just cut it out and join the wires..

- NerfHaven

- → Ultrasonic2's Content

Ultrasonic2's Content

There have been 12 items by Ultrasonic2 (Search limited from 19-December 96)

#360902 Stryfe voltage mod questions

Posted by

Ultrasonic2

on 03 July 2017 - 07:15 PM

in

Modifications

Posted by

Ultrasonic2

on 03 July 2017 - 07:15 PM

in

Modifications

#360900 Stryfe voltage mod questions

Posted by

Ultrasonic2

on 03 July 2017 - 06:28 PM

in

Modifications

Posted by

Ultrasonic2

on 03 July 2017 - 06:28 PM

in

Modifications

Instead of imr batteries, I've decided to go with ultrafires as they are much cheaper. I know that they are no where near as good as imrs, but I can't spend a lot on batteries now... It looks like I will use two ultrafires and two dummy batteries (roughly 7.4 volts). I just have four more questions: 1. For bypassing the thermistor, the goal is to make the two wires touch, right? So I can either twist them together, or connect them with a wire right (e tape a wire in place)? 2. Would running 7.4 volts hurt the internals drastically? I don't want burnt wires or anything... Although, the motors will probably burn out eventually. 3. How long do my internals have before dying? 4. What fps should I expect with 7.4 volts?

Thanks!

Bubba

Here we go i tested the stock stryfe at different voltages...

http://nerfhaven.com...erent-voltages/

Also Ultrafire batteries tends to be FAKE, claiming massive capacity when i fact they are WAY worse that other realistic capacity batteries.

#355628 Custom Motor Cage

Posted by

Ultrasonic2

on 18 August 2016 - 10:34 PM

in

Modifications

Posted by

Ultrasonic2

on 18 August 2016 - 10:34 PM

in

Modifications

And arduino will do exactly what you want, minus the trigger part. That's caused by the rev switch mechanism, unless your really confident with your modding skills I would just let that be.

Yeah man i've just done the code 400 lines.

Powered from a 4s

Features

- Hig Low mode... 3s mode or 2s mode . this is cos 3s has to much power when using close range at 5 year olds.

- When the trigger is pulled and you have NOT pulled the rev motor switch it will apply 4s for like a second to rev up the motors then start firing

- When the trigger is pushed it will apply 4S to the pusher for like 0.5s to get the shot off as soon as possible ( 0.5sconds might be to long )

- Auto fire mode as normal

- Semi auto mode.. Assuming you haven't pulled the motor rev trigger it will keep the fly wheel spinning for upto 5 seconds after the shot to ensure the motors dont start slowing down between trigger pulls.

#355549 Custom Motor Cage

Posted by

Ultrasonic2

on 15 August 2016 - 07:51 PM

in

Modifications

Posted by

Ultrasonic2

on 15 August 2016 - 07:51 PM

in

Modifications

"This cage was deign over the course of about 3 months with consolation from from Ryan from Make Test Battle and Tom from Foam Data Services as well as others."

"Dude, I'm sorry you are so hung up on flywheels that you feel like you need to make this. Really, really sorry."

Thanks guys..

Not sure whats wrong with fly wheel blasters other than the sound.

I have some plunger ones but i'd take an auto one any day .. with a plunger one you have one shot then you have to cock it and that throws of your aim.. Auto you just fling them till you hit them... Also much easier when your on the move shooting with one hand

#355543 Custom Motor Cage

Posted by

Ultrasonic2

on 15 August 2016 - 05:45 PM

in

Modifications

Posted by

Ultrasonic2

on 15 August 2016 - 05:45 PM

in

Modifications

So unfortunately my Rapid Strike died today .. Some kind of electrical fault. not sure what yet.

I should just buy another second hand rapid strike OR a new Hyperfire BUT the Hyperfire is just to hideous to look at and is huge so i can't bring myself to buy one.

Im considering replacing all of the logic within the RS ( now broken ) with an arduino which enables me to perform a few task i've always felt the RS should have.. EG pull trigger when fly wheels are stopped ... it starts the motors then starts shooting. And to OVER volt (14 +) all the motors for like a second to reduce spool up time.

The above should all be do able BUT the rapid strike is not accurate at all my sons Raven is much better. I see the new Hyperfire has a new cadge which has offset wheel to help rifle the rounds. I dont believe this is a new idea but it's new to Nerf. I really want a off set cage to help with accuracy.

