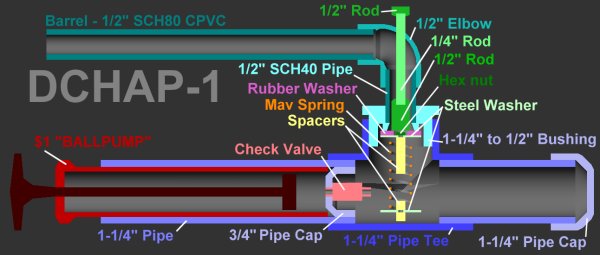

3DBBQ based all of his designs around a PVC check valve, which basically doubles the total cost of the gun. So instead of doing that I shopped around for the cheapest check valve possible and found a way to integrate it into the gun.

I'm VERY happy with this because not only does it work, but it went from concept to working gun in less than 24 hours.

This gun is primarily configured around the same size of parts that all of Carbon's SNAP series are using so that if you bought the supplies you need to make those then you already have the right sizes of pipe and fittings.

Pros

+ Cheap ($10-$15 total)

+ Adaptable

+ Push-button Trigger

+ Lightweight

+ Medium size

+ Very Durable

+ Can be disassembled for maintenance

Cons

- If the spring isn't tensioned enough the valve will leak during the first pump cycle. If the dart is already loaded this will push it out of the barrel. This can be fixed by adding a 1-1/4" washer to the spacer and screw added to the floor of the Tee.

McMaster part list

8745K41 - Gray PVC (Type I) Rod 1/4" Diameter = $0.48 per foot 8745K43 - Gray PVC (Type I) Rod 1/2" Diameter = $0.67 per foot 7757K43 - Polypropylene Spring-Loaded Ball Check Valve Buna-N Seat, 1/4" Barb X 1/4" Barb = $3.23 4880K21 - Std-Wall (Schedule 40) White PVC Pipe Fitting 1/2" Pipe Size, 90 Deg Elbow = $0.31 4880K44 - Std-Wall (Schedule 40) White PVC Pipe Fitting 1-1/4" Pipe Size, Tee = $1.28 90131A102 - 1/4" Screw Size, 3/4" OD, 1/8" Thick Large-OD Extra-Thick Reinforced Rubber Washer = $2.88 for 10 91090A101 - Zinc-Plated Steel Large-OD Flat Washer 8 Screw Size, 3/16" ID, 3/4" OD, .042"-.052" Thk = $2.80 for 100 4880K52 - Std-Wall (Schedule 40) White PVC Pipe Fitting 3/4" Pipe Size, Cap = $0.32 4880K54 - Std-Wall (Schedule 40) White PVC Pipe Fitting 1-1/4" Pipe Size, Cap = $0.72 4880K171 - Std-Wall (Schedule 40) White PVC Pipe Fitting 1-1/4" X1/2", Hex Bushing, Pipe End Male X Socket Fem = $0.99 + #6-32 or #8-32 screws in 1" and 2" lengths + 1/4" length spacers for the size of screw chosen + Hex nuts for the size of screws chosen + 1-1/4" SCH40 Pipe + 1/2" SCH80 CPVC + Maverick/Scout/LS Front Gun Spring (or equivalent)

Construction

The valve consists of a few very easy to make and acquire parts. I will need to update this list soon because the washer I'm using right now is simply too large and offers too much surface area for the tank to push on. With that aside here's basically what you have to do to make one.

