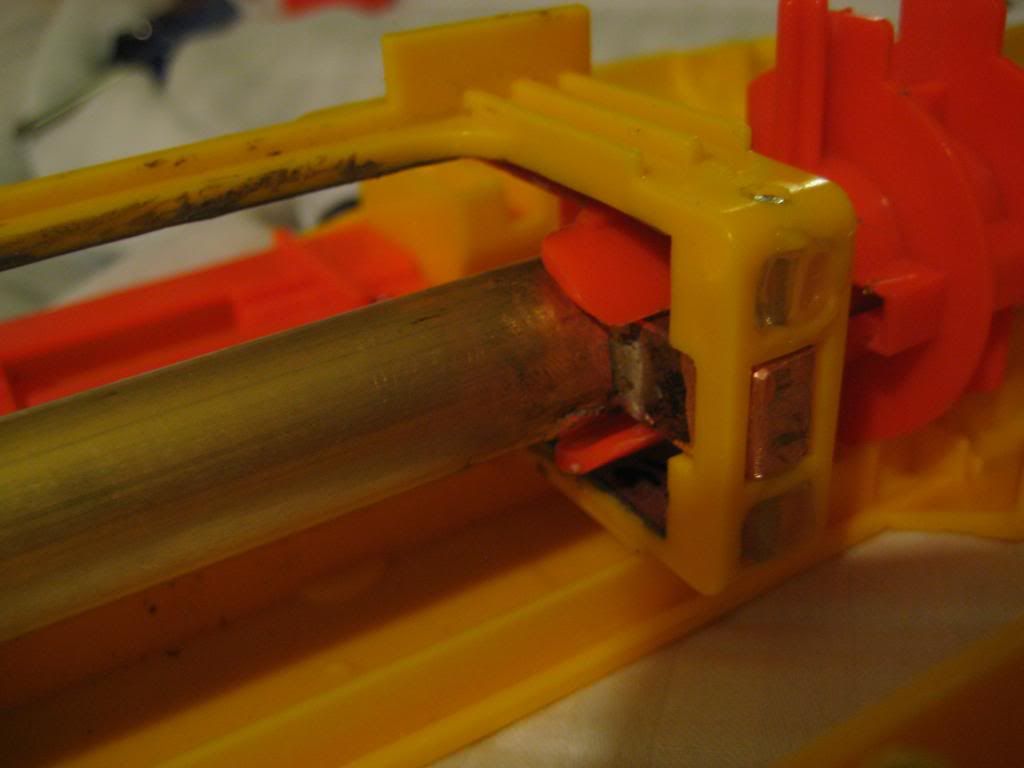

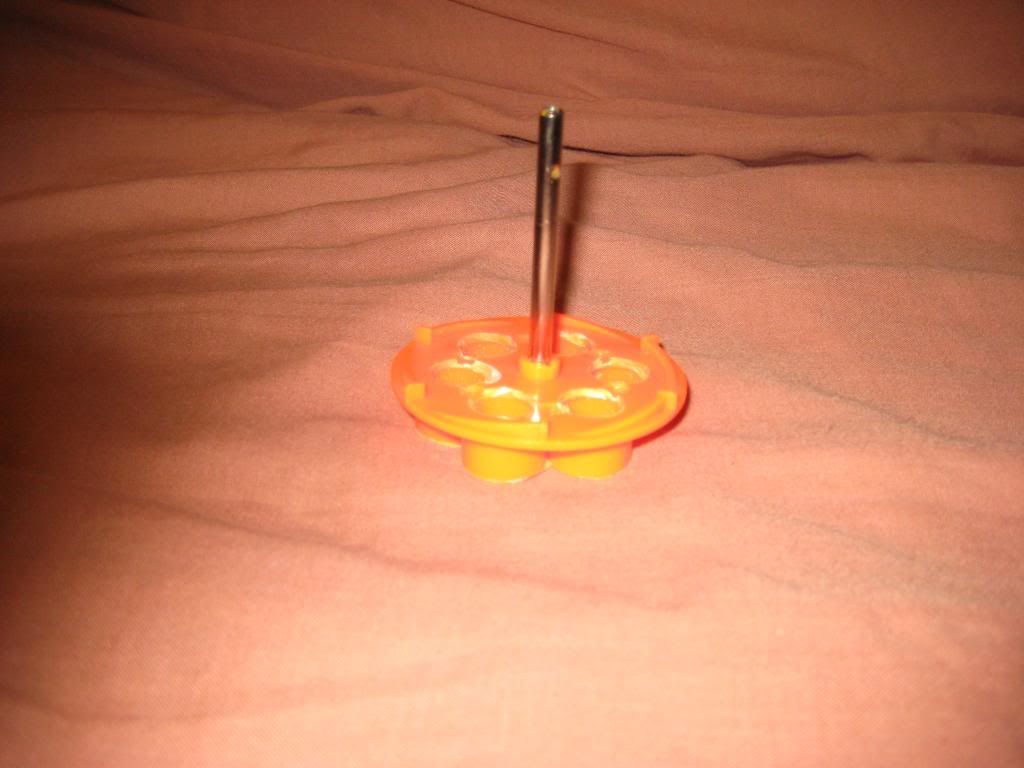

- Skewed hopper for better visibility

- Only the wye is glued in place, allowing for interchangeable barrels and hoppers

Check out the full write-up at my blog: http://nerfbuff.blogspot.com

Cheers!

~T da B

Posted by

Posted by