Greetings from the Dutch, Jaffe

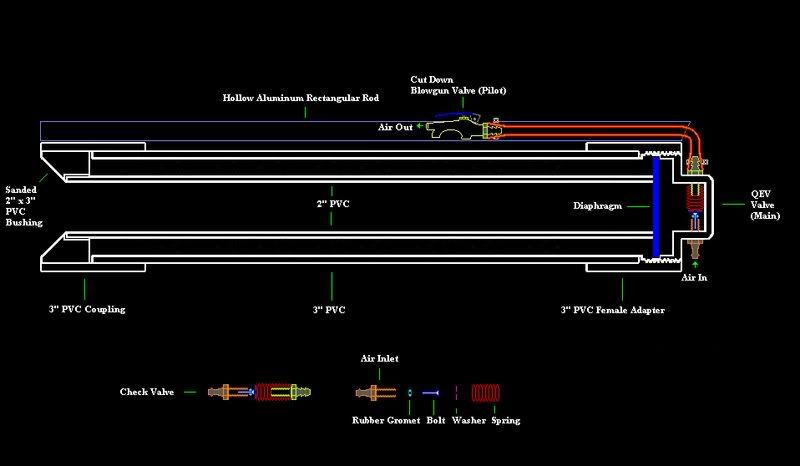

PS: My first valve I had ever made.

Posted 30 June 2007 - 05:06 AM

Posted 30 June 2007 - 10:48 AM

Edited by Flaming Hilt, 30 June 2007 - 10:50 AM.

Posted 06 July 2007 - 06:08 PM

Posted 07 July 2007 - 12:20 AM

Posted 07 July 2007 - 12:41 PM

Posted 07 July 2007 - 02:10 PM

Posted 07 July 2007 - 04:20 PM

Posted 07 July 2007 - 11:19 PM

This is sort of off-topic, but Torque, can you give us a brief update on that "Boomstick" of yours?

Posted 12 July 2007 - 03:35 PM

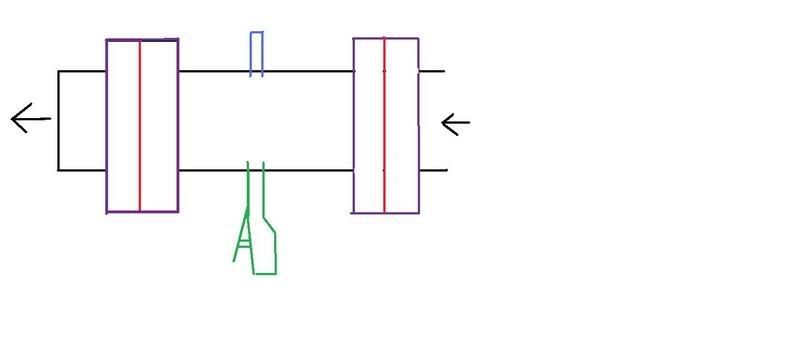

A very crudely drawn, triggered burst valve. I am using this in a project im working on currently.

-sponge

Edited by telekinetic, 12 July 2007 - 03:35 PM.

0 members, 1 guests, 0 anonymous users