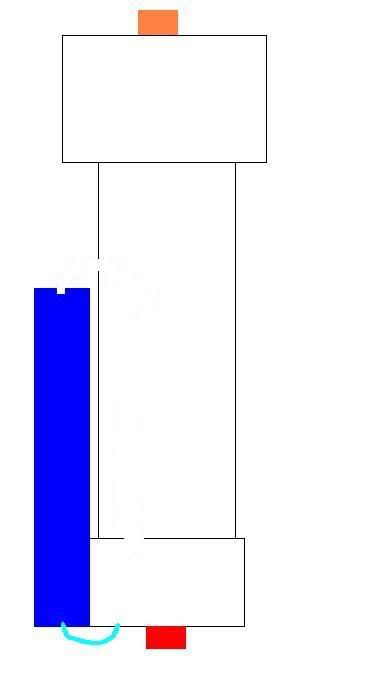

1/2" rod w/ 1/4" hole drill in one end -> 1/2" Pipe Elbow with 1/4" hole drilled in it -> 3" length 1/4" OD rod ->

1/2" rod with 1/4" hole drilled in one end and a 7/64" hole in the other -> 1/2" SCH40 Pipe -> 1-1/4" to 1/2" adapter bushing -> Rubber washer (trimmed to 1-1/8" outer diameter) -> #6-32 Hex nut -> Steel Washer -> 1" worth of spacers -> 1-1/2" length #6-32 screw -> Maverick plunger spring -> 1-1/4" Pipe Tee

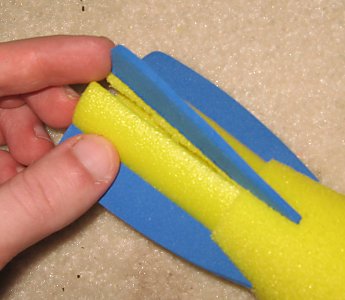

Valve assembled. Right image shows rubber washer trimmed to the correct size. Any size larger than a 3/4" outer diameter will work fine. Anything larger than 1" in outer diameter will need to be trimmed so that it's outer diameter is slightly smaller than the 1-1/4" OD steel washer.

Drill a 5/32" hole in the floor of the Tee and use a spacer, #6-32 screw and hex nut to fill it. This nub will keep the maverick plunger spring from sliding away when the trigger valve is pressed.

+ Use and X-acto knife to trim the mold seam excess away from the underside of the bushing adapter (this ensures a good seal with the rubber washer)

+ Valve inserted into Tee with spring.

Now simply glue a short length of 1-1/4" pipe and a 1-1/4" Pipe Cap onto one end of the Tee.

Any check valve will do. You simply need to mount it solidly inbetween the cheap pump and the blast chamber (air tank). This is one I had on hand and the cheapest one available ($3.23). It doesn't seem to like PVC cement fumes though.

Cut the barbs off of the check valve and drill a 9/64" hole in the center of the 3/4" Pipe Cap. Insert the check valve into the hole you drilled into the pipe cap while making sure that the arrow molded onto the body of the check valve WILL BE POINTING AWAY FROM THE PUMP. Glue the check valve into the center using copious amounts of hot glue. I would recommend putting this in the freezer for a minute or two to cool the hot glue quickly.

Cut a 9" length of 1-1/4" PVC pipe and glue the $1 "BALLPUMP" into it.

After cutting or sanding the key off the side of the 3/4" pipe cap, glue the 3/4" Pipe Cap + Check valve into the opposite end of the 1-1/4" pipe + Pump.

+ Glue the new pump assembly into the Tee

+ Install the valve and spring back into the Tee

+ Either drill and tap two holes in the Tee and valve body (don't drill too far) or simply glue it in place. Using screws will allow you to service the valve later. If you do use screws to hold the valve in place you will need either epoxy sealant or teflon tap to seal them when they're installed.

And you're finished! Wait an hour or two for the PVC cement to dry completely. Your first dozen or so shots may be finicky. The more you use the gun the more the rubber washer will get deformed around the steel washer. This improving the seal between it and the bushing, and thusly will improve the reliability of the gun. If the valve is leaky then you need to take the valve back apart and make sure that the washers are centered properly.

Ranges

--------------

2 pumps = 30-50 feet

3 pumps = 70-90 feet

4 pumps = 90-120 feet

The total build cost for this gun is around $14, but since I had almost everything on-hand I only spent about $4. If you build just one you will have enough leftover materials that the next gun you make will only cost $5

Edited by CaptainSlug, 07 June 2007 - 10:19 PM.