Does any one know if the Hyperfire's motor cage will drop right into the RS ?

Also what i really want to know is if any one has a 3d model of the cage that i could 3d print i know there are these metal ones BUT these are incredibly expensive especially if you include the postage to New Zealand. so i'd just like to 3d print some.. Also a while back someone in germany tested what was the right offset but i can't find that anymore

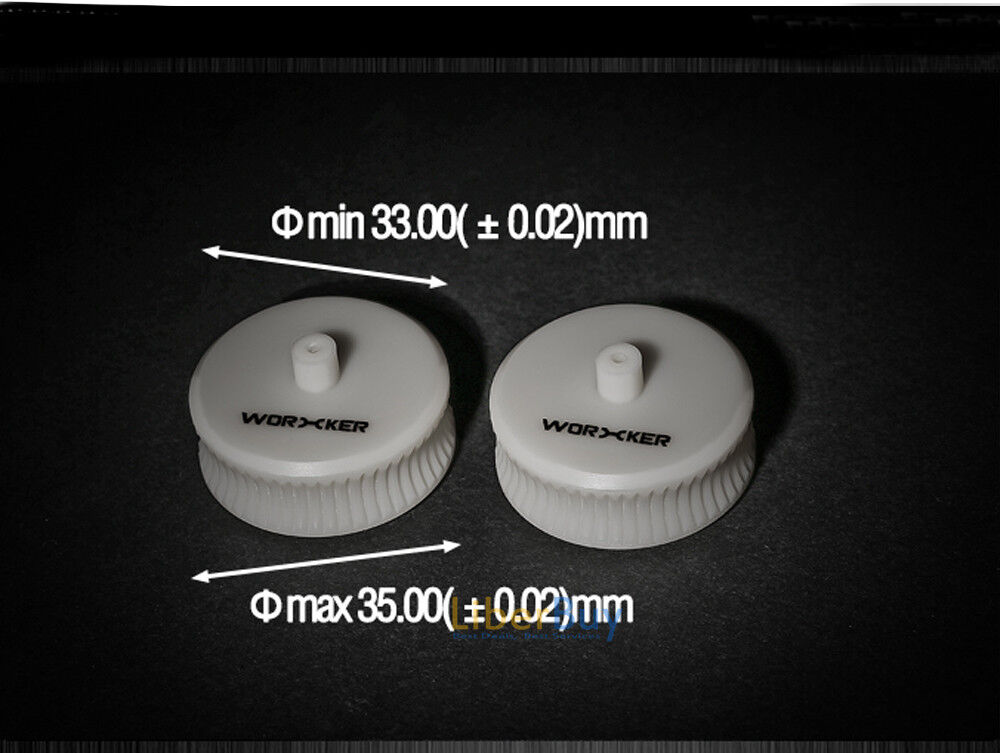

#349433 Worker flywheels reviewed

Posted by

Ultrasonic2

on 04 November 2015 - 05:18 PM

in

Modifications

Posted by

Ultrasonic2

on 04 November 2015 - 05:18 PM

in

Modifications

This test was using the stock motors then?

People thought that the "serrations" might increase air friction (thus slowing the motor down) and/or actually decrease dart grip.

If the problem is the former, more torque from the motor might help. If it is the latter, then these really are useless except if you are in desperate need of replacement flywheels.

Anyway, thanks for testing.

Yes stock motors at 12v

I believe others had predicted that these would not increase FPS because there is ultimately less friction area between the dart and the wheel now thanks to the serrations. I would really like to test ones without the serrations.

#349421 Worker flywheels reviewed

Posted by

Ultrasonic2

on 03 November 2015 - 05:26 PM

in

Modifications

Posted by

Ultrasonic2

on 03 November 2015 - 05:26 PM

in

Modifications

Nice work, it's always good to see someone verifying a performance increase like this, instead of making half a dozen changes and then demonstrating on youtube that their blaster 'shoots harder'. Did you record any data in a spreadsheet or anything like that? It would be cool to see photos of your testing rig, if you still have it set up.

YES youtube videos wind me up. How is that testing. When hand held and measuring it and saying "look, now it shoots further" I'm like you could not keep the blaster at a constant height or angle to get an where near accurate data.

The next thing i want to tackle is Motors. I've bought a few motors which people believe to be better than stock but in my testing they are not.

