#1

Posted 30 May 2007 - 06:27 PM

I was going to try something I haven't seen before, and have two plunger tubes about half the length of carbon's desing. These we be joined with a pvc tee-joint before going to a single barrel.

My other idea was to have a shorter plunger tube with a greater diameter.

My reasoning is that both of these designs should be just as effective as the standard SNAP. They may be even better because the plunger(s) has to travel a shorter distance, and may deliver the air to the dart (stefan) more rapidly.

Just wondering if anyone knows of any serious issues with either these designs or if they have been done before and I missed it.

Feedback would be cool, and feel free to call me a moron if my idea sucks.

Also, thanks carbon for your sweet write-ups

#3

Posted 30 May 2007 - 06:45 PM

Thinking about it, you may be able to get away with two half-size plungers, without even increasing the tube size. Bigger plungers have greater mass, and will accelerate slower. If you use two standard-size plungers, you can make them lighter (shorter chargerods). Smaller plunger = lighter = faster travel. Larger tubing may negate the benefits...but honestly, I don't know. Definitely interested to see what you come up with.

#4

Posted 30 May 2007 - 07:34 PM

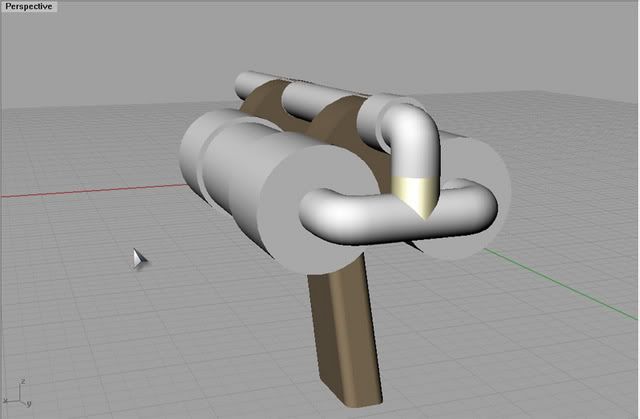

This is sloppy at best but might help illustrate what I'm saying.

#5

Posted 30 May 2007 - 07:45 PM

I don't know if that will happen though. The volume of air between the dart and the plunger shafts will be shrinking rapidly, regardless of a slight mistiming, so pressure will build up. Also, I think I am more worried about a mis-time coming from inconsistencies in the seperate plungers rather than the trigger mechanism.

thanks for the feedback, and at this point I think that I am going to go for the double-plunger design after some careful planning, if worse comes to worse, I will still have two seperate snaps

edit: currently working on some rhino3d renders

Edited by wintermute, 30 May 2007 - 07:49 PM.

#6

Posted 30 May 2007 - 09:15 PM

2) timing loss causes less energy transfered to the dart; the faster plunger shoots the dart from the barrel and the slower plunger does... not much.

Synching the two plungers would be a pain in the arse...

IDEA: one gun, two plunger chambers, TWO barrels. Along with a breech loading mechanism, that would make a bitchin primary. On a double barrel shotgun, there is one trigger in front of the other... you may want to try that set up.

Oh SNAP, I think I want one... yay new idea. Please excuse me while I steal my idea!!

(do what YOU wanna do, hope this helps)

All your base are belong to us!!"

{Presbyterian College Nerf}

#7

Posted 30 May 2007 - 10:09 PM

Maybe a tight-fitting / telescoping barrel could allow the pressure to build and both plungers to fire evenly.

also, maybe it is a dumb idea, and I should try the "fat" snap-single barrel and plunger with a pressure chamber that is only 6-7 inches long but made from 4" pvc

still working on some renders, i'll get them up in a bit

#8

Posted 31 May 2007 - 05:05 PM

looks awkward, but compact

I have also been toying around with privateer's idea, maybe something forearm mounted, like a super-manta

#9

Posted 31 May 2007 - 05:52 PM

The trigger/identical plunger issue would still be an...issue, but this design would address the main problem of the SNAP-4....it was pretty uncomfortable to push the plunger forward the five inches it needed to go. Using two smaller plungers would allow you to use a shorter stroke. It you played your cards right, you could match up the length of the plunger stroke with the amount of pull needed for the breech.

Build it...I think it has real potential. If I can scare up enough parts, I might try it as well (if you don't mind).

#10

Posted 31 May 2007 - 07:05 PM

It you played your cards right, you could match up the length of the plunger stroke with the amount of pull needed for the breech.

Build it...I think it has real potential. If I can scare up enough parts, I might try it as well (if you don't mind).

Duh!!!

wow carbon, I didn't even think of attaching the breech to the plunger handle. Man I am dumb. I'll get started with basic construction soon as I get some time/fund$

And I wouldn't mind at all if you built one of your own. You can probably execute the idea a hell of a lot better than I can.

as for that breech, I haven't made one before, but what is the standard pull length needed for a stefan?

#11

Posted 31 May 2007 - 07:19 PM

Depends on the size of your darts. My stefans are 2", and the throw of my breech is 3.25".as for that breech, I haven't made one before, but what is the standard pull length needed for a stefan?

The more I think about it, the more powerful this idea becomes...

A typical SNAP plunger has a stroke of about 5". The throw on the breech is 3.25", like I said. So, that becomes the plunger stroke. So, we're getting an effective plunger stroke of 6.5"...so, a 30% increase in air volume, with potentially a faster delivery (because of two lighter, shorter plungers)...

Wow.

