It's been waaaaay too long since I've posted a writeup here. Time to change that NOW.

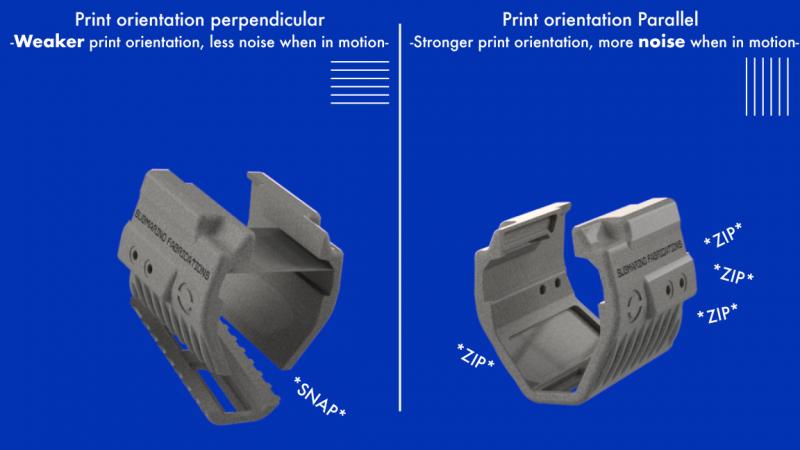

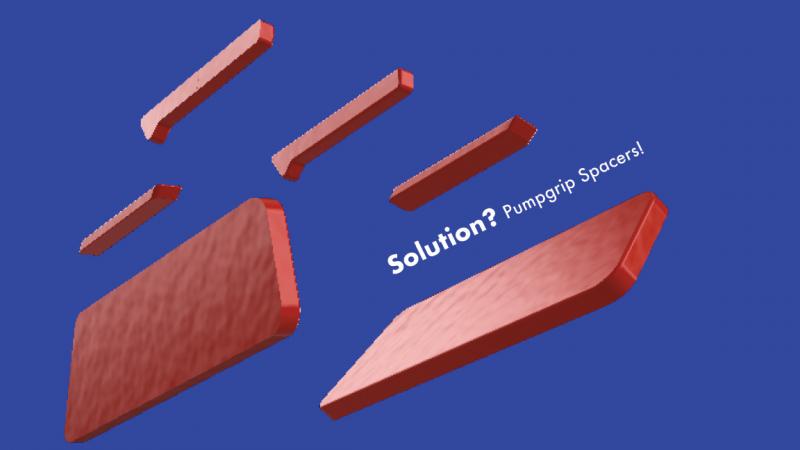

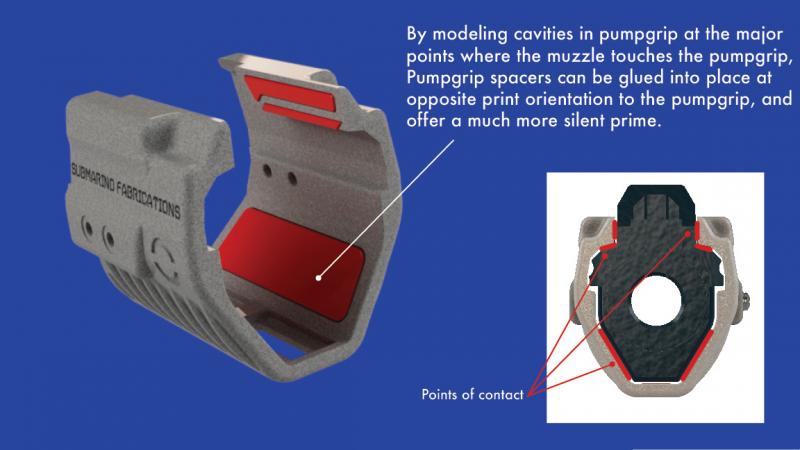

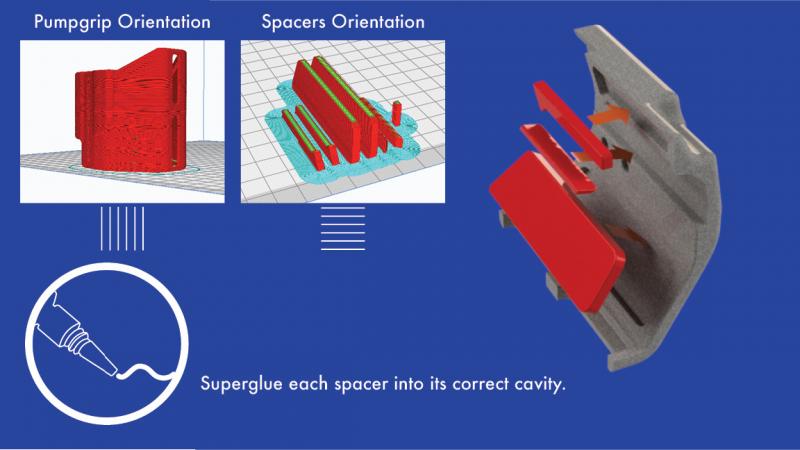

In the past few months in selling my Aeon Pro Pump Upgrade Kit on Etsy, I had a few issues early on with the strength of the pumpgrip, which had a lot to do with the print orientation I chose. In order to reduce the 'Print-Zip' effect created from two 3d printed parts printed at the same orientation and sliding against each other perpendicular to that, that a lot of our community DESPISES, I printed my pump grip in a weaker orientation which caused some breaks from my buyers. Getting tired of printing replacement parts for my gracious customers who chose to take a chance on a new seller, I wanted to alleviate my problem. While I initially just buffed up the print, I just felt like the print orientation as a whole would be an issue under stronger spring loads. It took me some time, but I think I found a really cool solution that could be applied to future builds within our community:

Pump Upgrade Kit in question (I really should probably make a little writeup for this on here too)

Video of Pump grip Noise Comparisons.

Edited by Spud Spudoni, 10 September 2021 - 03:54 PM.