I'm in the design phase of making a 130/180 Dyno. So i can see how quickly the different motor actually wind up ( torque ) and to what RPM and of course the all important factors of at different voltages cos of the different batteries people use

#349419 Worker flywheels reviewed

Posted by

Ultrasonic2

on 03 November 2015 - 03:59 PM

in

Modifications

Posted by

Ultrasonic2

on 03 November 2015 - 03:59 PM

in

Modifications

I bought two sets of these. One set to go in my sons Raven and one set to go in my Rapid Strike.

I’m quite particular about ensuring that testing is performed in a controlled manor.

For this sake I have a high amp adjustable PSU which I soldered onto the Raven for testing to ensure I had exactly the same voltage (12v) thought my testing. I also have a chronograph to check for changes in FPS

The flywheels are very well made BUT unfortunately the Raven lost between 6-10 FPS using the Worker flywheels over using the stock flywheels (With nerf dart residue on them)

So it looks like i wasted my money on these and will return to the stock wheels

#349228 Stryfe Resistor

Posted by

Ultrasonic2

on 21 October 2015 - 05:55 PM

in

Modifications

Posted by

Ultrasonic2

on 21 October 2015 - 05:55 PM

in

Modifications

Hey guys,

Will removing the resistors from the Stryfe make any differences?

yes it does make a difference if you remove ALL of the resistors

i tested this

http://nerfhaven.com...showtopic=25744

#344642 Flywheel Physics Explained

Posted by

Ultrasonic2

on 28 January 2015 - 02:09 PM

in

Modifications

Posted by

Ultrasonic2

on 28 January 2015 - 02:09 PM

in

Modifications

I will relook at making new wheels but it's clear i need to make a new housing too as the motors are not parallel and therefore the wheels aren't too. Machining new housing would fix this and reduce the deflection when the dart gets squeezed. Also it would allow me to make make large diameter wheels and make them close or further apart. The only problem being is that machining new housings that are correct would be difficult. Oh yeah other benefits is that machined wheels should be more round.

Doing all this is the only way to increase FPS so maybe i can look into this.

#344617 Flywheel Physics Explained

Posted by

Ultrasonic2

on 27 January 2015 - 02:16 PM

in

Modifications

Posted by

Ultrasonic2

on 27 January 2015 - 02:16 PM

in

Modifications

I have dome some testing and have found it's pretty much possible to reach the RPM limit with the stock motors at high voltage (not that they would last to long) So excluding spoolup time and life expectancy there seems little point in changing the motors when you can simply crank up the voltage at a far lower cost.

Now i have been considering making new wheels to increase the friction. However This also seems pointless because with the stock motors at high RPM it's already destroying the ends of the darts. I would think increasing friction would increase acceleration leading to increased wear on the darts making this option out of the question.

So i would think there is a practical FPS limit in a blaster like this

#344592 Stryfe FPS at different Voltages

Posted by

Ultrasonic2

on 26 January 2015 - 04:24 AM

in

Modifications

Posted by

Ultrasonic2

on 26 January 2015 - 04:24 AM

in

Modifications

Actually it seems i can't attach images so i can't show you.

Here are the results

100% stock Stryfe

4.8v (4x1.2) = 52.5 fps

6.0v (4x1.5) = 63.4 fps

9.0v (1x9v) = 85.7 fps

Now with the locks and resistors removed but stock motors

4.8v (4x1.2) = 56.5 fps

6.0v (4x1.5) = 69.3 fps

9.0v (1x9v) = 90.4 fps

11.1v (3x3.7)= 99.7 fps

14.8v (4x3.7)= 96.8 fps

The interesting thing is the reduction at 14.8 the rounds just vary so much on a vertical plain that it was impossible to get one through the chrono without it hitting it.

Also based on the range test i could only get 1 out of a lot of shots to travel further than at 11.1v. It's possible that all of this would be "better" if an extended barrel was added.

I presume the fundamental problem is that at this voltage the motors are unable to keep their RPMs anywhere near the same to ensure a consistent vertical plain.

At this point i would go with three 3.7 14500 batteries (11.1v) and one spacer OR the "Safer" option of possibly using four 14500 lifepo4 3.2v (12.8v) but i didn't test that voltage.

I will now be replacing the motors with high performance 130 Atomic ball bearing motors. This should at least drastically reduce the noise the gun makes.

- NerfHaven

- → Ultrasonic2's Content

- Terms of Service and Privacy Policy

- Code of Conduct ·