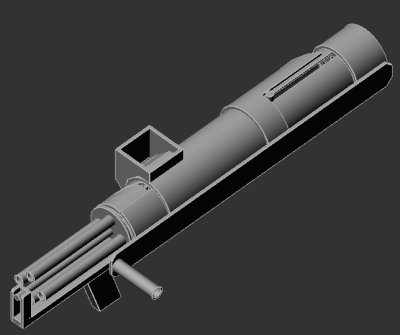

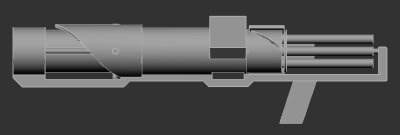

Okay I was going to keep this one under wraps but it's just too much fun. Carbon's simple Syringe Gun experiment gave me a serious epiphany that lead directly to this design. However, since the potential ROF is rather high for the configuration I decided early on that a large number of barrels and plungers would get to be too heavy to be managable. So I leaned my original concept down to just 4 barrels and a gravity-feed system to compensate for the lower number of barrels.

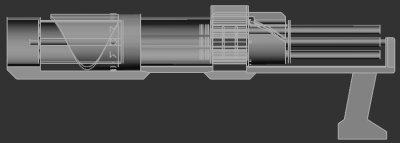

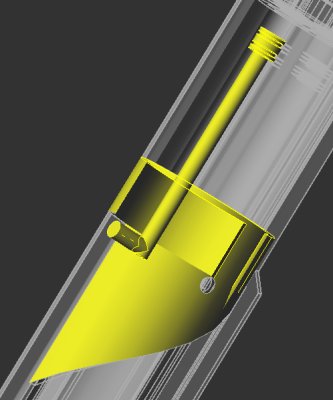

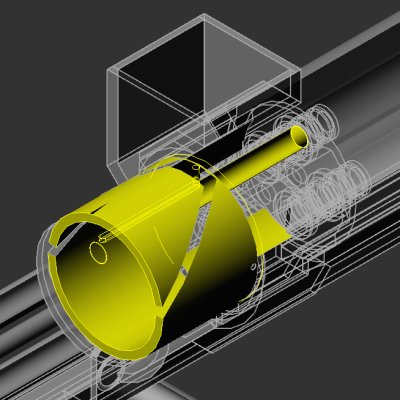

The barrel set will be powered by a cordless power drill with an adjustable clutch, which I will have to modify to move the handle/trigger/battery to the front of the gun but have the motor chucked onto the main axle in the rear of the gun. The plungers and brass breech covers will both be driven back and forth by helical tracks cut from large diameter PVC pipe or Acrylic scraps.

Here's the plunger and it's track.

And the 19/32 OD brass breech similar to what is commonly used for breech modifications.

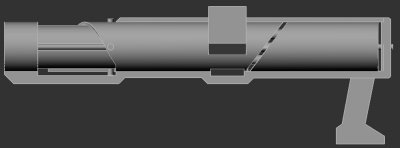

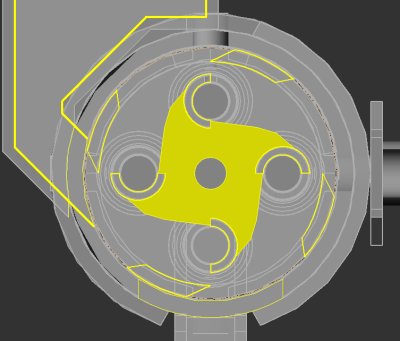

And taking many cues from actual gatling guns I had to make a set of feeding teeth that pull the darts from left to right as the fall in order to guide them into the opened breech.

The shuriken-esque piece in the center makes sure that only one dart advances inward far enough to allow the stopping gate to close off the hopper before the next dart tries to enter. I also added an eject port to the bottom of this chamber so that in the event that I find that I have to use shells I can simply cut the breech shorter so that it acts only as a vice for the shells and then once the dart gets fire the shell can be dropped out of the bottom of the gun.

The eject port on the bottom also allows darts that failed to fire to be dropped to prevent jamming.

What I find quite strange after completing this design is that it would actually be easier to make than my other designs, but it could cost quite a bit more if I can't find the large OD PVC pipes as scrap and I can't find a cordless power drill on clearance. Each barrel assembly is designed around standard PVC pipe sizes and fittings and would only require minimal cutting with a bandsaw to add the breech hole and it's track.

Thoughts?

Edited by CaptainSlug, 25 August 2007 - 02:51 PM.

This topic is locked

This topic is locked