So recently I aquired a chainblazer, without any chains. I had formulated plans to build chains from CPVC and couplers, but when the thing came, it was much smaller than I had expected.

Seeing the small size, I decided to build the gun as a large secondary rather than a chain-fed primary. I opted for the classic slap-the-barrels-on-the-rotation-device-and-go-with-it modification. Here's the writeup:

Materials needed:

1/2" CPVC

1/2" PVC

Chainblazer

Plumber's Goop

Spring (optional)

Tools needed:

Dremel

or

File

Sandpaper

Hacksaw

Paints (optional):

High Temperature BBQ grill paint (or any Flat Black)

Antique Gold Rub 'n Buff

Gold Leaf Rub 'n Buff

Satin Acrylic Clearcoat

Materials Not Needed:

CHAINS!

First, open up the gun and you'll find this:

Remove the large orange rotation piece at the front of the gun. You can't miss it.

Now, cut two segments of your 1/2" PVC to a length of 1.5". Clamp them down and cut them lengthwise with your dremel or hacksaw. After cutting lengthwise, you should have four 1/2" PVC halfshells that are 1.5" in length. Use your dremel or file (rounded edge) + sandpaper to thin down the inner wall of the 1/2" PVC segments until the 1/2" CPVC can fit easily inside the half-shell.

Now cut out your 1/2" CPVC barrels. You'll need four. I made my barrels 3" in length.

Take that large orange rotation piece and dremel down the circular grooves around the sides (where the chains fit in) until your 1/2" PVC sits flush against the orange groove. The 1/2" PVC serves as a spacer so the 1/2" CPVC barrel will line up correctly with the air chamber.

Use the plumber's goop (or your favorite, strong as hell adhesive) to attach the 1/2" PVC pieces onto the orange rotation piece. Make sure they are flush with the rear part of the orange rotation piece. Before you goop anything, though, use sandpaper to rough up the surface on the orange rotation piece--it is very slick plastic. Just a little roughing up will go miles for the plumber's goop to bond correctly.

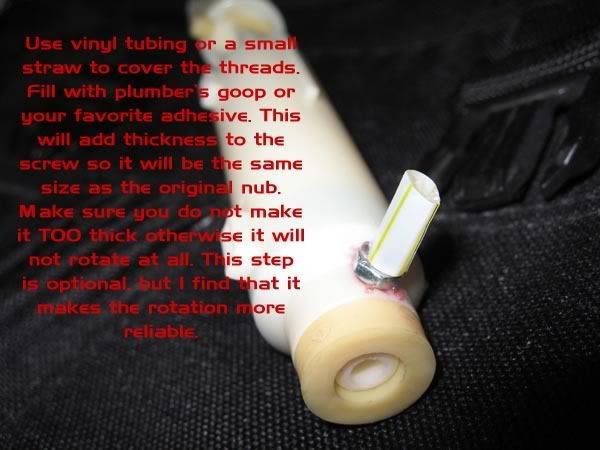

Use the plumber's goop to then attach your 1/2" CPVC barrels to the 1/2" PVC half shells. Do not glue them on flush to the rear end of the turret. Instead, let them stick out about 2mm from the edge of the rear of the turret. When you goop it, I suggest putting rubber bands around the entire turret to keep pressure on the CPVC and the PVC shells. Good contact will result in a high-strength bond.

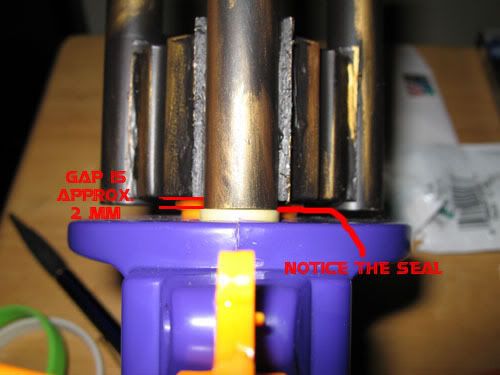

Here is a top view of the turret installed on the gun:

All of this spacing stuff is just so you maximize the air seal, but prevent jamming. The orange turret piece has a little "give" and moves forward/backward slightly. If the barrel stub length in the photo exceeds 2mm, you will experience jamming (I had them longer at first, but then I had to file them down until the damn thing stopped jamming). The white rubber piece in the photo is the tip of the air chamber, and it moves forward and backward. During rotation, it is pulled back inside the gun, once the barrel is in place, it will push forward and form a seal on the rear of the 1/2" CPVC barrel. The gun is then fired.

I also used an industrial spring instead of the original stock spring. It isn't much different from the old stock spring--it only has a wire gauge of .062, 13/16" O.D., and 3.5" length. I suspect the specs are similar to the stock chainblazer spring.

That wraps it up for the performance mods.

I decided to experiment with painting. I just wanted to paint the turret and nothing else (because I enjoy nerfing outdoors in public places).

First I used the sandpaper to rough up the surfaces (especially the orange plastic on the rotation device). I washed off the dust and put the internal parts under masking tape and newspaper. I hit it with my flat black. I then opened up the Gold Leaf rub'n'buff. I made my weathering marks by putting a dot on my finger, starting it on the flat black, then rubbing it in the direction I wanted to show wear. I then used Antique Gold to make the heavier weathering. The final look makes it seem like the gun was brass/copper that was painted black. Over the years, the black faded in some areas (barrel tips, edges, corners) and let some of the metal show through.

Lastly, I hit the thing with Satin Acrylic finish (do not use polyurethane with Rub'n'Buff--it will react). Prop makers dislike using clearcoat on Rub'n'Buff since it dulls the finish. Since this is a nerf gun, though, I don't want it to be rubbing off everywhere. I opted to just spray it down with clearcoat.

Slap everything back together and...

Range Test:

62' Average Flat shot, no wind, shoulder-level.

Video:

Edited by frost vectron, 05 February 2008 - 03:24 AM.