So I myself have tried, used and thought up many different for trigger ideas and well not all of them have worked so great and some didn't even work at all

So please post all tigger ideas that YOU yourself have configured or thought up. Please dont post Carbons clothspin trigger idea (unless you are Carbon) or anyone else's idea (other than your own) that you have seen posted before. Of course I understand that more than one person has thought up the same trigger idea as someone else before but if it has already been posted on here please dont repost it.

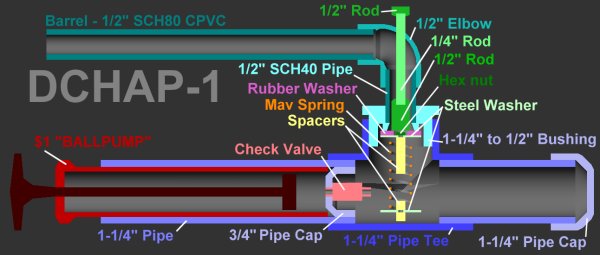

Ok so post your idea with a pic even if it a picture of a design scribbled on a napkin or part of a pen or a mspaint pic just so long as we have a visual reference; also in your post describe what the trigger is and how it is/ was supposed to work and state if it worked or didn't work.

Ok....GO!!!

**STICKIED BY PINEY** Get some ideas here before you start on your homemades.

Edited by Pineapple, 04 June 2007 - 01:29 PM.

This topic is locked

This topic is locked