#12

Posted 31 May 2007 - 07:49 PM

question: will a breech still allow for a telescoping barrel and a tight fit? It seems to me that a breech may not load correctly if the barrel is tight on the dart

#13

Posted 31 May 2007 - 08:22 PM

#14

Posted 31 May 2007 - 08:39 PM

By telescoping, do you mean nested?question: will a breech still allow for a telescoping barrel and a tight fit? It seems to me that a breech may not load correctly if the barrel is tight on the dart

My stefans are pretty tight in 17/32", enough that a straight breech load doesn't work. The back end of my breeches are made of 19/32", about 1" or so. When the breech closes, it shoves some of the dart into 17/32", enough that it fires well. So, you could start with 19/32", then have the starting bit of 17/32", then step your way up the sizes.

#15

Posted 31 May 2007 - 09:38 PM

(for reference, the barrel-including breech-is 12")

here is v2.0

Looks like I need to redesign the pimo handle to make it lighter. Something like the slider on the SNAP-4 would be ideal, but I don't know if my pvc skillz are up to that level. The slider would make also open and close the breech. The current design would require awkward barrel twisting.

#16

Posted 31 May 2007 - 09:43 PM

If you moved the handle a bit more forward, the clip could slide down between the two pluger chambers and you won't have a tower of darts obstructing your sights (that's if you're going to use a clip like the SNAP-4).

#17

Posted 31 May 2007 - 09:52 PM

Then connect the two plunger rods with a pair of threaded rods.

The handle that extends from the breech could simply be behind the threaded rods that link the plunger rods so that it pushes them forward but still allows you to pull it back before firing. You could even spring-load the breech if you wanted to then use a gravity clip.

#18

Posted 31 May 2007 - 10:40 PM

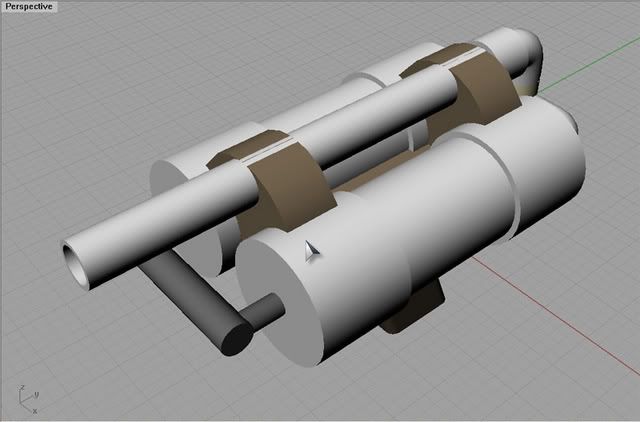

I spent some time tonight digging around in parts, seeing how this thing would fit together. I ran into a snag with the air delivery end of the plungers: elbows and tees take up too much physical space for the plungers to sit close together....not pleasing. So I got to wondering...why not run the barrel between them?

This is a mockup:

It works out rather well: the breech will be in a direct line with chargerods, so everthing can get a more-or-less straight pull. Plus, it means wit will be fairly staightforward to link everything together.

This will get built this weekend. Time to start hacking on that trigger....

#19

Posted 31 May 2007 - 11:23 PM

you could use what captain slug said and just use the barrel to prime the gun, possibly aided by a handle

I'm anxious to see how it yours turns (it feels good to inspire a god of homemades)

I think I'll be getting some parts this weekend, and begin some construction.

#20

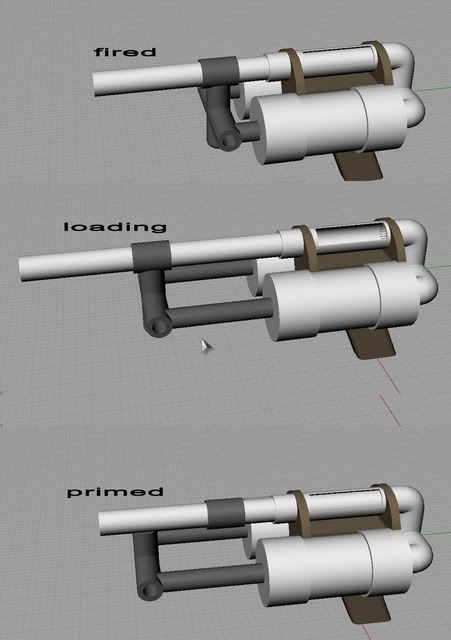

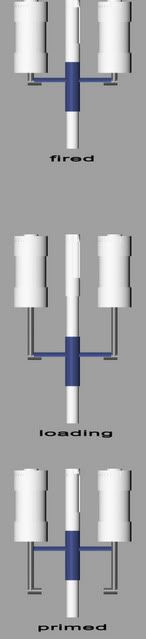

Posted 01 June 2007 - 01:39 PM

Putfile

sequence is fired, loading, primed

The placement of the breech on the pictures is arbitrary.

Edited by zaphodB, 01 June 2007 - 01:41 PM.

"Which road do I take?" she asked.

"Where do you want to go?" responded the Cheshire cat.

"I don't know," Alice answered.

"Then," said the cat, "it doesn't matter."

#21

Posted 01 June 2007 - 03:11 PM

add a clip = pump action

a handle on the bottom could add more leverage for priming

#22

Posted 03 June 2007 - 10:29 AM

#23

Posted 04 June 2007 - 10:50 PM

I have acquired a few PVC parts, but time and money for more parts is looking slim as of right now. I want to keep this idea alive, and hopefully I can gather parts and what not to finish this by august.

Two questions:

1) carbon, any progress on yours?

and 2) where can I find the rubber fender washer for the plunger?

#24

Posted 04 June 2007 - 11:02 PM

I had a car die on me over the weekend, so that's killed a lot of free time and money. I'm hoping to get a little done over the next few nights. Rubber fender washers are easier: check the small fasters aisle at Ace or True Value...they keep them in the Wall of Tiny Drawers®.Two questions:

1) carbon, any progress on yours?

and 2) where can I find the rubber fender washer for the plunger?

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users